Beruflich Dokumente

Kultur Dokumente

Manual Threaded Balancing Valves: Product Data Sheet

Hochgeladen von

halackOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual Threaded Balancing Valves: Product Data Sheet

Hochgeladen von

halackCopyright:

Verfügbare Formate

Manual Threaded Balancing Valves

750 Variable orifice double regulating valve

Product data sheet

5-year guarranty

Bidirectionnal

regulation

Long lasting

reliability

100% seat

tightness

09 ACC LY 117

European

production

Description

COMAP 750 series Manual Balancing valves are bronze

threaded variable orifice double regulating valves.

The oblique seat balancing valves are used when precise

commissioning of heating, air conditioning and plumbing

circuits is required (for hot or cold water with antifreeze

liquids).

The quality of Comap balancing valves makes it possible

to balance columns with great accuracy.

Features

Complete range from DN10 to DN50

Instantaneous test port connections

Can be mounted in all positions

Can be fitted on flow or return lines

Bidirectional: fluid can circulate in either direction

Contents

Description

Features

Benefits

Design

Material

Specifications and norms

Dimensions

Range overview & weights

Application example

Valve selection

Kv tables & Flow charts

6 - 15

Accessories

16

Installation

17 - 18

Correction factor

19

40-position digital setting with display

Indication of full or 1/10 rotation

Presetting can be sealed by tamperproof

Sealing of the memory

Sealing of the handwheel

5 functions in one balancing valve (750 model):

Flow control

Isolation

Drainage

Filling

Measuring

Special range for renovation (reduced Kv)

Benefits

After closing setting can be recover after isolation

Readable from above or below

Protection from unauthorized actuation

100% seat water tightness guarantee (o-ring)

Screw cap stops dirt entering

Quick measuring connections

Flow measurement also with reverse flow

Steam double sealing toward environment

Manual Threaded Balancing Valves

Design

1.

2.

3.

4.

5.

6.

Handwheel: blue for reduced Kv and orange for standard Kv

O-rings for double external sealing of the control

Drain cock with integrated ball valve

Body

Oblique seat

Double sealing of memorized setting provided by 2 o-rings, one of which

is interchangeable with the handle screw

7. Cap and rod in high strength cupro-alloy

8. Instantaneous pressure tapping (with protective threaded cap)

9. Cap / cowl sealing

10. Disc sealing of valve and seat

1

2

6

7

6

10

Material

Handwheel:

O-rings for double external sealing of the control rod:

Rotating globe:

Body:

Disc sealing of valve and seat:

Heat shielding 6-6 polyamide charged with 30% fibre glass

EPDM

Brass

DZR bronze

EPDM seal + Valve: DZR Brass

Specification and norms

Temperature :

Nominal Pressure:

Medium:

ACS agreement:

-25C to 120C

up to 16 bar

Water or neutral fluids, water-glycol mixtures

09 ACC LY 117 (sanitary application)

Threads conformity: ISO 7 / BS 21

DIN 2440 - NF A49.115

Dimensions

DN

10

3/8

1/4

1/4

104

88,5

106

15/15R

1/2/1/2R

1/4

1/4

104

88,5

106

20/20R

3/4/3/4R

1/4

1/4

104

95,5

112

25/25R

1/1R

1/4

1/4

108

96

116

32

11/4

3/8

1/4

117

117

127

40

11/2

3/8

1/4

122

125

133

50

3/8

1/4

126

149

146

Subject to change - all rights reserved

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Range overview & weights

Functions

Figure

Illustration

Pressure

test point

750

751

753

750R

751R

1752

1753

04/2010 / T.24.16-5.05.063.A

Drain

Cap

Digital

Handwheel

DN

Weight

(in kg)

Code

DN10

3/8

0.685

750403

DN15

1/2

0.637

750404

DN20

3/4

0.712

750406

DN25

0.903

750408

DN32

11/4

1.362

750410

DN40

11/2

1.532

750412

DN10

3/8

0.622

751403

DN15

1/2

0.585

751404

DN20

3/4

0.656

751406

DN25

0.860

751408

DN32

11/4

1.287

751410

DN40

11/2

1.447

751412

DN15

1/2

0.559

753104

DN20

3/4

0.620

753106

DN25

0.807

753108

DN32

11/4

1.250

753110

DN40

11/2

1.382

753112

DN15

1/2

0.643

7504041

DN20

3/4

0.700

7504061

DN25

0.885

7504081

DN15

1/2

0.581

7514041

DN20

3/4

0.630

7514061

DN25

0.827

7514081

DN15

1/2

0.580

175204

DN20

3/4

0.639

175206

DN25

0.865

175208

DN15

1/2

0.565

175304

DN20

3/4

0.495

175306

DN25

0.762

175308

DN32

11/4

1.199

175310

DN40

11/2

1.315

175312

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Application example

Application data

- Differential pressure from the pump: 0.5 bar [5 kPa ]

- Flow in each column:

Q = 3500l/h [3.5 m3/h]

- Installed balancing valves:

751 or 1753 DN50 2

- Installed pressure drop in column (circuit resistance):

C1: 0.15 bar [15 kPa]

C2: 0.25 bar [25 kPa]

C3: 0.33 bar [33 kPa]

C4: 0.38 bar [38 kPa]

Step 1: Calculate the resistance (pressure drop) that balancing valves will need to provide in order to balance column.

