Beruflich Dokumente

Kultur Dokumente

BT Flexx Metro 3000 Delhi

Hochgeladen von

download_2005Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BT Flexx Metro 3000 Delhi

Hochgeladen von

download_2005Copyright:

Verfügbare Formate

M-Size Bogies

FLEXX Metro 3000

Delhi application

This application of the BOMBARDIER* FLEXX* Metro 3000 bogie design reflects the existing infrastructure and the operational requirements of Delhi Metro Rail Corporation (DMRC). The bogies will be fitted to BOMBARDIER* MOVIA* metro vehicles.

The FLEXX Metro 3000 Delhi type bogie is based on the well proven MTRC bogie design configured for the Mass Transit Railway Corporation Limited (MTRCL) of Hong Kong in China. Both bogies have been developed from the well proven FLEXX Series 3 bogie. There are over 8,000 FLEXX Series 3 bogies in operation worldwide. This explains why this bogie was chosen for vehicles of the DMRC. The Delhi application bogie features a robust fabricated frame. The swing arm axle guidance with coil spring primary suspension and elastomeric cushion, gives a high level of steering performance yet low noise emission. Full advantage has been taken of the principle of fitting standard components and frame modules. This results in a bogie with a proven pedigree and low life cycle costs.

Artistic rendering, MOVIA train, DMRC, Delhi, India

680 bogies were ordered by Delhi Metro Rail Corporation in July 2007. This base order was followed by a second one for 168 units in 2008. After the first bogies are manufactured in Siegen, Germany, the serial production will take place at the Bombardier Site in Savli, India.

Bogies

FLEXX Metro 3000

M-Size Bogies

Characteristics

Welded H shape frame Primary and secondary suspension systems optimised for safety, stability and ride comfort for passengers Swing arm axle guidance with coil spring primary suspension and elastomeric cushion, giving a high level of steering performance as well as low noise emission High comfort secondary suspension comprising airsprings and auxiliary elastomeric spring Air orifice secondary vertical damping reduces weight, cost and complexity and improves vertical ride quality Frame mounted Anti-Roll bar connected to the car body by vertical links Transom mounted traction motors coupled to axle mounted gearboxes Braking is by wheel mounted brake discs with frame mounted actuators for both service and parking applications Axle end mounted Wheel Slide Protection sensors to optimise braking performance and reduce wheel damage Elastomer bushes used throughout to minimise noise transmission and reduce maintenance

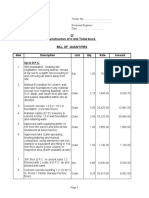

Technical Data

Gauge Wheel base Wheel diameter new Wheel diameter worn Operating speed Mass (trailer) Maximum axle load Pivot load Height over secondary suspension Power 1,673 mm 2,500 mm 860 mm 780 mm 85 km/h 8.5 (6.1) t 17 t 27,9 t 860 mm 2 x 220 kW

Bombardier Transportation Siegstrae 27 57250 Netphen, Germany Tel Fax + 49 271 702 0 + 49 271 702 222

www.bombardier.com

*Trademark(s) of Bombardier Inc. or its subsidiaries.

If you no longer require this brochure please recycle it responsibly. 2008, Bombardier Inc. or its subsidiaries. All rights reserved. Printed in France/10426/BOG/11-2008/en

Das könnte Ihnen auch gefallen

- BT Flexx Metro 3000 DelhiDokument2 SeitenBT Flexx Metro 3000 Delhidownload_2005Noch keine Bewertungen

- BT Flexx Metro 3000 DelhiDokument2 SeitenBT Flexx Metro 3000 Delhidownload_2005Noch keine Bewertungen

- Class 10 - NVHDokument38 SeitenClass 10 - NVHdownload_2005Noch keine Bewertungen

- CAIA Study Guide 2011Dokument64 SeitenCAIA Study Guide 2011Harish BarkeNoch keine Bewertungen

- Central TestDokument5 SeitenCentral Testdownload_2005Noch keine Bewertungen

- Appendix ADokument17 SeitenAppendix Adownload_2005Noch keine Bewertungen

- Ansys Consitent UnitsDokument2 SeitenAnsys Consitent Unitsdownload_2005Noch keine Bewertungen

- CAIA Study Guide 2011Dokument64 SeitenCAIA Study Guide 2011Harish BarkeNoch keine Bewertungen

