Beruflich Dokumente

Kultur Dokumente

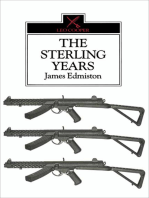

US Arisaka Manual

Hochgeladen von

Jeremy Griffen100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

360 Ansichten25 SeitenCopyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

360 Ansichten25 SeitenUS Arisaka Manual

Hochgeladen von

Jeremy GriffenCopyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 25

,

RESTRICTED s.c:urity Information

TECHNICAL MANUAL

FOR

RIFLE, U. S., TYPE 99, JAPANESE CAL. .30

ll ESTRICTfO Security . Informotion "

Contents

Genoral

1

Par.t Qte I CCI'letructton and Function

ehaptor 1 fW'le

I Construct1<m

A Barrel Group

B Reeel \fer Group

C Bolt.

.0 MDgo.z1ne

! St.ook Group

II Funotion of Breecb Mechanism

Chapter 2 kC"lIlIorles

Chapter.3 BayOllet and .c01l880l" lee

Chapter 4 Ammunition

Chapter 5 Spare Partll

Part Two: Haodl1n8

Chapter 1 Disallsetlbly and J.sseably

I Nor/ll!l.l D181!U1881:1bly end &.s88mbly

II Speoial Dlasas88mbly and .assembly

Chapter 2. Precautlon8 in Handling

Cblll'ter.3 Pecting

18rt 'fhrelll Preservation

Chapter 1 Care

I Daily Care

II Care Before Firing

III Care After Firil'lg

rv Carll During Special Instanc8e

Chapter 2 ~ t o r e . g e

1

1

. .,

Chspter J InSpeCtiOll

1

2

3

1 General Inspection

.A. Care

C Functioo

D Damage

II Inspection Before and Uter liring

III Inspection of Stared Rifles

Chaptsr I Ritls

I Construotion

, Barrel Group

Tho Inside of the barrel is dIvided into .. rifled s.otloo. challber,

bolt face seat.

The rifled eeetion conai st8 or tour 1'ight twiet ritllnlS ...boae land

eurface ia CbrOll'oII plated. The chaar i a s hape,d to tit th. cartridle

and its rear par tion ls rounded to farlll a bolt tao. ee .. t.

The bolt ace lJ8at aide in guiding the eQlullition and baa an extractor

groove on the r4!:ht aide. Tb8 outside aurface or tbe rear ent!. of bolt talle

seat is threaded . mer the receiver i s screwed 00 to tbe barrel, it 1e

aligned dth the ltarker.

The barrel att aclmante coneiet of rear eieht and rear eight baae, front

sight and fr ont al lht base .

The rear Bight ba8e is IIlOUTlted on tbe rear of the barrel and 1a pre-

vonted from moving by e s trali rear sigbt Osee sore" and a 8Nli rear sight

tipx'ing ecrew.

The rear s ight leal' is pivoted by a rear silbt Jolnt pill and lIILintaine

10'llored and r aised positions through rear ailbt sprinl IICtion. The rear

sight I eat' is graduatJtll fr om JOO to 1500 utere by etobed lines _paced into

2

100 meter unIte. Both sidell or the rear deht leat are notched at t ho above-

mentioned intervals to engage t he rear sIght slide eate'l when tho upper edge

of tIle slide c oIncides with t he previoue17 III!IntIoned e tc hed lines . The

circular peop 8Ie:ht formed at the bottou by lOfferIng the rear si ght loaf

hi used f ar firing at rangeG of 100 mters. The 8olll1circuls.r reap &i ght.

forllOd. by raisinS tbe rear sight loa!' and. slide 18 used far firine raflee::l

of 2CO !tOters.

The farward edge of the rear s i ght leaf SllI' i fig 18 dovetalled and fits

into Llw rear sl Sht base . It i:J held in place by set SCTen . The rroJec-

tion on the upper s urface prevents tho rOtlr uight leaf frOI'll tlOving to the

right or l eft. Tho spr1.ng I s curved upMrd so t hat it COnstant ly exerts

upward prOSSlU'8 on the 10'Pl8r ond of the rear r i ght baf.

The lI ild. 111 ins erted 001.0 the reer sight Ie", f and is held in t he

deaired position by Mana ot a s;:,ring loaded catch. The 1'e8r slht set

8cru on the upper rigbt s ide preV8nts t.., elide !'roJ! s U pping ofC. Ths

IIprln leeded elide catch h acrewed on e.ech aide of t he e Ud" by a s l N "

pin . The center peep s i ght is a liened ...!th the front s ight t or tiring rllnges

of JOO to 1500 IIIOteu . The catch of the s lid8 thl' OIlf!h tho aotion of th8

apr i ng enlag8e t he UOOVOS OIl bot h s i des of the rear s i gbt laaf IiIDd bolds

the slide in its 'VarioUS elewted poslt1or.e . Q, each s ide and at the back

of the elide :Is an antiaircraft leed Bieht arlll. The anti.alroratt load

8ight arBl has two scaled notche8, 2 and J . at the bottOIll. Notch 2 fa

far firing on a ircr aft traveltng direct IlOr izontal diste.nces tor 600 yard a

at sneads of 125 lII.1ldS per hoW' and Notch 3, at Hf'6edS of 185 m.1ltls per

hour . The antiaircraft lead s i ght 801'111 i tl attached by antiaircraft IMd

scr81'18 . The Bj'r lng attached to the botton holda the antiaircrart a1'1II

in foldeJ and extend ed positlor,s. v.:aine its oporat.ion t lle a1rcl, .. ft is

sllaned dth f ont and "eN' s ight ana fjr8\! upvn when it 8nUl r n the

3

I

proper notch on tl'.e bottol!) of the antilti.rcraft lead elj;ht &rill.

The tront slg!'lt blade is dOTIltallod tightly ir,to t he tront sieht bass.

The l'rout slght be.!le i s a t.tached t o the forward end or the barrel and held

in pOI'l1tlon by the l'ront sight base pin which 18 inserted hOrl 10ft to right.

The lJne fC'l'Did wlth the !'ront sight base ud the tront sight is determined

by Two hould6Ts whi ch project upward frO.f!l the front S18ht ba.St'l

tler ve S!l CUfU'da tor t he si6bt blade.

B Heceiver Cr oup

The receiver houses the bolt . The upper aurf a.ce or t he receivOt' bea

tf;O BO\l8611 holes . The one r.hlch Is c ut out !'rom the top t o the right eid8

S8rV68 (W 8 reCelV6l' port during loe.dtnB eoo as ell ejection port afteT tiring.

The cnTtridf,(o clip hous inG i s forlllSd by t he rear Bect.ion . Tha othar hole

sel'YSS as a path for t he bol t handl o. It 16 slanted tonrdo the tr ont on"

to facilitats the acti on of tl:tl bolt when it is !lulled back.

T'nere Is 8 Ions 11I.rrow reces!! along each Bide of the rece!ver in which

the bolt rides . Serial r.mr.ber or the rifle and t he nellIS ot the manutactUl' -

ine fLT_ are 8n81'avOO below the groove on the lett aids. .1 alot. wbich engagal

the bolt retainer Mes, and lip of ball ntainor, and an eJeotor groove are

four.d on t.he rlar lett s ide.

The sear rin seat is loeated to the rear of the rectaneular opening at

tho bottom. Tho safety lock hole i8 locat.ed on the forurd aection of the

sear r in seat ar.d f!rinE pin ca Leh hole in t he rear leclion . The fonard

ancl rear recei ver 1ll8s are drilled f or lor.g and short receiver screws. The

are us8ll to attach the trigger guard to the receivfll'. The butfer aoo.

recoil pIate aro attached to torward and rear l ugs , respectively, til'ld ser ve

t o lrc.nsm1t rscoil IIhock to the stock duri ng ftring.

en each side of the inner s urface ia a long1t.ud1nBl groove which per-

tdts the rldlng of bolt looking l ug and ext.ract or. The ronard portion of t.hl

4

6

uoove 1B wWened to house t be boH lOCl'J.llg lug. en the tor llUrf ace of thIs

housing 18 a gae par.t which permits g88 t o osotlpe. An ongraved Crtlst i s

lOCAted in the for1l'!l.rd portion of the gas port, and an engraved figure

"Type 99", reading l eft to right, is l ocated t o the NIM' or gila

port . The f'r ont end of the inside groove 111 alao ... !dened to provide passage

for tha bolt retaining lug. At the Teal' of t he Tecsiver ther e is a groove

tor the t ue on the setety knob and anot.herpoove f or the s&ar catch. .1

Oil whioh the safety catch lug rides 18 locat.ed 111 the sxtended pOl"tion of

the receiver , Thh g .. oove curves to the left. wld n r 'S8 &8 8 eulde and lock

fur t he safety cstch lug when the rUle is eet 1,ri safety posltioll .

Receiver attachlr.ents consist of. bolt lat.ch, ejector , slar , triseer ,

and reooll pl ate.

7 The bolt retainiJIg latch esselllbl] fits on the left reM' elde of the

receiver. The sear catch always rroJects out through the action ot bolt re-

taining lat.ch Spr1n8 attached to t he bolt retainer . It engages t.he bolt

retatning lug and lbdte the bacDiard II'oOVtllIlI!mt of t he bolt . In order to

rlllOye the bolt frOIl the receiver, the bolt retaining lat.oh 11.1 pulled out to

dbengase the catch. The ejector is attached to t.he bolt retalntne latch

Maeroly by the latch scre" aNt projocts into the eJector eroovo or the

receiver by th\! act.ion of ejector spring st.lached t.o t. he bolt. reta11ling latch

Bpt' i(18.

Then tho bol t 15 brought t o t !!e reu I the Ijector riding 011 t he ejector

eroove st.rikes the botto. of t he certr1ilge end throu tloe certrldee out to

the riGht. The cetch of the bolt. retaining latch elves proper pooi llon to

the ejoctor "'hen the boll is 1'8l:!Oved .

6

The sear haa s tiring pin catoh on the rear end and a Mrety lock 011

the !'ront end, and is at lB.ched t.o the seer pin seat or t ha receiver by l".8ans

or the eear pin .

