Beruflich Dokumente

Kultur Dokumente

185

Hochgeladen von

jeancdinOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

185

Hochgeladen von

jeancdinCopyright:

Verfügbare Formate

Dehydration of Methanol to Dimethyl Ether over ZSM-5 Zeolite

Bull. Korean Chem. Soc. 2004, Vol. 25, No. 2

185

Dehydration of Methanol to Dimethyl Ether over ZSM-5 Zeolite

Shan Jiang,a,b Jin-Soo Hwang,a,* Taihuan Jin,a Tianxi Cai,b Wonihl Cho,c Young soon Baek,c and Sang-Eon Parkd,* Catalysis Center for Molecular Engineering, Korea Research Institute of Chemical Technology, P.O. Box 107, Yuseong, Daejeon 305-306, Korea b Department of Chemistry, School of Chemical Engineering, Dalian University of Technology, Zhongshan road 158, Dalian 116012, P.R. China c LNG Technology Reseach Center, R&D Division, Korea Gas Co., Dongchun Dong, Yeonsu Ku, Incheon 406-130, Korea d Department of Chemistry, Inha University, Incheon 402-751, Korea Received September 9, 2003 Methanol dehydration to dimethyl ether (DME) has been investigated over ZSM-5 zeolites and compared with that of -Al2O3. Although the catalytic activity was decreased with an increase in silica/alumina ratio, the DME selectivity increased. H-ZSM-5 and NaH-ZSM-5 zeolites were more active for conversion of methanol to DME than -Al2O3. Na+ ion-exchanged H-ZSM-5 (NaH-ZSM-5) shows higher DME selectivity than H-ZSM-5 due to the selective removal of strong acid sites. Key Words : Dehydration, DME, Methanol, ZSM-5 zeolite

a

Introduction Dimethyl ether (DME) is a useful chemical intermediate for the preparation of many important chemicals, such as dimethyl sulfate and high-value oxygenated compounds.1-3 Recently, it has received much attention as an alternative diesel fuel due to its low NO emission, near-zero smoke and less engine noise compared with those of traditional diesel fuels.45 In addition, it has been used as an aerosol propellant to replace chlorofluoro carbonswhich can destroy the ozone layer of the atmosphere.6 DME has been produced by catalytic dehydration of methanol over a solid-acid catalyst. As an alternating process, the direct synthesis of DME from syngas was proposed over bifunctional catalysts,7 which had two kinds of active sites: one is for methanol formation and the other for methanol dehydration.8 This process is more favorable in view of thermodynamics and economy.9 The process of methanol production from synthesis gas has been used successfully for several decades, and the reaction mechanism and the role of each active ingredient in catalyst have been well studied. In contrast to methanol synthesis, the catalytic dehydration of methanol to DME has received less attention. Woodhouse et al. patented that methanol dehydration takes place readily on pure or phosphoric acid modified Al2O3 catalysts;10 however, water produced in the reaction process blocked active sites for methanol dehydration through competitive adsorption with methanol on catalyst surface.4 Concerning DME formation in methanol dehydration, different mechanisms have been proposed. Bandiera and Naccache11 suggested the reaction of methanol occurs at the Brnsted acid and its adjacent Lewis basic sites with formation of the two surface species [CH3OH2]+ and

*

[CH3O] which upon condensation give DME and water. Kubelkov et al.12 reported that methanol is initially adsorbed at the zeolite. With transference of the zeolitic proton the methoxonium ion, H3COH2+, is formed. This dehydrates leaving a methyl group bonded to the zeolite surface. Later on, those surface methoxy groups can react with another methanol molecule to form dimethyl ether. However, Blaszkowski et al. proposed that the two parallel reaction pathways for the production of DME are possible.13 In this paper we have studied the role of acid property in the methanol dehydration process. The purpose of the present study is to evaluate the H-ZSM-5 and modified HZSM-5 catalysts to develop a suitable catalyst for an integrated process of producing DME directly from syngas. For comparison, -Al2O3 catalyst also has been investigated. Experimental Section Catalyst preparation. -Al2O3 used commercial grade (Strem Chemicals, 99.7%). The ZSM-5 catalyts was obtained from P.Q Corporation. The ZSM-5 sample was supplied under ammonium form and transformed into the hydrogen form by calcining in flowing air at 823 K for 10 h with heating rate 10 K/min. H-ZSM-5 was treated with 1 M NaNO3 at reflux, washed three times with de-ioned water, dried at 393 K for 2 h and then calcined in flowing air at 823 K for 10 h with heating rate 10 K/min to generate NaHZSM-5. The Na content was quantitatively analyzed by an atomic absorption spectrometer. The degree of ion exchange was 36% (H/Al = 0.64, Na/Al = 0.36). Characterization of acidity. The strength and distribution of acid sites were tested by NH3-TPD technique, which were performed on a conventional apparatus consisting of a cylindrical quartz micro-reactor, a vertical furnace and a thermal conductivity detector (TCD) of a DS-6200 gas chromatograph. Typically, a 0.1 g zeolite sample was placed

