Beruflich Dokumente

Kultur Dokumente

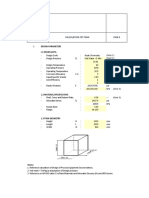

Hypochlorite Degassing Tank Design Calculations

Hochgeladen von

Brandon AllenOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hypochlorite Degassing Tank Design Calculations

Hochgeladen von

Brandon AllenCopyright:

Verfügbare Formate

Subject Size

: Hypochlorite Degassing Tank Design Calculations : 4000mm x 7700mm (Total height)

Design Standard BS 4994, ASTM 3299 Design Conditions: Design Pressure : Hydrostatic + 2 bar Design Vacuum Directly vented. Design Temperature 55oC Specific Gravity 1.03 Diameter 4000mm Shell height 6500mm Contents Sodium Hypochlorite in Sea water Configuration Vertical, Flat Bottom, Dished top head Wind Loading 160 Km/hr Design Factor (K) K = 3 x K1 x K2 x K3 x K4 x K5 Where K1 = 1.5 for filament winding & hand lay up process. K2 = 1.2 K3 = 1.22 K4 = 1.1 K5 = 1.1 K = 7.97 = 8 Pressure = P = 1.03 x 1000 x 9.81 x 6.4m + 2 bar = 2.65 ba = 0.265 N/mm2 Q = Circumferential unit load = 0.265 x 4000 = 530 N/mm. 2 = PDi 2

Maximum allowable strain CSM strain = UL x 100% where UL = U XZ K 1

2000 x 100% 8 x 14000 500 x 100% 8 x 28000 = 0.17%

= 0.17% = 0.22%

Filaments strain = Design strain Allowable loads 1) CSM 600 g/m2

U = 14000 x 0.0017 x 0.6 = 14.3 N/mm 2) Unidirectional filaments per Kg/m2 for 55o Circumferential U = 9500 x 0.0017 x 0.5 = 8.1 N/mm Longitudinal UX= 4500 x 0.0017 x 0.5 = 3.8 N/mm for 89o U = 26000 x 0.0017 x 1 = 44.2 N/mm Proposed Construction Two layers of 600g/m2 CSM 11 Kg/m2 of 89o filaments 2 Kg/m2 of 55o filaments Thickness 17 nos. of Radial 2400 Tex. 2 Nos. of helical 2400 Tex.

= 3mm + 17 x 0.5 + 2 x 1 = 13.5mm

ULam = 2 x 14.3 + 11 x 44.2 + 2 x 8.1 ULamx = 2 x 14.3 + 2 x 3.8 OK.

531 N/mm > QQ

= 36.2 N/mm > QX (See page 4)

Wind Load Reference : BS CP3 Chapter V, Part 2. VS = V S1 S2 S3 Where VS = Design wind speed V = Basic wind speed =160 Km/hr = 45m/s S1 = Topography factor S2 = Ground roughness & height factor S3 = Statistical factor VS = 45 m/s = 1221 N/m2 =1 =1

q = 0.603 x 452 Cf shell Cp dome

= 0.7 Pshell = 855 N/m2 = 0.8 Pdome = 977 N/m2

Dome projected area 1 x 4 = 4m2 Wind shear force = 855 x 4 x 6.5 + 977 x 4m2 Wind overturning moment Moment of Inertia =I = 22,230 N + 3910 N = 26,140 N

= 22230 x 3.25 + 3910 x (6.5 + 2/3 x 1m) = 100, 270 Nm = (D04 D14) 64

= (40274 - 40004) 64 = 3.43 x 1011 mm4

QX1 QX2

= My x t = 8 N/mm = longitudinal loading due to bending under wind pressure I = longitudinal loading due to shelf weight of shell + dome = (3.14 x 4 x 13.5 x 2.2 x 6.5 + 3.14 x 1.4 x 3.14 x 42/4 x 14 x 1.5 x 1) x 1.24 x 9.8) 3.14 x 4000 3

= 2.8 N/mm QX OK. = 10.3 N/mm < Ulamx (See page 3)

