Beruflich Dokumente

Kultur Dokumente

AISI304

Hochgeladen von

tony_abOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AISI304

Hochgeladen von

tony_abCopyright:

Verfügbare Formate

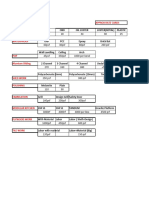

Quality

X5CrNi18-10 AISI 304

According to standards

Number

EN 10088-3: 2005

1.4301

Austenitic

Lucefin Group

Chemical composition

C%

max

0,07

0.01

Si%

max

1,00

+ 0.05

Mn%

max

2,00

+ 0.04

P%

max

0,045

+ 0.005

S%

max

0,030

+ 0.005

Cr%

N%

max

0,11

0.01

17,5-19,5

0.20

Ni%

Permissible

deviations on the

product

8,0-10,5

0.10

Temperature C

Melting range

Hot forming

Solubilization

Stabilization

1400-1420

1180-950

1000-1120

900

water

air

controlled atmosphere

Hardening

Welding

preheating

not demanded

can be increased only

by cold drawing

stress relieving

slow cooling

Mechanical properties

Hot rolled EN 10088-3: 2005

size

Testing at room temperature

mm

R

Rp 0.2

over

to

N/mm2

N/mm2 min

160

500-700

190

160

250

500-700

190

a) only for guidance

A%

min L

45

--

A%

min T

-35

Kv +20 C

J min L

100

--

Kv +20 C

J min T

-60

HB a)

max

215

215

Solubilization

Solubilization

Cold drawn +C EN 10088-3: 2005 (solubilization of material is recommended before cold drawing)

size

Testing at room temperature

mm

R

Rp 0.2

A%

A%

Kv +20 C Kv +20 C

over

to

N/mm2

N/mm2 min

min L

J min T J min L

J min T

35

700-850

350

20

---Tensile strength levels 700

25

800-1000

500

12

---Tensile strength levels 800

Cold processed bright bars EN 10088-3: 2005 in conditions 2H, 2B, 2G, 2P

size

R

Rp 0.2

A%

A%

Kv +20 C Kv +20 C

over

to

N/mm2

N/mm2 min

min L

J min T J min L

J min T

10 a)

600-950

400

25

---10

16

600-950

400

25

---16

40

600-850

190

30

-100

-40

63

580-850

190

30

-100

-63

160

500-700

190

45

-100

-160

250

500-700

190

-35

-60

a) In the range 1 mm < d < 5 mm valid only for rounds the mechanical properties of non round bars with thicknesses < 5 mm have to be

agreed upon at the time of enquiry and order.

Work-hardness by Cold drawing

R

N/mm2 600

700

Rp 0.2 N/mm2 300

560

A

%

35.0

25.0

C

%

72

70

Reduction %

0

10

850

720

10.0

68

20

Forged EN 10250-4: 2001 Solution-annealing

Testing at room temperature

size d / t

R

Rp 0.2

over to

N/mm2

N/mm2 min

675/450 500-700

190

d = diameter t = thickness

960

850

9.0

60

30

A%

min L

30

1100

960

8.0

55

40

1200

1080

7.0

47

50

Kv +20 C Kv +20 C Kv 150 C

J min L

J min T

J min L

100

60

60

Min. val. for the 0.2% proof strength at high temperature, properties after solubilization

Rp 0.2 N/mm2

-155

140

127

118

110

104

98

2

Rp 0.2 N/mm

-157

142

127

118

110

104

98

Testing at C

50

100

150

200

250

300

350

400

EUROPE EN

X5CrNi18-10

ITALY UNI

X5CrNi18-10

CHINA

0Cr18Ni9

1340

1200

6.0

44

60

GERMANY DIN

X5CrNi18-10

FRANCE AFNOR

Z5CN18-09

1480

1310

5.5

40

70

1650

1440

5.0

38

80

Kv -196 C

J min L

60

EN 10088-3: 2005 EN 10250-4: 2001

95

92

90

Hot rolled

95

92

90

Forged

450

500

550

U.K. B.S.

