Beruflich Dokumente

Kultur Dokumente

Spe62752 Viscous Pill Info

Hochgeladen von

Akkassin AbdullayevOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Spe62752 Viscous Pill Info

Hochgeladen von

Akkassin AbdullayevCopyright:

Verfügbare Formate

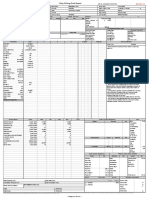

HAL.9002.0004.

0485

Cement Plug Guidelines

Common Causes of Plug Failure

Design No firm base for cement plug (see recommendations opposite for options to provide firm base) Poor well evaluation Poor written procedures Incorrect temperatures No allowance for contamination (top 30-60m of plug) Execution Poor mud/hole conditioning Insufficient slurry volume/excess Execution delays Poor coordination Poor equipment Impatience to set and tag the plug Over-displacement (from inaccurate volumes/calcs.)

Plug Setting Recommendations

Hole Size If possible, set plug at depths where washouts minimal Pump sufficient cement volume: Open hole - 50% excess Cased hole - 10 bbls for contamination Set plug well above kick off depth: Kick off plug set to place TOC at least 60 90m above desired kick off depth, to ensure competent cement at kick off point. Set plug on a firm base: Cased hole use EZSV / Fas-Dril packers Open hole 12 use Cement Support Tool (plus high vis pill in extreme situations) Open hole > 12 use Viscous Reactive Pill (VRP) Mud removal & displacement: While RIH, rotate (15-30rpm), reciprocate and wash interval at maximum pump rate. Minimise shutdowns, to keep the mud in a fluidized condition. Redirect flow with diverter tool: Use a side-port diverter tool (if a CST is not used) on the bottom of the cementing stinger to redirect flow, minimising intermixing and optimising hole cleaning. Use cement stinger to minimise stripping plug: 8 hole, use 3 stinger < 8 hole, use 2 7/8 stinger. Stinger should be at least 1.5 x length of cement plug Cement plug length: Limit plug length to 150 - 180m to allow stinger to be pulled slowly out of plug. Longer plugs increase the risk of cementing-in the stinger. If longer plugs necessary conduct appropriate risk assessment. Spacer system: To provide fluid separation and hole cleaning, sufficient volume of a suitable spacer should be pumped ahead to provide 150 - 300m of annular fill or a 10min contact time, plus spacer volume behind to balance. Pump rates: Pump spacer, cement and displacement at maximum practicable rates, slowing rate down to 1-2 bpm at 5-10 bbls before end of calculated displacement. Displacement volumes: Drill pipe and stinger should be drifted for accurate displacement. Under displacement: Under-displacing by a small volume (typically 5-10 bbls), allowing the cement to U-tube into position, can help ensure the plug balances out & the pipe does not pull wet. Rotate pipe while pumping cement & displacement: Use side entry sub/swivel or top-drive cement head to enable rotation (15-30rpm) - DO NOT reciprocate. Slowly pull out of cement plug: After plug is in place POOH slowly (10-15m/min) and break connections carefully to avoid stripping plug, whilst avoiding any delays. Circulate string clean: Do not circulate on top of plug, wait until a minimum of 150m above top of plug before circulating string clean, using wiper ball to clean string. Waiting on cement: Prior to testing a plug (tagging or pressure testing), time should be allowed for it to develop sufficient compressive strength at least the time for the plug to reach 500psi or 3,000psi for a kick-off plug.

Cementing swivel to allow drill pipe rotation

The most common contributor to cement plug failure and the necessity for remedial work is where no consideration is given to providing a firm base for the cement plug Allow for contamination in top 30 60m of cement plug

In deviated well bores cement slurry can slope down low side

Lo w er d e ns ity w ellf luid

In vertical well bores cement slurry can spiral or rope down hole

H igh e r d en sity c em en t s lip p in g o r flow in g

Hi gh er den si ty ce m e nt gra vi ta tin g wi th s pi ra l we llf lu id e xch an g e

Use diverter tool on bottom of stinger (if CST not used)

Typical Cement Plug Properties

Thickening time: Job time plus 60 mins for KO or Abandonment Plugs. Free Water: 1% for vertical or deviated wellbores. Rheology: To be measured at surface and BHCT. To be mixable at surface & stable down hole. Compressive Strength: ~ 2000psi in 24hrs for Abandonment Plugs & ~ 3000psi in 20hrs for Kick Off Plugs (compromise may be required at shallow depths / low temps) Fluid Loss: 200cc/30mins if plug is to be set in a permeable zone.

