Beruflich Dokumente

Kultur Dokumente

Carros Hibridos

Hochgeladen von

enriquecarlos1988Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Carros Hibridos

Hochgeladen von

enriquecarlos1988Copyright:

Verfügbare Formate

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 21, NO.

3, MAY 2006

567

Power Electronics Intensive Solutions for Advanced Electric, Hybrid Electric, and Fuel Cell Vehicular Power Systems

Ali Emadi, Senior Member, IEEE, Sheldon S. Williamson, Student Member, IEEE, and Alireza Khaligh, Student Member, IEEE

AbstractThere is a clear trend in the automotive industry to use more electrical systems in order to satisfy the ever-growing vehicular load demands. Thus, it is imperative that automotive electrical power systems will obviously undergo a drastic change in the next 1020 years. Currently, the situation in the automotive industry is such that the demands for higher fuel economy and more electric power are driving advanced vehicular power system voltages to higher levels. For example, the projected increase in total power demand is estimated to be about three to four times that of the current value. This means that the total future power demand of a typical advanced vehicle could roughly reach a value as high as 10 kW. In order to satisfy this huge vehicular load, the approach is to integrate power electronics intensive solutions within advanced vehicular power systems. In view of this fact, this paper aims at reviewing the present situation as well as projected future research and development work of advanced vehicular electrical power systems including those of electric, hybrid electric, and fuel cell vehicles (EVs, HEVs, and FCVs). The paper will rst introduce the proposed power system architectures for HEVs and FCVs and will then go on to exhaustively discuss the specic applications of dc/dc and dc/ac power electronic converters in advanced automotive power systems. Index TermsElectric propulsion, electric vehicles (EVs), fuel cell vehicles (FCVs), hybrid electric vehicles (HEVs), internal combustion engines, motor drives, power converters, semiconductor devices.

I. INTRODUCTION Y THE time the commercialization of the next-generation car comes around, advanced power electronics and motor drives will have already established themselves as prime components of advanced vehicular drive trains. Advanced power electronic converters and traction motor drives will be responsible for a major part of the vehicles energy usage. As of now, the automotive market is making rapid developments in case of the hybrid electric vehicles (HEVs). Commercially available HEVs include the Toyota Prius, Toyota Highlander Hybrid, Toyota Camry Hybrid, Lexus RX 400 h, Honda Insight, Honda Civic Hybrid, Honda Accord Hybrid, and Ford Escape Hybrid. In the case of future HEVs, power electronic converters and associated motor drives, which control the ow of electrical energy within the HEV power system, promise to be the keys to making HEVs more fuel efcient and emit lower harmful pollutants.

Manuscript received March 15, 2005; revised October 26, 2005. Recommended by Associate Editor J. Shen. The authors are with Electric Power and Power Electronics Center, Illinois Institute of Technology, Chicago, IL 60616-3793 USA (e-mail: emadi@iit.edu). Digital Object Identier 10.1109/TPEL.2006.872378

As is well known, in the rst half of the past century, the 6-V electrical system in automobiles served the purpose of ignition, cranking, and a satisfying few lighting loads [1][5]. Since then, there has been a constant rise in vehicular power requirement. Performance loads, such as electric steering, that were traditionally driven by mechanical, pneumatic, and hydraulic systems, are now increasingly being replaced by the electrically driven systems, in order to increase the performance and efciency of operation. Furthermore, luxury loads have also increased over time, imposing a higher demand of electrical power [3]. It must be pointed out here that the rate of increase of automotive loads is assumed to be about 4% per year. Thus, such load demands have resulted in the need to scale up the onboard vehicular power level. Considering these aspects, several decades ago, the voltage was raised from its earlier 6-V level to the present day 12-V level and, now with an ever-increasing demand forecasted into the future, there is a need to switch over to much higher voltage levels of 42 V, 300 V, or higher, as the case may be [3][5]. Due to the high voltage levels being produced in HEVs, it becomes essential to have dc/dc converters to supply all the auxiliary loads on board the vehicle. Although the dc/dc converter technology is well developed for low-power applications at lower cost, much work needs to be done for high-power applications. It is an immense challenge to meet all the vehicle standards for electromagnetic interference (EMI) and electromagnetic compatibility (EMC) as well as specications of reliability and packaging [4], [5]. In addition, power electronic converters also dictate how and when fuel/electricity is used in HEVs. A suitable dc/ac inverter draws dc power from the batteries to drive the electric traction motor, which in turn provides power to the wheels. The dc/ac inverter also performs the function of recharging the batteries during regenerative braking in HEVs. Based on this fundamental background, proving the criticality of power electronics for HEV applications, this paper will review the role of power electronics and compare the associated advanced power system architectures for HEV as well as electric vehicle (EV) and fuel cell vehicle (FCV) applications. The various design issues for power electronics intensive HEV and FCV power systems and the current and future trends will be highlighted. In addition, the proposed 42-V PowerNet is also focused upon, emphasizing on the description of its key capabilities and requirements. Furthermore, the paper will also discuss the mild hybrid vehicle, wherein the major opportunities for automotive power electronics are outlined. Finally, few system-level issues

0885-8993/$20.00 2006 IEEE

568

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 21, NO. 3, MAY 2006

Fig. 1. Conventional 14-V dc power system architecture.

that drive the relative power electronics size and cost functions will also be addressed. II. CONVENTIONAL AUTOMOTIVE POWER SYSTEMS AND CONCEPT OF MORE ELECTRIC VEHICLES (MEV) During the mid 1950s, the automotive industry decided to opt for 12-V electrical power systems for vehicles, since the then popular 6-V system was rapidly becoming plagued by the increasing vehicular load demands. The battery became a sixcell module instead of three cells, at approximately the same energy rating. The electrical system demand had risen from the 100 W of the early 1900s to typically about 1 kW by the 1990s, as more and more electrically powered devices were installed [6][8]. The conventional electrical system in an automobile can essentially be divided into the architectural elements of energy storage, generation, starting, and distribution. The distribution system of a conventional 14-V power system satises vehicular loads such as, interior/exterior lighting, electric motor driven fans/pumps/compressors, and instrumentation subsystems [6]. A simple rendition of the conventional 14-V electric power system architecture is shown in Fig. 1. As is clear from Fig. 1, the conventional power system arrangement has a single 14-V dc voltage level, with the vehicular loads being controlled by manual switches and relays. As mentioned earlier, the present average power demand in an automobile is approximately 1 kW. The voltage in a 14-V system actually varies between 9 and 16 V at the battery terminals, depending on the alternator output current, battery age, state of charge, and various other minor factors [6], [7]. This results in overrating the loads at nominal system voltage. In addition to these disadvantages, the present 14-V system cannot handle future electrical loads to be introduced in the more electric environment of the future cars, as it would be expensive and inefcient to do so. In more electric vehicles (MEVs), there is a trend toward expanding electrical loads and replacement of mechanical and hydraulic systems with more electrical systems. These loads include lights, pumps, fans, and electric motors for various functions. In addition, they also include some advanced, electrically assisted vehicular loads, such as power steering, air conditioner/compressor, electromechanical valve control, active suspension/vehicle dynamics, and catalytic converter [6]. Furthermore, additional advanced vehicular loads include, anti-lock braking, throttle actuation, ride-height adjustment,

