Beruflich Dokumente

Kultur Dokumente

Alcohol Tank Rev1

Hochgeladen von

ahmedlatif786Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alcohol Tank Rev1

Hochgeladen von

ahmedlatif786Copyright:

Verfügbare Formate

Tank Blanket, losing gas through pv valve#

Leut

Newbie Group: Members Posts: 2 Joined: 25-May 07 Member No.: 7,423

May 25 2007, 12:06 PM IP: 82.141.196.78 Post #1 Just wondering has anyone any experience of clearing lines with nitrogen. I have a 15m, 3" line entering a tank full of alcohol. The tank has a PV valve set at 40 mBarg and a PRV set at 56 mBarg. My Nitrogen line is pressured to 6 Bar. The alcohol is cleared from the line (less about a litre) with ease. Just wondering what effect the 6 bar pressure has on my system. As it enters does it just dissipate. The tank is nitrogen blanketed as well (another story for posting). Or is the venting just coming into operation. Am I missing something fundamental here? I'm not chemical in nature. Also is there any risk of leaving some alcohol in the line (vapors and nitrogen etc.) over a period of a couple of days just to sit there. Any direction would be great! Thanks in advance. Lt.

Art Montemayor

ChE Jedi Group: Admin Posts: 834 Joined: 8-March 03 From: Spring, Texas Member No.: 4

May 25 2007, 01:03 PM IP: Private Post #2 Leut: Your query is a sound one, but it generates a lot of questions: What is the configuration of your tank? What kind of alcohol are you referring to? Methanol? Ethanol? What does the 3 line normally transfer, and how is it configured vis--vis the tank? What do you mean by is the venting just coming into operation?

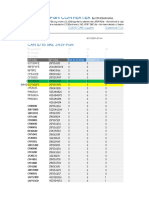

Please refer to the attached Excel Workbook and the sketch Ive supplied. Note that with a fill line configured like the one shown, you dont have to clear the line. Also note that I always locate my blanket Nitrogen supply line and valve above the tank so that liquid content is not admitted into this line. From this sketch, please indicate where and how your needs/problems with nitrogen and venting arise. Alcohol_Tank.xls ( 24k ) Number of downloads: 7

Leut

Newbie Group: Members Posts: 2 Joined: 25-May 07 Member No.: 7,423

May 27, 2007; 08:34 AM IP: 86.43.105.201 Post #3 Hello, Thanks for the reply first of all. The tank set up is actually 4 tanks, but each one as per your dwg attached. Flow through top and down through dip tube. N 2 Enters through separate line in on top. The conservation vent is there also complete with endurance burning flame arrestor. The liquid is IPA and the 3" line is dedicated to the IPA. To update from the last post as N 2 enters my tank it seemed to leak from the vent. Since then I had the fitters take out the vent, re-set it, and now the tanks seem to hold a constant pressure.

Newbie Group: Members Posts: 2 Joined: 25-May 07 Member No.: 7,423

Hello, Thanks for the reply first of all. The tank set up is actually 4 tanks, but each one as per your dwg attached. Flow through top and down through dip tube. N 2 Enters through separate line in on top. The conservation vent is there also complete with endurance burning flame arrestor. The liquid is IPA and the 3" line is dedicated to the IPA. To update from the last post as N 2 enters my tank it seemed to leak from the vent. Since then I had the fitters take out the vent, re-set it, and now the tanks seem to hold a constant pressure. From a batch integrity point of view I decided that each time a batch of IPA was drawn into the tank it would be separate from the next batch. So IPA in the lines from the transfer would be blown using N 2 up the pipe. Recently the batch integrity issue after much taught was deemed too hard to control at this stage but the procedure of N 2 blowing remains. Am I right in thinking the IPA is best in the tank, where oxygen level is controlled, vents are in position, Sprinklers present etc. and flame arrestors in-situ rather than in a closed pipe with none of the above. What is the industry standard on this? Is it common practice to leave lines full or empty (with possible nitrogen and IPA vapor)? Another question if I may. When I pump out of my tank my N 2 bank can't at present replenish the volume of free space left in the tank as quick. So when the vacuum valve opens and draws in more oxygen the potential for an explosive atmosphere is increased. From the German standards i believe the oxygen levels should be kept below 9%. Presently I have requested oxygen below 5% and actual am getting 2-3%. Must I get this balance right or is there a tolerance. Presently the ratio is about 1:3 for every m 3 of N 2 added 3m 3 of IPA is pumped out. Best regards, Leut.

