Beruflich Dokumente

Kultur Dokumente

What Is Drip Article

Hochgeladen von

Gunasridharan LakshmananOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

What Is Drip Article

Hochgeladen von

Gunasridharan LakshmananCopyright:

Verfügbare Formate

rip irrigation, also known as micro-irrigation or trickle irrigation, is a remarkable water technology first developed decades ago.

Today, it is commonly used all over the world in agricultural, nursery, greenhouse, landscape and a variety of industrial applications. In recent years, the demand for drip irrigation has grown rapidly and for good reason the technology can help solve serious problems associated with water use. The following will assist in understanding drip irrigation such that a system may be chosen, and ultimately operated, intelligently.

Conserve Water And Irrigate Intelligently

What Is Drip Irrigation?

Advantages of Drip

Today it is more important than ever to use water resources wisely and to irrigate intelligently. Intelligation refers to the process of taking full advantage of the benefits drip irrigation offers. For instance, many farmers have enjoyed improved profitabilit y with drip by increasing crop yield and qualit y while at the same time reducing costs from water, energy, labor, chemical inputs and water runoff. Many landscapers have

also enjoyed significant water and capital investment savings using drip, while simultaneously improving plant vigor by delivering water and nutrients directly to the plant roots and avoiding unnecessary wetting of plant leaves. In addition, drip irrigation allows for targeted, intelligent water applications, where runoff, leaching and the wetting of non-targeted areas such as roads, plant leaves, tree trunks, sidewalks, cars, windows and buildings are avoided or completely eliminated.

Revenue from Increased Yields

Revenue from Increased Quality

Drip irrigation allows for targeted water applications, where runoff, leaching and wetting of non-targeted areas is avoided or completely eliminated.

Water Costs

Labor Costs

Energy Costs

Fertilizer Costs

Enviromental Quality

Pesticide Costs

Whether the motivation is improved profitabilit y or better resource use, Intelligation clearly makes sense. To irrigate intelligently, one must first choose the right system and then use it properly. Choosing a system can be complicated because each application is slightly different and there are many options available. However, regardless of application, it is very important that the system delivers a very high application uniformit y that will distribute water evenly throughout the system. In general, gravit y irrigation systems deliver relatively low application uniformit y, sprinklers deliver relatively moderate application uniformit y, and drip systems deliver relatively high application uniformit y. A thorough understanding of drip irrigation will assist the end user in making the right choices for virtually any crop or terrain.

Components of Drip/Micro-Irrigation System

Drip irrigation systems consist of emission devices serviced by a water distribution network that ideally includes control zone equipment. At the water source, water is controlled with automatic valves, sometimes amended with nutrients or chemicals, filtered and regulated at levels suitable for the emission devices chosen and plants being grown. From there, water is delivered to each of the emission devices

Components of Drip/Micro-Irrigation System

through a network of PVC and PE pipes. The emission device, whether it is drip tape, a drip emitter, jet or micro-sprinkler, then delivers water and nutrients to the soil where plant roots may nourish the plant. All components have attributes that affect performance, and that are traded off with initial, installation, operation and maintenance costs. A thorough understanding will assist in selecting the proper equipment to achieve desired expectations for the given application. Drip systems are durable and are built to withstand outdoor conditions for reasonable lengths of time, but care should be taken to avoid damage by wildlife, foot traffic or field equipment. In many cases, the environmental conditions will dictate the choice of emission device for any given application. A brief description of the three equipment classes follows:

Drip systems are durable and are designed to withstand and perform in outdoor conditions.

1. Emission Devices

mission devices vary according to their flow rate, hydraulic characteristics and wetting pattern. The ideal emission device is durable (withstands outdoor conditions), resistant to clogging (large internal passageways, self flushing), insensitive to pressure variation that occurs as a result of slope and/or lengths of run (pressure compensating), accurate (low manufacturing Coefficient of Variation, or CV) and economically affordable. Drip emission devices are typically installed on the surface such that there is flexibility in placement, and convenience for management. These attributes are achieved via advanced plastics, hydraulics and injection molding technology. Drip Tape is a line-source product that incorporates a series of relatively inexpensive, engineered emission devices into a thin walled tube. Water is distributed evenly along the length of the tube through emission devices which may be spaced anywhere from 4 to 24 apart. To accommodate various crops and terrain, tube wall thicknesses are available from .004 to .015 (4 mil to 15 mil), emitter flow rates from .07 - .34 gph, and pipe diameters from 5/8 to 1 3/8. Drip tape is available in standard and pressure compensating models, and is used extensively for vegetable and field row crop cultivation. It may be installed above or below the ground, and may be retrieved for multiseason reuse or disposed at the end of each season. Drip tape is relatively inexpensive and is ready to install without any additional emission device installation labor.

