Beruflich Dokumente

Kultur Dokumente

Design Consideration of LO Skid Frame For A 14000 Ton Upper Hull Structure

Hochgeladen von

Affiq AimanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Consideration of LO Skid Frame For A 14000 Ton Upper Hull Structure

Hochgeladen von

Affiq AimanCopyright:

Verfügbare Formate

This article was downloaded by: [195.229.242.

55] On: 02 July 2011, At: 05:00 Publisher: Taylor & Francis Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

The IES Journal Part A: Civil & Structural Engineering

Publication details, including instructions for authors and subscription information: http://www.tandfonline.com/loi/tiea20

Design considerations of a loadout skid frame for a 14,000-ton upper hull structure

L. Y. Cheung & K. G. Foong

a a a

Marine Engineering Services Pte Ltd., 29 International Business Park, No. 07-05, Acer Building, Tower B, Singapore, 609923 Available online: 26 Oct 2007

To cite this article: L. Y. Cheung & K. G. Foong (2008): Design considerations of a loadout skid frame for a 14,000-ton upper hull structure, The IES Journal Part A: Civil & Structural Engineering, 1:1, 83-95 To link to this article: http://dx.doi.org/10.1080/19373260701620287

PLEASE SCROLL DOWN FOR ARTICLE Full terms and conditions of use: http://www.tandfonline.com/page/terms-and-conditions This article may be used for research, teaching and private study purposes. Any substantial or systematic reproduction, re-distribution, re-selling, loan, sub-licensing, systematic supply or distribution in any form to anyone is expressly forbidden. The publisher does not give any warranty express or implied or make any representation that the contents will be complete or accurate or up to date. The accuracy of any instructions, formulae and drug doses should be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims, proceedings, demand or costs or damages whatsoever or howsoever caused arising directly or indirectly in connection with or arising out of the use of this material.

The IES Journal Part A: Civil & Structural Engineering Vol. 1, No. 1, February 2008, 83 95

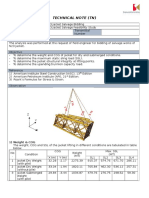

TECHNICAL PAPER Design considerations of a loadout skid frame for a 14,000-ton upper hull structure

L.Y. Cheung* and K.G. Foong

Marine Engineering Services Pte Ltd., 29 International Business Park, No. 07-05, Acer Building, Tower B, Singapore, 609923 (Received 17 April 2007; nal version received 14 May 2007) The objective of this study is to document the design considerations of a Loadout Skid Frame structure to loadout a 14,000 tons heavy Upper Hull Deck of a semi-submersible platform. It highlights the thinking that goes into the design to satisfy all the design constraints starting from load path consideration, dimension limitation to welding access and material availability. In essence, the purpose of the design is to support the new Jurong Shipyard fabrication method for semi-submersible platforms. This useful skid frame has since been used to loadout two upper hull structures, one in June 2003 and the other in May 2004.

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Keywords: loadout skid frame; semi-submersible upper hull structure; dry dock mating operation

1. Introduction In a highly competitive international fabrication market, the bidder with the lowest bid stands a good chance of winning a job and reducing fabrication manhour plays a crucial role in coming up with a low bid. Using better and up-to-date construction equipment on site or setting up a yard in a cheaper labor cost country can help but using an innovative idea to increase productivity will probably produce the best result with the least capital investment. This study documents the design principles of a skidding structure to support an innovative fabrication method proposed by Jurong Shipyard to fabricate semi-submersible platforms. In the fabrication of oshore structures, one way to minimize fabrication manhour is to fabricate as many items as possible on the ground, then lift them up in the air for nal assembly (Cheung et al. 1998). The lifting capacity of the available cranes in the yard will likely dictate the size of the components that should be fabricated. In recent years, many Oileld Operators have gone further to take full advantage of the savings by fabricating the entire deck structure onshore, then loaded it out in one piece and set it onto a pre-installed substructure by a oat-over method. In this development strategy, they saved both fabrication and installation cost (Gerwick 1986). This oat-over method is not a new technique as it has been practiced in the North Sea for over 20 years. In the North Sea, a super heavy topside deck of a concrete gravity platform is usually fabricated onshore, loaded out

onto two or three barges for mating with a pre-set gravity base concrete structure, and then sailed away to site for nal installation. Recently, Statoil also used the oat-over method to fabricate the Visund semisubmersible platform with a topside weight of 25,000 tons. Mating between the substructure and the deck was done in sheltered water. The dierence between this type of oat-over installation and the standard oshore oat-over method is that the former is done near shore where the weather condition is perhaps better whereas the standard oat-over is done onsite in open sea with a pre-installed jacket. However, both methods involve one xed body and one oating body. If mating were done between two oating bodies, the task would be innitely more dicult. Whether it is component fabrication or complete deck fabrication, the underlined message is that onshore fabrication is the cheapest and the quickest way to do fabrication, since every operation can be carefully controlled and quality can be ensured and hence better productivity and greater cost saving. However, oat-over installation is not always the cheapest as it depends on the availability of heavy installation equipment and the cost of extra steel needed for this kind of operation, for example, the weight of the present Loadout Skid Frame is over 3,000 tons and some of the plate thicknesses are more than 80 mm thick. So far, oil companies operating in this South-East Asia region prefer oat-over installation method for heavy decks; say over 5,000 tons, when big derrick barges are not readily available. In the real world, one has to weigh the cost of this kind of

*Corresponding author. Email: bcheung@mespl.com.sg or www.mespl.com.sg

ISSN 1937-3260 print/ISSN 1937-3279 online 2008 The Institution of Engineers, Singapore DOI: 10.1080/19373260701620287 http://www.informaworld.com

84

L.Y. Cheung and K.G. Foong pontoon and the Upper Hull Deck. The pontoons would have been pre-positioned inside the dry dock prior to loadout (see Figure 4). (3) The center-to-center separation of the two longitudinal loadout trusses SL and PL (as shown in Figure 5) is set at 36 m to provide enough sideway clearance from the edge of the column legs.