5

I

Tho trigger 16 attached to the seAl' with s trigger pin and fOJ'lDa a

largo and sltBll wavelike knoll . The large knoll engaees the lower surface

of t.h. rec.iver and adjusts the projection of the firing pin catch w!thin

the receiver. The catch 00 the tront end engages the bottoll! of the BeAl'

and seta the J'I08ition of the trigt;er. The sear ara-lng encircling Ule

safety l ock, pivots around the aear pin and alp yt. hold a the firlng pin

catoh in projected position 'rithln the receiver.

When the is pulled to the first pMlle (when t.he trie-ger play

16 taken up) J the sear spring 10 forced, and the bJg knoll turna whUe

enijag1ng the lower el.ll'fsce of tlle reclever. 5in.llt.aneoullly lI'ith the engsE,Lng

of the knoll dth the lower surface of the receiver, the firing pin catch

19 lowered to a certain extent. When tho trigser i8 pulled to the second

phase the sear i 8 engaged), the sear 8pring i s subjected t o 'urther

prU8ure, the rirbg pin cet.ch ill lowered C'urther, ond the safety lock ia

placed in tte safety lock groove of the receiver. 'l'hI'ough such action of

the Nfety lock, ssfety action 19 creeted. III short., the opening ot the

bolt handle is pre'\'ented during dbcMrt:e and the pulling of the trigger is

prevented when the rUle i s hal! cocked.

9

The reoot! plate is attached to the rear of the receiver. The rear lug

tho receiver Ie inserted tnto forward hole. It. h conr.eoted to the

trigger guard by 6Cr&1iing the trigger guard Icrew into t.he threaded hole in

the rear end. Together dth the buffer, it tranelflits recoll to the stock

during d i scharge . Furthermore, tocether with the trlCEer gua.rd it s tr(!ngth-

ens t.he rifle

C Bolt

10

Ths bolt consisting of the r ollOlfing j"tIrta 1& aUachM t.o tlle reca iver I

Bolt houaing, firing pin, firillg plll spring, safety cstch, extractor, and

bolt o(.over.

11 The bolt housing contaIns a firing pin olll\JWer , portion of

6 '

which is recused to limit the for1f&Xc.1 l.'Ot.lon of the f1r1rlg pin durIng til'ing.

the front eDd or ita head is called the breech surface. Tho embanked

1\18 .t t.he bead f'lmotl,one together with the lIll"tractor unt.il t.he cartr Idee la

extracted. 1'be lUBe on both aides of the head are oalled the bolt lockinS

catcb.a aDd the lua to the r&r of tbe lort bolt lock.ir:g lug 15 called the

bolt rete.1niJlg IllS. 1M narrow goo". extending t.iJrough tho centero ot

the groove oONlect. with the firing ph. cbubar and porll1te glle to escllpe

fro. the Fl_r. The bolt l"eta1zling lug engages the bolt retainer and

li.Idt. the back ... rd movement of the bolt. The elliptioal hole I!I1.dway be-

t ... n the boll looking lUiS and toward its raar the ga. to escape

trOll the bolt housing and at tbe SBIr.8 tillie lrlCUCllt the positIon for

assembling tho extractor. TM I'I%trector collar .hich adjoins t.he bolt

reta1nini lug Is attaohed to tha extractor and perllih natlD'al turnws

Two aballcnr groov811 OIle to the right tront and one to t.he bott.oll !'ront or

the bolt handle, are (-:J the bolt. houdog. The right tront grOOTe

11 the alot tor the sai"ety lot'k durine: fir1r1e. and the bot tOG front ia for

the wety lug during the backward I:IOveuot at the bolt. when t.he Bear

oatoh presses the aear dOllD. Approxi ... t. ely OI'Ie- 1''''11' of the circullf'erence

to the sear ia out off in fork shape . The elcD8ated out-off ill called the

onall-obaped sflotion and t.he shortfl r cut-off i6 oalled t.he 8uiclrcular

seotion. l'he anall-abaJ'I6d section, tgget.her with the turn1! i of the bolt

boWlinf: serves to withdraw the firini pin ao it anisgea t.he sear catch,

and ita bottom portion th. slot for sear cut.oh dUJ"lll8 firir.g. Tho

S8D'11C1roUlal' seot i on becomes the slot for the 8e/ll" catch when the riring

pin 18 "ithdra'll1l. A collar on the rear end of t.he bolt hOUflini engagea

the grogve on the 111aide of the safety knob snd holds tie bolL houllin8 and

the safety knob t.ogether.

emall proJeotlor. at the rear o! the bolt bandle engages the notch

cut tnto the outs ide of the sar.ty knob, and duriLg safety, together with

7

I

the safety catch, prevents the bolt bandIt'! from 0t'erdl1g.

Tb& f1r1:r' i pin assembly, consistit!g of striker end the flrllS pin

SlFiI1g operates in tthe fiXing pin chell!ber of the bolt hous1l!C. The right.

inside eurface at tbs rear of the fUiI1g pin hae e longitu:l inal groove

term1r.ating et the equare opening in its forward cnd. TIlie opon1na i:l

connected to the long narrow openirg on t.he upper surfece, These uoovae

and openir.gs serve as pa,esHges for tho projecti on on the safety knob shaft

(juring tl.6selT.bly and dbasseu:bl,.. Furthermore, the l ont; r:arrOYo' op8ining

serves as a raes8(lt'l for the !:'l'ojecticn on the se!'ety knob shaft d uring the

fal'wo.rd 1:I0tion of the firillg r>1n end prevents t he pill froll t.wping

freely. The proJecting portion at. the l'ear of the firwg pin Is called

the cetch. The sear catch engage e the firing pi n catch 8.Ild comprflsflt!;1;1

t he firing Sprblg. The slI'all circular port h. the froot I s a gas escape .

1) 'Ihe firing pin housed in the firing pin spring cbu.bl'l r activates

the f!.rit le pi n lind reintaille the pos ition of t he 86fety device.

11, The I'" r",t.y Imoh r.onner.tn with the bolt hou!!inc snu t he f!ring r i n

lIT1(l eneages the safety device. 'The rear of t he ".nob i a knln-led

with a srwll semicircul.er !lotch at t.he left side and eefety knob 1\.14: et

the bottom. The safety knob lug fits into the groove at the r ear end of

the reoeiver and prevents the Bafety knob 1\" 01:1 t.urning.

flhen the safet.y knob is locked hy preeSillg the safllty blOb f orwar d and

turnir,g t he safety knob l ug to t he left during cocked pos i t.ioll of the bolt,

the right side of th& notched aect ion or. the ouUide of t be eafety knob

ent;ages the sooll projection on t he rear of t. he bolt Iland1e sed r revents

the raisinS of the bolt handle . C\le - ba lf of the inner circumfe rallce has

a she lf-like re("ee9 iOhlch engagee t he collar on the rellr of the bolt housing

alld Musea it t.:I f unction to{:ethll l' dt h tho firing pin epring.

8

Tbe safety knob t!haft !Is the principal elelllllnt in the bolt

11111 projaction on the center of the shaft fits into the l ong narro'll groove

and opertin8, at tho firing pin spring chal:lbor ana fllCilital.lIs the asser.-.bly

at the bolt . During sssembly, tocetbsr wit h the eafety knob l ug, it pre-

vlilnts the firing pif1 frortl turning.

The safety device turn!) the firing pin to the right, engages the Seal'

cstch Lo the lt sear slot of t he rt!ceivllr, and prevliITlts oOl'll'ectioTl between

the sear a.nd firing pin,

15 Tho eJltractor 1s 8 flat. piece under s pr ing teneion . Its tip engages

the l' ear of cartridge and exlrttct.s It.. The projected section to the

rear at the tip fit s into t.he groove at the head of the bolt casiI1g which

prevents it fr om slipping forward,

The hollowed portion OIl the back surfeoe of the extractor engages the

project.ed portion 0. the extractor coller au! holds t he erlractor to the

holt housing. ":'lhen the holt handle ie opened, the extraotal' raMins in

t he rieht ina ide UOOVfI of the receiwl' without affected by the turn-

illg of t he bolt. housing !l' ince the e>:t.ractor collar turns frellly.

16 Since the bolt COVill' is attached to the receiver by r.eane of bent tiFs

on both sides, it covllrs tha upper l!urf6Ce of the receiver snd prevents

dust frOI'! entering t he receiver,

17

D )'e.gto"tille

Tlle rraeadne consista of magezine body, trigger guard and their

uccessories . The body is hax shaped end contains a follower !uid e mags.zine

spr iIlg. It is ussd f or loodlJlg tUIII;;unition. !he fr ont and beck of the

are attached to the trigger guard to px' l'Ivent it s Upping out

fr OIil t.he stoc k.

18 'Ihe t:rieger tuard forms a sest f or the fl'l9.ga?line and ellrW6 s e a shield

r ar t !m trigeer sl:d as r e-eI1 f Orcelf.ent f or t he stock grip. It is attachlld

9

I

t.o t he bottol.'! or tbe stoek with three emaIl lIorews. The long lIOuth towards

the froot. holds the bottolD end of the IIIIgadne , The floor plate catch housiDg

1B located at the rear seotion or the long lIOuth.

The 8bort 8cre1ll bole for the receiver Ie located at the forward tip or the

trigger guard . The trigger guard screw hole and a rectangular hole are round

at t be rear end and center, respectively. ThuI, roolll. for operation or

trieger is provided . The 5er:dcircular guard whioh proteots the trigger MS

a al!lllll hole i n the front end as a recess tar t.he floor plate catch. A long

19

20

set lIore1l' hole ror t be receiver is loeated at the nar of the other end.

l'be trigger guard tlcces60l'ies consist of the follower, megadn& IIprina,

floor plate , floor plate cstch, trigeer guard screws 4nd the long e.nd short

set tlCr8WS tor the recoiver .

The f oUO'I'Ier is fl long narrow rlate, the top surface of which 1.8 angled.

It is contained i n tbe IMIga r.ine Ilr.d tcgether with t he magazine spring, rahes

the Sl!IlIrunitiOIl in the rree:a2ine upl'l'srd. &. clup far holding the mgu1ne

aprine I s located in the fr ont under side of t he rollower.