Fig. 2. Typical representation of the more electric hybrid vehicle power system architecture.

and rear-wheel steering, which will be driven electrically in the future. As is well documented in related literature, most of the future advanced electric loads require power electronic controls. In advanced future vehicles, power electronics is forecasted to perform three major tasks. First task is simple on/off switching of loads, which is performed by mechanical switches and relays in conventional cars [7]. The second task is to act as a suitable controller for electric traction motors. Finally, power electronics intensive power systems will not only be used for the obvious task of changing system voltage levels, but also for converting electrical power from one form to another, using dc/dc, dc/ac, and ac/dc converters. As mentioned earlier, due to the ever-increasing electrical loads, the automotive industry is opting for more electric power systems. Due to this, MEVs will need highly reliable and faulttolerant electrical power systems to deliver high quality power from the source to the electrical loads. It is extremely important that the voltage level/form in which power is distributed be taken care of. A higher voltage will reduce the weight and volume of the wiring harness, among several other advantages [7], [8]. Fig. 2 shows the concept of a future hybrid MEV, making use of high voltage (300 V) automotive power system architecture. Currently, the proposed MEVs are at a transitional stage, involving different systems voltage levels [8]. It is expected that the future MEV power systems will most likely be comprised of a single main voltage bus (high voltage) with a provision for hybrid (dc and ac), multivoltage level distribution and intelligent energy and load management. III. ADVANCED DRIVE TRAIN ARRANGEMENTS FOR ELECTRIC, HYBRID ELECTRIC, AND FUEL CELL VEHICLES This section introduces the various drive train arrangements of pure battery electric vehicles (EV), series/parallel/series-parallel/complex HEV drive trains, and pure FCV/hybrid FCV drive trains. Based on the review done in this section, the ensuing sections will focus on the power electronics intensive

EMADI et al.: POWER ELECTRONICS INTENSIVE SOLUTIONS

569

Fig. 3. Topological arrangement for an electric vehicle (EV) drive train.

power system architectures for these advanced drive train arrangements. A. Battery Electric Vehicle (EV) Drive Train Topology A purely electric drive system principally replaces the internal combustion engine (ICE) and the various transmission systems with an all-electric system. As is well known, rechargeable chemical batteries are the traditional option as energy sources for EVs. But they tend to be heavy and expensive to replace over their limited lifetimes. In addition to traditional batteries like leadacid, nickel metalhydride (NiMH), and nickelcadmium (NiCd), there are advanced technologies like lithiumpolymer (Li-polymer) and lithiumion (Liion) batteries. Despite the popularity that these advanced batteries have gained for portable electronic applications, they havent quite maintained the same reputation for use in EVs. Most practical EVs still use lead-acid batteries, with the more sophisticated ones using NiMH batteries [8], [9]. A basic overview of a battery electric vehicle (BEV) is as shown in Fig. 3. More recently, the automotive industry is cutting back on EV production, and has declared HEVs and FCVs to be the future of advanced vehicle technologies. This is because BEVs cost signicantly more than gasoline vehicles, due to the fact that EV battery modules are currently being produced in very small volumes [9][11]. Higher vehicle prices are partially offset by the fact that fuel costs for battery electrics are about one-third those of a gasoline-powered vehicle. In addition, BEVs have fewer moving parts than gasoline cars, and hence, require less maintenance. The future of battery EVs is somewhat uncertain at this time, but their development has already made important contributions to advancing electric drive train and storage technologies needed by both HEVs as well as FCVs [10], [11]. If further breakthroughs in battery technologies occur, BEVs could yet prove to be the future of clean transportation. B. Series HEV Drive Train Topology A series hybrid vehicle is basically an electric vehicle with an on-board battery charger. An ICE is generally run at an optimal efciency point to drive the generator and charge the propulsion batteries on-board the vehicle, as shown in Fig. 4. When the state of charge (SOC) of the battery is at a predetermined minimum, the ICE is turned on to charge the battery [12][15]. The ICE turns off again when the battery has reached a desirable maximum SOC. The engine/generator set maintains the battery charge around 65%75%. It must be noted that, in a se-

Fig. 4. Typical layout of a series HEV drive train.

Fig. 5. Schematic of a parallel HEV drive train conguration.

ries HEV, there is no mechanical connection between the ICE and the chassis. The advantage with the series HEV conguration is that the ICE is running mostly at its optimal combination of speed and torque, thereby, having a low fuel consumption and high efciency. However, there are two energy conversion stages during the transformation of the energy between the ICE and the wheels (ICE/generator and generator/motor) [16], [17]. Some energy is lost because of the two-stage power conversion process. A series hybrid vehicle is more applicable in city driving. C. Parallel HEV Drive Train Topology A hybrid vehicle with the parallel conguration has both the ICE and the traction motor mechanically connected to the transmission. A schematic gure of the parallel hybrid is shown in Fig. 5. The vehicle can be driven with the ICE, or the electric motor, or both at the same time and, therefore, it is possible to choose the combination freely to feed the required amount of torque at any given time [18][20]. In parallel HEV, there are many ways to congure the use of the ICE and the traction motor. The most widely used strategy is to use the motor alone at low speeds, since it is more efcient than the ICE, and then let the ICE work alone at higher speeds. When only the ICE is in use, the traction motor can function as a generator and charge the battery. A parallel HEV can also have a continuously variable transmission (CVT) instead of a xed step transmission [19], [20]. With this technique, it is possible to choose the most efcient operating points for the ICE

570

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 21, NO. 3, MAY 2006

Fig. 6. Typical drive train conguration of a series-parallel combined HEV. Fig. 7. Schematic of a complex HEV drive train.