Right 1st Time

Injuries

Spills

Use EZSV packer as base for cement plug in cased hole

If using a CST - drift all pipe & crossovers

Das könnte Ihnen auch gefallen

- Tg-374 18.625in Cement Rev No. 1Dokument3 SeitenTg-374 18.625in Cement Rev No. 1Lessly Lorena Apala RamirezNoch keine Bewertungen

- Plugback Sidetracks - Off Cement PlugsDokument4 SeitenPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNoch keine Bewertungen

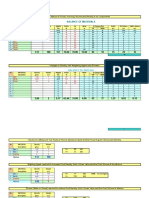

- Mud Plan CalculationsDokument6 SeitenMud Plan CalculationsHarjan Philipp C. GopaldasNoch keine Bewertungen

- Graphitepowder PDFDokument1 SeiteGraphitepowder PDFمحمد سعيدNoch keine Bewertungen

- Lab Test - AM - 17.5 - 01Dokument1 SeiteLab Test - AM - 17.5 - 01tungxuanbrNoch keine Bewertungen

- Drilling Fluids Guide for Well ConstructionDokument21 SeitenDrilling Fluids Guide for Well ConstructionFernando AybarNoch keine Bewertungen

- Field Fluids QaqcDokument38 SeitenField Fluids QaqcscrbdgharaviNoch keine Bewertungen

- Pumping LCM and Mud Pills Procedure When Using MWD ToolsDokument3 SeitenPumping LCM and Mud Pills Procedure When Using MWD ToolsOilEarthNoch keine Bewertungen

- Section - 10 Lost CirculationDokument16 SeitenSection - 10 Lost CirculationIbrahim DewaliNoch keine Bewertungen

- NLOG GS PUB 1387 Cementing EOWRDokument61 SeitenNLOG GS PUB 1387 Cementing EOWRWilson WanNoch keine Bewertungen

- Pilot Test: ScientificDokument12 SeitenPilot Test: ScientificHomam MohammadNoch keine Bewertungen

- 13 38 in TP-194 (HAS-2) Cement Program V1Dokument21 Seiten13 38 in TP-194 (HAS-2) Cement Program V1hakoubNoch keine Bewertungen

- Ali Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDDokument1 SeiteAli Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDMohamed Mahmoud Rezk DimoNoch keine Bewertungen

- 14 Contaminants - Part 2 NEWDokument26 Seiten14 Contaminants - Part 2 NEWLuis CarrilloNoch keine Bewertungen

- Cutting Transport 1999Dokument5 SeitenCutting Transport 1999Dicky PratamaNoch keine Bewertungen

- Kill SheetDokument17 SeitenKill SheetscrbdgharaviNoch keine Bewertungen

- 5 Effect of High Temp On MudsDokument8 Seiten5 Effect of High Temp On Mudsgplese0Noch keine Bewertungen

- Drilling Fluid Rheology ExplainedDokument22 SeitenDrilling Fluid Rheology ExplainedLazharNoch keine Bewertungen

- 04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage ToolDokument5 Seiten04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage ToolDrilling Engineering ChannelNoch keine Bewertungen

- HydraulicsDokument24 SeitenHydraulicsMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDokument2 SeitenBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarNoch keine Bewertungen

- Tds Premium GelDokument1 SeiteTds Premium Gelمحمد سعيدNoch keine Bewertungen

- Lost Circulation PDFDokument17 SeitenLost Circulation PDFSAKNoch keine Bewertungen

- Rules of Thumb To Improve High-Angle Hole CleaningDokument29 SeitenRules of Thumb To Improve High-Angle Hole CleaningjalalNoch keine Bewertungen

- Hole Cleaning: Downhole Motors in Deviated WellsDokument13 SeitenHole Cleaning: Downhole Motors in Deviated WellsJairo CortesNoch keine Bewertungen

- TVD & Kill Weight CalculationsDokument40 SeitenTVD & Kill Weight Calculationsfrancisryan4519Noch keine Bewertungen

- PillsDokument4 SeitenPillsbestman82Noch keine Bewertungen

- Vertical Development Well Mud ReportDokument12 SeitenVertical Development Well Mud ReportBOUBAKER LOGBINoch keine Bewertungen