Drip emission devices are designed to deliver the same amount of water from each outlet, ensuring even distribution and high uniformity.

On-line Emitters are small plastic devices which convey small streams of flow from polyethylene (PE) tubing to the soil. Water then moves through the soil via capillary flow and creates a wetted circle, the size of which is dependent upon the soil type, flow rate and irrigation schedule. On-line emitters are attached to the PE tubing wall by inserting the emitters barb shaped base through a precisely punched hole. On line emitters offer the user the advantage of installing an emission device exactly where wanted, and if the emitter is take-a-part, it may also be serviced. The disadvantage is that the end user must manually insert each emitter. Note: Although the ability to self-clean an emitter is an attractive feature, it should be viewed as an occasional event that is no substitute for proper filtration and maintenance. Drip systems may employ hundreds or even thousands of emitters, a quantity impractical to flush by hand. In-line Emitters, or Dripline, consists of small plastic emission devices similar in function to on-line emitters, but in this configuration they are pre-inserted into the PE tubing at specified intervals during the tubing extrusion process. The emitters may be cylindrical or flat boat shaped, and are attached to the inner tube wall via a controlled heating/adhesion process. Labor savings for the end user may be substantial since emitters are factory pre-installed. Flexibility is not affected since additional emission devices are easily added to the tubing in the field if desired. The drawback is that emission devices may exist where unneeded, and they are not serviceable. Unlike all other classifications of emission devices, dripline may be installed below the surface such that the soil surface may be kept dry and surface damage may be avoided.

Components of Drip/Micro-Irrigation System

Components of Drip/Micro-Irrigation System

Drip application rates can be tailored to fit the soil and plant type, allowing for flexible water applications above or below the soil surface.

Foggers are small plastic devices that emit water as a fairly confined mist, or fog, via a small plastic online device. In addition to irrigation water being applied to the soil, temperature may be manipulated and/or a humid environment may be created. Foggers were originally developed for the citrus industry, but work well for potted plants or hanging baskets as well where confined roots require frequent wetting. Jets are small plastic devices mounted on risers and/or stakes that jettison water through the air as separate streams which create finger shaped patterns of water in the soil. A variety of finger patterns are available including full circle, half circle, hi/low trajectory, butterfly, etc. The versatility of patterns provides a great deal of flexibility for the end user to accurately apply water only where wanted, such as enveloping each tree in an orchard without wetting the trunk, or in landscape beds with odd shapes, or in potted plants.

2. Distribution System

nce the emission device is chosen, a system of filters, chemical injectors, pipes, valves and fittings must be constructed to deliver water reliably, safely and efficiently to each outlet, and to facilitate system maintenance. The major categories are as follows: Filters are used to remove organic and inorganic debris from the water that could potentially clog the emission devices. In agriculture, sand media filters, screen filters or disk type filters are commonly used, and may be cleansed manually, semi-automatically or automatically. Even where potable water is used, which is typical of landscaping applications, disc or screen filters should be installed since scale and chemical precipitants may occur which present a potential clogging hazard. Depending on the

Micro-sprinklers are small plastic devices that emit water in a full circle spray/sprinkler pattern through the air via a rotating spinner. The device is attached to the PE lateral tubing via a separate plastic stake or via a combination of a plastic stake fitted with a length of PE micro-tubing. The advantage is that water is applied over a larger area using only one emission device, and that operating pressures and application rates are low. A possible drawback is that, similar to conventional sprinklers, water is delivered through the air and may be applied to non-target areas such roads, tree trunks, foliage or other non-target areas. In addition, water applied through the air is affected by wind. It should be noted that a performance overlap exists where the higher flow rate ranges of micro-sprinklers approach the lower flow rate ranges of conventional sprinklers.

emission device chosen, the degree of filtration should be 80-200 mesh. Chemical Injectors are typically installed in drip irrigation system in order to facilitate system maintenance with chlorine or acid, and also to supply nutrients or other liquid or gaseous substances to the plants being irrigated. Whatever type of injector chosen, extreme care should be taken to ensure that the system includes proper safety and backflow prevention devices. Pipe PVC pipe is widely used to transport water from the water source to irrigation equipment of all types. In drip/micro-irrigation systems, it is typically used in the control zone and in the delivery network as both mainline and sub-mainline. In some cases, it may also be used as the lateral servicing the emission devices. White PVC pipe is not UV resistant.