Downloaded by [195.229.242.55] at 05:00 02 July 2011

fabrication and installation methods against other alternative solutions to come up with the least cost. In this study, we are dealing with a skid-over mating method inside a dry dock. Jurong Shipyard wants to fabricate an upper hull of a semi-submersible platform onshore and then skid it out to mate with two prepositioned pontoons inside the dry dock. Their objective is to reduce fabrication schedule. In 1999, Hyundai Heavy Industries used a similar concept to fabricate the 25,500 tons semi-submersible drilling rig, the RBS-8M, where the topside deck weight is 11,000 tons. They rst fabricated the topside deck on the ground, and then used strand jacks to lift the deck 38 m above ground (Cho et al. 2001). The pontoons being fabricated on-site and located on either side of the deck will then be pushed into position for nal mating. Their cost saving was derived from on-the-ground fabrication and installation since it eliminated the need of the dry dock. But, they still had to loadout the assembled structure onto a submersible cargo barge and put it into the water by submerging the cargo vessel. This operation can be very expensive. This study documents how the Loadout Skid Frame was conceived and designed. The Jurong Shipyard engineers did all the loadout planning and job execution. 2. Design criteria and constraints The design of the Loadout Skid Frame has to meet the following fabrication and mating requirements: (1) The planned loadout sequence is to rst fabricate the Upper Hull Deck near the dry dock-head (see Figure 1). The Upper Hull Deck is skidded into the dry dock as shown in Figures 2 and 3. The pontoons are deballasted to mate with the Upper Hull Deck. The assembly is oated out of the dry dock. (2) During loadout, BOS (bottom of steel) of the Upper Hull Deck is set at elevation () 20,100 mm to provide 500 mm clearance between top of the supporting column of the

Figure 2.

Upper Hull at halfway position.

Figure 3.

Upper Hull at nal position.

Figure 1.

Upper Hull at starting position before loadout.

Figure 4.

Cross section view of pontoons inside dry-dock.

The IES Journal Part A: Civil & Structural Engineering

85

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 5.

Upper Hull blocks loading diagram.

(4) The existing service tunnel next to the dockhead is to be protected during loadout. This means that the skid beams have to bridge across the tunnel. (5) The reinforcement inside the dry dock is avoided such that other yard activities can continue during fabrication of the semisubmersibles. (6) Provide access driveways underneath the skid trusses (SL and PL) during fabrication. This is to enable construction equipment to move in and out of the center area of the Upper Hull structure during fabrication. (7) Provide additional supports for the Upper Hull Deck on the cantilever sides. This is to suit the planned block fabrication sequence (see Figure 5). All these supports must be removed prior to loadout. (8) Provide a safe working platform for the entire underside of the Upper Hull Deck. This is for the block installation sequence. (9) The Loadout Skid Frame is to be designed for skid-out as well as pullback operations because it will be re-used to loadout two more semi-submersibles in the coming years. (10) Materials will be sourced from Singapore whenever possible to cut down procurement time. This means that some old or dated materials may have to be re-certied due to unavailability of mill certicates.

3. 3.1.

Design considerations Load path

The Upper Hull of the semi-submersible is a square box having a plan dimension of 74.42 m by 74.42 m. In one direction, there are six transverse frames, including the two side shells, TF0, TF2, TF6, TF12, TF16 and TF18. In the other direction, excluding the side shells, there are two longitudinal bulkheads, PL7 and SL7 (see Figure 5). The center moonpool is bounded by TF6, TF12, PL7 and SL7. After mating, the Upper Hull will be supported by four columns at the four corners of the semi-submersible platform. The column leg size is 15.86 m by 15.86 m. Since the chosen loadout direction is in line with the longitudinal bulkheads and the Upper Hull is to be fabricated in 12 blocks, it is natural to have six transverse trusses (TFs) and two longitudinal trusses in the proposed skid frame conguration as shown in Figure 6. The basic load path of the structure during construction is to take the loads from the TFs to the two longitudinal skid trusses, which are supported by a total of 12 skid shoes, 6 per truss. The loadout skid shoes are located at the 12 intersection points between the 6 TFs and the 2 longitudinal trusses (PL and SL). The skid shoes are shown in Figures 11 and 12. This load path is correct during block assembly. This is because during fabrication, each block will be fabricated at dierent times according to the project schedule and when it is lifted into position on top of the skid frame, it is acting like a weight without overall