- Cement Plug ProgramDokument9 SeitenCement Plug ProgramMarvin OmañaNoch keine Bewertungen

- Drilling Fluid Contaminant Identification and Treatment MethodsDokument51 SeitenDrilling Fluid Contaminant Identification and Treatment MethodsAmine BiroukNoch keine Bewertungen

- C Competency TestDokument14 SeitenC Competency TestDudul BoruahNoch keine Bewertungen

- 05 - SRB Hydraulic ProgramsDokument22 Seiten05 - SRB Hydraulic ProgramsnelsonhugoNoch keine Bewertungen

- Surge - Swab ProgramDokument1 SeiteSurge - Swab ProgramHenry BritoNoch keine Bewertungen

- PillsDokument3 SeitenPillsAhmedMohsenNoch keine Bewertungen

- CMT Programm Spd18a-07 - 3Dokument9 SeitenCMT Programm Spd18a-07 - 3nabiNoch keine Bewertungen

- CemNET Well Service Lost Circulation SolutionDokument37 SeitenCemNET Well Service Lost Circulation SolutionLenin DiazNoch keine Bewertungen

- Cementing Design ReportDokument9 SeitenCementing Design Reportreza khNoch keine Bewertungen

- By-24 DMR 2013-05-18 G2Dokument1 SeiteBy-24 DMR 2013-05-18 G2Iqbal KarimNoch keine Bewertungen

- 45-Mud Hole CleaningDokument11 Seiten45-Mud Hole CleaningFreddy Quintero100% (1)

- Calcium Oxide Product Data SheetDokument1 SeiteCalcium Oxide Product Data Sheetsaa6383Noch keine Bewertungen

- Alaska Drilling and Wells Recommended Practice: Lost CirculationDokument4 SeitenAlaska Drilling and Wells Recommended Practice: Lost CirculationAdel Ahmed AlkhaligyNoch keine Bewertungen

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDokument4 SeitenAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNoch keine Bewertungen

- Drilling Fluid CourDokument120 SeitenDrilling Fluid CourBouazizizi MOHAMED100% (2)

- Settling Plug Mixing ProcedureDokument8 SeitenSettling Plug Mixing ProcedureKamel TouahriaNoch keine Bewertungen

- 13 Contaminants - Part 1 NEWDokument18 Seiten13 Contaminants - Part 1 NEWLuis CarrilloNoch keine Bewertungen

- MAX LOCK Lost Circulation Material SLSH PDFDokument2 SeitenMAX LOCK Lost Circulation Material SLSH PDFmehranNoch keine Bewertungen

- PBL Hole CleaningDokument2 SeitenPBL Hole CleaningOlgaLuciaNoch keine Bewertungen

- GOK-12 Wellbore Cementing ReportDokument5 SeitenGOK-12 Wellbore Cementing Report-BloodSeeker-Noch keine Bewertungen

- Casing & Cementing ConventionalDokument1 SeiteCasing & Cementing ConventionalDeepak TandonNoch keine Bewertungen

- DDR N°02 - Sydnw1 - Enf57 - 24122019Dokument3 SeitenDDR N°02 - Sydnw1 - Enf57 - 24122019Kenaouia Bahaa100% (1)

- Cementing Program For The 13 38 Inch CasingDokument40 SeitenCementing Program For The 13 38 Inch CasingMarvin OmañaNoch keine Bewertungen

- Water Based Mud Titration Chart.: Test Sample Indicator Titrate With Color Change Multiplier Units PF Cc'sDokument1 SeiteWater Based Mud Titration Chart.: Test Sample Indicator Titrate With Color Change Multiplier Units PF Cc'sjamesNoch keine Bewertungen

- Stab-in Cementing Job Risk AssessmentDokument2 SeitenStab-in Cementing Job Risk AssessmentIbnu HasanNoch keine Bewertungen

- Flow DataDokument5 SeitenFlow DataMiguel RodriguezNoch keine Bewertungen

- Cementing Proposal Programs TFT-473 - TP-211 PDFDokument25 SeitenCementing Proposal Programs TFT-473 - TP-211 PDFAmine MimoNoch keine Bewertungen

- Mud Engineers HandbookDokument29 SeitenMud Engineers HandbookWasif KarimNoch keine Bewertungen