Dished Top Head Design For Semi-ellipsoidal ends subjected to extend pressure Q = 0.66 PD1Ks From figure 15 Ks = 1.3 P = 5000 N/m2 + 977 N/m2 Q = 0.66 x 5977 x 10-6 x 4000 x 1.8 = 21 N/mm for CSM 450 g/m2 = U = 10.7 N/mm for WR 600 g/m2 U = 16000 x 0.0017 x 0.6 = 16.3 N/mm Choose 7 CSM 450 + 4 WR 600 g/m2 Check for buckling tm = 1.7 Ro PF ELam

Where F = 4 and Ro = 0.5 Do Ke = 0.5 x 4000 x 1.8 = 3600 Elam = Xlam t

Xlam = 14000 x 0.45 x 7 + 16000 x 0.6 x 4 = 82,500 t = 7 x 1 + 4 x 0.6 = 9.4

Elam = 82500 = 8777 N/mm 9.4 4

tm = 10.1mm > 9.4

Not OK.

use 8 CSM 450g/m2 x 5 WR 600g/m2 8 x 1mm + 5 x 0.6 = 11mm> 10.1m OK Check for internal pressure when the tank is full upto top of dome during testing. Pmax. = 1.03 x 1000 x 9.81 x 1m = 10104 N/m2

From eqn. 43 P 37 Q = 0.5 P Di Ks Ks = 1.3 from table 11 Q = 0.5 x 10104 x 10-6 x 4000 x 1.3 = 26.3 N/mm < Ulam OK. Flat bottom design Since bottom fully supported on concrete, choose same thickness of shell, t = 14mm Anchor lug Design Eqn 77 P 115 BS 4994 F = 4M W + P Di2 Dpc 4 x1 Nb

Nb = number of anchorage bolts = 6 Dpc = pcd = 4150mm

= 4 x 100270 x 103 25000 N x 1 4150 6 = 12 KN Check for 2m column uplift F = 3.14 x 42 x 2 x 1.03 x 1000 x 9.81 = 42.3 KN 4 6 5

Then the latter is governing: F pull out = 42.3 KN F pull out is quite high Use 12 Anchor lugs instead as Then F pull out = 21.2 KN F shear = 26.14 = 2.2 KN 12 Propose Hilti HAS M20 x 170 Galvanized Refer to Hilti Technical book Combined load angle = tan-1 2.2 = 6o 21.2 Then allowable combined load = 29 KN Actual combined load = 21.22 + 2.22 = 21.3 KN OK Overlay thickness: Using allowable shear stress = 1.4 N/mm2 Then area of required overlay Ar = 21.3 x 103 = 15215 mm4 1.4 Proposed dimensions 500 x 486 = 243000 mm2 > Ar OK Overlay thickness = 13 mm

Das könnte Ihnen auch gefallen

- Design-Calculation Acid Wash TankDokument5 SeitenDesign-Calculation Acid Wash TankWiz DomNoch keine Bewertungen

- Design of HCL FRP Storage TANKDokument21 SeitenDesign of HCL FRP Storage TANKHaries Bugarin GarciaNoch keine Bewertungen

- Cpp-Tank DSGN Calc-Rev CDokument42 SeitenCpp-Tank DSGN Calc-Rev CnamasralNoch keine Bewertungen

- 40 KL DesignDokument10 Seiten40 KL DesignSung Woong MoonNoch keine Bewertungen

- Anti-corrosion Lining for Concrete PoolsDokument4 SeitenAnti-corrosion Lining for Concrete Poolsmuchamad yasinNoch keine Bewertungen

- CD Module Datasheet PDFDokument8 SeitenCD Module Datasheet PDFunconformistNoch keine Bewertungen

- Calculation Cpi Tank: I. Design Parameters I.1 Design DataDokument5 SeitenCalculation Cpi Tank: I. Design Parameters I.1 Design DataikramNoch keine Bewertungen

- WI06-0260 Calculations For Obround Nozzle ConnectionsDokument4 SeitenWI06-0260 Calculations For Obround Nozzle ConnectionskumarNoch keine Bewertungen