at given torque demands freely and continuously. The result is lower fuel consumption due to the inherently more efcient fuel usage. Energy is also saved due to regenerative braking. The advantage with the parallel HEV conguration is that there are fewer energy conversion stages compared to the series HEV and, therefore, a lesser part of the energy is lost [19]. In fact, the parallel HEV drive train depicts fairly lower losses compared to other HEV topologies and, hence, has a comparatively higher overall drive train efciency. D. Series-Parallel HEV Drive Train Topology The series-parallel HEV is a combination of the series and parallel hybrids. There is an additional mechanical link between the generator and the electric motor, compared to the series conguration, and an additional generator compared to the parallel hybrid, as shown in Fig. 6. With this design, it is possible to combine the advantages of both the series and parallel HEV congurations [20]. It must be highlighted here that the series-parallel HEV is also relatively more complicated and expensive. There are many possible combinations of the ICE and traction motor. Two major classications can be identied as electric-intensive and engine-intensive. The electric-intensive series-parallel HEV conguration indicates that the electric motor is more active than the ICE for propulsion, whereas, in the engine-intensive case, the ICE is more active [20], [21]. A common operative characteristic for both types of series-parallel HEV systems is that the electric motor is used alone at start with ICE turned off. During normal driving, the ICE alone propels the vehicle in the engine-intensive case. On the other hand, the ICE and electric motor propel the vehicle in the electric-intensive case [20]. When acceleration is needed, the electric traction motor is used in combination with the ICE to give extra power in both of the congurations. During braking or deceleration, the traction motor is used as a generator to charge the battery and, in stand still, the ICE can continue to run and drive the generator to charge the battery, if needed. Another form of series-hybrid conguration is shown in Fig. 7, which is a power split HEV topology. This topology includes a planetary gearbox, which connects the ICE, traction motor, and generator. Varying the speed from the two planetary gear pinions, connected to the electric motor and the generator, can control the ICE speed. When the ICE turns off, the vehicle

is propelled in the pure electric mode. However, at most of the operating points, the energy ows in a similar fashion to either that of a parallel HEV or to that of a series HEV. In parallel HEV mode, energy ows from ICE via the gearbox to the wheels, whereas, in the series HEV mode of operation, the energy ows from generator and motor to the wheels [21]. The proportion between these two energy ows depends on the overall vehicle speed. Under most operating conditions, this conguration is a combination of series and parallel hybrid vehicle. It is also possible to operate this in parallel mode for some operating conditions. One of the motivating factors for use of the power split HEV topology is to increase the vehicle power capability for a given transmission. This in turn enables the usage of continuously variable transmission concept for light duty HEV propulsion applications, such as pick up trucks and small buses. E. FCV Drive Train Topology The potential for superior efciency and zero (or near zero) emissions has long attracted interest to fuel cells as the potential automotive engine of the future. However, systematic efforts to realize the efciency and emissions benets of fuel cells in the transportation sector have materialized only in the last 10 years. The overall goal of ongoing fuel cell research and development programs is to develop a fuel cell engine that will give vehicles the range of conventional cars, while attaining environmental benets comparable to those of battery-powered electric vehicles. Although the technology is currently quite expensive, fuel cells offer benets including high overall efciency and quiet operation due to few moving parts. A typical fuel cell based propulsion system is shown in Fig. 8. The hydrocarbon fuel such as gasoline, natural gas, methanol, or ethanol is rst reformed to obtain the required hydrogen using a reformer (or fuel processor) [22]. This hydrogen rich gas from the reformer is fed to the anode of the fuel cell. It is also possible to store the on-board the vehicle using a pressurized cylinder, instead of using the reformer for converting the fuel to -rich gas. The oxygen (or air) is fed in to the cathode fuel cell. Depending on the fuel cell stack conguration, and the ow of hydrogen and oxygen, the fuel cell stack produces the dc output voltage [22], [23]. The fuel cell stack

EMADI et al.: POWER ELECTRONICS INTENSIVE SOLUTIONS

571

Fig. 8. Typical topological arrangement of a hybrid fuel cell vehicle drive train.

output is fed to the power conditioner (power electronic converter) to obtain the required output voltage and current. Ideally, the power conditioner must have minimal losses leading to a higher efciency. Power conditioning efciencies can typically be higher than 90% [24]. IV. POWER ELECTRONICS INTENSIVE POWER SYSTEM ARCHITECTURES FOR HEVS A. Advanced Electrical Features in Future HEV Technologies As mentioned earlier, there is a trend in the automotive industry to replace more engine driven mechanical and hydraulic loads with electrical loads, due to higher efciency, safety requirements, and drivers comfort. All of these new functions require the application of power electronics. In most of the cases, the cost of the power electronics dominates the argument of introducing such functions. Many of these functions will only appear in concept vehicles in the projected future. Some of these include luxury loads, such as information and entertainment that have received lots of hype recently. The other class of features is -by wire, where stands for an advanced function such as, steer or brake. Another class of advanced electrical features includes power steering pump, electric active suspension system, electromechanical valve control, electrically heated catalytic converter, air-conditioning systems, and water/oil/fuel pumps [25]. There are also other loads such as throttle actuation, ride-height adjustment, rear-wheel steering, which are proposed to be driven electrically in the future. Fig. 9 depicts a summary of some of the future electrical features automotive power systems. It is virtually mandatory that most of the proposed future electric loads will indeed require power electronic controls of some sort. B. Advanced HEV Topology Using ISA System In view of research and development work for MEVs, it must be pointed out that one of the leading breakthroughs in the automotive industry is the introduction of the integrated startergenerator (ISG) system for mild HEVs [26]. The ISG is primarily an electric machine with a rotor instead of a ywheel mounted on the crankshaft between the ICE and transmission. A schematic diagram of an ISG system used in conjunction with a high-voltage vehicular power system is shown in Fig. 10. The

Fig. 9. Future electrical features in more electric vehicle power systems.

Fig. 10. Integrated starter-alternator (ISA) based HEV drive train.

ISG provides the functions of an electric starter and an alternator [26], [27]. By using suitable advanced power electronic converter systems, it is possible for the ISG to compensate the drive train oscillations to provide more comfort. The power electronic converter system controls the ISG operating state, depending on the load status and the battery charge status. Improved fuel economy and reduced emissions are two prime advantages of an ISG system. Using a start/stop cycle, the ICE is turned off during deceleration or after the vehicle comes to a complete stop. The ISG can be used to propel the vehicle from a stop condition (and/or at a set speed), to restart the ICE. The ISG will also be able to route power produced by regenerative braking into the energy storage devices (batteries or ultra-capacitors) [26], [27]. It can also be used to provide power enhancement, when taking off from a stop, or in added acceleration for passing. C. 42-V/12-V Dual-Voltage Vehicular Electrical Systems The 42-V/12-V dual-voltage architecture is being popularly touted as one of the solutions for the ever-increasing in-vehicle load demand. The operating voltage criteria being considered for 42-V systems are shown in Fig. 11. The maximum dynamic over voltage is limited to 58 V, including the transient voltages

572

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 21, NO. 3, MAY 2006

Fig. 11. Typical operating voltage criteria for 42-V HEV power systems.