86

L.Y. Cheung and K.G. Foong from the skid frame need to be provided. These out rigging trusses and towers will be removed before loadout and the load path will be altered again. For the fabrication condition, the structure has to be checked for various block installation sequences for all three semi-submersibles, as they may not have identical weight distribution. However, in the present design, it is assumed that all three semi-submersibles have the same dimensions and framing spacing, otherwise, the skid frame may have to be modied to suit a new layout. 3.2. Selection of structural conguration and connection details Once the load paths are selected and understood, it is straightforward to design the skid frame. To provide maximum stability during loadout and bigger moment arm to resist side load, which is caused by the wind in the transverse direction, the two vertical longitudinal trusses (SL and PL) are spaced at 36 m apart, the maximum spacing allowed, and the loads will go vertically down to the loadout skid shoes. If the two longitudinal trusses were slanted to reduce the 36 m span, the horizontal component of the Upper Hull Deck load at each column base would require a very large member to carry this horizontal force and the resulting connecting details would be very complicated and expensive to fabricate. Direct simple load paths will always cost less. The selected structural conguration is shown on Figures 610. It represents a simple direct load-transfer design. Two 3-D views are also provided in Figures 11 and 12. For access requirement, the depth of all the TFs should not be more than 7.5 m. This is to allow workers to move freely underneath the entire Upper Hull Deck without stepping over too many beams

structural stiness of the Upper Hull. It is clear that the weight will be transferred from the TFs to the two outer longitudinal trusses. One should bear in mind that during block assembly, there are 12 additional supporting towers supporting the blocks (Figure 5). However, after all the blocks are welded up, the TFs will become less eective. Since all the transverse frames in the Upper Hull have been designed to span between the two longitudinal frames, PL7 and SL7, most of the deck load will be transferred directly to the two longitudinal frames by virtue of the hull stiness. The true structural behavior of the combined Upper Hull and the Loadout Skid Frame system is however somewhere in between, depending on how the 300 mm by 300 mm wooden blocks are wedged into position (Figure 7), the oset between the skid trusses and the longitudinal bulkheads, the block assembly sequence, the heavy topside equipment loads and equipment installation sequence. One can conclude that there are two possible load paths to transfer the inner loads acting on the TFs to the two longitudinal loadout skid trusses, SL and PL. One is during block assembly and the other is during loadout. Before loadout, all 12 supporting towers will be removed and this change of the boundary conditions will create a dierent load path. For clearance reasons, the longitudinal skid trusses will have to be oset from the two longitudinal bulkheads (SL7 and PL7) by 3.35 m (see Figure 5), and the eect of the resulting eccentric moments on the Upper Hull Deck have to be checked. It is the oset that creates soft intersection points along the skid trusses and makes the load path for loadout dier from the load path for the in-place condition. Since the Upper Hull Deck is fabricated in blocks and then lifted into position for assembly in air, temporary supporting towers and temporary out-rigging trusses

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 6.

Loadout Skid Frame. Top framing plan @ () 13290.

The IES Journal Part A: Civil & Structural Engineering

87

Figure 7.

Loadout Skid Frame. Top framing plan @ () 15100.

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 8.

Bottom framing plan of Loadout Skid Frame.

during emergency evacuation and to provide free access to construction equipment on the ground (Figure 10). There will be no diagonal bracings obstructing passageways. During the loadout, the skid frame structure will experience dierent foundation stiness. For the onshore portion, many skin friction piles were installed to support the skidway; therefore, support point settlements will be small. When the Upper Hull Deck is being pulled into the dry dock, the same topside load will have to go through another supporting structure inside the dry dock before going down to the dock oor, which is supported by smaller piles. Therefore, settlements inside the dry dock are expected to be

greater. The self-imposed allowable dierential settlement is 20 mm, which is the limiting criterion to keep the Upper Hull and the loadout system within the allowable stresses during the loadout operation. To satisfy this allowable dierential settlement requirement, the proposed skid shoe design should accommodate rotation capabilities and the structure inside the dry dock and the dock oor supporting piles must be sti enough not to have settlements more than 20 mm. This is a dicult design requirement to meet especially when the dock oor is not to be hacked. In addition, the two longitudinal trusses (SL and PL) must be capable of re-distributing the load due to dierential settlement of 20 mm or more. The

88

L.Y. Cheung and K.G. Foong

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 9.

Longitudinal truss row.

Figure 10.

Transverse truss row.

re-distribution should take place among all the 6 skid shoes within the same skid truss, either SL or PL. In a standard oshore platform design, direct tubeto-tube connections would be the preferred connection details. However, this type of detail will call for opening up work-points to provide a 50 mm gap for welding and it usually leads to the requirement for heavy wall can material with special through thickness properties such as API Spec 2H Supplementary Requirement S4 (American Petroleum Institute 1999). This is to guard against laminar tearing in thick material. This special heavy wall steel will usually take 4 5 months for delivery to Singapore or may be longer since steel mills do not produce through

Figure 11. down).

Isometric view of Loadout Skid Frame (looking

The IES Journal Part A: Civil & Structural Engineering thickness plates on a regular basis and the small quantity ordered must t into their regular rolling schedule. This long delivery will aect Jurong Shipyard fabrication schedule. Therefore, it was decided to go for gusset connection details, which do not require through thickness properties because the load is transferred by shear. However, gusset connections will produce heavier structures. With the view to keep the weight as low as possible, it is necessary to avoid eccentricities in the skid frame structure. Therefore, gusset plates are used extensively to maintain single work-point at all the nodes. Whenever possible, overlaps are avoided for all the incoming braces and adequate welding access provided. In areas where overlapping is necessary, special welding details are required. If the single work-point design approach is not adopted, many of the gusset plate thicknesses would be more than 100 mm thick and welding could be more troublesome (see Figure 13). In normal oshore platform fabrication, if welding were to follow AWS D1.1 standard (American Welding Society 2000), direct tube-to-tube connections would require welders to have more stringent welding qualications. By using gusset details, this type of welder pre-qualication is not needed and the edge preparation between the gusset plate and the incoming slotted tubular is very simple. It should be noted that unless shipyard welders are engaged in jacket fabrication on a continuous basis, they usually do not have approved qualication to weld tubular connections. Therefore, welders would have to be re-qualied if plate gusset connections are not adopted. It is both time-consuming and expensive. Tubular structures require highly trained welders, tters and Non Destructive Testing (NDT) specialists. NDT and weld-repair procedures are much easier for simple butt welds than tubular connection details. It is also easier to handle the pre-heat and post-heat treatments as per AWS code (American Welding Society 2000), if required, and not many new welding procedure qualications would have to be prepared for the job. 3.3. Methods of skidding loadout In a normal loadout operation of oshore structures, the structure is pulled onto a oating barge, which is butting against the bulkhead by anchor lines. Winches on the barge or on land or barge mounted strand jacks can provide the pulling force. However, due to action and reaction, the barge will exert a pushing force to the quay wall of the bulkhead and horizontal frictional force under the skid shoes will also be applied to all the pile heads supporting the skid ways as shown in

