Beruflich Dokumente

Kultur Dokumente

Technical Specifications

Hochgeladen von

Basanth VadlamudiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Specifications

Hochgeladen von

Basanth VadlamudiCopyright:

Verfügbare Formate

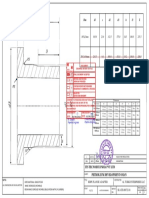

TECHNICAL SPECIFICATION OF CONVEYORS

1. Description of Conveyor System: Conveyors for conveying pipe line has two main structural systems, one the Rigid Frame Structure and the other is Tri series Chain system. The frame structure and chain drive system are rigidly fixed to each other in which the three chains are driven on the rigid frame made of rectangular pipe sections, C- channels, T-sections. The chains on the structural frame are driven by 30hp geared motor.

This Pipe Conveying Structure Consists of following parts (as shown in Fig 1) 1. Rigid Frame Structure 2. Tri-series Chain 3. Sprockets 4. Rubber Sheets 5. Rollers

6. Bearings 7. 30hp Geared Motor 8. Height Adjustment System We will be supply the complete Conveyor System as a set in an assembled condition. We will be responsible for the assembly of rigid frame structure with complete chain system and other sub systems. The complete design development and drawings of the total project will be provided by us as per your requirement .

2. Scope of Work : (a) Designing and preparing the work plan for raw material for rigid frame structure (b) Fabrication of complete frame structure by using familiar MIG welding techniques (c) Assembling the chain in the rigid structure with sprockets. Fixing the Rubber pads with special bonding to chain plates will be done. (d) Setting of the 30hp motor in the rigid frame and connecting the motor shaft with couplings to the linkage shafts of chain sprockets using universal joints (e) Setting the height adjustment using screw mechanism on the both either ends of the conveyor structure

(f) Enclosing the total conveyor body with sheet metal and is painted (g) Upto 10% deviation in the design and deliverables of the conveying system will be catered by us 3. Manufacturing Process (a) Rigid Frame Structure Manufacturing Process: The rigid frame structure of the conveying system is a fabricated body with mild steel material and different alloy steels. It consists of square and rectangular pipe sections, c-channels, T-sections, etc,. which are machined with accurate dimensions and welded with MIG welding process as per drawing designed.

(b) Tri Series Chain System: This chain system consists of chain and sprockets assembled in perfect manner. The chain is manufactured with pitch 50.80 mm and it is designed with a breaking load of 45.8 to 47.8 tons. The tolerance in the length of the chain will be 0.00 to +0.25%. The sprocket is manufactured with 297mm diameter.

(c) Metal Bonded Rubber Pads: The special metal bonded rubber pads are manufactured with copolymer of butadiene and acrylo nitrile and generally named as nitrile rubber, which is resistant to oil, abrasion and heat. (d) Panel Board : Each conveyor will have an individual pannel board with starter and mcbs , for geared motor. All the 10 conveyors are connected to a panel board contains PLC from which all ten conveyors are controlled at a time. 4. Machining: We will use precision machinery such as CNC vertical milling machine, CNC Lathe, MIG welding machine, etc,. The required Dies/Jigs/Fixtures and gauges will be developed by us for machining purpose. The dimensional tolerances, geometrical accuracies and surface finish will be maintained as per drawing and specifications. Profiles will be checked on CNC profiles measuring equipment and by profile gauge made out of SS material. All

components will be maintained as per dimensions and tolerances given in the drawings. 5. Material Properties: Chemical composition and mechanical properties for different alloy steels, rubber, are given in Appendices 6. Progress Monitoring: The work plan will be submitted by us before starting the work. The progress of work will be reviewed regularly at our premises at various stages of manufacturing. 7. Preparation of work piece: The parts to be welded will be effectively pre cleaned and scratch brushed with a stainless brush. Dirt, grease, Machining lubricants or any organic matter will be removed from the areas to be welded by cleaning with suitable solvent.