Flush Valves are used to periodically cleanse the conveyance and emission device components of organic and inorganic debris that could clog the emission devices if left unchecked. They may be simple manual valves fitted at the ends of mainlines, sub-mainlines and/or laterals, semi-automatic valves that flush only at start-up or shut-down, or fully automated solenoid valves. Air/vacuum Relief Valves To avoid general equipment failure, pipe rupture or pipe blockage, A/V relief valves are used to expel air that builds up in the pipeline network during startup and operation. A/V relief valves are also used to allow air to enter the pipeline network as water exits at shutdown. This avoids undesirable vacuum suction in both the pipelines and the emission devices. A/V relief valves are typically installed at high elevation points, at control points, and at periodic pipeline intervals. Pressure Regulators are installed to protect downstream components from excessive pressures. They are especially important in drip/micro systems because the plastic and PE construction materials typically have lower pressure ratings than conventional sprinkler systems.

Components of Drip/Micro-Irrigation System

Tubing PE tubing is widely used as the lateral pipe servicing the emission devices. It is available in numerous diameters, wall thicknesses and reel lengths with varying pressure ratings and hydraulic characteristics. PE tubing, regardless of the color, is UV resistant. Fittings PVC pipe connections are typically made using solvent welded fittings, while PE tubing is usually connected via compression, insert or ring-lock type fittings.

In addition to water, drip irrigation systems may be designed to efficiently deliver fertilizers and/or protective chemicals directly to the plants root zone.

3. Control Zone Equipment

ow the drip irrigation system must be monitored and operated. It cannot be stressed enough how important the first two categories (flow meters and pressure gauges) are to assess performance and guidance for operation, and how important the last two categories (valves and controllers) are to deriving the maximum benefit from a drip irrigation system.

Components of Drip/Micro-Irrigation System

Drip irrigation systems can be fully automated, offering an unprecedented degree of control over water and power costs, and over the crops growing conditions.

System Flow Meters are available in a range of sizes and types, and commonly provide both instantaneous and cumulative water flow with an accuracy of approximately two percent. Flow meters may also be fitted with electrical analog conversion units that are capable of transmitting flow rate data to a centralized irrigation control computer.

Pressure Gauges are an essential item for drip systems since visual monitoring is often impractical or impossible. Pressure gauges placed at the pump station, before and after the filter station, and upstream and downstream of each control valve will provide an immediate indication of system performance. If pressures are too low, a leak could be indicated, a filter plugged or a valve jammed. If pressure are too high, the system could be plugged or a valve may be set incorrectly. Similar to a flow meter, accurate pressure information is essential part of a well designed and operated drip system. Zone Control Valves are used to control the flow of water to the various blocks or network zones. They may be simple manually operated valves, or fully automated solenoid activated on/off or pressure reducing valves. They may be co-located at the pump station or other Point of Connection (POC), or may be dispersed throughout the farm or landscape.

A micro-irrigation system offers the user an unprecedented degree of control over his water and power costs, and over the growing conditions of his crop. To take full advantage of this ability to control the irrigation system, it is necessary to have useful feedback information on flow rates and total water applied during a given time period. Accurate flow rate information is also indispensable for the analysis of crop response to water and nutrients, and for monitoring the continuing performance of the irrigation system. A good quality system flow meter is therefore an essential part of a well designed micro-irrigation system.

Irrigation Controllers are used to automatically start and stop irrigation events by sending electronic current to solenoid activated valves. The electronic current is controlled by a user defined schedule that is entered for each zone control valve. More sophisticated controllers may allow automatic adjustment of the program based on sensor inputs such as weather (plant water use or rain), system flow or system pressure.