Co-Corresponding Authors: J.-S. Hwang (jshwang@pado. krict.re.kr); S.-E. Park (separk@inha.ac.kr)

186

Bull. Korean Chem. Soc. 2004, Vol. 25, No. 2

Shan Jiang et al.

in the fixed bed reactor of 1.5 cm thick bed and was heated up to 873 K with a temperature program of 10 K/min under He flow of 50-60 mL/min, and then the sample was further heated for 2 h at isothermal temperature. Adsorption of ammonia was carried out at 353 K for 10 min under atmospheric pressure. Prior to desorption, the samples were flushed with He for l h at 353 K to remove the physically adsorbed ammonia. Desorption of ammonia was done at a heating rate of 10 K minl from 353 K up to 873 K under a He flow (25 mL/min). The desorbed ammonia was detected by the TCD detector. Reaction system. Methanol dehydration was carried out in a fixed-bed reactor (4 mm inner diameter, 30 cm length) made of stainless steel tube. In a typical experiment, each catalyst (0.2 g, 20-40 mesh) was loaded in the reactor. Before the reaction, the catalyst was activated in a stream of pure N2 at 773 K for 4 h under atmospheric pressure. Methanol was injected by a syringe pump. The products were analyzed by a gas chromatography equipped with thermal conductivity and flame ionization detectors. Results and Discussion In Figure 1, the results of methanol dehydration to DME over different acid catalysts are presented. As shown in Figure 1(A), the activity of catalyst increases in the following sequence: H-ZSM-5(30) > NaH-ZSM-5(30) > -Al2O3. The value in bracket denotes the SiO2/Al2O3 ratio. The conversion of methanol dehydration to DME over NaHZSM-5(30) zeolite almost didnt change with time on stream. However, the conversion of methanol over H-ZSM-5 decreased slightly in 500 min, which might be due to the coke formation over strong acid sites.4 Although decreasing slightly at beginning, the conversion on -Al2O3 stabilized from 50 min. This indicates that water, which is one of reaction products, initially blocked the active sites on the surface of catalyst for methanol consumption.4 The change of the DME selectivity with time on steam in methanol dehydration over several acid catalysts is illustrated in Figure 1(B). The DME selectivity over NaH-ZSM-5(30) catalyst did not change during 500 min. In cases of -Al2O3 and HZSM-5(30), DME selectivity decreased with time on stream, but the decreasing rate of DME selectivity over H-ZSM5(30) was more steep than that over -Al2O3. It should be noted that there are significant differences in conversion and selectivity between NaH-ZSM-5(30) and H-ZSM-5(30) catalysts. NaH-ZSM-5(30) obtained from H-ZSM-5(30) by performing ion exchange with aqueous NaNO3 was found to have much reduced the number of acid sites and, especially, eliminated the strong acid sites (see Figure 3 and Table 1). Therefore, subsequent reactions of DME over strong acid sites to form light olefins were reduced by sodium ion exchange.14 Thus, NaH-ZSM-5(30) gave a higher selectivity for DME. The influence of the reaction temperature against the conversion of methanol and selectivity for DME over acid catalysts is shown in Figure 2. The conversion over NaH-

Figure 1. The results of methanol dehydration over various solid acid catalysts. (Catalyst loading = 0.2 g, 20-40 mesh; N2 flow rate = 360 mL/h; WHSV = 4 h1; T = 523 K). ( 1 ) H-ZSM-5(30); ( ) NaH-ZSM-5(30); ( : ) -Al2O3.