304S15

RUSSIA

07H18N10

USA AISI

304

Lucefin Group

X5CrNi 18-10 AISI 304

[ m/(mK)] 10-6

Thermal expansion

Modulus of elasticity

longitudinal N/mm2

Modulus of elasticity

tangential N/mm2

Specific electric resist. Ohmmm2/m

Conductivity

Siemensm/mm2

Specific heat capacity

J/(KgK)

Mean coefficient of linear expansion 106/K

Testing at C

Density

Kg/dm3

7.93

-193000

86200

0.72

1.39

500

-20

17.2

--0.78

1.28

-16.8

100

17.6

186000

83000

0.86

1.16

510

-200

17.8

179000

80000

----300

18.0

172000

76800

1.00

1.00

550

17.8

400

Thermal conductivity

Magnetic

W/(mK)

permeability

20 C 100 C 200 C 400 C 500 C 600 C 800 C r

15

16.3

17.5

19.9

21.5

22.5

25.1

1.008

18.2

165000

73700

----500

18.6

154000

60000

1.11

0.90

585

18.8

600

-127000

50000

1.21

0.83

630

20.2

800

---1.26

0.79

--900

Resist. to intergranular corrosion

in the

delivery cond.

sensitized cond.

yes

no

Das könnte Ihnen auch gefallen

- Rolling Process SimulationDokument16 SeitenRolling Process Simulationabhinav_ksskNoch keine Bewertungen

- Modeling Roller Burnishing Residual Stresses for Crankshaft Fatigue DesignDokument2 SeitenModeling Roller Burnishing Residual Stresses for Crankshaft Fatigue DesignhajamohamedNoch keine Bewertungen

- Tool Technology for Mechanical Metal Surface Improvement SolutionsDokument108 SeitenTool Technology for Mechanical Metal Surface Improvement SolutionsAmmarNoch keine Bewertungen

- WT32 ETH01 ManualDokument16 SeitenWT32 ETH01 ManualMember1FamilygmailNoch keine Bewertungen

- 14 v5 Gpsfordesigner Ws 14 030402Dokument20 Seiten14 v5 Gpsfordesigner Ws 14 030402catio000Noch keine Bewertungen

- Cogs Recessing Uygulama FormuDokument4 SeitenCogs Recessing Uygulama Formusamad behnodfarNoch keine Bewertungen

- Tutorial 14 - Importing Implicit Into ExplicitDokument6 SeitenTutorial 14 - Importing Implicit Into ExplicitPravinkumarGhodakeNoch keine Bewertungen

- Tools Et Outils Du Marketing DigitalDokument6 SeitenTools Et Outils Du Marketing Digitalhubert kratiroffNoch keine Bewertungen

- A Study of Mesh Sensitivity For Crash Simulations - Comparison of Manually and Batch Meshed ModelsDokument8 SeitenA Study of Mesh Sensitivity For Crash Simulations - Comparison of Manually and Batch Meshed Modelscharan2kNoch keine Bewertungen

- Ingenieur Vol 58 April-June 2014 Ingenieur Vol 58 April-June 2014Dokument84 SeitenIngenieur Vol 58 April-June 2014 Ingenieur Vol 58 April-June 2014Syǝd KhairiNoch keine Bewertungen

- Christian Nienhueser-Meshing Techniques in Asys ICEM CFD 50Dokument38 SeitenChristian Nienhueser-Meshing Techniques in Asys ICEM CFD 50reza rohani100% (1)

- Mechanical Surface Treatment Shot PeeningDokument25 SeitenMechanical Surface Treatment Shot PeeningArrokhman Bagus DharmawanNoch keine Bewertungen

- Ak 159 Metal Burnishing PDFDokument1 SeiteAk 159 Metal Burnishing PDFLea LeaNoch keine Bewertungen

- S235 Low Carbon Manganese Steel - Hillfoot Multi MetalsDokument1 SeiteS235 Low Carbon Manganese Steel - Hillfoot Multi MetalsIrshad AhmadNoch keine Bewertungen

- Heat transfer analysis of a teapotDokument11 SeitenHeat transfer analysis of a teapot염규정100% (1)

- Abaqus Tutorial: Axi-symmetric steel notched bar TensionDokument4 SeitenAbaqus Tutorial: Axi-symmetric steel notched bar TensionМаксим ФедоровNoch keine Bewertungen

- Saudi ArabiaDokument3 SeitenSaudi ArabiaCavz MediaNoch keine Bewertungen

- 2013 - S2E Technical and Technological - Intro - Final PDFDokument28 Seiten2013 - S2E Technical and Technological - Intro - Final PDFJose Kirby100% (1)

- Triple CNC MachineDokument27 SeitenTriple CNC MachineLeonardo Nicolas Paez100% (1)

- Bend AllowanceDokument2 SeitenBend AllowancewentropremNoch keine Bewertungen

- Flow Simulation Report PRIMER TTRABAJODokument29 SeitenFlow Simulation Report PRIMER TTRABAJOGian MorenoNoch keine Bewertungen