C1: 0.5 bar - 0.15 bar = 0.35 bar

C2: 0.5 bar - 0.25 bar = 0.25 bar

C3: 0.5 bar - 0.33 bar = 0,17 bar

C4: 0.5 bar - 0.38 bar = 0.12 bar

[35 kPa]

[25 kPa]

[17 kPa]

[12 kPa]

Step 2: Define presetting for each 750 balancing valve DN50 2 according to the chart (flow direction A-B)

- For 1753 valve type:

- For 751 valve type:

C1: 1.4 turns

C1: Position 14

C2: 1.6 turns

C2: Position 16

C2: 1.6 turns

C3: Position 18

C4: 2.0 turns

C4: Position 20

Example:

Position 20

Before commissioning

Subject to change - all rights reserved

Drain the circuit to eliminate air before starting measures (air being

compressive, measuring sensors

could indicate wrong values).

List balancing valves and associated

flow requirement. Define valve position presetting.

Install the nominal flow in the circuit

(full capacity) by opening all thermostatic or manual radiator valves, 3

ways valves

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Valve preselection

750 Series Manual Balancing Valve selection for optimum commissioning and balancing.

To carry out an optimum balancing, it is necessary to respect a certain number of selection criteria. The fundamental

starting point consists in choosing the valve which will provide sufficient resistance within the circuit in which it is fitted.

Practically, in the major cases, the valve size should be 1 to 2 diameters smaller than the pipe on which it is mounted.

Please note:

1) A minimum pressure loss is required to get an accurate measuring (please refer to measurer user guide).

2) The balancing valve must be at least in opening position 28/40 (30% of max. flow) in order to avoid creating turbulences in valve. Thus, the thread balancing valve must in position 15.

3) Depending on the flow and pressure losses, the complete opening of the balancing valve can generate acoustic

phenomena due at a too high speed of the fluid in the balancing valve.

4) Special case : mounting in flow direction B A (see flow curves).

Example

For Q = 600 l/h = 0,6 m,

P = 0,08 bar,

The diameter should be DN20.