ZSM-5(30) catalyst increased with an increase in temperature from 473 K to 598 K. The conversion rather decreased at the higher temperature than 598 K. The deactivation of NaHZSM-5(30) could be ascribed to coke or water at high temperature.5 Those results obtained over -Al2O3 was similar to those over NaH-ZSM-5(30), but the cause of deactivation was different with that for NaH-ZSM-5(30) catalyst. The decrease of methanol conversion over -Al2O3 at temperature beyond 598 K was due to reaching thermodynamically limiting regime at 598 K. Since the reaction of methanol dehydration to DME is exothermic, reaction equilibrium will move to left by further increasing of temperature. These reasons can also be applied to explain the results of H-ZSM5(30). H-ZSM-5(30) and NaH-ZSM-5(30) zeolite possess Lewis and Brnsted acid sites,15,16 however, the former has stronger acidity and much more acid site density (see Figure 3 and Table 1). So H-ZSM-5(30) catalyst exhibits higher catalytic activity for methanol dehydration, compared to that of NaHZSM-5(30) zeolite. For example, a conversion level of 78% was achieved at temperature as low as 473 K and conversion of methanol reached thermodynamic equilibrium at 498 K. Unlike NaH-ZSM-5(30) zeolite, -Al2O3 exhibits only Lewis acidity,15,16 Hence, it seemed that the catalytic activity

Dehydration of Methanol to Dimethyl Ether over ZSM-5 Zeolite

Bull. Korean Chem. Soc. 2004, Vol. 25, No. 2

187

Figure 2 Effect of reaction temperature on methanol dehydration (Catalyst loading = 0.2 g, 20-40 mesh; N2 flow rate = 360 mL/h; WHSV = 4 h1). ( 1 ) H-ZSM-5(30); ( ) NaH-ZSM-5(30); ( : ) -Al2O3; (---) Equilibrium conversion.

of -Al2O3 in the case of high reaction temperature over 575K was significantly higher than that of NaH-ZSM-5(30), as shown in Figure 2. Methanol dehydration is considered to occur on the acid sites of catalyst surface.17 The properties of acid sites have been studied by NH3-TPD and the results are shown in

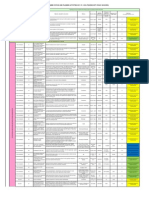

Figure 3. NH3-TPD profiles of various solid acid catalysts (Samples were dried at 873 K for 2 h in He stream. NH3 was adsorbed for 10 min. After desorption of physisorbed NH3 at 353 K for 1 h, TPD was measured from 353 K to 873 K). ( 1 ) H-ZSM5(30); ( ) NaH-ZSM-5(30); ( : ) -Al2O3. Table 1. Results of the NH3-TPD experiments

Catalyst Peak type* Temperature of peak center (K) Area (a.u.) (106) Total area (a.u.) (106)

Figure 3 and Table 1. It can be noticed that for H-ZSM-5(30) catalyst two main bands can be observed around 460 K and 690 K, in good agreement with other previous reports.18 However, there is only one peak appeared in the NH3-TPD profile of -Al2O3 and NaH-ZSM-5(30). The area below the TPD curves, which indicates the total number of acid sites on the surface of catalyst, decreases in the order of H-ZSM5(30) > NaH-ZSM-5(30) > -Al2O3. This fact is in good agreement with the activity sequence (Figure 1(A)). The peak center of NaH-ZSM-5(30) almost appear at same position as -Al2O3, indicating that these two catalysts has similar acid strength. On the other hand, the acid sites density of NaH-ZSM-5(30) is about two times higher than that of -Al2O3(Table 1). However, the dehydration activity of NaH-ZSM-5(30) is much higher than that of -Al2O3 (Figure 1(A)). It can be ascribed that water has a positive effect on methanol dehydration over NaH-ZSM-5 while a negative effect over -Al2O3.4 As mentioned above, acid property of catalyst has an apparent effect on methanol dehydration. And it is well known that H-ZSM-5 zeolite having different silica/alumina ratio possesses different acid property. Therefore, the catalytic dehydration of methanol over H-ZSM-5 catalysts having various SiO2/Al2O3 ratios has been studied (depicted in Figure 4). H-ZSM-5(30) has been found to be the most active among these three catalysts, but it gave lower DME selectivity. H-ZSM-5(50) and H-ZSM-5(140) gave almost same catalytic activity and the DME selectivity (>99%), although they have so much different acid properties (See Figure 5). The acidity of the three zeolites measured by NH3-TPD is presented in Figure 5. The TPD profiles show two peaks at 460 K and 695 K, a high and a low temperature peak corresponding to strong and weak acid sites, respectively.19 The area below the TPD curve decreased with increasing of SiO2/Al2O3 ratio. It shows that the higher SiO2/Al2O3 ratio H-ZSM-5 has, the lower total number of acid sites it possesses. It should be noted that LT (low temperature) and HT (high temperature) peak centers shift to low temperature synchronously as the SiO2/Al2O3 ratio increases. The results indicate that an increase in SiO2/Al2O3 ratio from 30 to 140 come to decrease the strength of both types of acid sites (weak and strong acid sites). Since zeolites having a higher SiO2/Al2O3 ratio possess less strong acid sites, fewer DME dehydration to olefin generates on these zeolites.18 As a result, it seems that the higher selectivity for DME is obtained.