- Design Calc. Oxygen Scavanger Inj. Tank R3-304-1Dokument18 SeitenDesign Calc. Oxygen Scavanger Inj. Tank R3-304-1m khaeronNoch keine Bewertungen

- Thickness Calculation of Pressure Vessel ShellDokument16 SeitenThickness Calculation of Pressure Vessel ShellClaudia BonocoreNoch keine Bewertungen

- Agitator DesignDokument3 SeitenAgitator DesignSmrutiNoch keine Bewertungen

- API 650 Baseplate DesignDokument3 SeitenAPI 650 Baseplate DesignmjlazoNoch keine Bewertungen

- ASME manual coil heating procedureDokument8 SeitenASME manual coil heating procedurehgagNoch keine Bewertungen

- Shell Thickness Calculation ..: MAWP Design PressureDokument6 SeitenShell Thickness Calculation ..: MAWP Design PressureSatish ShindeNoch keine Bewertungen

- FRP RF CalcDokument1 SeiteFRP RF CalcmukeshNoch keine Bewertungen

- Bulk Air Eliminator R1Dokument1 SeiteBulk Air Eliminator R1hydrothermsNoch keine Bewertungen

- WATER TREATMENT LAMP LISTDokument42 SeitenWATER TREATMENT LAMP LISTdikha haryantoNoch keine Bewertungen

- Design of lifting lug on spreader beamDokument2 SeitenDesign of lifting lug on spreader beamSabrang LorNoch keine Bewertungen

- Kpeter PDFDokument3 SeitenKpeter PDFlive4sankarNoch keine Bewertungen

- Half Pipe CalculationDokument3 SeitenHalf Pipe CalculationdhavaleshNoch keine Bewertungen

- Mathcad - Pond Hex - FinalDokument6 SeitenMathcad - Pond Hex - FinalMohammed A IsaNoch keine Bewertungen

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDokument5 SeitenBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNoch keine Bewertungen

- THK Design CalculationDokument3 SeitenTHK Design CalculationalexnomitaNoch keine Bewertungen

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDokument7 SeitenHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNoch keine Bewertungen

- Pump specifications and sizing for sewage treatment plantDokument3 SeitenPump specifications and sizing for sewage treatment plantbharathNoch keine Bewertungen

- GA GAS HOLDER - 120MLD-Layout2Dokument1 SeiteGA GAS HOLDER - 120MLD-Layout2epe civil1Noch keine Bewertungen

- API 650 RF Pad Calculation PDFDokument1 SeiteAPI 650 RF Pad Calculation PDFBimal DeyNoch keine Bewertungen

- TEMA Shell Bundle Entrance and Exit AreasDokument3 SeitenTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNoch keine Bewertungen

- Compress EvaluateDokument23 SeitenCompress EvaluateVishalDhiman100% (1)

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDokument1 SeiteHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNoch keine Bewertungen

- Inspection Report of Monolithic Isolation Joint DeliveryDokument9 SeitenInspection Report of Monolithic Isolation Joint DeliveryIqbal Nurrasa BaktiNoch keine Bewertungen

- AD 2000-Merkblatt: Pressure Vessels in Glass Fibre Reinforced Thermosetting Plastics N1Dokument16 SeitenAD 2000-Merkblatt: Pressure Vessels in Glass Fibre Reinforced Thermosetting Plastics N1Ray100% (1)

- Texas Flange - Product Catalog PDFDokument47 SeitenTexas Flange - Product Catalog PDFFranco Saenz SolisNoch keine Bewertungen

- WRC-107 lifting lug calculations procedureDokument5 SeitenWRC-107 lifting lug calculations procedureManoj MulikNoch keine Bewertungen

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDokument32 SeitenKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamNoch keine Bewertungen

- Test Report Long-Term Ring Bending Strain (SB)Dokument4 SeitenTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNoch keine Bewertungen

- Pipe 36pulg Stress Analysis ReportDokument3 SeitenPipe 36pulg Stress Analysis ReportJhony MedranoNoch keine Bewertungen

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDokument1 SeiteL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77Noch keine Bewertungen