04/2010 / T.24.16-5.05.063.A

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN10

3/8

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

14

0.205

23

0.63

32

1.5

15

0.225

24

0.74

33

1.58

16

0.25

25

0.84

34

1.645

17

0.265

26

0.94

35

1.71

18

0.295

27

1.04

36

1.755

10

0.12

19

0.345

28

1.155

37

1.8

11

0.14

20

0.39

29

1.235

38

1.85

12

0.16

21

0.46

30

1.31

39

1.915

13

0.18

22

0.54

31

1.44

40

1.95

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,12

14

0,225

23

0,56

32

1,56

0,19

15

0,245

24

0,67

33

1,645

0,25

16

0,26

25

0,775

34

1,73

0,33

17

0,275

26

0,865

35

1,82

0,4

18

0,3

27

0,98

36

1,9

10

0,135

19

0,32

28

1,105

37

1,965

11

0,16

20

0,35

29

1,21

38

2,05

12

0,19

21

0,395

30

1,32

39

2,11

13

0,21

22

0,47

31

1,435

40

2,15

DN10

3/8

BA

Subject to change - all rights reserved

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN15R

1/2R

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

14

0.185

23

0.62

32

1.47

15

0.205

24

0.73

33

1.565

16

0.225

25

0.84

34

1.62

17

0.25

26

0.925

35

1.675

18

0.285

27

1.015

36

1.74

10

0.115

19

0.325

28

1.095

37

1.77

11

0.13

20

0.375

29

1.175

38

1.83

12

0.14

21

0.43

30

1.28

39

1.87

13

0.165

22

0.515

31

1.375

40

1.90

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,14

14

0,235

23

0,61

32

1,51

0,22

15

0,25

24

0,715

33

1,63

0,32

16

0,285

25

0,82

34

1,76

0,43

17

0,31

26

0,905

35

1,815

1,915

DN15R

3/8R

BA

Subject to change - all rights reserved

0,53

18

0,33

27

1,01

36

10

0,15

19

0,365

28

1,105

37

1,93

11

0,17

20

0,415

29

1,185

38

1,965

12

0,19

21

0,475

30

1,305

39

1,995

13

0,21

22

0,525

31

1,395

40

2,04

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN15

1/2

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.1

14

0.67

23

1.75

32

3.9

0.16

15

0.73

24

1.99

33

4.02

0.22

16

0.8

25

2.28

34

4.16

0.28

17

0.87

26

2.61

35

4?28

0.36

18

0.95

27

2.91

36

4.35

10

0.41

19

1.08

28

3.18

37

4.37

11

0.48

20

1.21

29

3.42

38

4.41

12

0.54

21

1.35

30

3.63

39

4.45

13

0.6

22

1.54

31

3.79

40

4.47

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,105

14

0,74

23

1,65

32

3,61

0,155

15

0,8

24

1,92

33

3,7

0,215

16

0,87

25

2,22

34

3,75

0,29

17

0,93

26

2,38

35

3,81

0,36

18

0,99

27

2,68

36

3,88

10

0,47

19

1,12

28

3,02

37

3,94

11

0,55

20

1,24

29

3,24

38

12

0,61

21

1,36

30

3,42

39

4,06

13

0,69

22

1,51

31

3,53

40

4,13

DN15

1/2

BA

Subject to change - all rights reserved

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN20R

3/4R

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

14

0.185

23

0.62

32

1.465

15

0.21

24

0.72

33

1.525

16

0.23

25

0.815

34

1.6

17

0.255

26

0.91

35

1.64

18

0.29

27

1.015

36

1.69

10

0.115

19

0.32

28

1.095

37

1.74

11

0.13

20

0.365

29

1.185

38

1.8

12

0.145

21

0.43

30

1.265

39

1.83

13

0.165

22

0.515

31

1.365

40

1.89

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,21

14

0,235

23

0,545

32

1,405

0,32

15

0,25

24

0,635

33

1,515

0,49

16

0,28

25

0,725

34

1,61

0,67

17

0,295

26

0,825

35

1,725

DN20R

3/4R

BA

04/2010 / T.24.16-5.05.063.A

0,88

18

0,315

27

0,925

36

1,82

10

0,15

19

0,33

28

1,025

37

1,865

11

0,175

20

0,365

29

1,12

38

1,935

12

0,195

21

0,405

30

1,215

39

13

0,215

22

0,46

31

1,31

40

2,085

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN20

3/4

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.13

14

0.9

23

1.92

32

4.65

0.21

15

0.97

24

2.16

33

4.88

0.29

16

1.05

25

2.43

34

5.09

0.39

17

1.13

26

2.83

35

5.26

0.46

18

1.24

27

3.17

36

5.44

10

0.57

19

1.32

28

3.49

37

5.58

11

0.64

20

1.43

29

3.89

38

5.7

12

0.73

21

1.58

30

4.18

39

5.83

13

0.82

22

1.73

31

4.4

40

5.9

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,25

14

0,95

23

1,92

32

4,67

0,47

15

1,04

24

2,17

33

4,83

0,76

16

1,11

25

2,41

34

1,06

17

1,19

26

2,73

35

5,14

DN15R

DN20

3/8R

3/4

B

A

A

B

Subject to change - all rights reserved

10

1,37

18

1,26

27

3,06

36

5,33

10

0,63

19

1,33

28

3,39

37

5,51

11

0,7

20

1,44

29

3,75

38

5,64

12

0,78

21

1,55

30

4,14

39

5,82

13

0,86

22

1,72

31

4,45

40

5,95

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN25R

1R

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.1

14

0.68

23

1.84

32

4.49

0.13

15

0.75

24

2.18

33

4.65

0.19

16

0.8

25

2.43

34

4.7

0.26

17

0.88

26

2.73

35

4.78

0.32

18

0.95

27

3.01

36

4.9

10

0.4

19

1.05

28

3.34

37

4.94

11

0.47

20

1.18

29

3.64

38

5.03

12

0.54

21

1.37

30

3.99

39

5.14

13

0.61

22

1.6

31

4.23

40

5.19

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,28

14

0,755

23

1,69

32

4,19

0,39

15

0,825

24

1,975

33

4,38

0,8

16

0,875

25

2,275

34

4,53

1,21

17

0,95

26

2,505

35

4,805

DN25R

1R

BA

04/2010 / T.24.16-5.05.063.A

11

1,57

18

1,005

27

2,78

36

5,015

10

0,435

19

1,075

28

3,07

37

5,155

11

0,525

20

1,125

29

3,4

38

5,295

12

0,605

21

1,24

30

3,67

39

5,425

13

0,675

22

1,445

31

3,985

40

5,5

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN25

1

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.17