Fig. 13. Schematic of a dual voltage (14 V and 42 V) architecture using one battery.

Fig. 12. Schematic of a dual voltage (14 V and 42 V) architecture using two batteries.

[28]. In this case, the system charging voltage is set at 42 V. The entire electrical system in the vehicle is run at a nominal value of 42 V, whenever the engine is running. Some of the advantages of such a system include, high efciency and performance, less expensive operational procedures, reduced total installed power due to the integration of the mechanical and hydraulic power into the electrical power system, and reduction in the overall design complexity. The transition to an entirely 42-V dominated architecture cannot be done immediately. Therefore, it is assumed that a dual voltage automotive power system will exist at least for a while. There are various ways to implement a power electronics intensive dual voltage power system. The schematic used in Fig. 12 illustrates a dual (42 V14 V) battery system. Fig. 13 shows a schematic using only one single 42-V battery, and Fig. 14 illustrates a structure in which the dual voltage is generated by a single alternator, which has two output voltages. In the dual battery system, the rst (36-V) battery is optimized for high power delivery, while the second (12-V) battery is optimized for low powers to support key-off loads plus hazard lamp operation [28], [29]. In other words, in this structure, the starting function will be isolated from the storage function required for key-off loads. This architecture provides opportunities to improve existing high power loads by moving them to the 42-V side. It also minimizes changes to existing 14-V features, like lighting loads. However, this system has two batteries, which when compared with todays one 14-V battery, implies more cost, weight, and packaging space. The other new component in this system is

Fig. 14. Schematic of a dual stator dual voltage (14 V and 42 V) architecture using two batteries.

the 42-V/14-V dc/dc converter. The overall cost of power electronics is still considered too high for automotive applications. However, power electronic converters are capable of providing seamless energy transfer between two energy storage batteries and help improve reliability of some critical vehicular functions, which require a backup battery. In contrast, the single battery schematic of Fig. 13 is based on the desire to avoid cost, weight, and packaging problems created by the additional battery. The idea is that the power management system should be smart enough to manage the key-off loads from depleting the high-voltage battery to the point that the vehicle cannot be started [29]. It is critical to point out here that this architecture also uses a bidirectional dc/dc converter between the 42-V and 14-V buses. The schematic shown in Fig. 14 uses a more complicated alternator, with two sets of stator windings, to provide power separately to the 42-V and 14-V buses. In this structure, again, high power loads are connected to the 42-V bus and the 14-V bus supplies low-power electrical modules [29]. In addition to the above-described architectures, there exist many other strategies and variations of dual-voltage automotive power systems. The auto industry at this point is stagnant with regards to selecting appropriate dual-voltage MEV architectures. One of the main focal points of research in selecting

EMADI et al.: POWER ELECTRONICS INTENSIVE SOLUTIONS

573

a suitable MEV system is to determine which options provide the best economic value to possible customers. The other major concerns with the introduction of 42-V power systems are physical and practical viability aspects, such as arc faults and ensuing re hazards. These and various other practical issues are discussed in the following section. 1) Practical Issues Related to 42-V Automotive Power Systems: As is apparent, by increasing the present 14-V network to 42-V, signicant component and system changes within the vehicle will be necessitated. One of the major motives for this change is because of the nature of faults and their subsequent consequences, due to the higher current carrying wires in a 42-V automotive power system environment. It is obvious that the tendency is to produce longer arc faults, which have to be addressed to provide automotive safety. Wires that are semi-cut or scraped, in all probability, cause longer arc faults at higher system voltages. Furthermore, various research issues also arise from the point of view of vehicular power electronics and motor drives. For example, by reducing the mild HEV power system operating voltage (from 150 V/300 V to 42 V), the required current to provide the necessary power increases. Thus, this corresponds to the entire winding of the electric traction machine to be restructured. Issues such as heat transfer and protection also require a detailed investigation before the 42-V architecture becomes practicable in the auto industry. On the other hand, power electronic switches in 42-V systems may be required to handle RMS currents in the proximity of about 400 to 500 amps/phase [29]. Currently, in order to switch such high prole currents, parallel-operated power electronic switches are being proposed, since using single-level switches is highly uneconomical. Recently, advanced MOSFET switches have been introduced for use with prototype 42-V automotive power systems. Trench IGBTs have also made noteworthy progress from the point of view of providing 42-V architectural solutions, wherein the research focus is mainly on solving reliability and short-circuit current capability issues.

and FCVs is not possible without implementing new architectures, which are available using power electronics. 2) Power Conversion on Demand: Most of the auxiliary drives in vehicles are designed for worst-case scenarios. Power electronics and motor drive topologies make it easier to have higher efciency by providing adjustable speed drives. Especially, engine-cooling fans have been designed recently, implementing power electronic controls and adjustable speed drives. 3) Voltage Conversion on Demand: Different components in vehicles need different levels of voltages. Different voltage levels in dual-voltage architecture are available using power electronic converters. Induction or synchronous machines need ac voltages with high power for propulsion, and small motors for fans and pumps require ac voltage with low power [30], [31]. Converting dc-to-ac voltages and dc-to-dc voltages with different voltage levels is not possible without using power electronic converters. 4) Precise Electronic Control: Engine controls such as ignition or fuel injection need precise timing and dynamic control of actuators. Fuel injectors should work on very high pressure with more precise opening time. Engine developers are working on systems to replace the camshaft with electronically controlled variable valves, promising up to 25% more fuel economy. These controls cannot be imagined without the use of power electronics. 5) Fast, High-Power Motion: Fast and high-power industrial motion control is a demanding art requiring a mix of power electronics techniques coupled with modern digital signal processing. More and more additional functions in vehicles are being implemented, which require high-power actuation and dynamics. Electro-hydraulics, electro-mechanical brakes, steer-by-wire actuators, active suspension actuators, and new safety actuators are some of these functions [31]. Here again, power electronics with modern digital signal processing and dynamic motor control is the enabling technology. V. POWER ELECTRONICS INTENSIVE POWER SYSTEM ARCHITECTURES FOR FCVS As mentioned earlier, FCVs have advantages over the ICE vehicles in terms of emissions, fuel economy, and fuel exibility. The high-voltage bus in a FCV typically supplies the power for traction motor drive and other high-power loads, such as the air-compressor and air-conditioner. In addition, a low-voltage bus (with a 12-V conventional vehicle battery) supplies the existing conventional automotive loads. Similar to an ICE vehicle, the 12-V battery also provides the energy to start the fuel cell engine system. A suitable bidirectional dc/dc converter is used for this purpose. This bidirectional dc/dc power electronic converter is a key subsystem within the drive train, which manages the energy ow between the low-voltage and high-voltage buses within the FCV [32]. This section will rst deal with the basics of fuel cell based power processing systems, fuel cell based propulsion systems for cars and heavy-duty trucks/buses, and nally discuss the role of power electronic converters and some of the issues/solutions related to FCV power electronics.