- Mechanicalprojectsautomatic Bar Feeding Mechanism For Cutting MachineDokument3 SeitenMechanicalprojectsautomatic Bar Feeding Mechanism For Cutting MachineSanketDhandeNoch keine Bewertungen

- Chapter 34 Surface Treatments, Coatings, and CleaningDokument13 SeitenChapter 34 Surface Treatments, Coatings, and CleaningTrí NguyễnNoch keine Bewertungen

- TD ElectrochimieDokument41 SeitenTD ElectrochimieStep WeyNoch keine Bewertungen

- Velleman k8200 Printer ManualDokument16 SeitenVelleman k8200 Printer ManualbillyboyclydeNoch keine Bewertungen

- PHP Coding StandardDokument42 SeitenPHP Coding Standardarief prasetyaNoch keine Bewertungen

- Industrial Sensors PDFDokument11 SeitenIndustrial Sensors PDFGrace MendiolaNoch keine Bewertungen

- Wire EDM Lab ReportDokument5 SeitenWire EDM Lab ReportEdgar ThorpeNoch keine Bewertungen

- Ceratizit ToolsDokument340 SeitenCeratizit ToolsguimaslipaNoch keine Bewertungen

- CNC MachineDokument12 SeitenCNC MachineEr Faiyaz AhmedNoch keine Bewertungen

- Brochure MTFR 2017Dokument4 SeitenBrochure MTFR 2017MIGUEL LOPEZNoch keine Bewertungen

- Manual de Labview+solidworkDokument18 SeitenManual de Labview+solidworkTameClaudioNoch keine Bewertungen

- Solidworks IntroductionDokument6 SeitenSolidworks IntroductionSky PatelNoch keine Bewertungen

- 2 Machining Operations and Machine ToolsDokument57 Seiten2 Machining Operations and Machine Toolssakali aliNoch keine Bewertungen

- Plastic Injection Manual 2016 Amk PolyDokument43 SeitenPlastic Injection Manual 2016 Amk PolyChockalingam AthilingamNoch keine Bewertungen

- Understanding The Physics of Electrodynamic Shaker Performance by G.F. Lang and D. SnyderDokument10 SeitenUnderstanding The Physics of Electrodynamic Shaker Performance by G.F. Lang and D. SnyderBruno SotoNoch keine Bewertungen

- KR C2 KR C3 Operator ControlDokument167 SeitenKR C2 KR C3 Operator ControlmilanstrNoch keine Bewertungen

- Scan To 3d NewDokument22 SeitenScan To 3d Newanton widodoNoch keine Bewertungen

- AutoCAD 2013Dokument1 SeiteAutoCAD 2013Dreamtech PressNoch keine Bewertungen

- 3dconnexion - SpaceMouse EnterpriseDokument15 Seiten3dconnexion - SpaceMouse EnterpriseWandersonNoch keine Bewertungen

- 2.3.2 Procedure For Mounting MoldDokument4 Seiten2.3.2 Procedure For Mounting MoldMuhammad JohariNoch keine Bewertungen

- Design and Analysis Mini CNC Plotter Machine: Faculty of Engineering Department of Computer EngineeringDokument46 SeitenDesign and Analysis Mini CNC Plotter Machine: Faculty of Engineering Department of Computer EngineeringOmar S. ArabiyatNoch keine Bewertungen

- Kerajet CeramicsDokument4 SeitenKerajet Ceramicssonia patricia batista motaNoch keine Bewertungen

- SWActivateRequest 0000000000003486Q5HFFG98 67H3K2G7D68J963BDokument2 SeitenSWActivateRequest 0000000000003486Q5HFFG98 67H3K2G7D68J963Bنسيم مقدمNoch keine Bewertungen

- Failure Analysis and Simulation Evaluation of An Alloy Wheel HubDokument13 SeitenFailure Analysis and Simulation Evaluation of An Alloy Wheel HubShiva Kumar H GNoch keine Bewertungen

- Markem Imaje 9040 DS HQ A2Dokument2 SeitenMarkem Imaje 9040 DS HQ A2Leandro AguiarNoch keine Bewertungen

- Design and Simulation of A Plastic ChairDokument14 SeitenDesign and Simulation of A Plastic Chairafolabi oluwadaraNoch keine Bewertungen

- Laser Consumable Cat Rev10Dokument40 SeitenLaser Consumable Cat Rev10Popan AdrianNoch keine Bewertungen

