Beruflich Dokumente

Kultur Dokumente

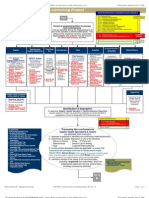

SOP-0012 Control of Non-Conforming Product & Materials

Hochgeladen von

Michael TayactacOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SOP-0012 Control of Non-Conforming Product & Materials

Hochgeladen von

Michael TayactacCopyright:

Verfügbare Formate

This printed document is an UNCONTROLLED COPY - Check B.O.S.

to verify validity prior to use

Date printed: Monday, March 03, 2008

SOP-0012 Control of Non-conforming Product & Materials

Start

Incidents of known or suspected product or process non-conformances may arise or be identified during the implementation of any of the activities identified below (blue boxes). The respective controls, responsibilities, and authority are detailed in the applicable Work Instructions (red text) identified under each of the individual scenarios

5.2 Customer Focus 7.2.3 Customer Communication 7.4.3 Verification of Purchased Product 7.4.3.1 Incoming Product Quality 7.4.3.2 Supplier Monitoring 7.5.5.1 Storage & Inventory 7.5.3 Identification & Traceability 8.2.1.1 Customer Satisfaction - Supplemental 8.3 Control of Non-conforming Product 8.3.1 Control of Non-conforming Product - Supplemental 8.3.3 Customer Information 4.1.1 Records Retention (L. 63) 4.1.5 Certification Body/Registrar Notification (L. 80) 4.5.3 Nonconformance and Corrective & Preventive Action

Notification by Supplier of defective Shipped Parts

Receiving Insp/ Supplier Qualification

Third Party Sort

Lab Inspections

Assembly

Environmental/Health & Safety Audits/ Housekeeping

External Returns

Upon notification from Supplier, Supplier Quality Analyst / Q.A. Analyst initiate action to trace, identify & segregate suspect/nonconforming materials WI-0151 Processing of Supplier Defects WI-0158 Purging the System for Defects WI-0314 Disposition of Suspect Material WI-0435 In-house Repair Report WI-0479 Returning Product to the Supplier

SQA/Q.A. Analyst identify suspect or non-conforming materials during inspection of incoming material or supplier qualification WI-0154 Nonconforming Purchased Product WI-0090 Receiving Inspection WI-0465 Supplier Annual Part Verification and Validation

3rd Party identifies & segregates suspect or known nonconforming materials and returns to Customer (accumulation returns)

Lab testing/ inspection results in identification of nonconformances See F-0595 ABCs Test Matrix for complete listing of Laboratory testing & Inspections

WI-0150 Third Party Sort

Plant Personnel identify & segregate known or suspected non-conformances Applicable Operation Work Instructions WI-0156 Quarantine Area (Assembly) WI-0160 Re-work Front Line Assist straps WI-0158 Purging the system for Defects Assembly WI-0221 Assembly Rework Instructions WI-0070 Utility Person Assembly

Unidentified, unlabelled or nonconforming materials or products found during environmental or health & safety audits, or by housekeeping are segregated and identified as nonconforming WI-0073 Written Hazard Communication Program WI-0391 Health, Safety & Environmental Audit

Customer returns nonconforming product to ABC Company returns product subsequent to Annual Verification and Validation (where applicable) WI-0153 Processing of Returns from Assembly WI-0157 Rework & Disposition of Customer Returns WI-0158 Purging the System for Defects WI-0347 Analysis of Warranty Return Parts

Engineering Periodic Layout, Functional & Dock Audits & Testing Respective Test/Audit results in identification of non-conforming product WI-0094 Dock Audit Assembly Q.A., WI-0044 Function Audit WI-0097 B.S.R. Testing Engineering Design change results in obsolete materials which must be identified and segregated

Identification & Segregation

As applicable, Supplier Quality Specialist or Quality Assurance Supervisor ensures suspect or known non-conforming materials are clearly identified & segregated or moved to designated HOLD/Quarantine area

4.2.4 Control of Records 4.1.1 Records Retention 4.2.1.16 Forever Requirements Extended Enterprise (L. 147, 152, 153, 154)