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Dokument1 SeiteShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNoch keine Bewertungen

- Horizontal Cylindrical Tank Volume and Level CalculatorDokument5 SeitenHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNoch keine Bewertungen

- New Storage Tanks Design GuidelinesDokument6 SeitenNew Storage Tanks Design GuidelineschrisevabNoch keine Bewertungen

- Digester Design2Dokument16 SeitenDigester Design2Pragathees WaranNoch keine Bewertungen

- Integral flange design documentDokument1 SeiteIntegral flange design documentHanda Bin AdiNoch keine Bewertungen

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDokument25 SeitenPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNoch keine Bewertungen

- ANSI-ASME B16.5 Blind Flange 300lb PDFDokument1 SeiteANSI-ASME B16.5 Blind Flange 300lb PDFVishal MistryNoch keine Bewertungen

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Dokument4 SeitenControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986Noch keine Bewertungen

- Dish End Weight CalculationDokument5 SeitenDish End Weight CalculationAniket royNoch keine Bewertungen

- ZENON MBR Tech (Chris Jeffery)Dokument70 SeitenZENON MBR Tech (Chris Jeffery)Srinivas DiviNoch keine Bewertungen

- Shell and Tube Heat Exchanger CalculationDokument9 SeitenShell and Tube Heat Exchanger CalculationKuldeep28883Noch keine Bewertungen

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDokument17 Seiten181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542Noch keine Bewertungen

- Flange Mawp Reduction PV Elite PDFDokument8 SeitenFlange Mawp Reduction PV Elite PDFDarshan PanchalNoch keine Bewertungen

- 194 2427 194 T Tot H H : Input OutputDokument19 Seiten194 2427 194 T Tot H H : Input Outputxuankhoi doanvanNoch keine Bewertungen

- Asme Viii Uhx Tubesheet CalcsDokument3 SeitenAsme Viii Uhx Tubesheet CalcsjdfdfererNoch keine Bewertungen

- RectangularDokument6 SeitenRectangularhgag selimNoch keine Bewertungen

- Design CalculationDokument5 SeitenDesign CalculationBrandon Allen60% (5)

- Design of HCL FRP Storage TANKDokument21 SeitenDesign of HCL FRP Storage TANKEleazar Mendoza86% (7)

- Rotary Drier DesignDokument29 SeitenRotary Drier DesignDharamvir Singh80% (5)

- Perhitungan Struktur Shelter - Meyerhoff AnlyDokument73 SeitenPerhitungan Struktur Shelter - Meyerhoff AnlyTaufik GunawanNoch keine Bewertungen

- FOUNDATION ANALYSISDokument14 SeitenFOUNDATION ANALYSISJuli NirwantoNoch keine Bewertungen

- 11kV Worked Example PDFDokument15 Seiten11kV Worked Example PDFtwinvbooksNoch keine Bewertungen

- E BrochureDokument17 SeitenE BrochureBrandon AllenNoch keine Bewertungen

- Unit 1 Introduction To Automobile Engineering: StructureDokument6 SeitenUnit 1 Introduction To Automobile Engineering: StructureSeth BeckNoch keine Bewertungen

- FACT Annual Report Highlights 2011-12Dokument31 SeitenFACT Annual Report Highlights 2011-12Brandon AllenNoch keine Bewertungen

- Time Table Deptl Test July 2017Dokument21 SeitenTime Table Deptl Test July 2017Brandon AllenNoch keine Bewertungen

- 001 How To Prepare IES, GATE & PSU Using My Notes IES AcademyDokument9 Seiten001 How To Prepare IES, GATE & PSU Using My Notes IES AcademyAtul kumar Kushwaha100% (2)

- Ticf Hm´¿ Atxm-Dn‰N: 2016 Unkw- - -Dn¬ /S-°P∂ Πw - Nwkv Ssek≥Kv) Co-£-Bv°P≈ At) £Dokument8 SeitenTicf Hm´¿ Atxm-Dn‰N: 2016 Unkw- - -Dn¬ /S-°P∂ Πw - Nwkv Ssek≥Kv) Co-£-Bv°P≈ At) £Brandon AllenNoch keine Bewertungen