Definition of Drip

Drip may be defined according to a number of performance parameters including flow rates, wetting pattern, pressure rating and construction material. Regardless of the specific type, make or model of a drip irrigation system or component, its performance is typically characterized as follows: Water is applied at a low flow rate emission device flow rates are typically measured in gallons per hour (GPH), resulting in low application rates. Water is applied for long periods of time irrigation duration may be hours rather than minutes when the application rate is low. Water is applied frequently irrigation events may occur daily, or even multiple times per day, when the application rate is low.

Water is applied at low pressure operating pressures typically range between 10-30 psi, rarely exceeding 60 psi, for most emission devices.

Water is applied through numerous emission devices in point source drip, each plant is fitted with at least one emission device to service the plants water needs. In broadcast drip, a gridwork of emission devices wets the entire area, servicing all plants within the wetted area.

Water is applied directly to the soil and the plants root zone water drips, or sprays, directly onto the soil and into the targeted plants root zone without wetting the plant or non-target areas, and without regard to the presence of wind. Depending on soil type and emission device, wetting patterns typically range from 0.5-6.0 feet for emitters and up to 40 feet for micro jets or sprays.

Fertigation is enabled since water is applied directly to the root zone, there is an opportunity to apply nutrients along with the water.

Water is filtered to avoid plugging the relatively small passages inside drip emitters, 150-200 mesh filters are used to remove mineral or organic materials from the irrigation water. Operation can be automated drip irrigation systems are often controlled with solenoid enabled valves that can be automatically actuated according to a user defined program entered into an irrigation controller.

Typical Layout of a Drip Irrigation System

Definition of Drip

Conserve Water And Irrigate Intelligently

What Is Drip Irrigation?

ince sprinkler irrigation is commonly used in both agriculture and in the landscape, one can further define drip by comparing it directly to sprinkler irrigation performance parameters. Conventional sprinklers typically apply water at a flow rate measured in gallons per minute (GPM) rather than GPH. As a result, application rates are generally higher, causing irrigation duration to be shorter and irrigation events less frequent. Higher application rates may also result in runoff if they exceed the soil and slopes ability to absorb water. Sprinklers typically operate at pressures ranging from 35-90 psi or more, spreading water through the air via spray or rotor type mechanical devices with wide distribution patterns. Thus, the plant material is typically wetted before water reaches the soil and root-zone, and non-targeted areas such as roads may be wetted as well.

Comparison with Gravity and Sprinkler Irrigation

Gravity irrigation is commonly used in agriculture to irrigate crops via a network of ditches, pipes, furrows and/or basins. After leaving ditches or pipelines, unpressurized water flows down furrows or across basins from one end of the field to the other, using gravity and a slight elevation drop for propulsion. On the positive side, gravity irrigation does not consume energy to pressurize the water and does not require high capital investments. However, the drawbacks to gravity versus drip include relatively poor application uniformity, high evaporative losses, unsuitability for hilly terrain, long lengths of run or sandy soils, and the inability to target the crops rootzone or to spoon feed applications as needed on a frequent basis.

Since sprinkler irrigation systems apply water through the air, wind may affect wetting patterns as well.

Drip irrigation provides superior uniformity, reduced evaporation, and less disease than other irrigation methods.

Comparing Drip/Micro to Sprinkler and Flood Irrigation Drip/Micro Sprinklers Gravity Emission device flow rate GPH GPM N/A Operating pressure 4-60 psi 30-90 psi Low Duration of irrigation seconds, minutes, or hours minutes hours, days Frequency of irrigation daily weekly monthly Filtration 150-200 mesh none none Quantity of devices More Less N/A Size/cost of each device Less More N/A Wetting patterns .5-40 feet 5-100 feet Broadcast Wetting plants Typically no Typically yes Typically no Wetting non-targeted areas Typically no Typically yes Typically yes Runoff on slopes Typically no Typically yes Typically yes

In summary, utilizing drip irrigation may be advantageous in many applications. Whether the end user wishes to improve profitability or simply reduce water use, there are a variety of emission devices and supporting system components to choose from such that plants may be irrigated efficiently, regardless of type or quantity. Once the drip system itself is more thoroughly understood, the next step is to use the system properly such that all potential benefits may be realized.