SOP-0007 Change Control

Process Input: Receiving Inspection List Supplier Rating Report F-0243 Stock on Hold Pending Disposition F-0252 F-0516 F-0633 F-0682 F-0780 F-1034 F-1093 Quality Cage Disposition Codes

Processing Non-conformances

4.5.4 Records

Supplier Quality Specialist/Q.A. Analyst per applicable Work Instruction 1) assesses suspected or identified non-conforming materials/products 2) Determines & assigns disposition of one of the following: - Return to Source - Scrap - 3rd Party Sort - Rework/reuse - Send to Lab for testing - Hold - Customer/Internal Waiver 3) communicates disposition status as applicable to ensure that customers are promptly informed of issues which might impact them (Materials Manager notifies customer of any actual or potential supplier

issues, or potential supply or capacity issues and Q.A. Manager notifies customer of any actual or potential non-conforming product which may have been shipped) Process Output: -

4) maintains records of the nature of all nonconformities, (including suspected nonconformities which are subsequently approved, and any actions taken, including concessions obtained)

Go to

A

Patricia Ravanello, Management Systems SOP-0012 Control of Non-Conforming Product and Materials, Revision: 1 Page: 1 of 3 pages

Das könnte Ihnen auch gefallen

- Sop ReceivingDokument6 SeitenSop ReceivingpoetoetNoch keine Bewertungen

- Traceability ProcedureDokument9 SeitenTraceability Procedurekingofpenetration100% (3)

- LicencesDokument5 SeitenLicencesstopnaggingmeNoch keine Bewertungen

- Context of The OrganizationDokument1 SeiteContext of The OrganizationBAla100% (4)

- SOP-06 (Supplier Evalutation)Dokument11 SeitenSOP-06 (Supplier Evalutation)Farhan75% (4)

- Procedure - CalibrationDokument3 SeitenProcedure - Calibrationiresendiz100% (1)

- Demand Letter For PaymentDokument1 SeiteDemand Letter For PaymentMichael TayactacNoch keine Bewertungen

- Pipe Welding and How To Pass A SMAW 6G (Open Root) Pipe Welding CertificationDokument13 SeitenPipe Welding and How To Pass A SMAW 6G (Open Root) Pipe Welding CertificationMichael TayactacNoch keine Bewertungen

- Identification and TraceabilityDokument3 SeitenIdentification and TraceabilityRainer-Slawetzki100% (1)

- Session4 Automotive Front End DesignDokument76 SeitenSession4 Automotive Front End DesignShivprasad SavadattiNoch keine Bewertungen

- Quality Policy Manual Rev 17Dokument52 SeitenQuality Policy Manual Rev 17CKGlive100% (4)

- Supplier Audit ProcedureDokument4 SeitenSupplier Audit Proceduresakshi patil100% (2)

- Sta-P08-02 Non Conforming ProductDokument6 SeitenSta-P08-02 Non Conforming ProductAnonymous B7pghhNoch keine Bewertungen

- Quality Objectives SummaryDokument1 SeiteQuality Objectives Summarymullanji0% (1)

- QSP 8.4 Control of Externally Provided Processes (Preview)Dokument4 SeitenQSP 8.4 Control of Externally Provided Processes (Preview)Centauri Business Group Inc.67% (3)

- Non Conformance ProcedureDokument3 SeitenNon Conformance ProcedureBharamu Patil33% (3)

- 11.1.0 Traceability ProcedureDokument5 Seiten11.1.0 Traceability ProcedureZed100% (1)

- QSP 8.3.1 Nonconforming Product - SampleDokument3 SeitenQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- 1.procedure For Supplier SelectionDokument2 Seiten1.procedure For Supplier SelectionKapil Karhana50% (2)

- Non Conformance Control ProcedureDokument12 SeitenNon Conformance Control ProcedurePanneer Bala100% (9)

- Supplier Quality QuestionnaireDokument4 SeitenSupplier Quality QuestionnairesutharitesshNoch keine Bewertungen

- QSP 05 - Corrective ActionDokument4 SeitenQSP 05 - Corrective ActionVivek V100% (2)

- 07.SOP For Receipt of Raw and Packing MaterialDokument6 Seiten07.SOP For Receipt of Raw and Packing MaterialBejoy KarimNoch keine Bewertungen