21

The I!Wlgszine spring is an Rll'" shaped flat. s pring, the narrow end of 'IIhioh

22

is attached to the foll01l'er; tb8 other end is conneoted to the floor plate.

rt conet.antly e:li'erts pressill'e to raise t ~ ammunition in the 1llIII.ge.lI1ne.

Tha hont er.o of the floor plate is atucbe<! t o the front end or the

trige:er guard magazina opel' irli hy meanS of II. pin. J. srulll recess in the

center of the floor plate engsges the floor plate catch and preventll it

frOIl opening. J. lip i s provided 01} the bs.c1c of the floor plate for inserting

one end of the magazine spring.

23

Tbe floor plate oatch 18 attached to the floor plate catch hOUDing or

the trigger guttrd. It consistll or the body, scre'll and spring. It is n]"

shaped and operated in the groove locat.ed in the for"ard end of the trigger

, __ -tion and ill Ilttacbed to the trigger BUN'd by a slI'411

guard semcircU.uu- ...

screw.

10

Tb. botto. front section of the catch hall a claw and the rear Bllction

u inletted. ! uaU bole in the center of the body i s used 88 6 cetch hook

for a tool when the noor plate catch oan not he released b:y tinGer. An

.ruptlcd hOle on the top sm"face or the body tcsether with II 8tell screw

eonuoh tt. IIOve_nt of the tloor plat. eatcb.

'I'ba sorell' 111 inserted into the elliptical opening on the t op of the

floor plat. ce:tcb and screwed m to the trigger guard , The epring 1& fitted

into the RJ. 'IIith one eoo being supported by the reAl' erod of the floor plate

catoh houaing. It constantly e:zerts torn.ro pr8B8ure or. the cIa'll ar.d prevants

the claw fro .. releasing the floor plate .

When the floor plate catch Is pullod to the rear I preslIUI'e I s applied to

th. catch IIprIng, and this disengages the oatcll frolll the floor plat.e, ther eby

causing the floor plata to open.

24

'!'be trigger guard Bcrew p8U8S through the sore'll sleeve att8.0h!Kl to the

etock aDd oonnects the rear. end or the trigger guard to the rear efl(l of the;

25 The lmg and short receiver screws pass through the acrew sleeve attached

to the stock. Th. 10118 screw conneotl the rear end of the s8lld.circuler por-

tiOD of the trigger guard to the rooar projection below the receiver aM tIle

sbort screwl the rorward end of the triBeer euard t o the forward p-oJeotion

below the receiver. The short Bcrew il the s hortect one in Lhe trigeer

26

gUlird group.

E Stock Group

Tha rUle stock 1.8 mde or walnut and its entire surface is lacqU6l'oo.

1'bs rille stock i8 used to hold t he rifle in firing and ti S a wearon with

the bayonet. It is attached to the. rifle by mEtana of 6Cl' 8W6, uppElr b&nd tillrl

lower band. FrOIl! the standpoint of convenience, t he s t ock is divided into

three Eleot.lOlls ; nlllt08l1, the atock, erip. alld butt.

11

I

The stock has a cleanin8 rod chamber and cleaning roil catch housing in

thtl flooot ar.d 4 magazine housing an the rear. 'l'hs acre. hole located at the

orlrog-.e !'root and of the steek Is U8ed tor the upper band olate. Tb. holes

follO'lling are used for upper band and lower band. reapectiva17.

... slIIBll hole is providvd ut the reaT right aide for l'apelr .. ark, and

groovee are provlded 00 both flidel5 in order to faoilitate boldina .. hen tiring.

The front. end is notched to fit the upper \Jand plat.e and upper baod . '/fater

dr.ill.gll hole for tl')e cloani ng rod chaaber is located at the tront botto.

8er.tlon of the JrB.Rsdne hous!nJl:.

The trigger slot Is found at the Tear . j. longltuUnai groave which

(l.coolNnodat.ea the forward projection of the reoeivar 1& found in the upper

farr.ard Beettem of the stock. An aperture for the butter 111 located at the

baCK er.cl of this groove. Two vertical 1101s6 locat.od in the groove wbioh ILOCOIII-

1I".008t88 the and roa1' proJectiOlls of the recelvar.

The 10'llCr baIld locat&d in tN!! oenter of the stock 1& atuched by maan&

or 101'1el" hIt-nd screw. narrow, long. IJJ'Id service holes tar tbe c1ean1Ila;

rod chamber are f owd in the rear, interior of the oleaning rod

e;rip Bactior. facilitat.es gripping or tbe ritle dl.U"iJlg firinS.

The hutt

la !Tade frOD t.o l:8\.1,rlel5 MId t08f1ther by mans of dovetail

JOints ar.d 1.:'1 TTovlded ldt!l butt sl1ng "wlvsl arod but.t r late.

The fQMIard

end of the butt. 11; re1nforcoo by'" recoil :llate and tr1aeer guard.

The rear

end ,jf tbe 'butt Is protected by the butt , late .

.a. screw sleeve 1& in8erted

into t!,e hole located at the rear of the recoil plate .

... .. 00 -olate upper bend. cleanl-"g

27 The s tock uttaclulJlnts conslat w. upper..... .

rod cbt.ch, hand gw:.rd cateh (ahort ritle only), 10'/o'or band, burrel'. b utt sling

slOivol, b;Jtt plata, bend gu.o.rd, .end cleaning rod .

nd

, tl stock and i8 attebh6d

1M upper banlj :-18tl! covers the fL"not e 0 1e

t o t ha upper bard by oaans of uppal' bend plate 8C1"01l .

1b 8aoicircul.ar notch

8Up;>OJ't S t he bend.

12 '

29

)1

The upper bBnd together Jd.th the upper band plate covers the head of t.he

et.ock and compresses trn barrcl fl'0I:, the top. It. u l1tted to the cleaning

rod catch base by ceans or two :'Icrews . The u pper band p13t.e atUched to

the upper band by insertba upper hand plate ,cre" rrulll ri6ht t.o left throug;,

the screw hole located in tre forward section of the upper band. The ba.1onet

lug round on the lo"""r portion of the upper band is used for attaching the

'n'e cleaning I"od catch consists of the body, spring and seat. A hole

for inserti ng the clean1nf: rod is made in the bod,;( Wld the seat. The body

operates "ithin the seat.. 'fbe sprina fitted in the sprin.; slot, IXlnstantJ.y

appUes pr8lJsure to 1he cleaning rod caten and CauS08 the hole cL the seat

and the hole of t.ne body to lock. 'Ihus the body eJIi(8ges the recess of the

cleaning 1"<Id and prevents the cleaning rod from sUppina out . In ordel" to

release tbe cleaning rod, tne body is presssd im,ard to disengage thl! cleaning

rod from the body and the I"od h pulled out .

Th. hand gU.3.l'd oll.t.ah i!l at.t.a.chod t.o the .stock of t.le 100101" baud :OlOCliun

located on the fOr"llard snd of the hand b'Uard in such a way that it holm the

berel from the bottom. 'lhe upper surfacs or hond guard catch clAmp,

into the hand g uard ana t060ther with the u:etal fl'8.tDe at the rsar portIon of

the hll.."l d cuaf'd prev-mts the Q'Overnent of tns hand ,;)lard.

'['he lOll'er band 13 attached t.o the central portion of the stoc!c. It

tight.9ns the M..'10 euarcl and prevents nove!!llnt of the barrs!, It 151 attached

t o the stock by reans of the l ower band scrOl'l .

The lower band consists of the body, swivel, scre;,. and monopod. The

shape of thfl 10'''er band for rifles and short rifles is different .

Itie IlDnopod consi::lts of the body, mount , IIKllnt pin, spling pin,

and nut. The body is inserted into the w.unt 8J\d 13 by lIIOunt pin

which connects the IIUlnt lind the lower bsnd . '!'he is attached by

IS

I

))

34

J5

)6

spring pin and nut and !'rom both sides, IIlIl1nt:l1.ns the rnonopod in tolded or

erect podUon. Whm the ..,nopod. i.s J.blded, etc., the rr:.nt end hooke:

on to lhe upper band screw. The lowerirl6 of th e mOl'loj)Od h prevented by

locking. The :!pring pin is inserted trom the right side 81 d locked from the

left si de with a I1\lt.

'(be s'ld.vel of ths rifle is attached to the bottOlll ot the lCMur band and

that of the short rifle to the left si de of the 101'l'er band. It 1.8 used for

attaching the s line. The monopod Can be bent conveniently accor ding to the

nature of the t errain .

The buffer is an a ngular shaft i nser ted from fight to left into the buffer

hole located in front of the /lBgazine housing of the stock . It is locked on

t he left side by means of a nut. It sustains the forward projection of the

recavar and together with the recoil plate transmits the reooil IiJ. ring fi re

t o toostod<.

The butt sling asaelllbJ.;,t consists 01" the seet and lIl9iv-e1. 'l'he seat 19 at-

tached to the butt and the swivel to the seat. '/he butt swivel and 101'l'er band

S'Nivel are used to attach the slin&, l'he .!Jhape and position of the butt sling

assembl,y for r1flh II'ld sha-t rifle differ. In the case of the rifle t he t:ut.t

sling asselllbl,y is attached to the ixlttom of the hltt by means of lona 8'ld st'Qrt

"crews. In the case of short rif-es it is attached to the left s ide of the

butt by two '/lood screws. Since the "eat of the butt .ding assembly for the

5hort ri fl e is elevated to limit the forward tripping of the 9"ivel, the s ling

can be easil,y adjusted for whi le weariOl a gas tllMk.

The butt plate is attached to th e IJ'Id of the s tock by /Teans of long and

.!Jna-t wood screws . It protects the butt 3ld strengthens the joint of the two

materials whim for ms the butt.

The ahape 0[ hand guaro for rifle and sn:. r t ri fle differs.

The hand guard for rifle consists of tl"ll boc\y and lll!ltal frame. It cOYers

the barrel f rom the t.op , prevQ'lts its an'" pro tects the hand f rom

14

)7

grasping t h e gun whl the barr el is heated. It, forwar d ooge iii clanq:led by

the lower band and tte groove on it" bottom surface fits Oller the hand guard

cat ch. Its rear end, the iM8r surface of which 1s attached to a metal f'l'ame,

is inserted into the f r ont end of the TeaT sight base. The metal frame covers

tm barrel and together with the hand &lard catch, prevents th e hand guard

from 1Il0ving.