14

1.5

23

3.36

32

7.04

0.3

15

1.64

24

3.69

33

7.26

0.44

16

1.78

25

4.05

34

7.54

0.59

17

1.95

26

4.45

35

7.68

0.73

18

2.11

27

4.84

36

7.87

10

0.91

19

2.28

28

5.38

37

8.02

11

1.04

20

2.49

29

5.92

38

8.22

12

1.19

21

2.76

30

6.36

39

8.38

13

1.33

22

3.04

31

6.77

40

8.52

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0,62

14

1,65

23

3,22

32

6,86

1,23

15

1,8

24

3,55

33

7,18

1,92

16

1,95

25

3,93

34

7,46

2,68

17

2,09

26

4,3

35

7,72

3,29

18

2,25

27

4,72

36

8 14

10

1,03

19

2,43

28

5,15

37

8,22

11

1,19

20

2,65

29

5,58

38

8,43

12

1,33

21

2,9

30

6,05

39

8,63

13

1,51

22

3,1

31

6,48

40

8,84

DN15R

DN25

3/8R

1

B

B

A

A

Subject to change - all rights reserved

12

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN32

11/4

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.2

14

2.29

23

5.07

32

10.94

0.4

15

2.53

24

5.52

33

11.51

0.65

16

2.82

25

6.03

34

11.89

0.88

17

3.14

26

6.63

35

12.33

1.13

18

3.37

27

7.29

36

12.97

10

1.33

19

3.71

28

7.99

37

13.44

11

1.55

20

4.05

29

8.67

38

13.99

12

1.8

21

4.42

30

9.61

39

14.4

13

2.07

22

4.74

31

10.39

40

14.88

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

14

2,5

23

5,19

32

11,02

15

2,66

24

5,34

33

11,86

16

2,96

25

5,69

34

12,52

17

3,29

26

6,48

35

13,19

18

3,64

27

7,24

36

19,15

10

1,57

19

3,98

28

37

14,7

11

1,8

20

4,27

29

8,84

38

15,24

12

1,96

21

4,67

30

9,47

39

15,72

13

2,2

22

31

10,28

40

16,11

DN32

11/4

BA

04/2010 / T.24.16-5.05.063.A

13

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN40

11/2

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.23

14

3.2

23

8.25

32

16.32

0.35

15

3.56

24

9.08

33

17.12

0.68

16

3.99

25

10.04

34

17.84

1.04

17

4.4

26

10.96

35

18.45

1.42

18

4.9

27

11.87

36

19.13

10

1.78

19

5.48

28

12.79

37

19.76

11

2.17

20

6.1

29

13.47

38

20.2

12

2.5

21

6.75

30

14.48

39

20.66

13

2.83

22

7.45

31

15.45

40

21.09

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

14

3,41

23

8,03

32

15,99

15

3,74

24

8,71

33

16,82

16

4,02

25

9,58

34

17,68

17

4,49

26

10,4

35

18,48

18

5,14

27

11,32

36

29,22

10

1,96

19

5,83

28

11,95

37

19,83

11

2,45

20

6,2

29

12,92

38

20,54

12

2,75

21

6,83

30

13,88

39

21,16

13

3,06

22

7,37

31

14,99

40

21,66

DN40

11/2

BA

Subject to change - all rights reserved

14

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Flow charts and Kv table

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density, please refer to the correction factor (page 19).

DN50

2

AB

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

0.55

14

5.79

23

13.71

32

28.57

1.11

15

6.32

24

15.1

33

29.87

1.72

16

7;

25

16.54

34

30.64

2.37

17

7.8

26

18.15

35

31.53

2.9

18

8.6

27

19.13

36

32.19

10

3.5

19

9.46

28

21.44

37

33.3

11

4.08

20

10.37

29

23.4

38

34.22

12

4.66

21

11.32

30

25.52

39

34.83

13

5.24

22

12.43

31

27.29

40

35.48

Pos.

Kv

Pos.

Kv

Pos.

Kv

Pos.

Kv

14

6,32

23

11,99

32

24,44

15

6,94

24

13,19

33

25,68

16

7,56

25

14,61

34

26,94

17

8,27

26

16,1

35

28,08

18

9,08

27

17,61

36

29,22

10

3,85

19

9,82

28

19,1

37

30,14

11

4,47

20

10,59

29

20,46

38

31,07

12

5,04

21

11,38

30

21,84

39

31,97

13

5,51

22

10,88

31

23,15

40

32,48

DN50

2

BA

04/2010 / T.24.16-5.05.063.A

15

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Accessories

Upstream

Downstream

Figure

2754

Description

Size

Code

1/4

VDP00A15

Cap + o-ring for valve from 11/4 to 2 upstream port

3/8

VDP00A16

Drain for

valve from 3/8 to 1 upstream port

1/4

VDP00A11

Drain for

valve from 11/4 to 2 upstream port

3/8

VDP00A12

Test point for

valve from 3/8 to 1 upstream port

1/4

276102

Cap + o-ring for valve from 3/8 to 1 upstream port

valve from 3/8 to 2 downstream port

1210

2761

valve from 3/8 to 2 downstream port

27

Test point for

valve from 11/4 to 2 upstream port

3/8

276103

Extension for

valve from 3/8 to 1 upstream port

1/4 - L = 50mm

VBG95C00

Extension for

valve from 11/4 to 2 upstream port

3/8 - L = 50mm

VBG95C01

Extension for

valve from 3/8 to 1 upstream port

1/4 - L = 20mm

VPDBWA43

Test point for

drain 1210

3/4

276200

Size

Code

275802

275801

27S

2762

Figure

2758

Description

Adapter between COMAP valves and measurers form:

COMAP, BROEN, Oventrop, Honeywell, Hezt ...

TA

Subject to change - all rights reserved

16

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Installation

Valve orientation

Can be mounted in both flow directions, though preferred flow direction is A B

(marked on the body).

Can be mounted 360 around pipe axis.

A

Can be installed in either the supply or the return pipe, but installation in the return

pipe is recommended.

Recommended pipe length

For safeguarding optimum measuring results, inlet and outlet distances of 15 x DN

are recommended.

The minimum length of the inlet section:

5 DN

- downstream of a pump should be 10 x DN,

2 DN

- downstream of valves or fittings should be 5 x DN.

The minimum length of the outlet section should be at least 2 x DN.

10 DN

2 DN

Reserved space for accessibility

For an easy connection of the measurer on the balancing valve, a minimum distance (L)

should be respected.