- Time Table Deptl Test July 2017Dokument21 SeitenTime Table Deptl Test July 2017Brandon AllenNoch keine Bewertungen

- Beam Deflection FormulaeDokument2 SeitenBeam Deflection Formulae7575757575100% (6)

- Drdo Syllabus MechanicalDokument2 SeitenDrdo Syllabus MechanicalArvind SinghNoch keine Bewertungen

- Vocational Teacher (Maintenance and Repairs of Automobiles)Dokument7 SeitenVocational Teacher (Maintenance and Repairs of Automobiles)Brandon AllenNoch keine Bewertungen

- Power PlantDokument15 SeitenPower PlantBuckshu PhdNoch keine Bewertungen

- 88Dokument3 Seiten88Brandon AllenNoch keine Bewertungen

- Syllabus Technicial SupervisorDokument6 SeitenSyllabus Technicial SupervisorBrandon AllenNoch keine Bewertungen

- Reduce Leaks: Using Water Audits and Leak Detection SurveysDokument6 SeitenReduce Leaks: Using Water Audits and Leak Detection SurveysBrandon AllenNoch keine Bewertungen

- Turnaround ManagementDokument7 SeitenTurnaround ManagementBrandon AllenNoch keine Bewertungen

- 88Dokument3 Seiten88Brandon AllenNoch keine Bewertungen

- Linear AlgebraDokument1 SeiteLinear AlgebraBrandon AllenNoch keine Bewertungen

- Me 601Dokument4 SeitenMe 601Deepak SunilNoch keine Bewertungen

- DrillingDokument27 SeitenDrillingBrandon AllenNoch keine Bewertungen

- Ee010 306 (Me) Mechanical TechnologyDokument2 SeitenEe010 306 (Me) Mechanical TechnologyBrandon AllenNoch keine Bewertungen

- M.E. MANUFACTURING ENGINEERING AU SyllabusDokument35 SeitenM.E. MANUFACTURING ENGINEERING AU SyllabusJoswa CaxtonNoch keine Bewertungen

- Changing Role of Trade Unions in Modern IndustriesDokument3 SeitenChanging Role of Trade Unions in Modern IndustriesBrandon AllenNoch keine Bewertungen

- (Engineering) - : B.Tech. Degree Examtnation, DecemberDokument2 Seiten(Engineering) - : B.Tech. Degree Examtnation, DecemberBrandon AllenNoch keine Bewertungen

- Nitcalicut ME 2006Dokument56 SeitenNitcalicut ME 2006Brandon AllenNoch keine Bewertungen

- Drdo Syllabus MechanicalDokument2 SeitenDrdo Syllabus MechanicalArvind SinghNoch keine Bewertungen

- Crack Growth Modelling in Industrial Welded StructuresDokument1 SeiteCrack Growth Modelling in Industrial Welded StructuresBrandon AllenNoch keine Bewertungen

- SCM Presen 14Dokument6 SeitenSCM Presen 14Brandon AllenNoch keine Bewertungen

- Introduction To GearsDokument28 SeitenIntroduction To Gearssandeep_gaikwad2100% (4)

- BearingsDokument18 SeitenBearingsBrandon AllenNoch keine Bewertungen

- Untitled Document-7Dokument13 SeitenUntitled Document-7Ranjan singh BhadoriyaNoch keine Bewertungen

- How The World Was Created (Panayan)Dokument25 SeitenHow The World Was Created (Panayan)Mary Kris De AsisNoch keine Bewertungen

- Um Centuris Pro Li900b1 - enDokument70 SeitenUm Centuris Pro Li900b1 - enOsires Ferreira100% (1)

- Aqua Regia - WikipediaDokument5 SeitenAqua Regia - WikipediaearthplightNoch keine Bewertungen

- Belecobeauty Company ProfileDokument19 SeitenBelecobeauty Company ProfileBisma BrawijayaNoch keine Bewertungen