The hand euard for the short rifle consista of the tDd.Y and JlEtal frame.

It covers the barrel from the top and prevents it fro m moving and pr otects

the hand in grasping the ritle when tile barrel 13 heated. It s rear end, the

inner surface of w hieh is attached to a metal [r&IO, i s inserted 1.nto the fro nt

end of the rear sight base. The nl)t.al frame covers the barrel from the top.

Its front 8'1 d is c overed by the upper band '" h1Ch , together 'fd til the 10lfer

band, prevents the hand g uard from lIlovi ng. The lower band 1s located about

three and one-halJ inches in front d: the rear sight base and holds the hand

guard and the stock together by IIEans of a screw.

The cl eanin/( rod is used for claaning and stacking rifles. A male screw

is provided Ilt the bottom end and a hole at the top end. When the occasion

arises , cleaning rod jag, s wab, and awdliarl cleaning rod can be attached to

the male screw, A piece of wood cr cloth mn be 'inserted 1n the top hole to

facilitate cleaning.

II Function of the breech roechani!llJl

J8 The relationship bet'lfeen the receiver and bolt during tire iSI

(a) When the bolt is opened and fhe rounds contained 1n the cartridge clip

are loaded into the ma.gaune l ocated at the front of the l1lc6iver, the rrunds

depresa the follower and stack up three to the r1gj:J.t and tlfO to tJ1e left

The rc:unds are raised upward by ceans of the magazine spring.

(u) Wh8'l the bolt 1s pUl!lhed fol'tjard. the clip is released by the press ure

I

exerted at the uottOlll by the bolt . The uppemost round, pUl!lhed from the rear,

15

,

I

slides up the cartridge ranp loeatetl in f r ont of the port at the bottom

of the receiver and ert.ers the charrber. At this instance the extractor engages

the rear gtloove of the cartridge in preparation for extraction.

(e) When the bolt is completely closed and the trigger pulled, the sear is

lowered, this disengaging it. fmlll tJle cocking lever . The cO'lllressed firing

pin .spring drives the firing pin forward until 1l'le firing pin stri kes the primer

of U\ e c &rtrilJge.

At this tiwe the b:llt handle will net open since the safety lock has

engaged.t.h&:s ai'et;rlock groove of 1l'le bolt . Furthermcrs, when the breech is not

elosed prope rly, the trisger cannot be pulled since the safety lock will not

be in Jl.ttfe liith the groove. ThIllI', a safety meansure is provided.

-bolt handle i e raised and t.he bolt 1:9 broudlt to the rear, the

ej ector, by means of ejector splings, !!Iters the ejector groove of the bolt

housing and ejects the cartridge, .tIidi has been extracted by the extractor.

When the Lvlt. is pu ... led back fu l l.7 , it. is prevented rn.:.m slipping out of the

l'e cfl'\. vl!r nCe thl! bolt. cRt.ch I!nVle"'" t.h .. holt. lug.

(e) When t ne bolt is again brought forward, the rext roU'1d is loaded, dis_

charged, 8:td eject.ed in t.he Sa'lle manner lUI the pr evious round.

(r) When all of the rwnds have been 8X?8nded the follo .....er catches the bolt

face and prevents i ts advll1ce. This indicat.es to the firer that the I!I8.gazine

is empt.y.

39 Safety CIl1 be Il'aintained by the saTety lock ann s afet:.y knob. The function

of the sai'et.y lock has been explained in (c) of 38. The safety knob in opera-

tion prevent.s the bolt. handle frolll and locks the tri gger. In shert,

the safety knob is operated in the followill6 IMrmer . When the safety knoh is

pressed forward , turned 45 degrees to t.ne ri l!J1t., t.he safety knob catch enters

the wrved gr oove in the resr of the receiver and locks the safety krob. \'lhen

this is done, the small projection at Ute rear of the bolt. handle engages t.he

races" 0:1 t.he outer fringe of the safety knob Md prevents the bolt handle

16

and wlt from opening. At the sane time the firing pin turns with the safety

knob, the sear cateh moves from the firil'l6 pin eatch, enters the left reeess

MId disengages the firing pin from the sear, thereb:1 locking the tr:!. l!ser.

When the 811.fety knob is l ocked, the position of the semicircular cut on

the rear upper 18ft of the safety knob is chanSed t.o an upward posi lion.

CMpter 2 Accessories

1.

2.

J.

4.

5.

6.

7.

B.

9.

Accessories include the folloong:

Accessories bag

Contents

Lubricating cord

Swab and

swab container

Cle aning rod tip

Awc.Ll1ary eleaning rod

Cleaning rod gui.ds

Cleaning rod

Sling (Different for lons rifle II1d shcrt rifle)

Ar.nunition pcuch, Type J.

arnJIIllnition pouch

Rear alfWlluniti on pouch

pouch, Type

Ammunition pouch, type C

Cartridge belt

llil container, Type A, 2 1/2 ounces

Oil container, Type B (0. 03 liter) 1 1/4 ounces

l::nr'1

AUJllImition pouch, Type A, B, MC C j eartJ:;'idge belt; oil cont.ainer, Type A

(21/2 ounces); oil container, Type a (11/4 ounces) are used according

to respective maintemnce classificat.ions.

17

41 The accessod. bag is made of c&nvall, i. ten inche:=! 101'18 and two and

one.oeighth inche:=! wide. It is opened ald closed by IlIIa'lS of a buckle type

strap ard contaiM the follo'll'ing :

(1) Lubricat.ing cord

'nl.is 18 used to clean the bore when time allows wring aarehell or

mJDbat. . It consista of a he!!p cord and wei&/1t with an over-&11 length of one

/IIeter . When using, <rop the weighted end into the bore, et.tach cleaning patch

to loop on opposite end and pull through to clean or lubricate bore.

(2) Cleaning rod tip

nus consist.s of the body an d the cleanins rod tip spindle 1t!ich is

sorllWed ont o the c.l8anini; rod or the auxiliary cleani ng rod. The bore is

cleaned by wrapping a clBanine patch a r Cll nd the body which rotates.

(3) SWab

This is made of br ass , equipp'Jd with. brush (hog bristles)' Wid a

connecting tUDe with a felllll "'-e screw at. the lower end. It is attached to the

cleaninl!, rod cr the auxiliary rod and used in the bore .

When not in it i., alw!.ys kept in the metal swab container t.o proteot Ute

brush.

(4) '" C.leanint; rod

Yade of brass , it is used La c1e;:n the bolt. , recilivlJ r, a nd othe r "grooves .

The1l1\Qle "erves in attaching cleaning patches .

(5) AWliliary c .lt!aning rod

'l'here are two rods ; one with a fewe screw, 8Ild the other lith a male

ser e... . The faude screw Join" into the canni ng r od am the male sere-" into

the clelC'lill8 roc tip or swab. WhlJl cleaning. the aux1lia ry rod is a t tached.

l6) Cleaning rod gui de

Made of cylindr ical wood with a catch toward the rear . \'fhm cl.e811ing,

this h attal:i!.ed to the.eceiver Ind the oleanins rod thru"t t hrough i t to

" '

prevent defacing ot the bore. 'lhe catch l'its into the mIt hllndle slot located

toward the re&r or the ",celvel' and prevents rroveMnt of the cleaning rod guide.

42 The gun sling is attached. to the swivel, located on the lower band and

the butt, by mearu of the snap fastener, bUckle, and l oose strap. The length

can be .:ljuoted by means of the buckle. 't'ha s111\3 for t.he short. tine differs

in t.hat it. is 1dder, 25-mra shorter, and equipped with a snIP link at the lower

end whic h, together Idth the butt swivel asaea.bly, wss delllOunt.ing c the

sling convenient.

4:3 AIII!I1n1t1on pooch , Type A is tt-e general nomenclature for two front am-

IWnition pouches and one ",ar alUlJlnition po.ach. !'he ,front pouches consist or

the body, belt loop, button, c Q1!le cting strap, Q)ver, l'Qstenlng loop, and

cover fastener . The rear ammuniti on pouch Q)nsists of the bod,y, l' as t ening

loop, button (wiUi "eat), belt loop, cover , cover fastener, partiti on Md

fastening etraps Type A and B. 'the belt loop i.s attached to t he bayonet belt.

The interior of each a mr:.un1.t1on pruch 111 partitioned into two compartUJent"

which hold the IllilUnition wr a;>ped i n a paper c ontainer. The a"",,'nition

pouch is equipped .... ith en exterior for oil container Type ,\

(2 1/2 ounces) . There are two elliptical holes in the botwlll. t.o facilitate

removal of the paper containers .

44 Anm.tnition poudt Type B consist.s of the oody, belt loop, cover fastener

button, fastening strap, buckle stra?, tutton, cover', cover fQ.lItener strap,

partition, fastening loop, and the belt. '!'he partition dividell the interior

into t.hree cOlllpartrnerta. 1'he mitldle coa:pnrtdnt hold" 011 contai ner 'JYpe Ii

(11/4 ounces) and the Side cOI!lpartn6nts hold the arnnunit1un wrapped in a

p4per container. lt ie cC;uipped w.i.U! an exterior corrpartlf,enl which holds the

cleaning rod WId cJo:1!liru r od tip. It is alune uver the kft shwlder by

trelln' of tne Ujltening st.rap (buckle str ap, bi,:.t.t.on) and faetened a rQJ.n'i the

waist by mean" of the belt .

19

I

45

41

'AIIJlunitlon pouch 'tn>e C is a/IIIUnit.1on pouch 'tYpe 3 without the belt lrId

tightanil'll: strap (buckle strap. button) .

The curtrldge belt is made of canvas and reinforced on top and bottor:l by

lMther . It is fast.ened around the waist by of the buckle strap and

tightenin..,; strap. It hal! larga, medium, and small pouches . Thera aTe two

.l.&rge pouches which hold one ha:ld grenade each, six rnediun pouche!l which hold

ten or .",munltion each, ard one 9111311 pouch Witch holds an 011 container.

011 container 'IYpe A consists of the body, applicator, cues A Rld B,

and screw cap. Oil c ontainer Type B con.si,ts r:I: the bo<tt', applicator, f'1.1ling

spout , m d calles ,\ and B.