D. Power Electronics Solutions for HEVs Power electronics is an enabling technology for next generation of vehicles, which should be cleaner, smarter, more precise, more efcient, and more exible. In the past decades, power electronic devices were avoided mainly because of their cost issues. The reasons for increased interest in automotive power electronics can be separated into the ensuing sections. 1) New Architectures: By increasing new electrical loads, cost and complexity of the system is on the increase. Such architectures need new switching and reliability features. Power electronics makes the possibility of integrating switching and fusing functions into one component with higher reliability. Possibility of implementing different control methods on power electronic systems is another reason to go away from relay switching. Also, by implementing integrated sensing techniques in power electronic devices, diagnosis and fault detection becomes easier to implement. Furthermore, development of clean and energy efcient vehicles in future vehicle technologies such as EVs, HEVs,

574

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 21, NO. 3, MAY 2006

Fig. 15. Typical fuel cell based power-processing system.

A. Fuel Cell Based Power Processing System A fuel cell is basically fed with hydrogen fuel and air at the anode and cathode, respectively. A low voltage dc is produced at the output, which is applied to an electric machine by processing it through a suitable power electronic dc/dc or dc/ac converter [33]. Basically, the electrical machine output is a mechanical output used to drive the wheels of the vehicle. A schematic diagram of a basic vehicular fuel cell electric power system with an on-board fuel processor is shown in Fig. 15. There are three major steps involved in the generation of power from a fuel cell. The rst step is to achieve purity of the available hydrogen gas. This is done with the help of a fuel processor. A suitable hydrocarbon fuel is fed to the fuel processor, which, in turn, produces a hydrogen rich gas at its output. This hydrogen rich gas is then fed to the anode electrode of the fuel cell. The generation of the dc voltage via the fuel cell makes up the second stage of the power-processing unit [33][35]. Last, the power output needs to be properly treated and passing it through an appropriate power conditioner does this. Ideally, the power conditioner must have minimal losses leading to a higher efciency. Power conditioning efciencies can typically be higher than 80%. B. Commercial FCV Applications A typical schematic diagram of the power system of a fuel cell based drive train for a passenger car is shown in Fig. 16. A low voltage dc produced by the fuel cell is stepped up using a dc/dc boost converter to obtain the required voltage at the input of the three-phase dc/ac inverter. The inverter converts the dc to a three-phase variable voltage/variable frequency power to vary the speed and torque of the electric machine that propels the vehicle [34], [35]. The electric traction machine output is a mechanical output used to drive the wheels of the vehicle. This drive train arrangement also includes a battery pack, making it a hybridized arrangement and, hence, facilitates regenerative braking. The secondary battery provides an input dc voltage to the dc/ac inverter during warm-up time of the fuel cell. Once the fuel cell starts providing the required power, the battery is disconnected and the system can completely run on the fuel cell and the dual power conversion circuitry. The battery system also provides voltage during transient conditions, thus, serving a dual purpose [35], [36]. The traction controller sends control signals to the fuel cell, dc/dc converter, and the

Fig. 16. Schematic of a fuel cell based power system for a passenger car.

Fig. 17. Typical block diagram of a heavy-duty fuel cell powered transit bus.

dc/ac inverter based on the feedback speed and torque signals as well as driver commands. Therefore, the speed and torque of the traction motor is controlled. The fuel cell output power is also used for powering the fuel cell system balance of plant (BOP) loads, such as pumps, blower motors, motor actuators, etc. as shown in Fig. 17. This conguration can also be used for heavy-duty vehicles such as transit buses. As is clear from Fig. 17, the dc/dc converter raises the level of the voltage from the fuel cell stack up to the level of the main dc bus voltage. The initial peak power during transients, such as start-up and acceleration, are supplied by the battery pack. The various dc and ac loads are fed from the main dc bus through appropriate dc/dc converters and dc/ac inverters [35]. The electric motor is controlled from a motor controller system, which, in turn, drives the wheels of the vehicle. C. Power Electronics for FCVs: Issues and Solutions The major challenge in designing automotive fuel cell power systems is converting the electrical output from the fuel cell into a usable power for various system sizes. Furthermore, the main goal is to realize the full potential of the fuel cell technology by using efcient methods to convert the fuel cell output to a useful electrical or mechanical energy. In addition, the conversion process must be implemented cost effectively. The primary power conversion required is three-phase variable ac output for the traction motor of the vehicle [35], [36]. It is important to note

EMADI et al.: POWER ELECTRONICS INTENSIVE SOLUTIONS

575

TABLE I RATIO OF ELECTRICAL AND ELECTRONIC DEVELOPMENT TO THE GROSS COSTS OF A CAR

is required between the fuel cell stack and the dc/ac inverter stage [36]. Another possible arrangement involves usage of a higher current output inverter and a 60-Hz output transformer, when the dc link voltage is below the required inverter operation voltage, namely about 400 V. Typically, dc link voltages in the 400-V range are favorable from the point of view of cost of power conversion components for power levels up to about 100 kW. VI. CURRENT RESEARCH ADVANCEMENTS AND FUTURE TRENDS FOR VEHICULAR POWER ELECTRONICS A. Current Vehicular Power Electronics Research Trends As discussed earlier, the complexity of conventional 14-V vehicular electrical systems, along with lots of different components, which have been designed to work in this system, makes it difcult to change the systems voltage spontaneously [37], [38]. Furthermore, there are some special components such as incandescent light bulbs and low power electronic modules, which prefer to work with low voltage. Before the whole system voltage goes to the higher 42 V, a dual voltage system will appear. In the dual voltage system, the high power loads will be fed through the high voltage bus and low power traditional loads will be fed simultaneously through the present 14-V system, at least for an interim period. In todays market, the complexity of electrical and electronic components in the automotive industry is increasing rapidly. Currently, about one third of the total costs of an advanced car might belong to electrical and electronic systems development and this share continues to grow steadily [38]. Table I shows the ratio of electrical and electronic development to the percentage total costs of a car. Simultaneously, lots of different variations on components are developed in a series of prototyping phases on different schedules, as depicted in Table I, for prototype -by-wire systems. B. Future Trends in Vehicular Power Electronics The needs for improvements in comfort, convenience, entertainment, safety, communication, and environmental issues necessitate the needs for improved electrical systems. This is a new motivation in restructuring the whole power system in vehicles. There will be more opportunities in the following areas of automotives power systemsimproved starting, integrated