- Failure Mode Analysis of Plastics Components & Parts: June 9th, 2008 American Engineering Group, Akron OHDokument3 SeitenFailure Mode Analysis of Plastics Components & Parts: June 9th, 2008 American Engineering Group, Akron OHdownload_2005Noch keine Bewertungen

- Good Solid Modeling Bad FEADokument5 SeitenGood Solid Modeling Bad FEAdownload_2005Noch keine Bewertungen

- Nokia 5230 RM-593 RM-594 UG en-US NAMDokument171 SeitenNokia 5230 RM-593 RM-594 UG en-US NAMdownload_2005Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Supply Chain Risk Management: Resilience and Business ContinuityDokument27 SeitenSupply Chain Risk Management: Resilience and Business ContinuityHope VillonNoch keine Bewertungen

- Relay Interface ModulesDokument2 SeitenRelay Interface Modulesmahdi aghamohamadiNoch keine Bewertungen

- 1 Ton Per Hour Electrode Production LineDokument7 Seiten1 Ton Per Hour Electrode Production LineMohamed AdelNoch keine Bewertungen

- Musings On A Rodin CoilDokument2 SeitenMusings On A Rodin CoilWFSCAO100% (1)

- Tecplot 360 2013 Scripting ManualDokument306 SeitenTecplot 360 2013 Scripting ManualThomas KinseyNoch keine Bewertungen

- Simplified Concrete Modeling: Mat - Concrete - Damage - Rel3Dokument14 SeitenSimplified Concrete Modeling: Mat - Concrete - Damage - Rel3amarNoch keine Bewertungen

- BS en Iso 11666-2010Dokument26 SeitenBS en Iso 11666-2010Ali Frat SeyranNoch keine Bewertungen

- Government of India Act 1858Dokument3 SeitenGovernment of India Act 1858AlexitoNoch keine Bewertungen

- M70-700 4th or 5th Axis Install ProcedureDokument5 SeitenM70-700 4th or 5th Axis Install ProcedureNickNoch keine Bewertungen

- LR Format 1.2Dokument1 SeiteLR Format 1.2Ch.Suresh SuryaNoch keine Bewertungen

- SVPWM PDFDokument5 SeitenSVPWM PDFmauricetappaNoch keine Bewertungen

- Surge Arrester: Technical DataDokument5 SeitenSurge Arrester: Technical Datamaruf048Noch keine Bewertungen

- Manulife Health Flex Cancer Plus Benefit IllustrationDokument2 SeitenManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNoch keine Bewertungen

- Omae2008 57495Dokument6 SeitenOmae2008 57495Vinicius Cantarino CurcinoNoch keine Bewertungen

- Chapter03 - How To Retrieve Data From A Single TableDokument35 SeitenChapter03 - How To Retrieve Data From A Single TableGML KillNoch keine Bewertungen

- Ahakuelo IndictmentDokument24 SeitenAhakuelo IndictmentHNNNoch keine Bewertungen

- Computer System Sevicing NC Ii: SectorDokument44 SeitenComputer System Sevicing NC Ii: SectorJess QuizzaganNoch keine Bewertungen

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDokument2 SeitenHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaNoch keine Bewertungen

- Planas V Comelec - FinalDokument2 SeitenPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)

- Best Practices in Developing High PotentialsDokument9 SeitenBest Practices in Developing High PotentialsSuresh ShetyeNoch keine Bewertungen

- T&B Detailed Plan: Ceiling LineDokument1 SeiteT&B Detailed Plan: Ceiling LineKuthbert NoceteNoch keine Bewertungen

- Catalog enDokument292 SeitenCatalog enSella KumarNoch keine Bewertungen

- 11 TR DSU - CarrierDokument1 Seite11 TR DSU - Carriercalvin.bloodaxe4478100% (1)

- COVID Immunization Record Correction RequestDokument2 SeitenCOVID Immunization Record Correction RequestNBC 10 WJARNoch keine Bewertungen

- MNO Manuale Centrifughe IngleseDokument52 SeitenMNO Manuale Centrifughe IngleseChrist Rodney MAKANANoch keine Bewertungen

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFDokument68 SeitenCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουNoch keine Bewertungen

- Labor Law 1Dokument24 SeitenLabor Law 1Naomi Cartagena100% (1)

- People V Superior Court (Baez)Dokument19 SeitenPeople V Superior Court (Baez)Kate ChatfieldNoch keine Bewertungen

- Payment Plan 3-C-3Dokument2 SeitenPayment Plan 3-C-3Zeeshan RasoolNoch keine Bewertungen

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Dokument6 SeitenType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNoch keine Bewertungen