89

Figure 14. This is the reason why the supporting piles should be designed for axial and lateral loads (Cheung and Gho 2002). In the present loadout system, we do not have a oating system inside the dry dock and tidal variation does not exist. As long as the dierential settlement is kept small, the loadout skid beam can be made continuous (Figure 15). The skid beam itself is in self-equilibrium, so there is no need to design the supporting piles under the skid beams to take the full lateral load. However, the very long skid beam itself must be checked for beam-column interaction. One of

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 12. up).

Isometric view of Loadout Skid Frame (looking

Figure 13.

Typical joint details in loadout skid frame.

Figure 14.

Typical oshore barge loadout.

Figure 15.

Dry dock loadout system.

90

L.Y. Cheung and K.G. Foong Cheung and Gho 2002), but they are outside the scope of this study. 4. Structural design

the key indicators for successful loadout is to monitor dierential settlement between the dock head and vertical deection inside the dry dock. This means that the structure inside the dry dock must be carefully designed to ensure the settlement limitation is met. The other design objective is to spread the topside load equally to all the piles inside the dry dock so that they will not be overstressed. 3.4. Foundation

Downloaded by [195.229.242.55] at 05:00 02 July 2011

During loadout, the soil must be able to support the highly concentrated traveling loads coming down from the skid shoes. Owing to the height limitation, the 500 mm gap requirement for mating and based on 458 spread, there is no way to spread out the load to a longer distance. This implies that bearing stress on the soil will be so high such that piles will be needed to avoid this type of bearing failure. Therefore, a piled skidway is required for the loadout operation. The pile design was handled by other civil engineering consultants who were engaged by Jurong Shipyard. Because of the dierential settlement of 20 mm, the reaction forces at the dock head can increase greatly during loadout and this has been taken care of by installing a few 1.3 m diameter piles at the dock head and dry dock interface. In other oshore platform fabrication yards, a special load-relief platform is installed to handle this load uctuation. There are other types of bulkhead stability issues associated with loadout of heavy structures (Cheung 1989 and

4.1. Design of skid frame The structure has been designed and code checked using standard oshore software, SACS (EDI 2001). All members and connections were checked against API-RP-2A-WSD (American Petroleum Institute 2000) and AISC (American Institute of Steel Construction 1989) codes for interaction equations and punching shear checks. Welding specications, procedures and qualications are to follow AWS D1.1 (American Welding Society 2000). Basically, the skid frame system including design and fabrication of all items is to follow standard oshore practice. The nite element model is shown in Figure 16. For an oshore design, the number of piles in a platform is usually not more than 20. But in the present problem, there are more than 150 piles. First of all, the Upper Hull Deck is sitting on many 300 mm by 300 mm timber blocks placed on top of the skid frame as shown in Figure 7. To simulate this condition, we used gap spring elements, which can take compression but no tension. This is the rst nonlinearity of the analysis. Once the loads have been transferred down to the skid beams, nonlinear soil and nonlinear structural-pile interaction eect will come in and hence the presence of second nonlinearity. The computer program using special built-in iteration procedure can handle this kind of nonlinear analysis.

Figure 16.

Complete computer model for Upper Hull, Loadout Skid Frame and Support structure inside the dry dock.

The IES Journal Part A: Civil & Structural Engineering

91

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 17.

Skid shoe and rocking details.

Figure 18.

Skid shoe link-bar details.

92

L.Y. Cheung and K.G. Foong under compression load or by gusset plates if under tension forces. In certain areas of the TFs (TF6 and TF12) where tubular member sizes available in the Singapore market at the time of fabrication, were not big enough to carry the load, shear plates were used instead. Since one of the design constraints is to use whatever materials can be obtained in the Singapore market to cut short the procurement period, some of the dated materials have to be down-graded to account for corrosion and others were tested locally to ensure the required minimum yield stress is met. In fact, the whole design has been modied many times to cater for what can be purchased in the local market and not based on what is needed in the design. In certain areas, the stress ratios are close to unity and in other areas the stress ratios are relatively low. This is a common practice in the oshore industry. Lateral restraints are provided to take care of the design wind load due to 31.3 m/sec (70 mph) wind. However, these restraints will not restrict thermo expansion during fabrication under the hot sun. Tubular connection details were either checked by the computer program using punching shear equations

Downloaded by [195.229.242.55] at 05:00 02 July 2011

All diagonal braces attached to the 12 columns, no matter whether they are from the longitudinal trusses and/or the TFs, are connected to the top of the columns for two reasons. One is to make sure load redistribution, if required, can be accomplished much quicker as bracing pattern can greatly aect load transfer (Cheung 1990). If there is a need for load redistribution due to dierential settlement, we want to get the load out of the troubled leg and transfer to other skid shoes as soon as possible; before it reaches the skid shoe below, otherwise the column or the shoe may be over-stressed. The second reason is that the connection between the skid shoe and the column base is already very highly stressed and it is better not to make it more congested than it needs to be. There is simply not enough space to do proper welding and tting up of all the components. Welding access is a major consideration in the connection design. Secondary trusses were designed and installed to transfer all the loads in between the TFs. They are pinended. This is to make sure that no end moments could get into the TFs and the only induced moments are caused by eccentricities of the pin connections. There were also few connections that failed the punching shear checks and were reinforced by grout injection if

Figure 19.