DN10 L = 165 mm

DN15 L = 165 mm

DN20 L = 165 mm

DN25 L = 170 mm

The 750 Series Manual Balancing Valves can be installed

on supply or on return lines and in all positions. It allows

the fluid flow in both directions. However, it is recommended to choose the preferred flow circulation from A to

B for optimum valve setting.

DN32 L = 180 mm

L

DN40 L = 185 mm

A flow direction arrow is marked on the valve body as well

as A and B to indicate the preferred flow direction.

DN50 L = 190 mm

When the pressure test point are located under the balancing valve, there is a risk of dirt stagnation on the pressure

test points. The sealing can become difficult. To eliminate these impurities, it is sufficient, time to time, to introduce the

hexagonal key in the pressure test point.

04/2010 / T.24.16-5.05.063.A

17

Subject to change - all rights reserved

Manual Threaded Balancing Valves

Presetting position

The presetting value of the valve is adjusted by turning the handwheel : the

valves closes when handwheel is turned clockwise.

The presetting position is shown by the digital display: from 0 (valve fully

closed) to 40 (valve fully open).

Each turn of the handwheel corresponds to one ten - display in the red window (example: 3).

The presetting subdivision correspond to 1/10 rotation of the handwheel display in the black window (example: 5).

Presetting memorization

The presenting value can be memorized in order to recover the presetting after having closed completely the valve for

instance: when reopening the valve the presetting will be limited to the memorized value.

Remove the protection screw

by using the long end of a 3mm

Allen key.

Replace and tighten the setting

memorization screw until its

seats. The setting is memorized.

Handwheel sealing

Presetting protection

Screw the protection screw in

which the sealing wire has

been fitted.

Subject to change - all rights reserved

Screw back the protection

screw. The setting is memorized and protected.

Pass the wire in the handwheel

eyes and fit the lead seal.

18

The handwheel can be locked

in any position: introduce the

ring of the plate in a hole located on the graduated collar of

the handwheel. The handwheel

position is sealed.

04/2010 / T.24.16-5.05.063.A

Manual Threaded Balancing Valves

Correction factor

A balancing valve is defined by its flow capacity, the Kv value - Kv0, in m/h which creates a differential pressure of

1bar [14.5 psi] and for fluids with a density of 0 = 1000 kg/m, (i.e. with pure water at a temperature of 20C [68F]).

For fluids with another density the Kv-value, Kvfluid, needs to be recalculated using a correction factor, f. In practice,

when using charts, the differential pressure must be multiplied by the correction factor, f:

Kvfluid = Kv0 x

Pfluid = P0 x F

Concentrations in Volume

In % of Propylene Glycol

50% 40%

30%

20%

1,09

1,09

1,07

1,07

1,07

1,07

1,05

1,05

1,03

1,03

1,03

1,03

1,01

1,01

1,01

1,01

0,99

0,99

0,99

0,99

1,97

0,97

1,97

0,97

1,95

0,95

1,95

0,95

20

40

40

Concentrations in Volume

In % of Ethylene Glycol

50% 40%

30%

20%

1,09

1,09

1,05

1,05

-20

-20

Correction factor F

for Aqueous Solutions of Ethylene Glycol

Correction factor

Correction factor

Correction factor F

for Aqueous Solutions of Propylene Glycol

Qfluid = Q0 x

60

60

80

100

80

100

Fluid temperature in C

-20

-20

00

20

20

40

40

60

60

80

100

80

100

Fluid temperature in C

Correction factor f

Fluid

% of glycol

5C

20C

35C

50C

65C

80C

Water

0%

1,000

0,998

0,994

0,988

0,981

0,972

10%

1,019

1,015

1,009

1,003

0,995

0,987

20%

1,036

1,031

1,025

1,018

1,010

1,001

30%

1,052

1,046

1,040

1,033

1,025

1,015

40%

1,067

1,061

1,054

1,047

1,038

1,028

50%

1,081

1,075

1,068

1,059

1,050

1,040

0%

1,000

0,998

0,994

0,988

0,981

0,972

10%

1,014

1,009

1,004

0,997

0,989

0,980

20%

1,026

1,020

1,014

1,006

0,998

0,988

30%

1,036

1,030

1,022

1,014

1,004

0,994

40%

1,044

1,037

1,029

1,020

1,010

0,998

50%

1,052

1,044

1,035

1,025

1,014

1,002

Ethylene glycol

Propylene glycol

04/2010 / T.24.16-5.05.063.A

19

Subject to change - all rights reserved

Das könnte Ihnen auch gefallen

- Manual de Reparatie Honda CBR 1000 RRDokument586 SeitenManual de Reparatie Honda CBR 1000 RRRazvan Grecu100% (1)

- 07 Donaldson HPK04 Series Data SheetsDokument4 Seiten07 Donaldson HPK04 Series Data SheetsCarlos Mauricio RodríguezNoch keine Bewertungen

- TraneDokument33 SeitenTranejake1000100% (1)

- TERRATEK-PSMS10L Sliding Miter Saw Artowrk Manual 110121Dokument61 SeitenTERRATEK-PSMS10L Sliding Miter Saw Artowrk Manual 110121HhhhCaliNoch keine Bewertungen