APPENDIX-I(A) MATERIAL SPECIFICATION

Specification of Rubber Pads: Polymer : Copolymer of butadiene and acrylo nitrile and Generally named as nitrile rubber. Having resistance to oil, abrasion and heat. Hardness : 60-70

Tensile Strength, kg/cm2 : 100-120 % Elongation at break : 300-340

Modulus at 300% Elong. : 40-50 Compression Specific gravity : 20% : 1.3(approx.)

Volume change in Fuel B : 50% 4 weeks at room temp. Volume change in ASTM no.3 Oil 70 hours at 100 deg.c : 30%

Specifications of Planetary Geared Motor: Model Ratio Output Speed Service Factor : MR 3E 446 FC 2C ----180L-4-230..400../B3 : 192 : 7,31 rpm : 1.8

Delivered Torque : 2615daNm 26150Nm Nominal Torque Peak Torque Efficiency Type Output Mounting : 6500da Nm : 7750 da Nm : 91% : Foot Mounting : Solid Cylindrical shaft : B3 Horizontal

Motor Specification: Power Speed Frame Poles Phase Duty Frequency Voltage Protection Class Efficiency : 22 KW : 1465 : 180L :4 : AC, 3PH : Continous S1 : 50 Hz : 230/400v : IP 55 : F-temp rise limited to class B : EFF2 90.8%

Load Calculation on conveyor: Weight per meter of pipe Weight of 12 meters of pipe Weight on 1 conveyor Sprocket Dia(PCD) of chain Speed of the conveyor Speed = 3.1472 x D(meter) x N N=speed/3.142x0.276=6.9rpm@7rpm Considering coefficient of friction as 1.0 Torque = massxdistance(pcd/2(meter))=15000x0.13825=2073.45kgm force Power= 2x3.1472xNxT/4500=2x3.142x7x2073.45/4500=20.25hp Assuming power without assuming loss. Factory of safety over power assumed 1.5 times 20.25x1.5=30.37HP@22KW : 1.2 tons : 14.4 tons @ 15 tons : 15 tons : 276.46mm : 6 meter / minute

Das könnte Ihnen auch gefallen

- SP-2094 Version 03Dokument27 SeitenSP-2094 Version 03Basanth VadlamudiNoch keine Bewertungen

- Dim d1 S d2 d3 H l3 Z: Document/ Drawing Review StatusDokument1 SeiteDim d1 S d2 d3 H l3 Z: Document/ Drawing Review StatusBasanth VadlamudiNoch keine Bewertungen

- Dim d1 S d2 d3 H l3 Z: Document/ Drawing Review StatusDokument1 SeiteDim d1 S d2 d3 H l3 Z: Document/ Drawing Review StatusBasanth VadlamudiNoch keine Bewertungen

- W P SD 010 Rev2 Gate ValvesDokument3 SeitenW P SD 010 Rev2 Gate ValvesBasanth VadlamudiNoch keine Bewertungen

- Data Sheet For Gate ValvesDokument3 SeitenData Sheet For Gate ValvesBasanth VadlamudiNoch keine Bewertungen

- Data Sheet FOR Axial Flow Control Valves: To Comply With Revised Valve Specification AKDokument2 SeitenData Sheet FOR Axial Flow Control Valves: To Comply With Revised Valve Specification AKBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-011 Rev1 Non Return - Check ValvesDokument3 SeitenW-P-SD-011 Rev1 Non Return - Check ValvesBasanth VadlamudiNoch keine Bewertungen

- PH-ATE-080722-02 Rev 1Dokument1 SeitePH-ATE-080722-02 Rev 1Basanth VadlamudiNoch keine Bewertungen

- Data Sheet For Non Return Valves: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleDokument3 SeitenData Sheet For Non Return Valves: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleBasanth VadlamudiNoch keine Bewertungen