Fig. 18. Fuel cell based single-stage power conversion system.

that a high peak to average power ratio is generally demanded of the power electronics. If there is no auxiliary energy storage system usage, the fuel cell also needs to maintain the above critical power ratio to a maximum. Secondary converters would be used for the 12-V (approximately 1.5 kW) or 42-V auxiliaries, and about 140 V or 300 V for other loads such as pumps, air-conditioning, and power steering applications. It is important, at the same time, to maintain high levels of efciency, low electromagnetic interference (EMI), low acoustic disturbances, and most importantly, low costs [36]. It is worthwhile mentioning here that it is critical for fuel cell based automotive power electronic systems to project approximately 1015 years of life span. In addition, an alternative automotive application involves using fuel cells to provide power for auxiliary loads, where the peak to average power ratio may be comparatively much more suitable for fuel cell operation. The challenge here is to nd combinations of the most economic arrangements of the fuel cell system and power electronic converters. To begin with, a simple power electronic dc/ac inverter system is shown in Fig. 18. This arrangement is suitable only if the fuel cell stack can produce a voltage that is suitable for the inverter to operate without any additional converter requirement. Mostly, this is not the case and, hence, an additional power electronic dc/dc boost converter

576

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 21, NO. 3, MAY 2006

management of power generation and demand, higher system integrity, higher efciency, and improvement of the electrical environment decreasing the component cost [38], [39]. These are achievable by hybrid multilevel power electronic systems, a distribution system with a separate communication bus and replacement of some conventional, engine driven, mechanical and hydraulic loads with electric loads to improve the efciency and packaging exibility [39]. All the same, it is widely believed that it will be a very long time before the 14-V system is completely eliminated from conventional vehicles, if ever, because most of the conventional automotive conventional loads are designed based on 14-V standards.

VII. CONCLUSION In order to universally increase the energy utilization efciency of advanced vehicular drive trains, the percentage of electrically controlled vehicular functions is steadily rising. Along with this, there is currently an expansion in the number of semiconductors installed in vehicles. In addition, even higher electrical energy is needed for advanced electrical loads. Thus, there is now a strong demand for the development of advanced power system architectures for future EV, HEV, and FCV applications. As outlined in this paper, power electronics is nding vast areas of usage for advanced HEV and FCV applications. Prospective advanced applications such as electric power steering and electromechanical engine actuators lead to higher electric power levels in cars, leading ultimately to higher system voltages. From this point of view, the paper introduced the popular HEV/FCV power system topologies as well as the proposed dual voltage automotive power system architecture (and the single voltage 42-V system, which is highly improbable in the very near future). Finally, the paper introduced varied opportunities presented by HEV/FCV technologies for advanced vehicular power electronics and motor drives. Bidirectional dc/dc converters are widely proposed to be employed with existing 12-V batteries on board a typical HEV power system. It is critical to point out that the 42-V idea might become the standard design of the automotive industry once related practical issues, as described in this paper, are taken into account.

REFERENCES

[1] A. Emadi, M. Ehsani, and J. M. Miller, Vehicular Electric Power Systems: Land, Sea, Air, and Space Vehicles. New York: Marcel Dekker, Dec. 2003. [2] X. Xu, Automotive power electronics: opportunities and challenges, in Proc. IEEE Int. Conf. Machines Drives, Seattle, WA, May 1999, pp. 260262. [3] D. J. Perreault and V. Caliskan, Automotive power generation and control, IEEE Trans. Power Electron., vol. 19, no. 3, pp. 618630, May 2004. [4] M. Weber and J. Weisbrod, Requirements engineering in automotive development: experiences and challenges, IEEE Software, vol. 20, no. 1, pp. 1624, Jan./Feb. 2003. [5] J. G. Kassakian, Automotive electrical systemsthe power electronics market of the future, in Proc. IEEE 15th Applied Power Electron. Conf. Expo., Feb. 2000, vol. 1, pp. 39.