Chapter J

Bayonet and Accessories

The ba.vonet and oUior steel parts are aU blued. It. consists of the

blade (hilt , potmel, guard, hilt griP. catch) and scabbard. 1'he bl.1.de 18

straight 'IIi th a groOVI!I on each si de an d an over-all length of 20 inch os ,

11\0 hilt a iUlll'd toward the blAda find And t.h .. pnrMlftl riv .. t.flrI tn it

at the but.t. ld. The b3"Yonet. lug e r oove 13 on t.re pOl!nlel l'Ihif:h 11.180 houses

t.he catch. The bayonet lug Otl the rifJe 1'ih int o the b8yotlet lug groove 11.00

the act.ion ot the catch unite:J the rifle and the b.a.tonet. "llie catch which is

equipped wit. h a spring is insorted into the catch ha19ing from rip}1.t and

fixed in place from the .left by ImIIWlS or 8t1 escutcheon. 'rhe escutcheon is cetlter

punchlKl . '1be end of the guard lt1..th tte round hole is knO'lfn as the "dragon' s

head" and when the ba,yonet is fixed the other end is ktlOWtl as the "dragon' s

tail". 'rhe eUily handled hilt grip is attached on b:lth sides of the hilt

by me<nS of two sets of screws, seat , and s:lcutcheon with the forward end

adjoining the guard and the other end adJoining the POIlltl'.el. The screws are

inserted from ttvil rlc?Jlt and se.lted with the escutcheon frolll the lett. '1'he

blade stuls 7 1/2 inches in .enctb frOl:l the forward end.

20 '

49

50

51

1

1he scabbard consists of a /aQ1th, ,aoabb&rd catch, 'Ild a pOinted tip. 'lbe

mouth reint'o rcss the upper end of the scabbard. A plate sprina is ""lded

bel"" this. The ecabbard catch is attached below the mwth by lIIIens of a

screw. The ba,yonet is fastened to the frog by means ot' the scabbard strap on

the trog. The pointed tip is welded and proteots the tip of the ::Icabbard

The plate spring which lei located within the scabbard sandldche8 the blade

and prevents it from slipping wt.

l:i!Lyonet accessories include the frog and the belt . The 'bayonet is attached

t o the frog and tt.! belt l'It!.ich suspends the frog is used to carry the bayonet

as a aideal'lll .

The frog is equipped with a buckle and a scabbard strap. The belt is

equipped ldth a buckle and strap. In the event the belt is too shert tor the

user, there is th e long belt Type A (B) .

Chapter 4 Ammunition

lbe regular cartridge, Ball cal. 30. M2, consists of the cartridge case.

primer, prop4ll.l.ent po,"cler III'Id l!. bullet. Ita over-all wo1&ht i5 )96 !jf'a.1t\.5

and its over-&ll length 18 J . 34 inches. 'lb- case ill made ot brass. 8J.llet

tip is plain a.nd W'IIlI8.rked. The bulbt is cOlllpoaed ot a gl.1din& metal and

a lead core.

Cartridge ArJllOr Piercing, cal. , JOt W2. This cartridge 1a a imilar in

appearance to the cartridge, Ball cal. .30, IQ except that the tullat tip is

black. The bullet consists of a gtlding lIIetal Jacket , a hard alloy s t eel

core, II. lead "T" shot point filler and a metal base tiller.

Cart ridge tracer cal 30 This cartridge is used in titles tor

3igno.l and incendiary purposes, t.ar get designation, r ange e s timation and target

practice. '1hia car t.ridge is readil,y identified by the red bullet tip

21

I

53

inclLcating the color of the t.race.

Cartridge tracer cill. 30 K25" (T-lO) . Thh cartridge 11 used in machine

guns primarily but. fN!t3 be used i:'l rifles abo.

'!tie differel:e between this cartri dge and t he cartridge tracer cal )0,

1111 hi that the ruUet from thi:J cartridge has a diM trace up to a?prox1mat.ely

100 yar ds, then the brilitlt trace begins 81d conti nues to approximately 1, 000

yards . The color of the bJ.llet tip 11 ol"llT8e.

54 Cartrid.6e blank cal 30 1&1909. '!hb cartrlda:e is used for silDl1l.a.ted fire

5'

56

in lII&I"Ieuvers ...-.d exercises, signallng PUl'ilOSeS and flr1.ng salutes. It is readi -

l,y ident1tied since it has no rullet.

Cart ridge dummy cal. . 30, 162 . This cartr idge i s ussd for trainina; per_

sonnel in the operation of loadlng and unload!.. ng rifles an d s inulating rifle

tire and in the i nspection of weapoM, It is easily identified by the three

holos dr illed in the cartridge casc and the absence of a pri mer.

Cart ridge, Rifle Grenade , cal 30, 10. 'nils cartr:l.die Is lcaded with

live craine of black p.,..d..r And f o rty gra1.n$ or 'lIIOk.l.au powd.r. This c:art_

rlc1ge Is used only with stmdard rifle srenades .. d srenade proJectJ.on adapters.

Length ot cartrld&e is 2.49 inch 'the cartridge be readily Ident:J.tied

by the characteriatic ns" petal rose cri ap of ths IIIQ.L tho

Part 'l'w:Il Handling:

Chapter I Disassembly and

57 There are two types tA dilJ&.!selllb.l,y, regular and s pecial. Hcwever, the

special d1suumbl,y shall be l1.mited to repairs and other J1IlI c&.S8ary instances

perlo1'l'll8d by Orcin .. ce peraonnelllld the basic principle sha.ll be that it is

not ClD nducted i n general. Alao the users of arM and sdl oola are Jr0hibited

disanemblies other than those mentioned 1n thie chapt er. Except in specially

mentioned cases, the as s embly shall generoll,,:r be conducted In the reverse order

I

I

I

I

All far as the disassemb.lJ md Ib.mnbl are CO:'lcerned, the 1'"ollOlling

l!JJSt. be noted carefulq and "flY defecUve parts o[ t.he rUle must be

repai red iJmledl..at.el,y.

I Nor:tlll disa9sembl.,y and asselcol1

58 Parts that can be by the usbg unit.

Regular diaassmnbli ea are:

.11""

bolt

c18anln,g r od

follower spring an::! the follaJler

The aanerr.bl,y and disassembly of the sling are as 1bllows:

( l) In order to disassemble the rifle sling,

(a) Unfasten the link catch and break the connection with the

upper band.

(l::) Lcwer the strap.

(c) Unfasten the buckl

(d) "When the end of the sling is Wlfutened fro:u the strap;

(e) 'nIe sling becomes detached from Ule bJ.tC.

(2) In order to aasOllble the rifle Sling,

(a) Slip the sling through the luck Ie.

(b) The Sling ia sUpped through so that th e stitches or the

str ap are on the left side of tt. r ifle.

(c) Pa.!s the IS"l d oX the sling frolll the rear through t.hs bJ.t.t

,ling swivel,

( d) Pass the strap thrl)u,gh.

(e) Paas the m d or tAl ,ling t hr ough the buckle the [ront

side.

to Utat or the dlaassemb.l,y. (t) Fasten at the apprOpriate eyslet..

22 ' 23

I

(g) Place the end of the sling into 1.he atrap.

(h) Push the strap up until it is bela. the ruck1e.

(i) Connect the front end of the sling "ith the lower band

-

safety knob will beCOIte detached fnlal the bolt hcusing.

(2) Firing pin

Remove from the 'r:olt housing

3'11'ive1. 0) Firing pin spring.

0) DiaaSSelllbl,y of' the short rifle sling. Remov e from the atriker

(a) Unfaoten the link button and detach fro m the lower band.

(b) The removal of the ruckle, strap and the spring catch are

the 8M1e 88 with the r ifle.

(c) In the very end, tlle spring catcn is detacned from the rutt

slina swivel.

(4) Assembl of the sh(l("t rifle sling.

(a) Fit the buckle.

(b) In8ert the 8trap.

(c) Fit the spring catch 80 that the open and close aection

faces tne stock.

(d) After this, the steps are the same as w\.th the rifle.

60 In order to dstach the bolt, place the rifle in a horizontal position

with t he barrel facing up; while 8upport.i. ng the rifle wi th t It! left hand

gra"p the bolt handle "ith tm M.Stt hand and place in an upright po3ition.

pull it completel,y backward. tllen open the bolt catch to the left with

the left thumb, Q'\d pull the bolt handle s l(ll'l'l3 backward to 1'8l11OVe from

the

61 The bolt is disassembled in the following o r der after the bolt

cover is removed.

(1) Safety knob

Hold the bolt ' .. 1 th the left hand and place the palm of the dB'lt

hand on the re<U' of the safety knob . Exert sufficimt pressure on thi3.

and turn cOl!pletel,y to the li6tt then if the pressure is released the

24

,

(4) Extractor

Grasp the rolt housing wi. th tlle l\!1ft hand. After /IlOving the

position of the extractor to above the elliptical hole. preas the ex-

tr3Ctor fonrard and detach.

(5) Precauti :.>ns should be exercised in the following cases in

the Q'\ d assembl,y of the bolt.

(a) When relllOVing the I;Qlt. care shculd be taken so tnat the

butt will not be damaged by the sarety knob lug.

(b) In asselllbl,ying the extractor. align the extractor collar

ears witll the elliptical hole of the \xIlt hoosing, fit the hole on the

bottom surface of the extractor, and with the left hand grasp the rult

bod,y together ld.th tm 3pring porti;)n of the extractor, then press the

extractor lIltn the right thumb and pU3h into place .oien connects

it "ith the extractor collar. Afte r assembl3, turn the extractor to the

lett and engage tne projection bohind the extractor hooks 1fIto the groove

of the extractor hcusinl!. then place it accuratol over the rillt lock-

ing lug of' the bolt .

(c) In inserting the fl.r.ing pin into the tolt housing. the

sear lug !lUst be Jitted into the rear seu:dcircle, otherwise it will

be i mpossible to assemble the bolt .