- Data Sheet For Diaphragm Control Valves: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleDokument2 SeitenData Sheet For Diaphragm Control Valves: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-015 Rev1 Air Release ValvesDokument2 SeitenW-P-SD-015 Rev1 Air Release ValvesBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-014 Rev1 Diaphragm Control ValveDokument2 SeitenW-P-SD-014 Rev1 Diaphragm Control ValveBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-015 Rev1 Air Release ValvesDokument2 SeitenW-P-SD-015 Rev1 Air Release ValvesBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-014 Rev1 Diaphragm Control ValveDokument2 SeitenW-P-SD-014 Rev1 Diaphragm Control ValveBasanth VadlamudiNoch keine Bewertungen

- W P SD 010 Rev2 Gate ValvesDokument3 SeitenW P SD 010 Rev2 Gate ValvesBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-011 Rev1 Non Return - Check ValvesDokument3 SeitenW-P-SD-011 Rev1 Non Return - Check ValvesBasanth VadlamudiNoch keine Bewertungen

- Data Sheet For Gate ValvesDokument3 SeitenData Sheet For Gate ValvesBasanth VadlamudiNoch keine Bewertungen

- W P SD 010 Rev2 Gate ValvesDokument3 SeitenW P SD 010 Rev2 Gate ValvesBasanth VadlamudiNoch keine Bewertungen

- W-P-SD-015 Rev1 Air Release ValvesDokument2 SeitenW-P-SD-015 Rev1 Air Release ValvesBasanth VadlamudiNoch keine Bewertungen

- ITS - ITP - CCED - USTS - SE 01, Rev.1.Approved ITP & DWGDokument4 SeitenITS - ITP - CCED - USTS - SE 01, Rev.1.Approved ITP & DWGBasanth VadlamudiNoch keine Bewertungen

- Organization ChartDokument2 SeitenOrganization ChartBasanth VadlamudiNoch keine Bewertungen

- Kalite: Prepared by Emine Karaca Quality System SupervisorDokument33 SeitenKalite: Prepared by Emine Karaca Quality System SupervisorBasanth VadlamudiNoch keine Bewertungen

- Borealis ART399 WeldingDokument19 SeitenBorealis ART399 WeldingBasanth VadlamudiNoch keine Bewertungen

- Quality PolicyDokument1 SeiteQuality PolicyBasanth VadlamudiNoch keine Bewertungen

- General/All Locations: Vendor A4 Document Cover SheetDokument2 SeitenGeneral/All Locations: Vendor A4 Document Cover SheetBasanth VadlamudiNoch keine Bewertungen

- Mechanical Behavior of Welded and Un-Welded HDPE Pipe MaterialsDokument11 SeitenMechanical Behavior of Welded and Un-Welded HDPE Pipe MaterialsBasanth VadlamudiNoch keine Bewertungen

- Borealis ART399 WeldingDokument19 SeitenBorealis ART399 WeldingBasanth VadlamudiNoch keine Bewertungen

- Its-Usts-Gen Itp-Se-01Dokument3 SeitenIts-Usts-Gen Itp-Se-01Basanth VadlamudiNoch keine Bewertungen

- TEGA Presentation ENGDokument90 SeitenTEGA Presentation ENGBasanth VadlamudiNoch keine Bewertungen

- PhotosDokument15 SeitenPhotosBasanth VadlamudiNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Calling 24o7 BPO Services Pvt. PMAX Solutions LLP Call CentrDokument3 SeitenCalling 24o7 BPO Services Pvt. PMAX Solutions LLP Call Centrwaris bhatNoch keine Bewertungen

- CBR MethodDokument5 SeitenCBR MethodThiruchelvam Paneer SelvamNoch keine Bewertungen

- Garden cultivators and rotary tillers guideeditDokument2 SeitenGarden cultivators and rotary tillers guideeditMauris BelmonteNoch keine Bewertungen