- Create Virtual Reality Stirling Engine ModelDokument53 SeitenCreate Virtual Reality Stirling Engine ModelMátyás AttilaNoch keine Bewertungen

- SurfaceRoughnessTester SRT-6210 SRT-6200 CatalogDokument2 SeitenSurfaceRoughnessTester SRT-6210 SRT-6200 CatalogMbimbikNoch keine Bewertungen

- AC CUT EDM-Expert InterfaceDokument16 SeitenAC CUT EDM-Expert InterfaceJosh TaylorNoch keine Bewertungen

- Chenhsong Plastics Machinery CPC-6.0 Injection Moulding Machine Controller Operation ManualDokument119 SeitenChenhsong Plastics Machinery CPC-6.0 Injection Moulding Machine Controller Operation ManualAndré SilvaNoch keine Bewertungen

- CSWP Segment - 1Dokument1 SeiteCSWP Segment - 1maulikNoch keine Bewertungen

- Pac8000 Controllers Ds Gfa1831Dokument2 SeitenPac8000 Controllers Ds Gfa1831mealysrNoch keine Bewertungen

- Lamina Machining GuideDokument320 SeitenLamina Machining GuideHumberto José Reyes CevallosNoch keine Bewertungen

- Digital Testing of High Voltage Circuit Breaker Seminar Topics With Reports and PPT in PDF DOC For EEE StudentsDokument3 SeitenDigital Testing of High Voltage Circuit Breaker Seminar Topics With Reports and PPT in PDF DOC For EEE Studentssujendranarayana100% (2)

- 1 4571a316ti69Dokument2 Seiten1 4571a316ti69Admir TalicNoch keine Bewertungen

- Quality 1.4021 Chemical Composition: Lucefin GroupDokument2 SeitenQuality 1.4021 Chemical Composition: Lucefin Groupmohamedbadawy0% (1)

- 1 4305a30365Dokument2 Seiten1 4305a30365skidanjeNoch keine Bewertungen

- 42CrMo4 Datos Tecnicos PDFDokument2 Seiten42CrMo4 Datos Tecnicos PDFjlplazaolaNoch keine Bewertungen

- HyspinDokument3 SeitenHyspintony_abNoch keine Bewertungen

- SurfaceTexture MachHandbook23rd PDFDokument6 SeitenSurfaceTexture MachHandbook23rd PDFpoetmbaNoch keine Bewertungen

- AISI304Dokument2 SeitenAISI304tony_abNoch keine Bewertungen

- Silicone OilDokument3 SeitenSilicone OilPrakash SharmaNoch keine Bewertungen

- Steel Plates Asdfjdslfja LSDJF Lasas Dklfja Lsdfjasldjf Alsdjf LasjfDokument14 SeitenSteel Plates Asdfjdslfja LSDJF Lasas Dklfja Lsdfjasldjf Alsdjf Lasjftony_abNoch keine Bewertungen

- Lagerwey's Next Generation of Direct Drive: DurabilityDokument2 SeitenLagerwey's Next Generation of Direct Drive: Durabilitytony_abNoch keine Bewertungen

- Moulds - 2mw LagerweyDokument2 SeitenMoulds - 2mw Lagerweytony_abNoch keine Bewertungen

- 01-Hexagon Head BoltDokument1 Seite01-Hexagon Head BoltTony AbrahamNoch keine Bewertungen

- Overview Electrical Insulation MaterialDokument12 SeitenOverview Electrical Insulation Material곽기열100% (2)

- DIN 46235 - Compression Cable LugsDokument41 SeitenDIN 46235 - Compression Cable LugsVinay Mandi100% (1)

- Emergency ExitDokument1 SeiteEmergency Exittony_abNoch keine Bewertungen

- Trichloroethlene QuotationDokument2 SeitenTrichloroethlene Quotationtony_abNoch keine Bewertungen

- Spark Gap TransformerDokument20 SeitenSpark Gap Transformertony_abNoch keine Bewertungen

- Amie Exam CentersDokument6 SeitenAmie Exam Centerstony_abNoch keine Bewertungen

- BHCN 2700 TS 20249C 1020 EnglishDokument40 SeitenBHCN 2700 TS 20249C 1020 EnglishandersonNoch keine Bewertungen

- Combustion Properties GuideDokument41 SeitenCombustion Properties GuideHarshini BaskaranNoch keine Bewertungen

- Crosslinker CX100 MsdsDokument59 SeitenCrosslinker CX100 MsdsMimi rastamNoch keine Bewertungen