(d) In f1 tting the safetl knob, the lug in the middle of the

I

axle 1s fitted into the rarrOlf groove on the In$1de of the rear part.

o! the tiring pin, thtn pressure il'l exerted. It it does not. enter even

atter application of pressure, tum dlghtl,y to left or ri."t 110 that

proper contact ia made. After the lI&l'ety knob enters, turn it compietel,y

to the 111ft then relieve the pressure.

(e) l! the sear lug of t.he tlrlng pin is l1tted by matalto

into the lnall.-shaped portion at the rear of the bolt. hOUsing. grup

the bolt housing 'll'ith the ltItt. hand, prllss the saffltl knob aufficientl,y

with ttl! nilt hand and turn the sear lug to tlle r11ilt. along the snail-

shaped part . After it stops, reapply pressure and "hen the fir1ng pin

spring willlllOVe no further, the sear lug 13 1l.tted into the semicircular

part. Then tbe safety knob is rotated to the left . It ill now correctlT

auembled.

(t) If throu61 error the bolt is placed into the racsiver

withrut aaaembl,yi", the extractor, withwt forcing an,ything. first

ascertain the po5it1on of the safety knob lug. Then after guiding

it ca"rectly to the right, ax.tract UtI! b:llt dO'l'll,y. v."nen the ex-

tractor ia bm.ng detached bI!IClllse or jamming during tire, after the

extractor collar 13 1II0ved to the dght e1de, the bolt is puahed for-

ward carefully and the sxtractor ill I8&&ed I'd. ttl the extractor collar.

'then the bolt 1s p.i.Ll.ed oeck. Also when the empty cartr1d&e case

remains 1n the cartridge chamber due to jamming, a clean cleaning rod

is inserted into tte bore and the cartridse ejected befa"e engaging

the ejector.

(g) When the bolt is f1 tted into the receiver, the cor r ect-

ness of the: b:llt assembl,y is rechecked, the catches on both sides of

the !:olt covers are titted into the grooves on the outside of the

26

=

receiver, the bolt retainer is openlKl outward, the bolt puehed f orward,

maguine platfOTIII depressed downward and assembly complet.ed . Then the

t.rigger is pulled and tte fi ring pin 13 left. in t.he sear catch position.

62 In removing.. ttl e c leaning rod. place the r HIe in a vertical po.s1. tion.

wit.h the barrel lacing frontward . WitJ'l tha left. hand graap below the

cleaninc rod catch and press the catch with the I1IWl1b. Then Uft alt

t.he cleaning rod.

63 In removin& thl! follower spring IIld the follower, pull the floor

plate catch. Aft.er the floor plate opens, grasp it "il1l the left hand .

With the riiV\t IwJ:I. grasp tho 10ll'or blade of the spring slightly above

the bent portion, lift upward slightly and pull back"ard. Thill it will

become detached from the floor plate . The follol'fer and the follower

apring are also disassembled in thl! satle I!I8mor .

II Special disassembl,y and asselllbl,y. (Dy Ordna1ce peraonnel onl.y)

64 Special d1.sassembl,y is I!xe\::utlil d after the regular diSMsembl,y are:

f ront upper band an:l. the Uj:lper band plAte.

iD.ar band .

Hand guard

Barrel 80:1 receiver (base maintenance only)

I6agazine

Floor plate catch

C l e a ~ rod catch

IiItt plate

Butt sling swivel

27

Ycnopod

65 The order of the special di5as,embl11S as tollows I

(a) Front. stlflt bue and Iront !d.ght.

Uter the ca1lked pin is extracted frolll l:1/1lt to lett, t .. e seat.

ie tipped forward. 'lbe sight can be pounded rut either tftIm the left

or Care lIIlst be exerciseli net to damage the front sigti; bl4de.

WMn realilSelllbl"d it !D.lst be zeroed-in asain, the old laarker line erased

and replaced by a new fIlIU"ker 11ne.

(b) Uf:peT band and tm upper band plate

Remave the left and rl&1'tt aCTO'II'S and the plate bolt, and detach

with the plate.

(c) Lowet' band

Place the barrel lacing 18ft, unscrew the alll&llacrew and remove

together IItth the monopod.

(d) Kand guard

B&rrelia placed facing upward, Grasp the front end of the hand

rail and I8I11tl'le together "II.th the metal trame by pulling alo.l,y to the

f1'Ont while .s11Sttly lifting upward.

(e) Barrel and recEli.ver

After removing the long and short receiver screws and t bI trigger

guard acrew, place the rifle in a level pos!.Uon with the barrel facirl$

up, gras p th II r IICd. vel' wi tn tn e righ t. hand an d t. he front. si ght sect.ion

witn t.he left hand, t.hen upward . Next. det.ach t.he rec01.1 plat.e,

In order to disassemble the reAr Si ght, the rear Axle pin is

removed lind t.he rea; si/tlt detached. The rear sight spring is dls-

asseJllbled froal t.he base by nUlOvlng the ,mall re/U' sight. ecI'G'lf

and tipping it lfBitl,y forward. In the dl3aufllrbl,y of the sUde,

28 '

-

Cir!lt. rtl mave the smU 1 :rear sight screw and detach the :lli de from

the rear SilPt , Next, Ul\screlll the left end sUde cat. ch pins

then det..lch the sUde catches and slide catch aprings !rom the sli de.

In the disa:lsembl,y of the antiaircraft lead s ight. anns , the a:'ltiair-

craft lead s ight arm screws are Ul\acrtnred and the a 1'!llS r emoved. Th e

springs are rext detached. The spring will beCOll:e detached it p ulled

abo.lt ttree millimeters froa the outside in'lfard.

I n t.he disas9l!mbl,y of the rear sight base, the r ear si ght base

scrl!,rl 1s removed and the base pulled out to the f o re, In the d1a_

&l58emb),v of the bolt retair1!lr and the ejector, after pulling out the toll.

retai ner spring, unscrl!l'f t,he oolt ret.ainer pin. Then detach the bolt

ret.n1ner 1'rom the recel. v er and the ejector Crom t:olt r etainer. The

ej ector spring 13 inserted in the bolt retainer latch In

disassem'ol,yine the sear anc! the t.rigger, the s ear pin b ext.rll.cted,

t.hen tile s ear and the trigger are detaChed CltIlIl the receiver . Next.,

the t.rigger pin is removed II'\d the t.rigger det.ached troo Ute sear .

(f) Jo!.l8azine

In the disassea:b4' or the IfAgazine, the trigger guard is det.ached

fr O!:! Ut e !ltock. the front pin eJtt.racted, and the floor plate removed

Croln tho t.ri

6

ger guard. Then the &l&gadne can b e readll,y disassembled

all it is merel,y insert.ed into tke chal"..ber in the s to d<'.

When asaet:lbl,ying the magnzine, f: lKce the lower side t.Ol'Iard the

front. W'ld t.ne 3.n&ular aide rac10J up.

29

(g) Floor plate ca.tch

The floor plate catc h is disassembled by rlJllovin& 0. slIIIlll !lcrew

to the roor of the trigger guard, then pulling 1 tout to,;ethlJl" with

the spring.

( h) Cleaning rod catch

The cleaning r od catch h rellJ:lved by pushing it inward fI'Qm the

outside. In :ouch cases the base and the spri ng of the cleaning r o d

catch d1$as5eQ'.bles together from the srock .

(1) Butt plate

'llle lutt plate i s d i sassembled by unscrO'lling the wood SCTo-liS .

When allsenil 4rin,g t.he longor wood scre-H is S CTawed in at the lower

end 6Ild the shorter l'Dod screw is screwed 1n at the t.op,

(j) Dutt sling s llivel

'rhe butt sling :nlivel is disass embled by removing the wood

scre;'IS. With the rifle, the longer wood sere-If is screwed in on the

s i de th at 1s closer to I.he front end and t he shorter wood SCTelf on

t.he side that. 15 closer to the rear end . With the short rifle the

:.lant ed !;urface is placed facing the rear end . I)e. sure that error

not r.-.ade a3 to the tront and the rear sides .

(Jt) Monopod

The monopod 1s disassembled from the l ower band, the spring

pill II'\d nut are removed then the s p ring detached, the

baSI! pin is I'ereoverl. then the Irlnopod base i s detached from the

l oweI' band, and the mOlOOpod from the base.

66 Care IliIlSt. be exercised in the llpecilil. diSIISSBlllbl,y and

assembly of t. he following cases .

(a) During the disassembly an d a3sembly of the upper and

l ower band.s , t.he blUing of th e barI'el !Just not be scraped off and

the stock t Lll s t nn t dau:.aged.

30

=

-

67

68

( b) Ule dlsassembl,y of the hand guard, care Il1l st be taken in

order not to damage the aetal !'ru e and the rear m d .

(c) 'Rhen I'emovin.: the barrel a nd receiver, the fr ont and the rear ImlBt

be remov ed evenl,y from the stock, otherwise the stock may be dB./l'B.ged.

(d) The barrel and the recldver are 'Hsass embled only when re placement

or ttl e barrel is necessary .

(e) When the trigger !!!lard screws and ttJI recel.ver screws are being

screwed in, be sure thf&' are turned evenl,y, otherwise the trigger guard fM3

become tilted and ClI'\not be p roperl,y tightened; aLeo when the sma.l.l screw is

not tightened properl.Y, it afCects the accuracy of the nfle. f'1 r:i ng.

the contact point between the stock ald the recd-ver is often damaged when the

barr el r eooils.

(f) During B.SBcmbl,y. the pins and screwe IWst be inserted in the dir ec-

tion stipulated.

Chapter 2 Precautione in IUrldling.

The point to be ncted in the tests mentiO'hed below is thg,t the ea.sil,y

damaged parts must be handled with care. Althrueh the other detail:! a r e

identical to thoBe described in the manual on preservati on of arms . the main

points are I

'!he IllUzzle , front sight. rear siglt, and the bolt rust not be allowed

to touch the gl"Cllnd.

When the rifle is not i n use the bolt is clolled Bl\d tt.! pin is

placed in the atter-Cire position

The use of wood, paper, cloth, etc all a cap for the !!Uzzle mus t be

avoided because of the pOBsibility oC damage to the barrel.

70 The aowunition is first loaded into the ID!l gazine en d then inserted into

the chamber by the b:dt. When the 4fMIUnition ill placed d:L rect 13 in the chamber

and the bolt closed the e:xtractor will be dalllBged.