The Toro Company Micro-Irrigation Business 1588 N. Marshall Avenue, El Cajon, CA 92020-1523, USA Tel: +1 (800) 333-8125 or +1 (619) 562-2950 Fax: +1 (800) 892-1822 or +1 (619) 258-9973

www.toromicroirrigation.com

ALT142 08/07

Das könnte Ihnen auch gefallen

- Snap Bore Ring PDFDokument8 SeitenSnap Bore Ring PDFlaaliNoch keine Bewertungen

- GSM Based Irrigation SystemDokument122 SeitenGSM Based Irrigation Systemmayur_rughani86% (7)

- Basic Operation Electrical - Total - Eng - Prot PDFDokument439 SeitenBasic Operation Electrical - Total - Eng - Prot PDFdidik setiawan100% (2)

- Harmonized Household Profiling ToolDokument2 SeitenHarmonized Household Profiling ToolJessa Mae89% (9)

- Operation and Maintenance Manual - Irrigation SystemsDokument13 SeitenOperation and Maintenance Manual - Irrigation SystemsVinay Tunge75% (4)

- LDL Design GuideDokument18 SeitenLDL Design GuidebhupsjangirNoch keine Bewertungen

- Drip IrrigationDokument8 SeitenDrip IrrigationNatesa IndrasenanNoch keine Bewertungen

- Design and Construction of An AutomaticDokument74 SeitenDesign and Construction of An AutomaticAbdallaNoch keine Bewertungen

- Study of Drip Irrigation SystemDokument5 SeitenStudy of Drip Irrigation SystemSougata DasNoch keine Bewertungen

- Techniques OF Drip Irrigation and FertigationDokument25 SeitenTechniques OF Drip Irrigation and FertigationBhuvnesh Kumar100% (2)

- Cane Production ManualDokument193 SeitenCane Production ManualGunasridharan LakshmananNoch keine Bewertungen

- PowderCoatingResins ProductGuide 0Dokument20 SeitenPowderCoatingResins ProductGuide 0zizitroNoch keine Bewertungen

- Drip Irrigation and Fertigation Drip Irrigation SystemDokument20 SeitenDrip Irrigation and Fertigation Drip Irrigation SystemRudra Goud100% (1)

- Drip Irrigation Design GuideDokument11 SeitenDrip Irrigation Design GuideSiva KumaravelNoch keine Bewertungen

- Drip Irrigation BrochureDokument6 SeitenDrip Irrigation BrochureHRagheb100% (1)

- Drip Irrigation : Efficient Water Delivery for Crop GrowthVon EverandDrip Irrigation : Efficient Water Delivery for Crop GrowthNoch keine Bewertungen

- 9 - Drip IrrigationDokument58 Seiten9 - Drip Irrigationgregorio roaNoch keine Bewertungen

- Mulching & Drip Irrigation System Design For Mango Plantation in 1 Acre FieldDokument22 SeitenMulching & Drip Irrigation System Design For Mango Plantation in 1 Acre FieldRohit ThakreNoch keine Bewertungen

- Irrigation Systems For Organic Greenhouse Product-Groen Kennisnet 414564Dokument37 SeitenIrrigation Systems For Organic Greenhouse Product-Groen Kennisnet 414564Uday AndhaleNoch keine Bewertungen

- Drip Irrigation: Submitted By: Geetanjali BeheraDokument38 SeitenDrip Irrigation: Submitted By: Geetanjali Beherapurna_s08100% (1)

- Drip IrrigationDokument17 SeitenDrip IrrigationLohithReddyNoch keine Bewertungen

- Drip Irrigation - Management and MaintenanceDokument3 SeitenDrip Irrigation - Management and Maintenancepfdc GuwahatiNoch keine Bewertungen

- SHOCK 2006 Drip Irrigation An IntroductionDokument8 SeitenSHOCK 2006 Drip Irrigation An IntroductionMoaed KanbarNoch keine Bewertungen

- Irrigation Semester Paper AssignmentDokument5 SeitenIrrigation Semester Paper Assignmentnewsim linkNoch keine Bewertungen

- SDI Subsurface Drip IrrigationDokument4 SeitenSDI Subsurface Drip IrrigationArief IhsanNoch keine Bewertungen

- Global Reach and Market Leaders: Netafim Jain IrrigationDokument14 SeitenGlobal Reach and Market Leaders: Netafim Jain IrrigationAyush KumarNoch keine Bewertungen