- NF A49-711 Steel Tubes External Polypropylene CoatingDokument40 SeitenNF A49-711 Steel Tubes External Polypropylene CoatingDARYONO sudaryonoNoch keine Bewertungen

- OPSS 369 Nov08Dokument7 SeitenOPSS 369 Nov08Muhammad UmarNoch keine Bewertungen

- Screw Gluing Pressure Distribution and Bond StrengthDokument10 SeitenScrew Gluing Pressure Distribution and Bond Strengthm2auNoch keine Bewertungen

- Z-ABS Material Safety Data Sheet-1 PDFDokument7 SeitenZ-ABS Material Safety Data Sheet-1 PDFLaurentiu-Florin MosinoiuNoch keine Bewertungen

- Pop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovalDokument5 SeitenPop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovaluserNoch keine Bewertungen

- Adventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyDokument58 SeitenAdventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyRC DomeNoch keine Bewertungen

- Cunningham 2011Dokument3 SeitenCunningham 2011januar fitrianaNoch keine Bewertungen

- Applications of Isotopes C11!3!01&C11!3!02Dokument12 SeitenApplications of Isotopes C11!3!01&C11!3!02Olivia M OliverNoch keine Bewertungen

- Hemoglobin Oxidation-Reduction BiochemistryDokument5 SeitenHemoglobin Oxidation-Reduction BiochemistryYasmine AzzackiyahNoch keine Bewertungen

- Evaluation of Mechanical and Tribological Behavior of Al-4 % Cu-X% SiC Composites Prepared Through Powder Metallurgy TechniqueDokument11 SeitenEvaluation of Mechanical and Tribological Behavior of Al-4 % Cu-X% SiC Composites Prepared Through Powder Metallurgy TechniqueAruno AnbuNoch keine Bewertungen

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDokument2 SeitenSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNoch keine Bewertungen

- Guideline Repeated Dose Toxicity Revision 1 - enDokument9 SeitenGuideline Repeated Dose Toxicity Revision 1 - ennimirani2012Noch keine Bewertungen

- Is Amendment List of Colourants For Use in Plastics in FoodstuffsDokument3 SeitenIs Amendment List of Colourants For Use in Plastics in Foodstuffsjai soniNoch keine Bewertungen

- Bond Length: Measuring the Average Distance Between Atoms in a Covalent BondDokument9 SeitenBond Length: Measuring the Average Distance Between Atoms in a Covalent BondMiteigiNoch keine Bewertungen

- CODEX STANDARD FOR FERMENTED MILKSDokument11 SeitenCODEX STANDARD FOR FERMENTED MILKSvabimhah100% (2)

- Question Bank HTDokument12 SeitenQuestion Bank HTgreatrijuvanNoch keine Bewertungen

- Ipacs - Report - Thermal Properties of Concrete PDFDokument23 SeitenIpacs - Report - Thermal Properties of Concrete PDFRodrigo LameirasNoch keine Bewertungen

- Material Safety Data Sheet Konkreton XSDokument9 SeitenMaterial Safety Data Sheet Konkreton XSDaniel DaiaNoch keine Bewertungen

- Alimentos Funcionais em UanDokument12 SeitenAlimentos Funcionais em UanEduardo MartinsNoch keine Bewertungen

- Industrial Training Presentation: PETRONAS Chemicals Methanol Labuan Sdn. BHDDokument9 SeitenIndustrial Training Presentation: PETRONAS Chemicals Methanol Labuan Sdn. BHDAbdul AzizNoch keine Bewertungen

- Aditya Dixit2223bag16gt002 Module 2 Org..Dokument18 SeitenAditya Dixit2223bag16gt002 Module 2 Org..DADADADGGGNoch keine Bewertungen

- Lecture 1 Pendahuluan BiokatalisDokument18 SeitenLecture 1 Pendahuluan BiokatalisSabar SitioNoch keine Bewertungen

- Clavijas y Recept HubellDokument40 SeitenClavijas y Recept HubellArturo Pérez LohmanNoch keine Bewertungen

- Rate CardDokument6 SeitenRate CardRavi SrivastavaNoch keine Bewertungen

- Catalog Copeland KCLDokument40 SeitenCatalog Copeland KCLIsidro MendozaNoch keine Bewertungen

- BS 4660Dokument17 SeitenBS 4660danferreiro8318Noch keine Bewertungen

- The Chemicals of LifeDokument12 SeitenThe Chemicals of LifeGabriel XuerebNoch keine Bewertungen