31

71 After exposure to dust, the bore, conditions perad.ttLng, should be cleaned

berore tiring. The muzzle section should be spot checked.

72 wtMIn exposed to rain or snow the I:ore aust be cleaned as soon as time

permits. The presence r moisture in the interior r: the rirle JrOllle5

rustinn.

7J The plugging of mU27;le 'Id. th vaseline or greMe in order to prevent

the entry or "ater into the bore DWlt be avoided because if tired "hile p.luued,

it cause the barrel to bulge or burst.

It the monopod 1.a bent du ring use, it ia cOlTfleted the soldier him-

sell it poeaible.

7$ Precautions that should be ta; en in :lUbzero areas.

(a) It misfires oocur frequentl,y, dpe the oil rrom the bolt. atlselllbly.

(b) When the rifle inwors after use, proper 011 wet be applied

to it. 'Ilte sling /lUst be kept May from fires. end it is also necessary to

take preceutions agslnat free7;ing 118 the leather sling cracks eaail,y.

(e)' D.lring the period6ti!e rifle is not in use. 1t. m..,.t. b", in II

"arm pla.ce or indoors as much as possible to prevent it from rreering. IT

kept Outdoors unavoid&bl,y, it must be covered 'Id th a blanket ur a atr"lt mat.

It pOSsible a fi 8 hwld bo built indoors to prevmt am- trouble lIIhen cslled

upon for unexpected fi ring.

(1) When a rifle i8 curled in from out of doors, the change ot tem-

perature induce, moisture to fol'lll on the metallic parts causint; it to rust.

Theretore, it rust be wiped off: the bore especially Jl.Uat be cleaned.

(2) 'n'IcI hulllidity or buildings in $llnero aresa e quipped 'ld.th heaters

becomes exceedingly 10'lf and unle:ls the 8tock 13 oiled , it "ill becolne exces!livl!_

l,y dry. Aa this Callses the stock to warp, t.tle rirIe rack muet be placed in

a position ae far a9 poS!Jible from the l'2:ate r, anu huud.dity must be ma.1ntained

at the proper .level.

32

7. n" l'olloldng precautions IilUst be exercised in tropical areas.

(a) It conditions psrlllit, open the bolt rrequentl.Y when tiring and cool

by vent.ilatint; wi thin the bore in order to aid in the dissipation of t.at.

(b) Kxpoaure to direct sunll,ght teats the gun causing ttm wooden parts

to warp. 'lherefore. ir conditions perndt, place in the shade or in a l ocation

wiUI a steadJ dran.

Chapter J Packing

77 In pecking rifles, in add1t:!on to the consideration of the III:!thod of

shipping and the dhtance, it it! necsssary to take lnUl cONl icieration the

weatmr iIll d th e season berare deciding on the uegre. and the metlx/d.

78 The fol1CMing precautiDns ahoold be taken with the inner paCking.

(8) Dip rifle in preservative (coslIIOline) as directed in Til.

(b) It is necessary t hat the supports and braces of the crate be rig1dl,y

fixed to prevent dllalage Ul the contents when the crate ia placed on its

side, overturned or jarred '"while in transit.

Part ntree Preservation

Chapter 1 eare

79 'rne care 13 generalJ,y a.s rullomll

00

Care of the bore and

!.Oare of the bolt mechanism

Care of the other parts or ttz rifle and the wooden parte

!.Oo.re of the leather articles

l:are of Unen lin d CO tton go ods

In the care of the bore, place the rifle in a level poeition on a stand

or a rack, rer..ove the bolt, insert the cleaning rod fitted with the cleaning

rod or a cleaning rod fitted with a claaning rod tip on which a paten

is tied, int.o the b:lre, and llm'e it slowly .forwards and backwards. After

repeating Lnis several limes {and when the bore is c lean} a thin coat of

ail in the 3tJf\e marner.

-33

I

. a1

When cleaning a rifle. rotate tn, c leaning rod tip t o follow the riflings ,

fX) reover. it is necessary to revolve the rifle appropriately in order to

the. rubbing of any one particular spot in the bore .

De careful so ttJl.t t.he rod t.ip aJd the rod do not

directl,y rub alainst the surface of the bore. At the sane t 1me check to see

if Ulls is conwcteci correctly, and a v oid the use of bent rods.

The care of the chambe r con31st" of inserting the chamber cleaning rod

fitted with a rag in the s lot on its f ront. e nd in order t o re move the old oil

or to apply fr esh oil.

,\s tne bore is chromium pla ted, cleaning is unnecessar y. There_

fore, it is necessary to obsorve the condition of the bJre an d the s tain on tne

rug, and adopt a suitable metbod anti f requency o f cleaning

In the ca r e 0(" the b>lt. 83sembls , a fte r the old oil and duat have been

removed fru m alch appl..v oil somewhat rrore heavily on tbe wo rn of

the 001t. by of a brus.'l or an ol.l,y ran. and llJht l,y on oth er parts.

The use of a cleani!'\} rod in the and oilirui. of tn, insi de a no

out.sl,le or til ..: bolt i1O'J9i nd, corner s , and the housing d: the firing

pin s ;>l"i"1t, i s reCUfilmenJed .

the bolt face i s chror.jUlu ;>1ated as b tfJe bore of the barrel

l

Ctlre llUSt ue exercis ed in it .

s:! Olli o il and oust arc re.a.oved f rom the othe r steel parts wi th a ra

s

a)

wrd.ch oil is Ilpplien witJl an 01l,:.r rag . A sar.eTlhllt greater IlIIIrunt of oil

is 3.ppuad to pina an d functi .ming parts. '!he exposed surfaces of the woo:!

parts are cleaned wit.h a rag . Any oil. that adheres to t.he wood parts boo

off.

It is neCeSsary to the a mount of oil appile.1 if an ex-

ce3sive amc.u.n t is applied. it not only increasos thl! adhe!'1Jnce of dust, but

t.1'e excess accU/lIUlates in the lower p3l'ts an d leaks out on t o the stock C8usin.&

34 '

1

it to become stained; Il)r8over. it !Ilf\Y be blown into the eye8 of the b'\lruler

whEn firing.

84 Leather goods are cared 1' 0r by applying a thin fi lm of Noats Foot Oil

'5

66

B7

on the top 8u rface with a piece of rag . Appl,y spari ngl,y. then wipe ar f the

excess wi th a dry cl oth .

When sp pl,yb g 01 ... to t}e leath er sling, it must be rubbed CrOSSM. s e

and not. lengthll'i5e.

AI\)' oil rwoaining on te;or;til.e fabric products II1l5t be reClCIVed as it

Oaraages the fibers.

If any lllildew is d etected. clean immediately wi th e1tner a d r ;! or a

cloth. 1I 0000evcr , vtLen this IJlltbod is net. adequate. care IlU!It be exercised

becal,l.se i t freqlOlltly promotes fli r Uler g rowth; moreover, a rag once used to

miJ.dew IllIst not be used on other unaffflcted leather parts .

Soiled web canvas are washed in soa;>y wate r .

fire, the rifle is cleMed a nd cared for as a>nrtltions p"nut.

II Care Firing

"':are befcr e fire consi5ts of a thorou4t cleaning of the bore and the

dlauber follO'li ed by an appliclltion of a thin filta of oil. An "Pil licati::ln of

an I!Xces:ilve amou.t.n of oi.1. becomes a hindrlillce. \\hen firi. ng blank

a 9Or.lewhat greater IlIIIrunt of 011 shoul::i be applied.

III Care .l. ft er Fir ing

68 As the quality of the after-fi re care areatl,y influences tl1e ..,"

of the rifle, it is neCesSllry to exercise special ca re. In ad'litbn to the

general dll1ly care the followi ng car e must ue rendered.

(a) Ilhen exposed to wash the contalllin:1ted parts as soon 115 p05st'ole

with the bo re c.1.eanirm fluid or a $oap"y solution uaiR!! s swab. or clean with

bore oil.

(b) After removi ng the cootamlnant a'l d di rt "o1 ith a raG. appl oil.

35

I

89

(c) When the parts exposed to gas as the bolt. face, firing

pin hruaing, .-d t.he st.riker are left withm t cleanin&, 1 t hinders firing,

tDDreove r . it. in corrosion, making proper care

(d) l! t.i hle is not available for proper care i:nr.:led1at.el,y followin!, fire.

appl,y a quantit.y of oil ,,1 th II. thong; teq:.orar ll preventi ng corrosion

and at the sarne t.ime loosening the cCtltami:l.S.nt makin& cleaning later easier.

(e) Every effol"t lIJJ!<t btl made to rSllO'Je the frulinG adherln: to the bore

Rille tore cleaner ond wire ltruah are used for this purpose.

IV Care 0.11'1 Special Instances

}>recautiq\e to be taken in hot areas are generall:f as fo110\9s :

(a) "'!II t.hB flO'lt aod the vaporization of the oil and t.he Nst.1. na of the

steel pll r t.s Ilrc hastened Wl<ler extrcmel;.l hot conditions, care IllU3t be exercised

in the selection of t. he oil. !'he IiIlwnt. of t.he oil appUed and the frequency

oC application must be increased, and the rifle kept In a horizontal position

'fhm not. in us c to prevEnt ttJe 011 from Nnmn,,: ocr.

90 PrecautJ.un.s to be taten 1n extremel,y cold areas are gencrall as follows :

(a) The freezing of oil applied to mechanical part.9 h.lntlers functioning;

therefore, at extremel,y 1(M' tenperature, wipe the bolt dry .

(1) A r ifle clcaned of it!! ollllll!!t not be ldt witilcut oil-

ing due to danger of Nst.ing.

(b) Conduct a dty run precedind ti re t.o te!!t the force of the

!ilin!; p1:"l. . It this 1s weak, for abcut t.he partl'll ,

the actual resistance ot the firin6 p1:"1 spr1ng. then COI"'l."ct these to prevmt

the occurrence of trouble 1n firing.

(e) Trouble m.B,;l arise it a. mixture of powder frulinii oil 13 frozen

or stuck t.o the parts in the bolt hous1ng. !'he reuoval of these becomes

d11'firult after tl"e ritle cools; thereJbre. 1f possiole. the rifle should

be cleaned durina the firing period or 1l11r.1ediatel,y follerdn..!!; fire.