- FEMA Heavy Equip and Rigging TrainingDokument22 SeitenFEMA Heavy Equip and Rigging TrainingTimbo6808Noch keine Bewertungen

- 7 Comap Balancing Valves Catalogue PDFDokument24 Seiten7 Comap Balancing Valves Catalogue PDFBùi Trần Trung HậuNoch keine Bewertungen

- Stad en MainDokument12 SeitenStad en Mainm_moreira1974Noch keine Bewertungen

- Applications Shaft SealDokument23 SeitenApplications Shaft SealMandisa Sinenhlanhla NduliNoch keine Bewertungen

- ATOSs Valves DHI-0711Dokument4 SeitenATOSs Valves DHI-0711Cardoso MalacaoNoch keine Bewertungen

- Three Way ValvesDokument8 SeitenThree Way ValvesWalter JosephNoch keine Bewertungen

- Solenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06Dokument4 SeitenSolenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06RFIGUEROACNoch keine Bewertungen

- AMOT Datasheet C Thermostatic Valve 0512 Rev6Dokument12 SeitenAMOT Datasheet C Thermostatic Valve 0512 Rev6mlfaranoNoch keine Bewertungen

- Rexroth 4we10 Data SheetDokument10 SeitenRexroth 4we10 Data SheetOrlando Arias100% (1)

- DKC-DMC enDokument46 SeitenDKC-DMC enmarine_dieselNoch keine Bewertungen

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDokument10 SeitenHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111Noch keine Bewertungen

- TA-FUSION-C EN LowDokument16 SeitenTA-FUSION-C EN LowTroi LauraNoch keine Bewertungen

- Rexroth PumpsDokument24 SeitenRexroth PumpsAmanda SmithNoch keine Bewertungen

- EHV EHVF AccumulatorsDokument9 SeitenEHV EHVF AccumulatorsMetin GüvenNoch keine Bewertungen

- Rexroth FDDokument116 SeitenRexroth FDIvan GudeljNoch keine Bewertungen

- SDM140EDokument36 SeitenSDM140Eseaqu3stNoch keine Bewertungen

- Ta-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsDokument16 SeitenTa-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsCatalin DinuNoch keine Bewertungen

- 4wre 6-10 Sew1xDokument12 Seiten4wre 6-10 Sew1x2267airportNoch keine Bewertungen

- Double Reg Valves PDFDokument15 SeitenDouble Reg Valves PDFNoushad P HamsaNoch keine Bewertungen

- Rexworth Hydraulic MotorDokument28 SeitenRexworth Hydraulic MotorSorin-Adrian Learschi100% (1)

- Rexroth 4WE6D6X-G24 Directional ValveDokument12 SeitenRexroth 4WE6D6X-G24 Directional ValveCosma Petru-RaulNoch keine Bewertungen

- SDM 102 eDokument24 SeitenSDM 102 eseaqu3stNoch keine Bewertungen

- Elettrovalvole Denison HydraulicsDokument62 SeitenElettrovalvole Denison HydraulicsZMCONTROLNoch keine Bewertungen

- Direct Acting Excess Pressure ValvesDokument8 SeitenDirect Acting Excess Pressure ValvescartarNoch keine Bewertungen

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDokument5 SeitenSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNoch keine Bewertungen

- SDM 141 eDokument28 SeitenSDM 141 eseaqu3stNoch keine Bewertungen

- 'C' Series Control ValvesDokument12 Seiten'C' Series Control Valvesابزار دقیق100% (1)

- p405 01Dokument8 Seitenp405 01Utku KepcenNoch keine Bewertungen

- TD Brochure A4 01-09-2000Dokument9 SeitenTD Brochure A4 01-09-2000mishraenggNoch keine Bewertungen

- Reciprocating CompressorDokument6 SeitenReciprocating CompressorEDUARDONoch keine Bewertungen

- TA-FUSION-P EN LowDokument20 SeitenTA-FUSION-P EN LowradudolNoch keine Bewertungen

- Yukenmodularvalves Yuken CatDokument140 SeitenYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Hydraulic Power Units Vertical Mount Fixed DisplacementDokument32 SeitenHydraulic Power Units Vertical Mount Fixed DisplacementSujata Roy100% (1)

- Atos HidraulicaDokument8 SeitenAtos HidraulicaFabinhoTowerNoch keine Bewertungen

- Rexroth Bomba HidraulicaDokument52 SeitenRexroth Bomba HidraulicaHernan LopezNoch keine Bewertungen

- Fix Displacement MotorDokument28 SeitenFix Displacement MotorIan MuhammadNoch keine Bewertungen

- Bomba Hidrailica A10VSODokument44 SeitenBomba Hidrailica A10VSOkiarabenitezparejaNoch keine Bewertungen

- Guth VSR Modulating ValvesDokument8 SeitenGuth VSR Modulating ValvesRaul Guevara TorresNoch keine Bewertungen

- SD 18 eDokument32 SeitenSD 18 eseaqu3stNoch keine Bewertungen

- 608 750GDokument2 Seiten608 750GbioarquitecturaNoch keine Bewertungen

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDokument8 Seiten4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNoch keine Bewertungen

- Series 825Y Specification SheetDokument2 SeitenSeries 825Y Specification SheetFEBCONoch keine Bewertungen