- Bikes Peds Safety ScriptDokument13 SeitenBikes Peds Safety ScriptingcarasanNoch keine Bewertungen

- Yetta Company ProfileDokument6 SeitenYetta Company ProfileAfizi GhazaliNoch keine Bewertungen

- ISPS CodeDokument14 SeitenISPS CodeDirgantara100% (2)

- TRBC Quick GuideDokument5 SeitenTRBC Quick GuideCarlos MartinsNoch keine Bewertungen

- Operation Management (Case: MRP at A-Cat Corp.)Dokument44 SeitenOperation Management (Case: MRP at A-Cat Corp.)Camelia Indah Murniwati77% (13)

- Ucm03 038939 CrusherDokument1 SeiteUcm03 038939 CrusherEndro SuhadiNoch keine Bewertungen

- Ballou 09Dokument105 SeitenBallou 09Andrew RhoNoch keine Bewertungen

- BP On Off Highway Product Range LeafletDokument4 SeitenBP On Off Highway Product Range Leafletmedidas012Noch keine Bewertungen

- ATPL RequirementsDokument4 SeitenATPL RequirementsKevin DsouzaNoch keine Bewertungen

- Cut and Cover Bridge Construction with Rolling RCC BoxDokument5 SeitenCut and Cover Bridge Construction with Rolling RCC BoxradhakrishnangNoch keine Bewertungen

- Is 10096-1-1 (1983)Dokument14 SeitenIs 10096-1-1 (1983)slamienkaNoch keine Bewertungen

- Taconic High School GMPDokument5 SeitenTaconic High School GMPiBerkshires.comNoch keine Bewertungen

- Road Accidents in BangladeshDokument3 SeitenRoad Accidents in BangladeshKorom ChandNoch keine Bewertungen

- 7200 ABCON M-STERN TUBE Type 2 PI DKSalg-GB PDFDokument2 Seiten7200 ABCON M-STERN TUBE Type 2 PI DKSalg-GB PDFLucian IftemieNoch keine Bewertungen

- Bell Cantilever 200 300 ManualDokument20 SeitenBell Cantilever 200 300 Manualjimmie65Noch keine Bewertungen

- Set Files For Ac Research 2ndDokument26 SeitenSet Files For Ac Research 2ndstarsalingsoul8000Noch keine Bewertungen

- AUMUND Pan Conveyors Fd0a10Dokument24 SeitenAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- Western Resume ExampleDokument5 SeitenWestern Resume ExampleGage Floyd Bitayo0% (1)

- GST Invoice for Flight BookingsDokument3 SeitenGST Invoice for Flight Bookingsreddi.demullu007Noch keine Bewertungen

- KW.09.0128 - DOC - 11.12.12 - 1 of 5 - Specifications - Structural & Architectural PDFDokument661 SeitenKW.09.0128 - DOC - 11.12.12 - 1 of 5 - Specifications - Structural & Architectural PDFCrazyBookWorm100% (1)

- Good Manufacturing Practices in Food IndustryDokument18 SeitenGood Manufacturing Practices in Food IndustryShahida Hussain100% (6)

- ABS HIMP - Hull Inspection Maintenance Guide - 2012Dokument14 SeitenABS HIMP - Hull Inspection Maintenance Guide - 2012Glen AshwellNoch keine Bewertungen

- CompReg 21APRIL2017Dokument1.770 SeitenCompReg 21APRIL2017Mangal GuptaNoch keine Bewertungen

- Evershine Modular KitchenDokument14 SeitenEvershine Modular Kitchenwonders_24108631Noch keine Bewertungen

- Standard Data Book For RoadsDokument1.082 SeitenStandard Data Book For RoadsMonjit Gogoi100% (4)

- Autocheck Vehicle History ReportDokument4 SeitenAutocheck Vehicle History ReportkhananlolNoch keine Bewertungen

- Company ProfileDokument8 SeitenCompany ProfileD Wahyu Bawono0% (1)