1.196.78 Post #1

15m, 3" PRV set at line (less

t just the venting emical in en etc.) hanks in

P: Private Post #2

-vis the

ote that with Also note that hat liquid and how

.105.201 Post #3

ough top vation vent is he 3" line is

Since then I pressure.

ough top vation vent is he 3" line is

Since then I pressure. wn into the would be as deemed ight in thinking prinklers above. What with

sent replenish and draws erman quested ere a s pumped out.

N2 blanket feed gas @ 6 barg Conservation Vent

Original Configuration Concept Pump-in Pump Pump-out Pump

Block valve

N2 blanket feed gas @ 6 barg

N2 blanket feed gas @ 6 barg Block valve Conservation Vent

Block valve

Typical pipe supports (5-7 m high) - Real life

Isopropyl Alcohol Storage Tank Drain valve

Pump-in Pump (located @ grade)

Revised Configuration - Real life To clear all previous IPA from the elevated feed line on the pipe rack, the pump feed pump is shut down, the block valves on the feed line located at the pump and at the entry to the tank's dip pipe are shut off, and the drain valve at the pump is opened to a hose leading to a 55 gallon portable tank. The Nitrogen block valve is opened sufficiently to purge all IPA from the feed line and into the 55 gallon tank.

ation Vent

Pump-out Pump

Das könnte Ihnen auch gefallen

- Tank Venting Calculation Guides - CheresourcesDokument4 SeitenTank Venting Calculation Guides - CheresourcesSteve WanNoch keine Bewertungen

- Coil Circuiting - SerpentineDokument8 SeitenCoil Circuiting - Serpentinebruce1312100% (1)

- Can Id To Sae J1939 PGNDokument171 SeitenCan Id To Sae J1939 PGNdiana aragon100% (1)

- Newbie Group: Members Posts: 2 Joined: 20-February 08 Member No.: 11,741Dokument37 SeitenNewbie Group: Members Posts: 2 Joined: 20-February 08 Member No.: 11,741huyNoch keine Bewertungen

- Chemical Engineering Interview Questions and Answers 90Dokument25 SeitenChemical Engineering Interview Questions and Answers 90dpnmmbs9mhNoch keine Bewertungen

- Trans Chapter6 PDFDokument106 SeitenTrans Chapter6 PDFsammar_10Noch keine Bewertungen

- Cavitation CarlsonDokument4 SeitenCavitation CarlsonjimborenoNoch keine Bewertungen

- Determining Back Pressure When Sizing For PRV - Relief Devices Forum - Cheresources - Com CommunityDokument5 SeitenDetermining Back Pressure When Sizing For PRV - Relief Devices Forum - Cheresources - Com CommunityKyriakos MichalakiNoch keine Bewertungen

- Respond Comment 180815Dokument10 SeitenRespond Comment 180815Rizki HusniNoch keine Bewertungen

- Tank Vent Sizing - Cheresources - Com CommunityDokument13 SeitenTank Vent Sizing - Cheresources - Com CommunityharmlesdragonNoch keine Bewertungen

- Boiler Question and AnswersDokument9 SeitenBoiler Question and AnswersAnup JhaNoch keine Bewertungen

- L 5 and L 10 Troubleshooting GuideDokument8 SeitenL 5 and L 10 Troubleshooting GuideJohn DawsonNoch keine Bewertungen

- Check Valve Failure - Closed: HariniDokument5 SeitenCheck Valve Failure - Closed: Harinimarco8garciaNoch keine Bewertungen