- k512 en MainDokument8 Seitenk512 en MainSani PoulouNoch keine Bewertungen

- Re 10460Dokument20 SeitenRe 10460Ahmed Abd ElhakeemNoch keine Bewertungen

- Supape Solare RomstalDokument1 SeiteSupape Solare RomstalCraciun DanielNoch keine Bewertungen

- Re92711 2012-01Dokument48 SeitenRe92711 2012-01Edson Huarachi FloresNoch keine Bewertungen

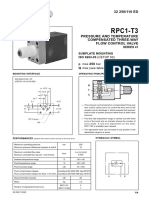

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Dokument4 SeitenFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNoch keine Bewertungen

- Bul 36115 Servo Valve OperationDokument12 SeitenBul 36115 Servo Valve Operationrikkitech100% (1)

- Lift Check ValvesDokument4 SeitenLift Check Valveslejyoner62Noch keine Bewertungen

- Catalogo Chiller Trane CGAD Cg-prc002e-En - 07012012Dokument38 SeitenCatalogo Chiller Trane CGAD Cg-prc002e-En - 07012012Leandro P SilvaNoch keine Bewertungen

- A17FODokument16 SeitenA17FOJose SalvadorNoch keine Bewertungen

- Tour and Andersson MD60 SpecificationsDokument14 SeitenTour and Andersson MD60 SpecificationsblindjaxxNoch keine Bewertungen

- About Axial Displacement Pump A4VSoDokument68 SeitenAbout Axial Displacement Pump A4VSomrkadu_61Noch keine Bewertungen

- LOGICOSDokument82 SeitenLOGICOSManoloEskobarNoch keine Bewertungen

- Shut-Off Butterfly Valves 3 0 enDokument12 SeitenShut-Off Butterfly Valves 3 0 en윤병택Noch keine Bewertungen

- Pump CalculationDokument20 SeitenPump Calculationcoolsummer1112143100% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Industrial Equipment Design in A Web BrowserDokument6 SeitenIndustrial Equipment Design in A Web BrowserhalackNoch keine Bewertungen

- Parametric CAD Process FlowchartDokument1 SeiteParametric CAD Process Flowcharthalack100% (1)

- Part Optimization and Tolerances SynthesisDokument17 SeitenPart Optimization and Tolerances SynthesishalackNoch keine Bewertungen

- Time Response of Temperature Sensors Using Neural NetworksDokument8 SeitenTime Response of Temperature Sensors Using Neural NetworkshalackNoch keine Bewertungen

- An Analysis On The UncertaintyDokument8 SeitenAn Analysis On The UncertaintyhalackNoch keine Bewertungen

- How To Write Powerful Macros From ScratchDokument4 SeitenHow To Write Powerful Macros From ScratchhalackNoch keine Bewertungen

- Not Like Riding A Bike Get The Most Out of Your CAD Software With TrainingDokument21 SeitenNot Like Riding A Bike Get The Most Out of Your CAD Software With TraininghalackNoch keine Bewertungen

- A Systematic Approach For Geometrical and Dimensional Tolerancing in Reverse EngineeringDokument29 SeitenA Systematic Approach For Geometrical and Dimensional Tolerancing in Reverse EngineeringhalackNoch keine Bewertungen

- SW Feature GuideDokument1 SeiteSW Feature GuidehalackNoch keine Bewertungen

- Ajromiya MatnDokument31 SeitenAjromiya MatnhalackNoch keine Bewertungen

- Generation of Functional Tolerancing Based On Positioning FeaturesDokument18 SeitenGeneration of Functional Tolerancing Based On Positioning FeatureshalackNoch keine Bewertungen

- Ajromiya Matn PDFDokument31 SeitenAjromiya Matn PDFhalack100% (1)

- DimensioningDokument15 SeitenDimensioninghalackNoch keine Bewertungen

- Expert System For DFM of Die Cast Components PDFDokument10 SeitenExpert System For DFM of Die Cast Components PDFhalackNoch keine Bewertungen

- Assembly in The Large - Basic Issues PDFDokument18 SeitenAssembly in The Large - Basic Issues PDFhalackNoch keine Bewertungen

- Calculating The Clamping Force For MachiningDokument3 SeitenCalculating The Clamping Force For MachiningVignesh DeepNoch keine Bewertungen

- 7-Day Diet DiaryDokument1 Seite7-Day Diet DiaryhalackNoch keine Bewertungen

- 2002 EngDokument1 Seite2002 EnghalackNoch keine Bewertungen

- WP Wood Plastic CompositesDokument11 SeitenWP Wood Plastic CompositeshalackNoch keine Bewertungen

- 07 Fields Wall Chart ActualDokument1 Seite07 Fields Wall Chart ActualhalackNoch keine Bewertungen

- 2001 EngDokument2 Seiten2001 Engខ្មែរ ពិសេសNoch keine Bewertungen

- Tool AuthDokument1 SeiteTool AuthhalackNoch keine Bewertungen

- 2000 EngDokument1 Seite2000 EngNiranjan PrasadNoch keine Bewertungen

- Vibration Welder: Table Size 1829 MM (72") by 610 MM (24")Dokument2 SeitenVibration Welder: Table Size 1829 MM (72") by 610 MM (24")halackNoch keine Bewertungen