H-ZSM-5(30) LT 461 6.58 9.45 HT 694 2.87

-Al2O3 456 3.01

NaH-ZSM-5(30) 454 6.98

Note: Samples were dried at 873 K for 2 h in an He stream. NH3 was adsorbed for 10 min. After desorption of physisorbed NH3 at 353 K for 1 h, TPD was measured from 353 K to 873 K. *LT: Low temperature peak; HT: High temperature peak.

188

Bull. Korean Chem. Soc. 2004, Vol. 25, No. 2

Shan Jiang et al.

Figure 4. Effect of SiO2/Al2O3 ratio of H-ZSM-5 on methanol dehydration. (Catalyst loading = 0.2 g, 20-40 mesh; N2 flow rate = 360 mL/h; WHSV = 4 h1; T = 523 K). ( 1 ) H-ZSM-5(30); ( : ) H-ZSM-5(50); ( ) H-ZSM-5(140).

Figure 6. Methanol conversion and DME selectivity versus time on stream. (A) H-ZSM-5(30); (B) NaH-ZSM-5(30). (Catalyst loading = 0.2 g, 20-40 mesh; N2 flow rate = 360 mL/h; WHSV = 4 h1; T = 523 K). ( 1 ) Conversion of methanol; ( : ) Selectivity for DME.

Figure 5. NH3-TPD profiles of H-ZSM-5 zeolites (Samples were dried at 873 K for 2h in He stream. NH3 was adsorbed for 10 min. After desorption of physisorbed NH3 at 353 K for 1 h, TPD was measured from 353 K to 873 K). ( 1 ) H-ZSM-5(30); ( : ) H-ZSM5(50); ( ) H-ZSM-5(140).

sites of catalyst. Thus, it could be expected that stability of NaH-ZSM-5(30) was different from H-ZSM-5(30). Figure 6 shows the methanol conversion and selectivity for DME as a function of time on stream at 523 K. Catalyst NaH-ZSM5(30) was indeed more stable than H-ZSM-5(30). The methanol conversion over H-ZSM-5(30) zeolite decreased from 86% to 72% during a dehydration period of ca. 20 h, while that over NaH-ZSM-5(30) decreased slightly. This might show that the deactivation probably due to coke more quickly over H-ZSM-5(30) than NaH-ZSM-5(30). It should be noted that the DME selectivity over H-ZSM5(30) was low in the initial time and soon reached a stable level. Initially, H-ZSM-5(30) has strong acid sites (see Figure 3), which catalyzed the DME to olefins.14 Thus the DME selectivity was transiently decreased. With the reaction proceeding, coke deposition reduced the acidity on the surface of H-ZSM-5(30). Consequently the DME selectivity over H-ZSM-5(30) was recovered during 8 h. This results demonstrate that NaH-ZSM-5(30) is a promising catalyst for methanol dehydration to DME. Conclusions All the H-ZSM-5 catalysts in this study were active and

As discussed in previous part, Na+ ion-exchange of H-ZSM-5(30) has a notable effect on its acidity. The methanol dehydration to DME is mainly controlled by acid