- Typical Questions For Piping EngineerDokument4 SeitenTypical Questions For Piping EngineerBudy SinagaNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- The Voltage Intensifier CircuitDokument38 SeitenThe Voltage Intensifier CircuitDirk MatthesNoch keine Bewertungen

- Tubing Check - Multiple Events: Test InformationDokument3 SeitenTubing Check - Multiple Events: Test InformationAnre Thanh HungNoch keine Bewertungen

- PSV - Second Term of API FormulaDokument5 SeitenPSV - Second Term of API FormuladebjpaulNoch keine Bewertungen

- Boiler Questions and AnswersDokument10 SeitenBoiler Questions and AnswersAustin UdofiaNoch keine Bewertungen

- Boiler Questions and AnswersDokument10 SeitenBoiler Questions and AnswersAustin UdofiaNoch keine Bewertungen

- Pumping Away - From What?: Not From The Boiler, But From The Point of No Pressure ChangeDokument6 SeitenPumping Away - From What?: Not From The Boiler, But From The Point of No Pressure ChangesalamrefighNoch keine Bewertungen

- c30 OrigmodDokument8 Seitenc30 Origmodguitar1985Noch keine Bewertungen

- Dentron MLA-2500 GI7B Modification Procedure 3Dokument27 SeitenDentron MLA-2500 GI7B Modification Procedure 3david bonilla pinoNoch keine Bewertungen

- Fill-Up System Filling PlantersDokument4 SeitenFill-Up System Filling Plantersmattpac3Noch keine Bewertungen

- 300E Airflow Sensor ReplacementDokument2 Seiten300E Airflow Sensor ReplacementDharmin DslrNoch keine Bewertungen

- Natural Gas CompressorsDokument4 SeitenNatural Gas CompressorsmegNoch keine Bewertungen

- AG-101 Frac Design Proposal V2Dokument30 SeitenAG-101 Frac Design Proposal V2ayman morsyNoch keine Bewertungen

- Cavitations 1-3: The Mcnally InstituteDokument5 SeitenCavitations 1-3: The Mcnally InstituteBaqirMuhammadNoch keine Bewertungen

- Calculation K ValueDokument12 SeitenCalculation K ValueAshrafMostafaNoch keine Bewertungen

- OTC-28409-MS Use of Premium Connection To Justify Avoiding Pressure Testing Completion Tubing Prior To Setting Packer. Is This Always Correct?Dokument18 SeitenOTC-28409-MS Use of Premium Connection To Justify Avoiding Pressure Testing Completion Tubing Prior To Setting Packer. Is This Always Correct?ysuyycNoch keine Bewertungen

- Contra Wound CoilsDokument26 SeitenContra Wound CoilsmiguelteixeiramaNoch keine Bewertungen

- When Sizing A Water Storage Tank For Exclusive Fire Protection UseDokument4 SeitenWhen Sizing A Water Storage Tank For Exclusive Fire Protection UsemengineeringNoch keine Bewertungen

- MODUL DE EXPANSIUNE Pressosmart-En-Ecf00107en-1611Dokument4 SeitenMODUL DE EXPANSIUNE Pressosmart-En-Ecf00107en-1611georgianconstantinNoch keine Bewertungen

- EDC Pump Testing ProceduresDokument8 SeitenEDC Pump Testing ProceduresCadet Raparivo100% (7)

- Water Pressure Problems in Your Caravan by Greg Lakeman PDFDokument3 SeitenWater Pressure Problems in Your Caravan by Greg Lakeman PDFBenito CazNoch keine Bewertungen

- Apeks Service AdviceDokument16 SeitenApeks Service AdviceElton HodgesNoch keine Bewertungen

- Biasing The Vintage SeriesDokument8 SeitenBiasing The Vintage SeriesRui OliveiraNoch keine Bewertungen

- Finishing A Basement Bathroom - Part 9: Liberty Sewage PumpDokument15 SeitenFinishing A Basement Bathroom - Part 9: Liberty Sewage PumpBrad FloresNoch keine Bewertungen