- Research Paper On Micro Irrigation SystemDokument5 SeitenResearch Paper On Micro Irrigation Systemegxnjw0k100% (1)

- Drip IrrigationDokument17 SeitenDrip IrrigationA pushpa lathaNoch keine Bewertungen

- Lecture 3 Greenhouse Irrigation and Fertigation SystemsDokument6 SeitenLecture 3 Greenhouse Irrigation and Fertigation SystemsAtul RajNoch keine Bewertungen

- Drip Irrigation: Drip Irrigation, Also Known As Trickle Irrigation or Micro Irrigation or Localized Irrigation, IsDokument6 SeitenDrip Irrigation: Drip Irrigation, Also Known As Trickle Irrigation or Micro Irrigation or Localized Irrigation, IsSougata DasNoch keine Bewertungen

- Summer Training ReportDokument35 SeitenSummer Training ReportDeepak Goel60% (5)

- Technical Seminar ON: Drip IrrigationDokument26 SeitenTechnical Seminar ON: Drip IrrigationWorkless 0207Noch keine Bewertungen

- Modular IrrigationDokument26 SeitenModular Irrigationtetuko100% (1)

- Irrigation For Peaches Irrigation Systems For PeachesDokument5 SeitenIrrigation For Peaches Irrigation Systems For Peachesamijoski6051Noch keine Bewertungen

- Water Irrigation System ThesisDokument8 SeitenWater Irrigation System Thesiscarolinafoxpembrokepines100% (2)

- History: Micro-Irrigation Water Roots Soil Root Zone Evaporation Valves Pipes Tubing Emitters Surface IrrigationDokument6 SeitenHistory: Micro-Irrigation Water Roots Soil Root Zone Evaporation Valves Pipes Tubing Emitters Surface IrrigationnanaoNoch keine Bewertungen

- Research Paper On Sprinkler IrrigationDokument8 SeitenResearch Paper On Sprinkler Irrigationafnkjdhxlewftq100% (1)

- Pressure 3drip IrrigationDokument41 SeitenPressure 3drip Irrigationsleshizenebe2017Noch keine Bewertungen

- PI Chapter 3 DIDokument41 SeitenPI Chapter 3 DIsleshizenebe2017Noch keine Bewertungen

- Santiago - Green Water Recycling SystemsDokument3 SeitenSantiago - Green Water Recycling SystemsJoshua Santiago100% (1)

- Urban Rooftop Agriculture Irrigation System: A Case Study of Drip IrrigationDokument8 SeitenUrban Rooftop Agriculture Irrigation System: A Case Study of Drip IrrigationHelal AhmmedNoch keine Bewertungen

- Drip IrrigationDokument17 SeitenDrip IrrigationPriyadarshiniNoch keine Bewertungen

- Research Paper On Drip Irrigation PDFDokument7 SeitenResearch Paper On Drip Irrigation PDFafnhkvmnemelfx100% (1)

- Drip Irrigation For The Yard and GardenDokument6 SeitenDrip Irrigation For The Yard and GardenladydonnaduqueNoch keine Bewertungen

- BU Plumbing ConceptDokument6 SeitenBU Plumbing ConceptGweneth EncelaNoch keine Bewertungen

- Horticulture Home 2008-02pr PDFDokument4 SeitenHorticulture Home 2008-02pr PDFpuskesmas seulimeumNoch keine Bewertungen

- Micro-Sprinkler Irrigation For Orchards: Quick FactsDokument3 SeitenMicro-Sprinkler Irrigation For Orchards: Quick FactsLefere QottrerrNoch keine Bewertungen

- Lec09 Irrigation System Used in Greenhouses-Rules of Watering, Hand Watering, Perimeter WateringDokument3 SeitenLec09 Irrigation System Used in Greenhouses-Rules of Watering, Hand Watering, Perimeter WateringSooraj S KollamNoch keine Bewertungen

- Micro IrrigationDokument4 SeitenMicro IrrigationKowalski2008Noch keine Bewertungen

- HariDokument21 SeitenHariHari ChigurupatiNoch keine Bewertungen

- Irjet V9i6485Dokument5 SeitenIrjet V9i6485kzakari.1231Noch keine Bewertungen

- Rain Water HarvestingDokument23 SeitenRain Water HarvestingHARSHAVARDHAN KNoch keine Bewertungen