Dehydration of Methanol to Dimethyl Ether over ZSM-5 Zeolite

Bull. Korean Chem. Soc. 2004, Vol. 25, No. 2

189

selective for methanol dehydration to DME. NaH-ZSM-5 zeolite was moderately active and highly stable for methanol dehydration to DME, compared with -Al2O3. The catalytic activity was decreased with an increase in a silica/alumina ratio, whereas the DME selectivity was increased. H-ZSM-5 modified by Na+ ion-exchange (NaH-ZSM-5) was found to have much reduced the number of acid sites and eliminated the strong acid sites especially. As a consequence, very robust DME catalyst can be developed by eliminating the strong acid sites of H-ZSM-5 zeolite, and moreover it can be achieved not only long-term stability but also the 100% DME selectivity. Acknowledgements. This work was supported by the Korean Ministry of Science and Technology through Research Center for Nanocatalysis (KN-0329), one of the National Science Programs for Key Nanotechnology, and the Korean Ministry of Environment (HE-0302). References

1. Shikada, T.; Fuimoto, K.; Miyauchi, M.; Todriaga, H. Appl. Catal. 1983, 7, 361. 2. Kaeding, W. W.; Butter, S. A. J. Catal. 1980, 61, 155.

3. Chang, C. D. Cat. Rev. Sci. Eng. 1983, 25, l. 4. (a) Xu, M.; Lunsford, J. H.; Goodman, D. W. Appl. Catal. A: Gen. 1997, 149, 289. (b) Jun, K.-W.; Lee, H. S.; Roh, H. S.; Park, S.-E. Bull. Korean Chem. Soc. 2003, 24, 106. 5. Xu, M.; Goodman, D. W. Appl. Catal. A 1997, 149, 303. 6. Bohaeun, L. J. M. Aerosol Rep. 1979, 18, 413. 7. Hansen, J. B.; Joensen, F. H.; Topsoe, H. F. A. US patent 5189203 (1993). 8. Ge, Q. J.; Huang, Y. M.; Qiu, F. Y.; Li, S. B. Appl. Catal. A: Gen. 1997, 167, 23. 9. Li, J.-L.; Zhang, X.-G.; Inui, T. Appl. Catal. A: Gen. 1996, 147, 23. 10. Woodhouse, J. C. US patent, 2014408 (1935). 11. Bandiera, J.; Naccache, C. Appl. Catal. 1991, 69, 139. 12. Kubelkov, L.; Novkov, J.; Nedomov, K. J. Catal. 1990, 124, 441. 13. Blaszkowski, S. R.; Van Santen, R. A. J. Am. Chem. Soc. 1996, 118, 5152. 14. Fleish, T.; McCarthy, C.; Basu, A.; Udovich, C.; Charbonneau, P.; Slodowski, W. DAE International Congress; Detroit, 1995; SAE Paper 950064. 15. Tope, N.-Y.; Pedersen, K.; Derouane, G. J. Catal. 1981, 70, 41. 16. Sun, Y.; Campbell, S. M.; Lunsford, J. H.; Lewis, G. E.; Palke, D.; Tau, L. M. J. Catal. 1993, 143, 32. 17. Chen, N. Y.; Reagan, W. J. J. Catal. 1979, 59, 123. 18. Hidalgo, V.; Itoh, H.; Hattori, T.; Niwa, M.; Murakami, Y. J. Catal. 1984, 85, 362. 19. Bhat, Y. S.; Das, J.; Halgeri, A. B. Appl. Catal. A: Gen. 1995, 122, 161.

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 05 Parker Adsorbcne Susicky PNEUNDRIDokument23 Seiten05 Parker Adsorbcne Susicky PNEUNDRImaintenanceNoch keine Bewertungen

- Rice Husk and Sugarcane Baggase Based Activated Carbon For Iron and Manganese RemovalDokument8 SeitenRice Husk and Sugarcane Baggase Based Activated Carbon For Iron and Manganese RemovalFariz AbdiNoch keine Bewertungen

- Molecular Sieves PresentationDokument19 SeitenMolecular Sieves PresentationVasant Kumar Varma100% (1)

- 1 s2.0 S1110016821005068 MainDokument28 Seiten1 s2.0 S1110016821005068 MainpaulinaNoch keine Bewertungen

- Wire Fin Heat Exchanger Using Aluminium Fumarate For Adsorption Heat PumpsDokument11 SeitenWire Fin Heat Exchanger Using Aluminium Fumarate For Adsorption Heat PumpsIndra WahyuNoch keine Bewertungen