- CPE603 GuideDokument6 SeitenCPE603 GuideainmnrhNoch keine Bewertungen

- Water HammerDokument5 SeitenWater HammerPaldex100% (1)

- Rapid Sequencing gDNA - Field Sequencing Kit (SQK-LRK001) - MinionDokument3 SeitenRapid Sequencing gDNA - Field Sequencing Kit (SQK-LRK001) - MinionMarNoch keine Bewertungen

- CavitationDokument28 SeitenCavitationvenkeekuNoch keine Bewertungen

- Minute of Meeting 1Dokument1 SeiteMinute of Meeting 1PanduNoch keine Bewertungen

- Svoemesto Kayfun V3.1es User ManualDokument18 SeitenSvoemesto Kayfun V3.1es User ManualAkhmad Haiqal AtbNoch keine Bewertungen

- Aljac Catg On Closed SamplerDokument2 SeitenAljac Catg On Closed SamplervuongNoch keine Bewertungen

- Capillary2 - Capillary2 FP - Dilution IssueDokument15 SeitenCapillary2 - Capillary2 FP - Dilution IssueAliNoch keine Bewertungen

- Hilux GEET Conversion ConstructionDokument6 SeitenHilux GEET Conversion ConstructionKumaran Sanmugathasan100% (1)

- GhareebDokument17 SeitenGhareebMohamed OthmanNoch keine Bewertungen

- BETA-2 Pancake Geiger TubeDokument4 SeitenBETA-2 Pancake Geiger TubeqqazertyNoch keine Bewertungen

- Max Rhov 2 For Nozzle - Industrial ProfessionalsDokument4 SeitenMax Rhov 2 For Nozzle - Industrial ProfessionalssgrsthNoch keine Bewertungen

- ITT Steam BookDokument110 SeitenITT Steam BookFred SchreinerNoch keine Bewertungen

- Hydraulic Ram Pump ThesisDokument8 SeitenHydraulic Ram Pump ThesisProfessionalPaperWriterCanada100% (2)

- A Guide To Well ConstructionDokument127 SeitenA Guide To Well ConstructionEliezer JimenezNoch keine Bewertungen

- LCQ Deca - Duo Hardware Troubleshooting - 8601Dokument111 SeitenLCQ Deca - Duo Hardware Troubleshooting - 8601degindelNoch keine Bewertungen

- 10K/10K 4Mmbtu/Hr With 3"Xxs Pipe ArrangementDokument26 Seiten10K/10K 4Mmbtu/Hr With 3"Xxs Pipe ArrangementSIVANoch keine Bewertungen

- Autotrol 255-268 742-762Dokument84 SeitenAutotrol 255-268 742-762doctorstrambalemneNoch keine Bewertungen

- PWMcircuit 08Dokument10 SeitenPWMcircuit 08kcarringNoch keine Bewertungen

- Plumbing VentsDokument21 SeitenPlumbing Ventsmazen zaloudNoch keine Bewertungen

- Pump and Pipe Sizing For A Solar WaterDokument17 SeitenPump and Pipe Sizing For A Solar WaterPajooheshNoch keine Bewertungen

- How to Install Electric Bells, Annunciators, and AlarmsVon EverandHow to Install Electric Bells, Annunciators, and AlarmsNoch keine Bewertungen

- XDV Xtra Duty V BeltsDokument3 SeitenXDV Xtra Duty V BeltsJohel ClNoch keine Bewertungen

- Compax CL: Operator S ManualDokument114 SeitenCompax CL: Operator S ManualPicek30Noch keine Bewertungen

- Outdoor UnitsDokument47 SeitenOutdoor UnitsSayeed AnwarNoch keine Bewertungen

- NGL PumpsDokument4 SeitenNGL Pumpsamol patkiNoch keine Bewertungen

- 15 - Orbital Angular Momentum and Spherical Harmonics PDFDokument13 Seiten15 - Orbital Angular Momentum and Spherical Harmonics PDFUltrazordNoch keine Bewertungen