- Manufacturing Process Audit: Example ReportDokument25 SeitenManufacturing Process Audit: Example ReportJawad rahmanaccaNoch keine Bewertungen

- F Control of Non - Conforming Product ProcedureDokument3 SeitenF Control of Non - Conforming Product ProcedureNgonidzashe Zvarevashe100% (1)

- Sop 9 Procedure For Identification and TraceabilityDokument3 SeitenSop 9 Procedure For Identification and Traceabilityvaishnavi100% (5)

- Procedure For Supplires EvaluationDokument3 SeitenProcedure For Supplires EvaluationShiraz Khan100% (1)

- CLAUSE 8.5 Production and Service ProvisionDokument10 SeitenCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNoch keine Bewertungen

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Dokument11 SeitenISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureDokument2 SeitenQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007Noch keine Bewertungen

- QMS 075 Procedure For Product Identification and Traceability SampleDokument2 SeitenQMS 075 Procedure For Product Identification and Traceability SampleAli Saifullizan Ismail100% (1)

- PM - 7.08 Product Identification and TraceabilityDokument6 SeitenPM - 7.08 Product Identification and TraceabilityMangBedjoNoch keine Bewertungen

- Control of Non ConformingDokument5 SeitenControl of Non ConformingNaveenkumar R100% (1)

- CalibrationDokument6 SeitenCalibrationListen TawandaNoch keine Bewertungen

- Outsourced Processes 9001 2015Dokument2 SeitenOutsourced Processes 9001 2015Navnath Tamhane0% (1)

- Non Conformance ManagementDokument22 SeitenNon Conformance Managementssoni_famycare100% (1)

- Supplier Evaluation and Approval - Disapproval PGP2001ADokument6 SeitenSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasNoch keine Bewertungen

- Customer Complaint HandlingDokument7 SeitenCustomer Complaint HandlingpapplionNoch keine Bewertungen

- ISO 3834-2 Compliance Check ListDokument1 SeiteISO 3834-2 Compliance Check ListMichael Tayactac100% (1)

- A6. Control of Nonconforming ProductDokument6 SeitenA6. Control of Nonconforming ProductStanley MtamboNoch keine Bewertungen

- 06.supplier QMS Development Audit ChecklistDokument5 Seiten06.supplier QMS Development Audit ChecklistvishvendanNoch keine Bewertungen

- Supplier Evaluation FormDokument12 SeitenSupplier Evaluation FormMoiz NaeemNoch keine Bewertungen

- ISO 3834-2 Compliance Check List PDFDokument1 SeiteISO 3834-2 Compliance Check List PDFMichael TayactacNoch keine Bewertungen

- Fifo ProcedureDokument2 SeitenFifo ProcedureHaseem Ali100% (1)

- Procedure Recall ProductDokument3 SeitenProcedure Recall ProductLinda Setya Wati100% (2)

- FCP-Nonconforming Product ProcedureADokument7 SeitenFCP-Nonconforming Product ProcedureAjirt2011Noch keine Bewertungen

- Bushcraft Knife AnatomyDokument2 SeitenBushcraft Knife AnatomyCristian BotozisNoch keine Bewertungen

- Comment Response Sheet FormatDokument2 SeitenComment Response Sheet FormatMichael TayactacNoch keine Bewertungen

- Dispatch of Goods and Receipt of Materials Audit ChecklistDokument3 SeitenDispatch of Goods and Receipt of Materials Audit Checklistandruta197850% (2)

- Manufacturing ProcedureDokument3 SeitenManufacturing ProcedureAkhilesh KumarNoch keine Bewertungen

- QSP 621 01customer Satisfaction ProcedureDokument6 SeitenQSP 621 01customer Satisfaction ProcedureMacel100% (1)

- Weld Cladding Overlay - Topics by ScienceDokument73 SeitenWeld Cladding Overlay - Topics by ScienceMichael TayactacNoch keine Bewertungen

- PR020 Control of Non Conformances ProcedureDokument6 SeitenPR020 Control of Non Conformances ProcedureSandraNoch keine Bewertungen

- Control of Non-Conforming Products ProcedureDokument4 SeitenControl of Non-Conforming Products ProcedureAlmario Sagun100% (1)