36

,

,

91 Precauticnl'll to be taken ..,hen the dUlt .1l'JI severe:

(a) In order to prevent adheSion and penetration of dWlt, application

of oi.l. to ext.ernal parts must be w.!l1m1zed.

(b) "Mlen the pos8ibility of penetration is great. , the bore nut be

cleant!o frequently I'Iith an oiled cloth. tied loosel,y to ttl ... cle:t"linG rod.

'I'he cloth /W.$t be chan/ied dten. i'he bore IIlUSt be oiled on1il atter i t 1l'11 ab-

f ree 01" sund. If the daily cle,:min,J p r ocedure 1s used from the start.,

the ot d8!Coage and wear to the !:ore is creat since it. \ould be

like rubllirlg the bore with pol1shin& powder. When the bore is l:Ilina cl.eiifled

trall the r::uzzle end, special care 1n cleaning IIltst be directed to the cart_

char,bel' l'IIince the s<rLd 1"rol:l the bore will a.c:CU!Ja.lhte in tt,e co.rtr1dge

chamber.

92 Precaut.ions t o be dur in; rain and lIncw .

(a) In rain and snt.W, oiling r;u,!!t be done on1,:' after the lI".oisture hal'll been

co;rplete.!.y wiped oCC ,,1 th a dry cloth . '!'his operation must be con<bct.ed 1"'_

peatedly.

Chapter 2 Storage

93 The purpose of l'IItor inl! anr.s is to take appropriate u;easuras t.o prese"e

9'

them Ibr long or short perioul'll 1n order that they IM be used again without

any breakdown . The lUIt.hod ( 5ioraBe a-\d t.r.e handling of stored goo:ls pre-

scrioeC ill rechnical Manual 9-8;;0 U. 3. AriI\o' will be follO\'led .

Chaotar ,3 IOl'IIpection

1 !Jeneral lnspecLion

A Care

PrinCipal points of Inl'll?l!ct.ion

(a) &..rrel

(1) Forei J n ;x.Lter (3.) nnt, pits and corr03ion,

(2) Metal Fouling a dhe:5hn.

37

I

95

96

(b) Receiver

(1) Chc<:k to see it bolt locking lug ha.l3ing, ga3 port, anti ejector

hous ing are p roperly cleaned and oiled.

(c) Bolt

(1) Adhesion of for ei&n IT.atter on boh face, flr1.ng pin, chamber

and gas port, (2) corrosbn and r ust 1n the firing pin hole .

(d) Firing pin

Corr osi on and rust on striker, adhesion of forci:! matter on Jl r i:l8 pin

spring.

{ e} :!.Gather an::! hOllp ite!ll3

(1) (2) elasticity , 0) hardness, (4) rrJ. lr.!ew, (5) dirt.

Jf the 18ath f!r strap shadd crack when it. is rolled up between the fil'\!t ers,

it i ndicates insufficient oiling. If oilsho-..1lci seep ttle z atbcr \'tIen

it is unrolled, exCf!S3i Vf! oi1111; is i ndicatf!d .

a Assembl,y

Principal points 01' inspect.ion

(1) Loos e barr el, (2) loose upper (lO'Ner) band, (3) loose screws on

uj.:per (lower) band, (4) fsulty bend1ng md f aulty spring of IWnoooo, (5) loose

upper plate. (6) maUJ.I1c tion of c leminc rod , (7) Wlusual r roj ecti:>n . de nection

and looseness of t. r igge r iJlar d , (3) loose m.!Lgazine, (9) l oose trigger guar d

sc r ew and l ong (short) scr ows for rece!Vllr, (10 loose woa:\ scrows for 'outt

plate and butt. sling swivel , (11) use of wrong part numbers .

C functi on

Principal points of inspection

( 1) Malfunction of safetj' knub

(2) Malfunction of safety lock

(3) ka liunct.ivn of extractor

Wal! unc t.ion of eject...lr

Walfuncti un of f ollower

38 '

97

( 6) ttl r u (14) Faulty trigger mechanbm

(15) Faulty function of bayonet in mounting and dlslIKllnting.

o DlI.IIlage

PrinCipal points of i nspect i on

(a) Bore and chat:ber

( 1) Bulge, (2) pit.s , (3) .bend, (4) wear, (5) dent s .

(b) Receiver

(1) Weak bolt luss anti ejector (2) weak floor plate cdtch

sprlng, (3) dents of upper surface of recoil plat.e and safety knob l U6 groove .

(c) Bolt.

(1) Enlar gement 01' 1'iring pi n hole, (2) dent. on bolt face, (3) dent

armnd snail- shaped section, l4) wear on la-ller surface of bolt. .

(d) Fin ng pin

(1) Bend and wear on firil16 pin : malfonuation of striker point,

(2) wear and tenr on seal" catCh, (3) excessive bah face (amo.1 nt

of pr ojection ahwid range oetween . 044 and . 059 inch) , (4) bent, weak , or

sagging il rln8 pin ,pring.

( e) Ext.ractor and safety kno\)

(1) Wear o n extractor cl aw and weak: tlxtr actor spri ng,

(2) loose sa fety knob shaft and wear in safety knob l ug.

(f) Fr ont t

( 1) 1.0:1088 front sight. base, (2) def18Clion of front sight, lJ) bont

or worn f ront s1 gl\t.

(g) Rear sight .

(1) Faulty rear sight pin, (2) of rear sight (3) loos e

r ear aiWt, (4) loose tn d creaky slide I'Ilth irreguhr graduat.ion, (5) de nt.ed

peep .:d!'tlt, (6) peeled rust proof coati ng sid,ht and f r ont 'iWtt) ,

( 7)

(9)

loose antiaircraft lead sight arllls , (8) bent. antiaircr aft lead sight ar;ns ,

,

'Ilea;'; and bent antiair cra!"l l ead sidl t arlll spring.

39

I

(h) 5bJck

( 1) Cracked. and dented stock, (2) enl..,rbed groove fbI' r ecal.l pate

(l/J2 inch allowed) . 0) bent stOQ(, (4) cracked .rid loose lund guard, (5)

bent cleani n& rod , loose cleaning rod nead, 3ld worn thread, (6) brolcen snap

ring fu r s 11ng.

(1) Leather tnd her.1p it.1:!f1l8

(l) Cracks, (2) scars and dall",ages , () unraveled se&lllS .

(J) Acce.s8orie.s

(1) Crooked Md bent cleaning rod jag. ltOrn threads anc! corr oded

steel section, (2) bent and lNrn cleani/'E rod, () dan:a.gcs to screw cap f or

oi ... can, weak oil can case, an::! oil can leaks .

II Inspect io n I3etore and After Hrl ng

98 aefore and after various pa.rts, especiall.Y the bore, &I'd chlWber,

Special in$pecti on IILll:rt be made for the pres ence 0 1' foreign in the bore

and challtler befoce tiring.

Pr ior to zeroing-in , parts whim will a lfect the accuracy o r

saroing- in IIl.l st be carefully noted, inep ected and, it necessary, repaired.

When large aro:llnts of gas leaks f r om the rear du rin& Uring, inspe ction

roc iM'egularities rlllst be na de o n the changer , tolt face , tolt l oc\(.ing lug,

firing pin head, extractor, Md boll. housin&.

III Inspection of Stored RUles

99 Prior to storage, special att.e ntion !!lust be pdd t o the J%'esence r:f I"USt.

of J.Ilrt nwzbers, proper !'Unction, an:! proper a;>pUcation o f preserva-

the. <l.>re and chamber must be axamined with sp<'!cial t hOrQu,sMe8S.

40

8. LIST: (Iig-l)

1.

2.

3.

4.

5

6.

7.

8.

9.

10.

ll.

l>

1).

14.

15.

16.

17.

18.

19.

20.

2l.

22.

23 .

24.

25

26.

2'/.

28.

29.

30.

3l.

)2.

33.

)4 .

35

36 .

37.

38 .

39 .

40.

4l.

42 .

43 .

44 .

45 .

46 .

Sight. front.

Ba.nd, upper

Lug, bayooet.

Barrel

Band, lower

Guard, hand

SWivel, sling, upper

Yooopod

Receiver

Spr1n&, rear sight

ScrewiJ, antiaircraft leading siftlt arrns

Ar.s, leading aight , antiaircraft

Lear J rear sight.

Extractor

Slide , rear eight

Pin, rear sight

Cover, bolt

Botl hous in&

Pi n, tiring

Spring, firing pin

Knob, safety

Ejsct.or

Latch, bolt. reatainer

Spring, latch, bolt retainer, and IIpring, ejector

Screw, utch, bolt retainer

Plate , upper band

Sc rew, upper plate

Screws, upper band

Screw, lower band

Stock

Plata, recoil

Swivel , lower iJling

Screw, short , butt plate

Plate, but t

Screw, long butt. plate

Spring, aear

Pin, r ocker

Sear

Pin, trigger

TriUer

Rocker arm

GUide, :;ear spring

Magazine

FoUowe r

Spring, follower

Pin, floor pl ate

I

NOMENCLATURE LIS! (Fig . 1) Cont 'd

47 . Plate. floor

48. Gtuird, trigger

49. Catch , fl oor plate

50 . Screw, forward. trigger guard

51 . Screw, rear. trigger guard

52. Sc r aw, recoil plate

53 . Rod, cleaning

....

Ct'\

.-

l..

J)ID

I

l:l

ii)

....

~

l..

~

1...1

C)

...J

~

....

~

~

1 ~ 1 1r ','1

RESTRIC"fm Se{urily Il'Iformotiol'l

, "

, .

. .

' ,,' ,

,

,,.

,

, .

I ,

,

lESTRICTEt' Setllrrty Il'Iformatiol'l

Das könnte Ihnen auch gefallen

- Bren LMG ManualDokument7 SeitenBren LMG ManualGasMaskBobNoch keine Bewertungen

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsVon EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNoch keine Bewertungen

- The Arisaka Rifle: Disassembly InstructionsDokument12 SeitenThe Arisaka Rifle: Disassembly InstructionsSerteco Coleccionista MilitariaNoch keine Bewertungen