- Six Sigma As Applied in Quality Improvement For Injection Moulding ProcessDokument8 SeitenSix Sigma As Applied in Quality Improvement For Injection Moulding ProcesshalackNoch keine Bewertungen

- Bolted Connexion SheetDokument48 SeitenBolted Connexion SheethalackNoch keine Bewertungen

- WP A Case For Round Energy DirectorDokument8 SeitenWP A Case For Round Energy DirectorhalackNoch keine Bewertungen

- WP Aesthetic AssemblyDokument6 SeitenWP Aesthetic AssemblyhalackNoch keine Bewertungen

- Guide IFAC ISQC1 Third EditionDokument171 SeitenGuide IFAC ISQC1 Third EditionJay Mark ReponteNoch keine Bewertungen

- The Effectiveness of Using Iec61660Dokument4 SeitenThe Effectiveness of Using Iec61660halackNoch keine Bewertungen

- Gray Iron Gate Valves, Flanged and Threaded Ends: MSS SP-70-2011Dokument16 SeitenGray Iron Gate Valves, Flanged and Threaded Ends: MSS SP-70-2011LUISNoch keine Bewertungen

- FMDS0208Dokument65 SeitenFMDS0208Vasile Alexandru-DanNoch keine Bewertungen

- Aluminator RC LOW RESDokument2 SeitenAluminator RC LOW RESAARON HERRERANoch keine Bewertungen

- BS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFDokument28 SeitenBS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFSorin Tzuri ClimNoch keine Bewertungen

- Keystone - GR SeriesDokument16 SeitenKeystone - GR SeriesMohd Khairi Mohd NorzianNoch keine Bewertungen

- GSL Actuator Sizing CalculationDokument0 SeitenGSL Actuator Sizing CalculationAnonymous yQ7SQrNoch keine Bewertungen

- Power Screw Rod DesignDokument52 SeitenPower Screw Rod Designramkumar121Noch keine Bewertungen

- How To Run A Horizontal Metalworking ShaperDokument43 SeitenHow To Run A Horizontal Metalworking ShaperALLEN FRANCIS100% (2)

- SA RawlboltDokument2 SeitenSA Rawlboltpower_generator133850% (2)

- Technical Data Sheet For The HUS3 Screw Anchor Technical Information ASSET DOC 3357463Dokument32 SeitenTechnical Data Sheet For The HUS3 Screw Anchor Technical Information ASSET DOC 3357463ZerekkuNoch keine Bewertungen

- Topaz Partfill Info 2017Dokument3 SeitenTopaz Partfill Info 2017Wayne SeamanNoch keine Bewertungen

- A320-20 Standard PracticesDokument37 SeitenA320-20 Standard Practices867189399Noch keine Bewertungen

- Gear SolutionDokument16 SeitenGear SolutionmadhavikNoch keine Bewertungen

- Cortadora de Metales Makita LC1230 - DespieceDokument5 SeitenCortadora de Metales Makita LC1230 - DespieceLisandro GianottoNoch keine Bewertungen

- Mechanical and Metal Trades Handbook 2 PDFDokument432 SeitenMechanical and Metal Trades Handbook 2 PDFCarlos Martinez100% (3)

- Weld & Shear CapacityDokument3 SeitenWeld & Shear CapacityHanmant OulkarNoch keine Bewertungen

- GS Ep Cor 356Dokument7 SeitenGS Ep Cor 356SangaranNoch keine Bewertungen

- 2003 Subaru Baja - Bed Mounted Bicycle Carrier InstallationDokument11 Seiten2003 Subaru Baja - Bed Mounted Bicycle Carrier InstallationSubie SecretNoch keine Bewertungen

- Ormco InstrumentsDokument44 SeitenOrmco Instrumentsorthodontistinthemaking100% (1)

- Liss DFDokument48 SeitenLiss DFthomsoon010% (1)

- Ball Bearing Oval Flanged units-FYTB 30 TFDokument2 SeitenBall Bearing Oval Flanged units-FYTB 30 TFCosmin ManoleNoch keine Bewertungen

- 03) PIPE193.7x8 V-BRACE - GUSSET PLT.Dokument114 Seiten03) PIPE193.7x8 V-BRACE - GUSSET PLT.Civil StructureNoch keine Bewertungen

- TRAF-12-BAL SESTFt 02eDokument21 SeitenTRAF-12-BAL SESTFt 02eJAIMENoch keine Bewertungen

- Model QRNG 370 Model QRNG 370 Model QRNG 370 Model QRNG 370 Model QRNG 370Dokument22 SeitenModel QRNG 370 Model QRNG 370 Model QRNG 370 Model QRNG 370 Model QRNG 370roalcalo_uanNoch keine Bewertungen

- Anchor ChairDokument2 SeitenAnchor ChairDebarun DuttaNoch keine Bewertungen

- 20 TMSS 02 R0Dokument0 Seiten20 TMSS 02 R0renjithas2005Noch keine Bewertungen

- Catalog SchwitzerDokument43 SeitenCatalog SchwitzerHilal MelhemNoch keine Bewertungen