[6] P. T. Krein, T. G. Roethemeyer, R. A. White, and B. R. Masterson, Packaging and performance of an IGBT-based hybrid electric vehicle, in Proc. IEEE Workshop Power Electron. Transport., Dearborn, MI, Oct. 1994, pp. 4752. [7] J. G. Kassakian, The future of electronics in automobiles, in Proc. 13th Int. Symp. Power Semicond. Devices ICs, Osaka, Japan, Jun. 2001, pp. 47. [8] M. Ehsani, Y. Gao, S. E. Gay, and A. Emadi, Modern Electric, Hybrid Electric, and Fuel Cell Vehicles: Fundamentals, Theory, and Design. Boca Raton, FL: CRC, Dec. 2004. [9] K. K. Afridi, R. D. Tabors, and J. G. Kassakian, Alternative electrical distribution system architectures for automobiles, in Proc. IEEE Workshop Power Electron. Transportation, Dearborn, MI, Oct. 1994, pp. 3338. [10] G. Maggetto and J. Van Mierlo, Electric and electric hybrid vehicle technology: a survey, in Proc. IEE Sem. Electric, Hybrid, Fuel Cell Vehicles, London, U.K., Apr. 2000, pp. 111. [11] X. Xu and V. A. Sankaran, Power electronics in electric vehicles: challenges and opportunities, in Proc. IEEE Ind. Applicat. Soc. Annu. Meeting, Toronto, ON, Canada, Oct. 1993, vol. 1, pp. 463469. [12] I. J. Albert, E. Kahrimanovic, and A. Emadi, Diesel sport utility vehicles with hybrid electric drive trains, IEEE Trans. Veh. Technol., vol. 53, no. 4, pp. 12471256, Jul. 2004. [13] V. Wouk, Hybrids: then and now, IEEE Spectrum, vol. 32, no. 7, pp. 1621, Jul. 1995. [14] F. A. Wyczalek, Hybrid electric vehiclesyear 2000, in Proc. 35th IEEE Intersoc. Energy Conv. Eng. Conf., Las Vegas, NV, Jul. 2000, vol. 1, pp. 349355. [15] A. Sciarretta, M. Back, and L. Guzzella, Optimal control of parallel hybrid electric vehicles, IEEE Trans. Contr. Syst. Technol., vol. 12, no. 3, pp. 352363, May 2004. [16] B. A. Welchko and J. M. Nagashima, The inuence of topology selection on the design of EV/HEV propulsion systems, IEEE Power Electron. Lett., vol. 1, no. 2, pp. 3640, Jun. 2003. [17] B. A. Kalan, H. C. Lovatt, M. Brothers, and V. Buriak, System design and development of hybrid electric vehicles, in Proc. IEEE Power Electron. Spec. Conf., Cairns, Australia, Jun. 2002, vol. 2, pp. 768772. [18] A. R. Gale and M. W. Degner, Voltage trade-off evaluation for electric and hybrid electric vehicle applications, in Proc. IEEE Workshop Power Electron. Transport., Auburn Hills, MI, Oct. 2002, pp. 1115. [19] S. Delprat, J. Lauber, T. M. Guerra, and J. Rimaux, Control of a parallel hybrid power train: optimal control, IEEE Trans. Veh. Technol., vol. 53, no. 3, pp. 872881, May 2004. [20] C. C. Lin, H. Peng, J. W. Grizzle, and J. M. Kang, Power management strategy for a parallel hybrid electric truck, IEEE Trans. Contr. Syst. Technol., vol. 11, no. 6, pp. 839849, Nov. 2003. [21] X. He and J. W. Hodgson, Modeling and simulation for hybrid electric vehiclespart I: modeling, IEEE Trans. Intell. Transport. Syst., vol. 3, no. 4, pp. 235243, Dec. 2002. [22] K. Rajashekara, J. Fattic, and H. Husted, Comparative study of new on-board power generation technologies for automotive applications, in Proc. IEEE Workshop Power Electron. Transport., Auburn Hills, MI, Oct. 2002, pp. 310. [23] A. Emadi, K. Rajashekara, S. S. Williamson, and S. M. Lukic, Topological overview of hybrid electric and fuel cell vehicular power system architectures and congurations, IEEE Trans. Veh. Technol., vol. 54, no. 3, pp. 763770, May 2005. [24] S. S. Williamson and A. Emadi, Comparative assessment of hybrid electric and fuel cell vehicles based on comprehensive well-to-wheels efciency analysis, IEEE Trans. Veh. Technol., vol. 54, no. 3, pp. 856862, May 2005. [25] A. Emadi, M. Ehsani, and J. M. Miller, Advanced silicon rich automotive electrical power systems, in Proc. 18th Digital Avionics Systems Conf. Air, Space, Ground Veh. Electron. Syst., St. Louis, MO, Oct. 1999, [CD ROM]. [26] I. Boldea, Starter/alternator systems for HEV and their control: a review, KIEE Int. Trans. EMECS, vol. 4-B, no. 4, pp. 157169, Jul. 2004. [27] A. Emadi, B. Fahimi, M. Ehsani, and J. M. Miller, On the suitability of low-voltage (42 V) electrical power systems for traction applications in parallel hybrid electric vehicles, in Proc. SAE Future Car Congress, Arlington, VA, Apr. 2000, [CD ROM]. [28] K. Rajashekara, 42 V architectures for automobiles, in Proc. IEEE Elect. Manufact. Coil Winding Expo., Indianapolis, IN, Sep. 2003, pp. 431434. [29] P. Nicastri and H. Huang, 42 V PowerNet: providing the vehicle electrical power for the 21st century, presented at the SAE Future Transportation Technology Conf. Expo., Costa Mesa, CA, Aug. 2000.

EMADI et al.: POWER ELECTRONICS INTENSIVE SOLUTIONS

577

[30] H. Huang, J. M. Miller, and P. R. Nicastri, Automotive electrical system in the new millennium, presented at the SAE International Truck and Bus Meeting and Expo., Detroit, MI, Nov. 1999. [31] J. G. Kassakian, The future of power electronics in advanced automotive electrical systems, in Proc. 27th IEEE Power Electron. Spec. Conf., Baveno, Italy, Jun. 1996, pp. 714. [32] M. J. Riezenman, Fuel cells for the long haul, batteries for the spurts, IEEE Spectrum, vol. 38, no. 1, pp. 9597, Jan. 2001. [33] S. S. Williamson and A. Emadi, Fuel cell vehicles: opportunities and challenges, in Proc. IEEE Power Eng. Soc. General Meeting, Denver, CO, Jun. 2004, pp. 16411646. [34] K. Rajashekara, Power conversion and control strategies for fuel cell vehicles, in Proc. 29th Annu. Conf. IEEE Ind. Electron. Soc., Roanoke, VA, Nov. 2003, vol. 3, pp. 28652870. [35] F. R. Kalhammer, P. R. Prokopius, V. P. Roan, and G. E. Voecks, Fuel cells for future electric vehicles, in Proc. 14th Annu. IEEE Battery Conf. Applicat. Advances, Long Beach, CA, Jan. 1999, pp. 510. [36] L. E. Lesster, Fuel cell power electronics: managing a variable-voltage dc source in a xed-voltage ac world, Fuel Cells Bull., vol. 3, no. 25, pp. 59, Oct. 2000. [37] H. P. Schoner and P. Hille, Automotive power electronics: new challenges for power electronics, in Proc. 31st IEEE Power Electron. Spec. Conf., Jun. 2000, vol. 1, pp. 611. [38] J. M. Miller, Power electronics in hybrid electric vehicle applications, in Proc. 18th IEEE Appl. Power Electron. Conf. Expo., Feb. 2003, vol. 1, pp. 2329. [39] J. Shen, A. Masrur, V. K. Garg, and J. Monroe, Automotive electric power and energy managementa system approach, in Proc. Bus. Brieng: Global Autom. Manufact. Technol., Apr. 2003, pp. 15.

vehicle conversion), the 2005 Richard M. Bass Outstanding Young Power Electronics Engineer Award from the IEEE Power Electronics Society, the Best Professor of the Year by the students at IIT in 2005, the Ralph R. Teetor Educational Award from the Society of Automotive Engineers (SAE) in 2005, the 2002 University Excellence in Teaching Award from IIT as well as the 2004 Sigma Xi/IIT Award for Excellence in University Research. He directed a team of students to design and build a novel motor drive, which won the First Place Overall Award of the 2003 IEEE/DOE/DOD International Future Energy Challenge for Motor Competition. He is an Associate Editor of the IEEE TRANSACTIONS ON POWER ELECTRONICS, the IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, and the IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS. He was the General Chair of the 2005 IEEE Vehicle Power and Propulsion and SAE Future Transportation Technology Joint Conference.

Sheldon S. Williamson (S01) received the B.Eng. degree in electrical engineering from Bombay University, Mumbai, India, and the M.S. degree in electrical engineering from the Illinois Institute of Technology, Chicago, IL, where he is currently pursuing the Ph.D degree in power electronics and motor drives. His research deals with the study and analysis of hybrid electric and fuel cell vehicular power systems.