Loadout jacks mounting arrangement.

The IES Journal Part A: Civil & Structural Engineering as per API RP-2A (American Petroleum Institute 2000) or by elastic nite element analysis with the combined stress less than yield stress. In oshore practice, we usually set the limit to 90% of yield stress. In areas that punching shear check has failed and thicker heavy wall can material is not available, grout injection is used to overcome the problem. Other connection details were checked by hand. 4.2. Design of skid shoe

93

All the topside loads are transferred to the skid shoes via shear plates located inside the column legs (Figure 17). Each leg has two shear plates, which are butt welded to the inside of the 1,524 mm (60 in.) diameter column. The shear plates will then transfer the load to the shoe by bearing. To allow for misalignment, the half circular bearing plates on both side-webs of the shoe have been oversized to cater for 12 mm installation tolerance. In between the two shear plates, an additional fabricated T-beam was added to the top of the half pipe to provide additional load path to transfer the load to shoe if the need arises. The rotation capability to handle the dierential deection is also provided by two tightly tted half pipes. Traveling speed is assumed to be about 2.54 mm/sec (6 in. per minute). On the basis of past experience in heavy structure loadout from other oshore platform fabrication yards and further conrmed by simple calculation, such speed will not generate signicant inertia forces on the Upper Hull Deck as long as the whole loadout process is carried out very slowly. The Upper Hull is sitting on the skid frame and is not welded down. On the basis of past experience and also conrmed by site measurement, the expected static friction should be less than 7% of the loadout weight and the dynamic friction is much lower. However, the design static friction for the present system is 20% of the total loadout weight. The actual pulling force required to break the static friction will depend on the type of grease used and the levelness of the skid beam. Being a new skid way, the 20% assumption is reasonable. The timber underneath the shoe is the Balau timber with a very high allowable compressive stress parallel to grain. They are vacuum treated with timber preservative to guard against insect, fungal and termite attack. This is to ensure they can be re-used for future loadouts. Since the pulling force is applied only to the front skid shoes, we have to make sure that this load will only be transferred to the rest of the skid shoes without going through the deck. If this is not done, the skid frame will be over-stressed at the front columns and may cause major failure to the upper hull structure. To overcome this diculty, a special gusset

connection is provided as shown in Figure 18. This innovative detail will allow the connection to bend or rotate in one direction without transmitting any pulling load to the deck. A usual padeye and shackle pin detail will not work in this case. Skid shoes are tted with anchor brackets to accommodate the cable jacks as shown in Figures 1921. They are designed for pulling from either direction. The pulling force must be balanced on either side of the skid shoe and the shoe is not designed to twist. In general, if it is a single point pull, the load should be applied at the centerline of the skid shoe. If it is in tandem pull, the force must be applied equally on

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 20.

Skid shoe jacking bracket details, type 1.

Figure 21.

Skid shoe jacking bracket details, type 2.

94

L.Y. Cheung and K.G. Foong moment, therefore side restraints must be provided to cut down the slenderness ratio. At the end of the skid beam where the cable jack anchor block is located, a special holding down detail must be provided to keep the skid beam in place. Jurong Shipyard provided this detail using stationary barges. Since pulling is done at two locations using two sets of cable jacks, racking will occur during loadout. The skid frame has been checked for 5% dierential racking forces, but it is still necessary to minimize the jerking forces due to unequal pull. This is very much an operational problem that required very close cooperation from the loadout crew.

both sides of the shoe. In the present design, the pulling forces come from two independent sources and one would expect certain amount of jerking motion to happen. 4.3. Design of skid beam

One of the most critical areas is to bridge across the tunnel near the dock head. The designed span is 7.2 m as shown in Figures 22 and 23. During pulling, the skid beam is in self-equilibrium and is subject to very large axial load and bending

Downloaded by [195.229.242.55] at 05:00 02 July 2011

Figure 22.

Skid beam arrangement.

Figure 23.

Skid beam cross section.

The IES Journal Part A: Civil & Structural Engineering 5. Concluding remarks References

95

Downloaded by [195.229.242.55] at 05:00 02 July 2011

The advantage of this fabrication method using Loadout Skid Frame is that during mating, every step can be carefully controlled in a stable environment inside the dry dock. In other fabrication methods such as the one used by Hyundai in 1999, they also enjoyed the same advantage but the total cost for lifting the deck for mating, skidding the two pontoons into position as well as the nal loadout and tiedown operation using a submersible material barge would probably cost more than the Jurong method. It is extremely dicult to nd a submersible barge in this region capable of carrying 25,000 tons concentrated topside load and the cost could be prohibitive to bring in a big barge from elsewhere. Therefore, the present skid/mate fabrication method is not very expensive considering the productivity gained and the extra cost can be spread over three projects. Jurong Shipyard engineers have since successfully loaded out and mated Upper Hull Decks with the Lower Hull Pontoons on two occasions. One was on June 18, 2003 and the latest one was on May 19, 2004. The success of this fabrication method by JSL clearly demonstrated their ability and the usefulness of innovative approach in fabrication and also showed the importance of the concept of Design Economics in Engineering, which emphasizes the need to come up with designs to suit fabrication and installation to generate more prots (Cheung 1990). This is much cheaper than heavy investment in new equipment to improve productivity. Both investment and innovation are essential, but from the Singapore perspective, innovation is much more important in view of the high labor cost in Singapore. Acknowledgements

The authors wish to express their thanks to the following persons for their cooperation: Mr. Seow Tan Hong, Mr. Goh King Kwee and Dr. Zhong Kui (from Jurong Shipyard Private Limited), Associate Professor Choo Yoo Sang and Professor N E Shanmugam (from the National University of Singapore), Assistant Professor Gho Wie Min (from Nanyang Technological University) and Mr. Yeo Ah Tee and Mr. Ng Seng Chow (from Marine Engineering Services Pte Ltd).