- SOP For Training Procedure For Quality Control - Pharmaceutical GuidelinesDokument2 SeitenSOP For Training Procedure For Quality Control - Pharmaceutical Guidelinesnbpgr gmoNoch keine Bewertungen

- D-1 Incoming Material ReceivingDokument3 SeitenD-1 Incoming Material ReceivingAlonso Diaz0% (1)

- Basic GMP Inspection Checklist - Written Sanitation Program 2015ADokument1 SeiteBasic GMP Inspection Checklist - Written Sanitation Program 2015AMarkNoch keine Bewertungen

- 2 - Control of Non-Conforming Product & MaterialsDokument3 Seiten2 - Control of Non-Conforming Product & Materialskalite gurusuNoch keine Bewertungen

- CounterfeitDokument5 SeitenCounterfeitVivek GoudNoch keine Bewertungen

- Product Identification and TraceabilityDokument5 SeitenProduct Identification and TraceabilityAriz Joelee Artha100% (1)

- CBC Shielded Metal Arc Welding NC IDokument82 SeitenCBC Shielded Metal Arc Welding NC IBroderick Dispo100% (2)

- HAYAT - CLINIC BrandbookDokument32 SeitenHAYAT - CLINIC BrandbookBlankPointNoch keine Bewertungen

- Traceability Audit To Suppliers: SQE / SD-Check-listDokument43 SeitenTraceability Audit To Suppliers: SQE / SD-Check-listMarceta BrankicaNoch keine Bewertungen

- SOP Control of Non-Conforming ProductDokument1 SeiteSOP Control of Non-Conforming ProductR Bunardi60% (5)

- Material Handling and Preservation ProcedureDokument2 SeitenMaterial Handling and Preservation ProcedureIman Z100% (1)

- PR-5 - Docuent Control ProcedureDokument7 SeitenPR-5 - Docuent Control ProcedureSAMEER JAVEDNoch keine Bewertungen

- Customer Complaint ProcedureDokument4 SeitenCustomer Complaint ProcedureTomNoch keine Bewertungen

- Positive Release FormDokument2 SeitenPositive Release FormFloreid100% (3)

- SAES-W-014 - Old SpecDokument12 SeitenSAES-W-014 - Old SpecMichael TayactacNoch keine Bewertungen

- Department: M.R. & Quality Control Document Title: Control of Non-Conforming ProductDokument3 SeitenDepartment: M.R. & Quality Control Document Title: Control of Non-Conforming ProductJamil VoraNoch keine Bewertungen

- Incoming Inspection-Qmp-Qc-01Dokument2 SeitenIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNoch keine Bewertungen

- 1.0 E S A. P - A: Issue Date Description Originated by Reviewed by Approved byDokument4 Seiten1.0 E S A. P - A: Issue Date Description Originated by Reviewed by Approved byMichael TayactacNoch keine Bewertungen

- PW TEA CMT Twin 2013 ENDokument1 SeitePW TEA CMT Twin 2013 ENMichael TayactacNoch keine Bewertungen

- Form of Acknowledgement: Provision Zone Coating ServicesDokument1 SeiteForm of Acknowledgement: Provision Zone Coating ServicesMichael TayactacNoch keine Bewertungen

- AcknowledgmentDokument1 SeiteAcknowledgmentMichael TayactacNoch keine Bewertungen

- Vendor Document No.: Contractor Documentation Status Company Review CodeDokument2 SeitenVendor Document No.: Contractor Documentation Status Company Review CodeMichael TayactacNoch keine Bewertungen

- Lecture 13 - Welding DefectsDokument4 SeitenLecture 13 - Welding DefectsMichael TayactacNoch keine Bewertungen

- Tungsten ReferenceDokument26 SeitenTungsten ReferenceMichael TayactacNoch keine Bewertungen

- Connect 2019 (Manila) Registration Faq - SG DelegatesDokument1 SeiteConnect 2019 (Manila) Registration Faq - SG DelegatesMichael TayactacNoch keine Bewertungen

- Natcon ProgramDokument2 SeitenNatcon ProgramMichael TayactacNoch keine Bewertungen