- Gas Lift Valve MechanicsDokument22 SeitenGas Lift Valve Mechanicsاسلام الشتيوي100% (1)

- Managed Pressure Drilling MPD BrochureDokument5 SeitenManaged Pressure Drilling MPD Brochureswaala4realNoch keine Bewertungen

- Pennbarry SX Catalogue TS v9bDokument34 SeitenPennbarry SX Catalogue TS v9bjacaNoch keine Bewertungen

- Clutch Damper ChangeDokument6 SeitenClutch Damper ChangeAaron StaubNoch keine Bewertungen

- Grasso Screw Compressor Package Pi - tcm11 38504Dokument84 SeitenGrasso Screw Compressor Package Pi - tcm11 38504Twfeek AhmedNoch keine Bewertungen

- LatheDokument127 SeitenLatheneelesh singh75% (4)

- Service Bulletin: Troubleshooting DTC P1456 and P1457Dokument4 SeitenService Bulletin: Troubleshooting DTC P1456 and P1457Vic3501Noch keine Bewertungen

- Al Steel Buildings: Design Guide 1, 2Nd EditionDokument14 SeitenAl Steel Buildings: Design Guide 1, 2Nd EditionINNOBUNo7100% (1)

- Arcusaflex - REICH-AC - 2020-03 - en - REICH - 20200210Dokument32 SeitenArcusaflex - REICH-AC - 2020-03 - en - REICH - 20200210Rinadi Airlangga FernandezNoch keine Bewertungen

- Piston, Connecting Rod and Cylinder Liner L28/32H: DescriptionDokument57 SeitenPiston, Connecting Rod and Cylinder Liner L28/32H: DescriptionERepublikPolskaNoch keine Bewertungen

- 1206-1906 QapDokument2 Seiten1206-1906 QapSambit NayakNoch keine Bewertungen

- Fast Metal Removal SolutionsDokument124 SeitenFast Metal Removal SolutionsvrjrNoch keine Bewertungen

- Asme B18.31.4M-2009 (2017)Dokument16 SeitenAsme B18.31.4M-2009 (2017)vijay pawarNoch keine Bewertungen

- SI8 Errata 00Dokument11 SeitenSI8 Errata 00Vigilancia ViajerosNoch keine Bewertungen

- Small Amplitude Soliton Propagation in A Weakly Relativistic Magnetized Space Plasma: Electron Inertia ContributionDokument10 SeitenSmall Amplitude Soliton Propagation in A Weakly Relativistic Magnetized Space Plasma: Electron Inertia ContributionSukhmander SinghNoch keine Bewertungen

- JOHN - DEERE - 360plus Rotary Harvesting UnitDokument136 SeitenJOHN - DEERE - 360plus Rotary Harvesting UnitАлександр CheryNoch keine Bewertungen

- Tennant s20Dokument64 SeitenTennant s20Umar ShamsudinNoch keine Bewertungen

- M-630 Material Data Sheets For PipingDokument85 SeitenM-630 Material Data Sheets For Pipingsun2meltNoch keine Bewertungen

- Solving Kitchen Ventilation ProblemsDokument6 SeitenSolving Kitchen Ventilation ProblemsJohn DiasNoch keine Bewertungen

- Flow Types: - Base of SpillwayDokument6 SeitenFlow Types: - Base of Spillwaygizem cenikNoch keine Bewertungen

- SC-01 Safety Code On Storage, Handling & Use of Gas CylindersDokument8 SeitenSC-01 Safety Code On Storage, Handling & Use of Gas CylindersSandeep ShettyNoch keine Bewertungen

- Drillmec DrawworksDokument8 SeitenDrillmec DrawworksPrashant Rajput100% (1)

- Panel Mounting Valve M5 DPDokument2 SeitenPanel Mounting Valve M5 DPBiswanath LenkaNoch keine Bewertungen

- Steering: Description and Operation Electro Hydraulic Power Steering (EHPS)Dokument49 SeitenSteering: Description and Operation Electro Hydraulic Power Steering (EHPS)rodolfodiaz100% (1)