American Institute of Steel Construction, 1989. AISC specication for structural steel buildings (allowable stress design). 9th ed. Chicago, IL: American Institute of Steel Construction. American Petroleum Institute, 1999. API spec 2H specication for carbon manganese steel plate for oshore structures. 8th ed. Washington DC: American Petroleum Institute. American Petroleum Institute, 2000. API RP 2A (WSD), Recommended practice for planning, designing, and constructing xed oshore platforms (working stress design). 21st ed. Washington DC: American Petroleum Institute. American Welding Society, 2000. ANSI/AWS D1.12000, Structural welding codesteel. Florida: American Welding Society. Cheung, L.Y., 1989. SIA hangar roof at Changi airport: Bidding, fabrication and installation. Journal of The Institution of Engineers, Singapore, 29, 6781. Cheung, L.Y., 1990. Design economics of oshore structures. Journal of The Institution of Engineers, Singapore, 30, 7384. Cheung, L.Y., Gho, W.M., Fung, T.C. and Soh, C.K., 1998. Design economics of oshore structures: Eccentric jacket. Journal of The Institution of Engineers, Singapore, 38, 4248. Cheung, L.Y. and Gho, W.M., 2002. Eect of soilstructure-barge interaction for loadout analysis of oshore steel jackets. Journal of The Institution of Engineers, Singapore, 42, 3035. Cho, K.R., Kim, Y.S. and Fern, D.T., 2001. 11000 t Deck superlift for RBS-8M drilling semi-submersible. In: Proceedings of the Institution of Civil Engineers, Structures and Buildings 146, May 2001, Issue 2, 203216. EDI, 2001. Structural analysis computer system (SACS), Version 5.1. Engineering Dynamics Inc. Gerwick, B.G., 1986. Charter 10 concrete oshore platforms (gravity-base structures) construction of oshore structures, Wiley.

Das könnte Ihnen auch gefallen

- Jacket Weighing ProcedureDokument14 SeitenJacket Weighing ProcedureBolarinwaNoch keine Bewertungen

- Offshore StructuresDokument24 SeitenOffshore StructuresSaaiyogeshNoch keine Bewertungen

- Modeling and Analysis of Offshore Jacket PlatformDokument9 SeitenModeling and Analysis of Offshore Jacket Platformgkc1977100% (1)

- Quay Walls - Combined - Wall - Buckling - TubesDokument12 SeitenQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteNoch keine Bewertungen

- Offshore Structures Design Construction and Maintenance - Online Course - 2019Dokument5 SeitenOffshore Structures Design Construction and Maintenance - Online Course - 2019elreedymanNoch keine Bewertungen

- 2) Supplementary Design Criteria For Marine Facilities WorksDokument4 Seiten2) Supplementary Design Criteria For Marine Facilities WorkshiyeonNoch keine Bewertungen

- CE134P ESCRUZ SyllabusDokument5 SeitenCE134P ESCRUZ SyllabusAsa KaNoch keine Bewertungen

- Presentation For Supercritical TechnologyDokument113 SeitenPresentation For Supercritical TechnologyVIVEK100% (1)

- 2 U4 TrigpracticeDokument2 Seiten2 U4 Trigpracticeapi-292718088Noch keine Bewertungen

- Week 7 and 8 Performance of Single Phase Short Transmission LinesDokument21 SeitenWeek 7 and 8 Performance of Single Phase Short Transmission LinessensamedicNoch keine Bewertungen

- Offshore General Introduction AnalysisDokument28 SeitenOffshore General Introduction AnalysisOkolo Obinna100% (3)

- Esdep Offshore Structures General IntroductionDokument187 SeitenEsdep Offshore Structures General Introductiondfal13Noch keine Bewertungen

- Welding of Hollow Structural Sections PDFDokument5 SeitenWelding of Hollow Structural Sections PDFKooroshNoch keine Bewertungen

- 2 12 2010 IHC Internal Pile Lifting ToolDokument2 Seiten2 12 2010 IHC Internal Pile Lifting TooldungrelNoch keine Bewertungen

- 04) ZEEPod & Other Project ExperienceDokument72 Seiten04) ZEEPod & Other Project Experiencebapaobao100% (1)

- Imp Design GuideDokument32 SeitenImp Design GuideRahulNoch keine Bewertungen

- Mudmat Bearing CapacityDokument11 SeitenMudmat Bearing CapacityMathew Simon100% (1)

- DANA-Technical Note (TN)Dokument8 SeitenDANA-Technical Note (TN)Samsul Imran BahromNoch keine Bewertungen

- Seismic DesignDokument74 SeitenSeismic DesignnathychidazNoch keine Bewertungen

- Remark Calculation Sheet: Pipe PropertiesDokument4 SeitenRemark Calculation Sheet: Pipe Propertiesmoseslugtu6324Noch keine Bewertungen