- Green Roof IrrigationDokument5 SeitenGreen Roof IrrigationKanchana RandallNoch keine Bewertungen

- Sprinkler-System PDFDokument136 SeitenSprinkler-System PDFEmerito PerezNoch keine Bewertungen

- Intership: Title:-Rain Water HarvestingDokument14 SeitenIntership: Title:-Rain Water HarvestingAnanya SharmaNoch keine Bewertungen

- Acp 10 - PPT - Q3 - M1Dokument69 SeitenAcp 10 - PPT - Q3 - M1Yeye VillaflorNoch keine Bewertungen

- Chapter (Chapter (Chapter (Chapter (7 7 7 7) ) ) ) Trickle Trickle Trickle Trickle Irrigation Irrigation Irrigation IrrigationDokument22 SeitenChapter (Chapter (Chapter (Chapter (7 7 7 7) ) ) ) Trickle Trickle Trickle Trickle Irrigation Irrigation Irrigation Irrigationmohamed ahmedNoch keine Bewertungen

- Drip IrrigationDokument6 SeitenDrip IrrigationJaston MwicheNoch keine Bewertungen

- GB Unit 4Dokument112 SeitenGB Unit 4Harish V7Noch keine Bewertungen

- Sprinkler Irrigation ThesisDokument5 SeitenSprinkler Irrigation Thesisaflowbbqfbjdnl100% (2)

- Rainwater Harvesting DoneDokument19 SeitenRainwater Harvesting DoneOmkar RajwadeNoch keine Bewertungen

- Water ConservationDokument4 SeitenWater ConservationAleena ZiaNoch keine Bewertungen

- IrrigationVon EverandIrrigationNoch keine Bewertungen

- Rainwater Harvesting: Understanding the Basics of Rainwater Harvesting (Transform Your Home and Farm With Rainwater to Uncover Self-sufficiency Secrets)Von EverandRainwater Harvesting: Understanding the Basics of Rainwater Harvesting (Transform Your Home and Farm With Rainwater to Uncover Self-sufficiency Secrets)Noch keine Bewertungen

- Agrometeorology Wind and Plant GrowthDokument3 SeitenAgrometeorology Wind and Plant GrowthGunasridharan LakshmananNoch keine Bewertungen

- Agrometeorology Temperature and Plant GrowthDokument3 SeitenAgrometeorology Temperature and Plant GrowthGunasridharan Lakshmanan100% (1)

- Crop Insect Pest - Cash Crops - Pest of SugarcaneDokument7 SeitenCrop Insect Pest - Cash Crops - Pest of SugarcaneGunasridharan LakshmananNoch keine Bewertungen

- Agrometeorology - Crop PlanningDokument2 SeitenAgrometeorology - Crop PlanningGunasridharan LakshmananNoch keine Bewertungen

- Agrometeorology Solar Radiation and Plant GrowthDokument1 SeiteAgrometeorology Solar Radiation and Plant GrowthGunasridharan LakshmananNoch keine Bewertungen

- Agriculture - Mineral Nutrition - IntroductionDokument2 SeitenAgriculture - Mineral Nutrition - IntroductionGunasridharan LakshmananNoch keine Bewertungen

- Agrometeorology - Micro Climate and Plant GrowthDokument2 SeitenAgrometeorology - Micro Climate and Plant GrowthGunasridharan LakshmananNoch keine Bewertungen

- Agriculture Home7Dokument1 SeiteAgriculture Home7Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture Home8Dokument1 SeiteAgriculture Home8Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture - Mineral Nutrition - Introduction 4Dokument2 SeitenAgriculture - Mineral Nutrition - Introduction 4Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture Home11Dokument1 SeiteAgriculture Home11Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture - Home5Dokument1 SeiteAgriculture - Home5Gunasridharan LakshmananNoch keine Bewertungen

- Cane Production ManualDokument192 SeitenCane Production ManualGunasridharan LakshmananNoch keine Bewertungen

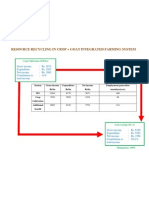

- Agri Major Areas Ifs Ressourceflow RainfedDokument1 SeiteAgri Major Areas Ifs Ressourceflow RainfedGunasridharan LakshmananNoch keine Bewertungen