- Manzalai-07 Daily Mud Report (10!7!20)Dokument1 SeiteManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedNoch keine Bewertungen

- Dog Leg Severity CalculationDokument30 SeitenDog Leg Severity CalculationChristian LianNoch keine Bewertungen

- Pilot testing for contamination issuesDokument25 SeitenPilot testing for contamination issuesEjaz ul Haq kakar100% (1)

- 09 Plug Setting Best PractisesDokument1 Seite09 Plug Setting Best Practiseshamora33Noch keine Bewertungen

- Dynamic Soil Structure Interaction - 01 - Chapter 1 - NaganoDokument42 SeitenDynamic Soil Structure Interaction - 01 - Chapter 1 - Naganonevam21100% (1)

- General Physics 1 1st Quarter Module 1 ActivitiesDokument16 SeitenGeneral Physics 1 1st Quarter Module 1 ActivitiesMica LopezNoch keine Bewertungen

- Fluidized Bed CombustionDokument600 SeitenFluidized Bed Combustionvikasnar100% (7)

- Vector CalculusDokument62 SeitenVector CalculuswaleedNoch keine Bewertungen

- Adrian Stan MFQMCourseHsL2006Dokument60 SeitenAdrian Stan MFQMCourseHsL2006禿公Noch keine Bewertungen

- Induction Heating - VerDokument2 SeitenInduction Heating - Verdenivaldo2009Noch keine Bewertungen

- NTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINEDokument23 SeitenNTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINETarundeep SinghNoch keine Bewertungen

- Heat ActivityDokument3 SeitenHeat ActivityMG Untalan Bauzon0% (1)

- Signature RedactedDokument49 SeitenSignature RedactedG Pavan KumarNoch keine Bewertungen

- Ashish PPT 2Dokument9 SeitenAshish PPT 2Ankit JaglanNoch keine Bewertungen

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkDokument287 SeitenStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkluis morales100% (2)

- Acids and Bases: Answers To Worked ExamplesDokument12 SeitenAcids and Bases: Answers To Worked ExamplesDana CapbunNoch keine Bewertungen

- Introducing JiFi ST Petersburg 2014Dokument4 SeitenIntroducing JiFi ST Petersburg 2014danjohhnNoch keine Bewertungen

- WISDM-dataset-description 2Dokument5 SeitenWISDM-dataset-description 2yuliasihkripsianditaNoch keine Bewertungen

- AW Meter Aqualab PREDokument2 SeitenAW Meter Aqualab PREDebrina ANoch keine Bewertungen

- Additive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Dokument35 SeitenAdditive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Mazhar HussainNoch keine Bewertungen

- Introduction To Tribology and Tribological ParametersDokument13 SeitenIntroduction To Tribology and Tribological ParametersEsteban CorderoNoch keine Bewertungen

- Electric Current and Charge RelationshipDokument9 SeitenElectric Current and Charge RelationshipLokman HakimNoch keine Bewertungen

- Flux 10 4 New Features Presentation ValideDokument22 SeitenFlux 10 4 New Features Presentation ValideleelNoch keine Bewertungen

- Q3 ST 1 GR.6 Science With TosDokument4 SeitenQ3 ST 1 GR.6 Science With TosRed MariposaNoch keine Bewertungen

- Led t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaDokument3 SeitenLed t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaNailza BizerraNoch keine Bewertungen

- Avr GeneralDokument67 SeitenAvr GeneralRukma Goud Shakkari100% (2)

- T3-Revision-Internal-ResistanceDokument22 SeitenT3-Revision-Internal-Resistancejordan2gardnerNoch keine Bewertungen

- LaminateDokument154 SeitenLaminateAbhishek VaggarNoch keine Bewertungen

- Lift EstimationDokument5 SeitenLift EstimationAvinash SinghNoch keine Bewertungen

- Air Preheater Technical PaperDokument21 SeitenAir Preheater Technical Paperchekoti koushikNoch keine Bewertungen

- Revised Design Report of Jetty 06.04.2014Dokument10 SeitenRevised Design Report of Jetty 06.04.2014Priodeep Chowdhury100% (2)

- Phased Array Probes and Wedges: Probe CatalogDokument3 SeitenPhased Array Probes and Wedges: Probe CatalogDavidMontillaNoch keine Bewertungen

- SMS LteaDokument11 SeitenSMS LteaArdi CikaNoch keine Bewertungen