- AC 91-56 Amdt. 0 - Continuing Structural Integrity Program For Transport Category AirplaneDokument18 SeitenAC 91-56 Amdt. 0 - Continuing Structural Integrity Program For Transport Category Airplaneyogaga100% (1)

- Tzu Chi Medical Journal: Xiao-Jun Lin, I-Mei Lin, Sheng-Yu FanDokument5 SeitenTzu Chi Medical Journal: Xiao-Jun Lin, I-Mei Lin, Sheng-Yu Fanperisici4_535458722Noch keine Bewertungen

- BNC Lesson 1-4Dokument34 SeitenBNC Lesson 1-4Alyssa LoisNoch keine Bewertungen

- A Study On Financial Analysis of Tri Van Drum AirportDokument81 SeitenA Study On Financial Analysis of Tri Van Drum AirportN.MUTHUKUMARAN100% (1)

- Tactile Internet MSC V2Dokument28 SeitenTactile Internet MSC V2hendNoch keine Bewertungen

- Dorma FloorspringsDokument28 SeitenDorma FloorspringsanilNoch keine Bewertungen

- Chapte4 ZamznDokument24 SeitenChapte4 ZamznAHMED DARAJNoch keine Bewertungen

- The Global Commitment 2021 Progress ReportDokument39 SeitenThe Global Commitment 2021 Progress ReportComunicarSe-ArchivoNoch keine Bewertungen

- Artists Budget TemplateDokument9 SeitenArtists Budget TemplateMaia CelloNoch keine Bewertungen

- Roman Helmet From SivacDokument33 SeitenRoman Helmet From SivacArachne DreamweaverNoch keine Bewertungen

- B 7 B 139 Bee 14 Faea 5Dokument23 SeitenB 7 B 139 Bee 14 Faea 5Ola E. MohamedNoch keine Bewertungen

- Surge Arrester Function and Working PrinciplesDokument25 SeitenSurge Arrester Function and Working PrinciplesMidhun Varghese100% (1)

- Book ReviewDokument4 SeitenBook ReviewṬhanuama BiateNoch keine Bewertungen

- BCH102 Unit - III: Physiology Topic: BloodDokument18 SeitenBCH102 Unit - III: Physiology Topic: Blooddivya vajpayeeNoch keine Bewertungen

- Atomic Structure WorksheetsDokument21 SeitenAtomic Structure Worksheetssantoshkumarsir7706100% (1)

- Spence J Chemistry PHD 2018 PDFDokument383 SeitenSpence J Chemistry PHD 2018 PDFFLAVIANoch keine Bewertungen

- Manual Tud300Dokument70 SeitenManual Tud300DionicioCasanovaNoch keine Bewertungen

- W6 Ome - THTDokument4 SeitenW6 Ome - THTStevanie SesiliaNoch keine Bewertungen

- Air Travel and Tours: Chapter ObjectivesDokument22 SeitenAir Travel and Tours: Chapter ObjectivesLê Thành LuânNoch keine Bewertungen

- Dubai UAE InformationDokument28 SeitenDubai UAE InformationsefdeniNoch keine Bewertungen

- IDENTIFICATION. Identify The Following Questions Being Asked. (2 Points Each)Dokument5 SeitenIDENTIFICATION. Identify The Following Questions Being Asked. (2 Points Each)Myla Rose AcobaNoch keine Bewertungen

- Hydrolysis of Lactose in Whey Permeate For Subsequent Fermentation To EthanolDokument13 SeitenHydrolysis of Lactose in Whey Permeate For Subsequent Fermentation To EthanolkaltoumNoch keine Bewertungen

- CT AC 72A<INV=<90A 70A<REC=<135A Part SpecDokument7 SeitenCT AC 72A<INV=<90A 70A<REC=<135A Part SpecEdwin Mosos RamosNoch keine Bewertungen

- 200 300 Series Installation Guide USDokument48 Seiten200 300 Series Installation Guide USLhexter Mhervin CoNoch keine Bewertungen

- SEISMIC LOAD ANALYSISDokument9 SeitenSEISMIC LOAD ANALYSISAditya RoyNoch keine Bewertungen