- SACS Software Offshore Structures Design Rev1Dokument2 SeitenSACS Software Offshore Structures Design Rev1Boonme ChinnaboonNoch keine Bewertungen

- Pile Driving in Calcareous SedimentsDokument15 SeitenPile Driving in Calcareous SedimentschookinenNoch keine Bewertungen

- SCV Load Out Service Requirements Rev.01Dokument15 SeitenSCV Load Out Service Requirements Rev.01Fahmy ArdhiansyahNoch keine Bewertungen

- Offshore Fixed Platform NotesDokument37 SeitenOffshore Fixed Platform NotesAnkushkumar MaliNoch keine Bewertungen

- 18704Dokument32 Seiten18704KhoironSyamdatuNoch keine Bewertungen

- Design of Steel ColumnDokument22 SeitenDesign of Steel ColumnN.S.M.RAVI KUMARNoch keine Bewertungen

- Spreadsheets To BS 8110: Carrefour PC 2Dokument48 SeitenSpreadsheets To BS 8110: Carrefour PC 2orode franklynNoch keine Bewertungen

- Structural Design OffshoreDokument27 SeitenStructural Design OffshoreantofirdausNoch keine Bewertungen

- Offshore Structures Design Construction and Maintenance - Online Course - 2019Dokument5 SeitenOffshore Structures Design Construction and Maintenance - Online Course - 2019elreedymanNoch keine Bewertungen

- Boat Landing Systems-2Dokument6 SeitenBoat Landing Systems-2Guilherme LealNoch keine Bewertungen

- Crown Shim & Stabbing SCFDokument9 SeitenCrown Shim & Stabbing SCFRajat KatyalNoch keine Bewertungen

- Sample Cleat For 20Ft SeafasteningDokument2 SeitenSample Cleat For 20Ft SeafasteningMohd Reza MohsinNoch keine Bewertungen

- Measurement of Ship's MotionsDokument3 SeitenMeasurement of Ship's Motionsgk80823Noch keine Bewertungen

- Jetty System Pontoon PDFDokument6 SeitenJetty System Pontoon PDFdndudcNoch keine Bewertungen

- SacsDokument3 SeitenSacsjiokoijikoNoch keine Bewertungen

- Lecture 15A.12-Connections in Offshore Deck StructuresDokument20 SeitenLecture 15A.12-Connections in Offshore Deck StructuresLinh Tran100% (1)

- A Dropped Object Test Using Ansys LS - DYNA - FinalDokument18 SeitenA Dropped Object Test Using Ansys LS - DYNA - FinalNavalArchitectureNoch keine Bewertungen

- Offshore StructureDokument12 SeitenOffshore Structureg4goharNoch keine Bewertungen

- (2013.05.21) Loads On Offshore Structures Webinar - MAXSURF - MOSES - SACS - Wiki - MAXSURF - MOSES - SACS - Bentley CommunitiesDokument8 Seiten(2013.05.21) Loads On Offshore Structures Webinar - MAXSURF - MOSES - SACS - Wiki - MAXSURF - MOSES - SACS - Bentley Communitiesnazeer_mohdNoch keine Bewertungen

- Offshore Platforms Design OverviewDokument12 SeitenOffshore Platforms Design OverviewΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- (DNV) Det Norske Veritas - 2005 - Material Risk - Ageing Offshore InstallationsDokument66 Seiten(DNV) Det Norske Veritas - 2005 - Material Risk - Ageing Offshore InstallationsKaroline Neumann100% (1)

- Compliant TowerDokument4 SeitenCompliant TowerjohariakNoch keine Bewertungen

- 5 Guidelines For Struct Integrity Assessment of Existing PlatformsDokument8 Seiten5 Guidelines For Struct Integrity Assessment of Existing Platformssreedevi gummadiNoch keine Bewertungen

- Time and Cost Analysis of Jacket Structure Load Out Using SkiddingDokument6 SeitenTime and Cost Analysis of Jacket Structure Load Out Using SkiddingYadi KusmayadiNoch keine Bewertungen

- 02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopDokument6 Seiten02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopImam Saja DechNoch keine Bewertungen

- Anchor Design HILTIDokument14 SeitenAnchor Design HILTIRohit GadekarNoch keine Bewertungen

- Track Record Seafastenings PDFDokument14 SeitenTrack Record Seafastenings PDFashaikhNoch keine Bewertungen

- Mathcad - Grout Connection HSE RulesDokument3 SeitenMathcad - Grout Connection HSE RulesRayodcNoch keine Bewertungen

- Design of Floating Offshore Platform: January 2021Dokument29 SeitenDesign of Floating Offshore Platform: January 2021vucokt100% (2)

- Load CombinationsDokument14 SeitenLoad CombinationsHiren DesaiNoch keine Bewertungen

- Jacket Design ProcedureDokument59 SeitenJacket Design Procedurebhagyalaxmi50% (2)

- Opd Office Civil C 001Dokument1 SeiteOpd Office Civil C 001Justin BeiterNoch keine Bewertungen

- Doubler Plate ConnectionsDokument2 SeitenDoubler Plate ConnectionsBolarinwaNoch keine Bewertungen

- Design For Steel Structures (Jackets)Dokument12 SeitenDesign For Steel Structures (Jackets)Kathia Lorena Espinoza RojasNoch keine Bewertungen

- Structual Analysis Design of VesselsDokument3 SeitenStructual Analysis Design of VesselsRPDeshNoch keine Bewertungen