Ali Emadi (S98M00SM03) received the B.S. and M.S. degrees in electrical engineering (with highest distinction) from the Sharif University of Technology, Tehran, Iran and the Ph.D. degree in electrical engineering from Texas A&M University, College Station. He is the Director of the Electric Power and Power Electronics Center (EPPEC), Illinois Institute of Technology (IIT), Chicago, where he has established research and teaching facilities as well as courses in power electronics, motor drives, and vehicular power systems. He is also the Founder, Director, and Chairman of the Board of the Industry/Multi-university Consortium on Advanced Automotive Systems (IMCAAS). He is the author/co-author of over 160 journal and conference papers as well as several books including Vehicular Electric Power Systems (New York: Marcel Dekker, 2003), Energy Efcient Electric Motors (New York: Marcel Dekker, 2004), Uninterruptible Power Supplies and Active Filters (Boca Raton, FL: CRC, 2004), and Modern Electric, Hybrid Electric, and Fuel Cell Vehicles (Boca Raton, FL: CRC, 2004). He is also the Editor of the Handbook of Automotive Power Electronics and Motor Drives (New York: Marcel Dekker, 2005). Dr. Emadi received the Eta Kappa Nu Outstanding Young Electrical Engineer of the Year Award in 2003 (for his outstanding contributions to hybrid electric

Alireza Khaligh (S05) received the B.S. and M.S. degrees in electrical engineering (with highest distinction) from Sharif University of Technology, Tehran, Iran, in 1999 and 2001, respectively, and is currently pursuing the Ph.D. degree in electrical engineering at the Illinois Institute of Technology, Chicago. In 2005, he was an Intern with C. E. Niehoff and Co., Evanston, IL, where he was involved with the design and implementation of an embedded control system regulator for automotive applications in Embedded Electronics Group. He is the author of several papers, books, and one U.S. patent. His major research interests include modeling, analysis, design, and control of power electronic converters, micro and nano scale power electronics and machineries, DSP/FPGA-based control of power electronic converters and motor drives, automotive/aerospace power electronics systems, electric and hybrid electric vehicles, and design of energy-efcient power supplies for battery-powered portable applications. Mr. Khaligh received the Exceptional Talents Fellowship from Sharif University of Technology, the Distinguished Undergraduate Student Award in Sharif University of Technology presented by the Minister of Science, Research and Technology, and is also listed in the Whos Who Among Students in American Universities and Colleges. He is a Member of the IEEE Power Electronics Society (PELS), Industrial Electronics Society (IES), and the Society of Automotive Engineers (SAE). He is a Member of the Vehicle Power and Propulsion Committee, IEEE Vehicular Technology Society (VTS).

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Motores MGM CatalogoDokument72 SeitenMotores MGM CatalogoJose IrimiaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Unidrive SP-User Guide - I14 (Size 0-6) PDFDokument306 SeitenUnidrive SP-User Guide - I14 (Size 0-6) PDFferiferiNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- LT Hanyoung Nux Timer Series User ManualDokument7 SeitenLT Hanyoung Nux Timer Series User ManualDanang MTANoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Sew Brake MotorsDokument6 SeitenSew Brake MotorsMohd Baharuddin Mohd Abu100% (1)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Fronius Symo Spec SheetDokument6 SeitenFronius Symo Spec SheetBrad MannNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Battery-Powered Drive Systems: Latest Technologies and OutlookDokument7 SeitenBattery-Powered Drive Systems: Latest Technologies and OutlooknilvalenNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Osmometro 3d3Dokument190 SeitenOsmometro 3d3Alga SebasNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- SMX 0602 0100 G4K User Installation Guide V1.5 2021Dokument313 SeitenSMX 0602 0100 G4K User Installation Guide V1.5 2021obadaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Specifi UltrasonicDokument79 SeitenSpecifi Ultrasonicethiomoney15Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Power Distribution at NFC EeeDokument70 SeitenPower Distribution at NFC EeeTeEbhan ChAnthira SeEkaranNoch keine Bewertungen

- Ac FundamentalDokument23 SeitenAc FundamentalaliahmiaemirNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Zxdu68 ST601Dokument2 SeitenZxdu68 ST601Lorena YancánNoch keine Bewertungen

- B21 B22 B23 Eee1001-Ecs Tee QPDokument2 SeitenB21 B22 B23 Eee1001-Ecs Tee QPADARSH JHANoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

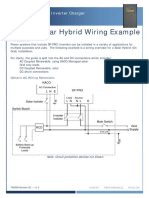

- TN0059 - 02 SP PRO Solar Hybrid Wiring ExampleDokument2 SeitenTN0059 - 02 SP PRO Solar Hybrid Wiring ExamplePower Eng100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- (Alex Ward) Biophysical Bases of ElectrotherapyDokument184 Seiten(Alex Ward) Biophysical Bases of ElectrotherapyColleen WhiteNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Relays Re7tp13buDokument10 SeitenRelays Re7tp13buraulraul82Noch keine Bewertungen

- Model PM130 Series: Plus P MDokument4 SeitenModel PM130 Series: Plus P MAndres DiazNoch keine Bewertungen

- PM 17saDokument16 SeitenPM 17saenergiculNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Abstract 1Dokument14 SeitenAbstract 1Shivam VermaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 3VL 1706-1dd36-0aa0Dokument4 Seiten3VL 1706-1dd36-0aa0Omkar ThakurNoch keine Bewertungen

- Abb Drive Library ExportDokument28 SeitenAbb Drive Library ExportAlex Aros CNoch keine Bewertungen

- A. Number of TowersDokument17 SeitenA. Number of TowersJosNoch keine Bewertungen

- Suction CompressedDokument12 SeitenSuction Compressedعلی علیزادهNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Ansi CodesDokument2 SeitenAnsi CodesCristian Salgado CarrascoNoch keine Bewertungen

- ABB Plug Socket 2CMC700006C0201 PDFDokument80 SeitenABB Plug Socket 2CMC700006C0201 PDFEdwin Arnan MursidiNoch keine Bewertungen

- Basic Power Factor CorrectionDokument52 SeitenBasic Power Factor Correctiondto_otb100% (1)

- BESS VENCON Battery - Specs - 820VDokument1 SeiteBESS VENCON Battery - Specs - 820VSerg MarushkoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Pilot Devices - 3SB5Dokument4 SeitenPilot Devices - 3SB5JeyakumarNoch keine Bewertungen

- Electrical Principles - Peter PhillipsDokument684 SeitenElectrical Principles - Peter PhillipsKarina Hernández Luna100% (1)

- SimbolDokument26 SeitenSimboldrion67Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)