- Edc Power Plant FacilitiesDokument32 SeitenEdc Power Plant FacilitiesMichael TayactacNoch keine Bewertungen

- Wilhelm Fold 040115Dokument8 SeitenWilhelm Fold 040115Michael Tayactac100% (1)

- Technical Clarification FormatDokument2 SeitenTechnical Clarification FormatMichael TayactacNoch keine Bewertungen

- Performance Through: TechnologyDokument3 SeitenPerformance Through: TechnologyMichael TayactacNoch keine Bewertungen

- PDS (OTO360) Form PDFDokument2 SeitenPDS (OTO360) Form PDFcikgutiNoch keine Bewertungen

- Unit 1 - Lecture 3Dokument16 SeitenUnit 1 - Lecture 3Abhay kushwahaNoch keine Bewertungen

- Discrete Mathematics and Its Applications: Basic Structures: Sets, Functions, Sequences, and SumsDokument61 SeitenDiscrete Mathematics and Its Applications: Basic Structures: Sets, Functions, Sequences, and SumsBijori khanNoch keine Bewertungen

- Understanding The Marshall AttackDokument6 SeitenUnderstanding The Marshall Attacks.for.saad8176Noch keine Bewertungen

- Power Control 3G CDMADokument18 SeitenPower Control 3G CDMAmanproxNoch keine Bewertungen

- Avid Final ProjectDokument2 SeitenAvid Final Projectapi-286463817Noch keine Bewertungen

- Research Paper On Air QualityDokument4 SeitenResearch Paper On Air Qualityluwahudujos3100% (1)

- Assignment 3Dokument2 SeitenAssignment 3Debopam RayNoch keine Bewertungen

- A Review of Stories Untold in Modular Distance Learning: A PhenomenologyDokument8 SeitenA Review of Stories Untold in Modular Distance Learning: A PhenomenologyPsychology and Education: A Multidisciplinary JournalNoch keine Bewertungen

- Protection in Distributed GenerationDokument24 SeitenProtection in Distributed Generationbal krishna dubeyNoch keine Bewertungen

- Water Tanker Check ListDokument8 SeitenWater Tanker Check ListHariyanto oknesNoch keine Bewertungen

- Power System Planning and OperationDokument2 SeitenPower System Planning and OperationDrGopikrishna Pasam100% (4)

- Microeconomics Term 1 SlidesDokument494 SeitenMicroeconomics Term 1 SlidesSidra BhattiNoch keine Bewertungen

- Buildingawinningsalesforce WP DdiDokument14 SeitenBuildingawinningsalesforce WP DdiMawaheb ContractingNoch keine Bewertungen

- 01 - A Note On Introduction To E-Commerce - 9march2011Dokument12 Seiten01 - A Note On Introduction To E-Commerce - 9march2011engr_amirNoch keine Bewertungen

- TMPRO CASABE 1318 Ecopetrol Full ReportDokument55 SeitenTMPRO CASABE 1318 Ecopetrol Full ReportDiego CastilloNoch keine Bewertungen

- Hindi ShivpuranDokument40 SeitenHindi ShivpuranAbrar MojeebNoch keine Bewertungen

- Specialty Coffee Association of Indonesia Cupping Form (ARABICA)Dokument1 SeiteSpecialty Coffee Association of Indonesia Cupping Form (ARABICA)Saiffullah RaisNoch keine Bewertungen

- Mule 4 Error Handling DemystifiedDokument8 SeitenMule 4 Error Handling DemystifiedNicolas boulangerNoch keine Bewertungen

- Minuets of The Second SCTVE MeetingDokument11 SeitenMinuets of The Second SCTVE MeetingLokuliyanaNNoch keine Bewertungen

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceDokument1 SeiteParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariNoch keine Bewertungen

- Chem Resist ChartDokument13 SeitenChem Resist ChartRC LandaNoch keine Bewertungen

- UntitledDokument13 SeitenUntitledTestNoch keine Bewertungen

- BECIL Registration Portal: How To ApplyDokument2 SeitenBECIL Registration Portal: How To ApplySoul BeatsNoch keine Bewertungen

- Course Projects PDFDokument1 SeiteCourse Projects PDFsanjog kshetriNoch keine Bewertungen