- Construction Presentation - Container Terminal PDFDokument60 SeitenConstruction Presentation - Container Terminal PDFdndudc100% (1)

- FoundOcean Fabric Formwork Grout Bag CatalogueDokument20 SeitenFoundOcean Fabric Formwork Grout Bag Cataloguejptl6477Noch keine Bewertungen

- T13mra001 Mra STR 103 SLD 004 Rev B Pile Soil InteractionDokument19 SeitenT13mra001 Mra STR 103 SLD 004 Rev B Pile Soil InteractionTannaz HadizadeNoch keine Bewertungen

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsVon EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNoch keine Bewertungen

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityVon EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNoch keine Bewertungen

- 1 s2.0 S0029801804002264 Main PDFDokument29 Seiten1 s2.0 S0029801804002264 Main PDFPrasetyanto UtomoNoch keine Bewertungen

- Drilling Strategy in Maureen FieldDokument11 SeitenDrilling Strategy in Maureen Fieldmatheus_moreira0990Noch keine Bewertungen

- Introduction To Offshore Structural EngineeringDokument11 SeitenIntroduction To Offshore Structural Engineeringanandakoe100% (1)

- Densit® Wear Protection ProductsDokument9 SeitenDensit® Wear Protection ProductsMuhammad IqbalNoch keine Bewertungen

- Field Visit ELS SooriyawewaDokument12 SeitenField Visit ELS Sooriyawewajanitha100% (2)

- Solution To Extra Problem Set 5Dokument13 SeitenSolution To Extra Problem Set 5物理系小薯Noch keine Bewertungen

- TechNote - B008-20-Basic C-Shaped Wall Stud Behavior-WEBFINALDokument6 SeitenTechNote - B008-20-Basic C-Shaped Wall Stud Behavior-WEBFINALsahanNoch keine Bewertungen

- Moisture in The Atmosphere and Weather ChangesDokument40 SeitenMoisture in The Atmosphere and Weather ChangesPatricia Sofia DizonNoch keine Bewertungen

- Calero Caes Model Power SystemDokument13 SeitenCalero Caes Model Power Systemzain ul AbideenNoch keine Bewertungen

- Lec 16 CDokument66 SeitenLec 16 CSalman MemonNoch keine Bewertungen

- Mechanics of Bolted ConnectionsDokument12 SeitenMechanics of Bolted ConnectionsJunaid AliNoch keine Bewertungen

- Organic Sheet # 3 Reactions To Differentiate Organic CompoundsDokument32 SeitenOrganic Sheet # 3 Reactions To Differentiate Organic CompoundsxgfhdxjxNoch keine Bewertungen

- JGS 1811 To 1816 EnglishDokument34 SeitenJGS 1811 To 1816 EnglishNeetu Bhargava100% (1)

- Leaflet VertiDrive M3Dokument2 SeitenLeaflet VertiDrive M3Kenan mira Mohammed NasherNoch keine Bewertungen

- Din en 10130Dokument14 SeitenDin en 10130Ricardo VitorianoNoch keine Bewertungen

- (Maa 3.9) More Trigonometric FunctionsDokument18 Seiten(Maa 3.9) More Trigonometric FunctionsAli GorganiNoch keine Bewertungen

- Mass / G: Example: Hydrocarbon Y Contains 0.6g of C and 0.15g of H. Its Relative Molecular Mass Is 30Dokument3 SeitenMass / G: Example: Hydrocarbon Y Contains 0.6g of C and 0.15g of H. Its Relative Molecular Mass Is 30LAKIESHANoch keine Bewertungen

- Molecular Orbitals in Hetero Nuclear Diatomic Molecules: FOR I M.SC A& B VICAS StudentsDokument10 SeitenMolecular Orbitals in Hetero Nuclear Diatomic Molecules: FOR I M.SC A& B VICAS StudentsJeevanantham VelayuthamNoch keine Bewertungen

- FIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )Dokument10 SeitenFIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )mahmoud_allam3Noch keine Bewertungen

- Spur Gear Calculations and FormulasDokument2 SeitenSpur Gear Calculations and FormulasBilal Tayyab100% (2)

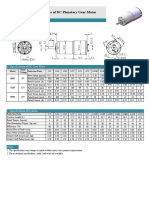

- OD32mm DC Gear Motor-1Dokument8 SeitenOD32mm DC Gear Motor-1Humberto GalvezNoch keine Bewertungen

- E-01 Electrical SymbolsDokument10 SeitenE-01 Electrical SymbolsPham Hoang TuanNoch keine Bewertungen

- Fire SafetyDokument101 SeitenFire Safetyvino rubanNoch keine Bewertungen

- Sturm-Liouville EquationsDokument16 SeitenSturm-Liouville Equationsvanaj123Noch keine Bewertungen

- AFM 34 en PDFDokument4 SeitenAFM 34 en PDFDee RajaNoch keine Bewertungen

- MID 082 - CID 0885 - FMI 05: TroubleshootingDokument4 SeitenMID 082 - CID 0885 - FMI 05: TroubleshootingCory PurbaNoch keine Bewertungen

- Expt Bevel ProtractorDokument3 SeitenExpt Bevel ProtractorAnkan BeraNoch keine Bewertungen

- Kinetic FacadesDokument68 SeitenKinetic FacadesRitikaNoch keine Bewertungen

- Sacrificial Anode Cathodic Protection Systems For The Interior Submerged Surfaces of Steel Water Storage TanksDokument32 SeitenSacrificial Anode Cathodic Protection Systems For The Interior Submerged Surfaces of Steel Water Storage TanksChristian LeobreraNoch keine Bewertungen