- Degomagem - TrisylDokument1 SeiteDegomagem - Trisylricm152Noch keine Bewertungen

- Relevance of Isotherm Models in Biosorption of PolDokument17 SeitenRelevance of Isotherm Models in Biosorption of Polkarri100% (1)

- Adsorption Engineering, Suzuki (1990)Dokument278 SeitenAdsorption Engineering, Suzuki (1990)Nigel Mitchell80% (5)

- Synthesis of Metal-Organic Frameworks MOFs MIL-100Dokument16 SeitenSynthesis of Metal-Organic Frameworks MOFs MIL-100LUKMANNoch keine Bewertungen

- Calculation of The Platinum's Active Surface PDFDokument3 SeitenCalculation of The Platinum's Active Surface PDFUriel Cedeño AntunezNoch keine Bewertungen

- The Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFDokument10 SeitenThe Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFYohana MelianthaNoch keine Bewertungen

- Literature Review of Zno NanoparticlesDokument4 SeitenLiterature Review of Zno Nanoparticlesaflsjcibl100% (1)

- Amer Et AlDokument8 SeitenAmer Et AlNadarlis Binti DarmawiNoch keine Bewertungen

- Minerals Engineering: Keith QuastDokument8 SeitenMinerals Engineering: Keith QuastMuhammad IdrisNoch keine Bewertungen

- Microbial Lipases and Their Industrial Applications: A Comprehensive ReviewDokument42 SeitenMicrobial Lipases and Their Industrial Applications: A Comprehensive ReviewMaulana A'inul YaqinNoch keine Bewertungen

- Batch Adsorption Process of Metals and Anions For Remediation ofDokument331 SeitenBatch Adsorption Process of Metals and Anions For Remediation ofCesar Orlando Villalobos HipolitoNoch keine Bewertungen

- Ccs 125m FundingDokument3 SeitenCcs 125m Fundingkirandas_mullasseryNoch keine Bewertungen

- EE518 - Epitaxial Dep.S07Dokument19 SeitenEE518 - Epitaxial Dep.S07Vandana ThakurNoch keine Bewertungen

- 11.6202 MUS - KS07 - Active - Carbon - Filter - Dryer - 2009Dokument40 Seiten11.6202 MUS - KS07 - Active - Carbon - Filter - Dryer - 2009Jessica ThomasNoch keine Bewertungen

- Natural Gas ProcessingDokument35 SeitenNatural Gas ProcessingAleem AhmedNoch keine Bewertungen

- Adsorption by BhanuDokument20 SeitenAdsorption by BhanuHiren vaghaniNoch keine Bewertungen

- OC POC E (Eduwaves360)Dokument32 SeitenOC POC E (Eduwaves360)John DoeNoch keine Bewertungen

- Food ChemistryDokument7 SeitenFood ChemistryDinh Thi Kim HoaNoch keine Bewertungen

- Water Hyacinth (Eichhornia Crassipes) - An e Cient and Economic Adsorbent For Textile e Uent Treatment - A ReviewDokument11 SeitenWater Hyacinth (Eichhornia Crassipes) - An e Cient and Economic Adsorbent For Textile e Uent Treatment - A ReviewErras Alfiano AdityaNoch keine Bewertungen

- Sample Paper Chemistry Theory (043) MM:70 Time: 3 HoursDokument10 SeitenSample Paper Chemistry Theory (043) MM:70 Time: 3 HoursJabez Jeena100% (1)

- Cinética Oscilatoria en Catálisis Heterogénea - Gerard Ertl - 1995Dokument37 SeitenCinética Oscilatoria en Catálisis Heterogénea - Gerard Ertl - 1995Daniel A. BarragánNoch keine Bewertungen

- Lecture Notes On Surface ProcessesDokument4 SeitenLecture Notes On Surface ProcessesStun GrenadeNoch keine Bewertungen

- Technical Discovery New Climatic and Thermostatic ChambersDokument15 SeitenTechnical Discovery New Climatic and Thermostatic Chambersjohnny chuNoch keine Bewertungen

- IRP FST-14 MEGA 14022021 (MAIN PATTERN) : Page 1 of 15Dokument15 SeitenIRP FST-14 MEGA 14022021 (MAIN PATTERN) : Page 1 of 15RonnyNoch keine Bewertungen

- CarbonDokument21 SeitenCarbonBandana SaruNoch keine Bewertungen