- Agriculture - Home3Dokument1 SeiteAgriculture - Home3Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture - Home4Dokument1 SeiteAgriculture - Home4Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture - Home2Dokument1 SeiteAgriculture - Home2Gunasridharan LakshmananNoch keine Bewertungen

- Agriculture - HomeDokument1 SeiteAgriculture - HomeGunasridharan LakshmananNoch keine Bewertungen

- Sugarcane TechnicalDokument5 SeitenSugarcane TechnicalGunasridharan LakshmananNoch keine Bewertungen

- Sugarcane Trash ManagementDokument42 SeitenSugarcane Trash ManagementGunasridharan Lakshmanan100% (1)

- Sugarcane Budchips For Seed MultiplicationDokument4 SeitenSugarcane Budchips For Seed MultiplicationGunasridharan LakshmananNoch keine Bewertungen

- Hydrogen Production From The Air: Nature CommunicationsDokument9 SeitenHydrogen Production From The Air: Nature CommunicationsdfdffNoch keine Bewertungen

- Latihan Soal Bahasa Inggris 2Dokument34 SeitenLatihan Soal Bahasa Inggris 2Anita KusumastutiNoch keine Bewertungen

- Data Performance 2Dokument148 SeitenData Performance 2Ibnu Abdillah MuhammadNoch keine Bewertungen

- APPSC Calender Year Final-2017Dokument3 SeitenAPPSC Calender Year Final-2017Krishna MurthyNoch keine Bewertungen

- Week 1 Seismic WavesDokument30 SeitenWeek 1 Seismic WavesvriannaNoch keine Bewertungen

- Environmental Product Declaration: Plasterboard Knauf Diamant GKFIDokument11 SeitenEnvironmental Product Declaration: Plasterboard Knauf Diamant GKFIIoana CNoch keine Bewertungen

- Chapter 11-15Dokument172 SeitenChapter 11-15Mansoor AhmadNoch keine Bewertungen

- High School Students' Attributions About Success and Failure in Physics.Dokument6 SeitenHigh School Students' Attributions About Success and Failure in Physics.Zeynep Tuğba KahyaoğluNoch keine Bewertungen

- Just Another RantDokument6 SeitenJust Another RantJuan Manuel VargasNoch keine Bewertungen

- PaintballDokument44 SeitenPaintballGmsnm Usp MpNoch keine Bewertungen

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaDokument9 Seiten13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanNoch keine Bewertungen

- Imagine Unit 1 P 10 11Dokument1 SeiteImagine Unit 1 P 10 11נויה לבדובNoch keine Bewertungen

- Global Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirDokument24 SeitenGlobal Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirinderpreetNoch keine Bewertungen

- DSM-5 Personality Disorders PDFDokument2 SeitenDSM-5 Personality Disorders PDFIqbal Baryar0% (1)

- Private Standard: Shahram GhanbarichelaresiDokument2 SeitenPrivate Standard: Shahram Ghanbarichelaresiarian tejaratNoch keine Bewertungen

- Data Sheet FC SIDokument2 SeitenData Sheet FC SIAndrea AtzeniNoch keine Bewertungen

- Manual Chiller Parafuso DaikinDokument76 SeitenManual Chiller Parafuso Daiking3qwsf100% (1)

- Rahu Yantra Kal Sarp Yantra: Our RecommendationsDokument2 SeitenRahu Yantra Kal Sarp Yantra: Our RecommendationsAbhijeet DeshmukkhNoch keine Bewertungen

- Polikanov 2019-05-14 Curriculum Vitae YuryDokument6 SeitenPolikanov 2019-05-14 Curriculum Vitae Yuryapi-460295531Noch keine Bewertungen

- Cough PDFDokument3 SeitenCough PDFKASIA SyNoch keine Bewertungen

- Course Syllabus Manufacturing Processes (1) Metal CuttingDokument4 SeitenCourse Syllabus Manufacturing Processes (1) Metal CuttingG. Dancer GhNoch keine Bewertungen

- Reading Assignment Nuclear ChemistryDokument2 SeitenReading Assignment Nuclear Chemistryapi-249441006Noch keine Bewertungen

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDokument1 SeitePoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswNoch keine Bewertungen

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDokument29 SeitenUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemNoch keine Bewertungen

- NCP On DiabetesDokument2 SeitenNCP On DiabetesShumaila AlviNoch keine Bewertungen