Beruflich Dokumente

Kultur Dokumente

Installation and Operating Instructions For The Copra Fiber Cutter

Hochgeladen von

Rakesh GuptaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Installation and Operating Instructions For The Copra Fiber Cutter

Hochgeladen von

Rakesh GuptaCopyright:

Verfügbare Formate

INSTALLATION AND OPERATING INSTRUCTIONS FOR THE COPRA FIBER CUTTER Disconnect the electrical supply from the

e cutter. Move the cutter to a free space you would need a 3 m x 3 m space for making the adjustments. Ensure there is no copra fiber around, if it exists it should be shielded, so that, it does not catch fire when you are either welding or grinding in proximity. You shall need tools like spanners, Keys, Grinding Machine, Welding Machine and a few extra nuts and bolts. Open the safety cover of cutter, by opening all the bolts and nuts

Bring the cutter and feeder close to each other, adjust the height as per the following Para:

The initial adjustment needs to be made so that the conveyors of the feeder reach right close to the front plate of cutter. (This may require cutting the front right leg of feeder) The feeder is being made slightly taller then the height actually required, (for it to fit accurately with the main cutter). Maintain the top portion of the lower conveyor at the same height as that of the metal plate in front of the cutter, cut the extra height of the feeder by chopping off the legs suitably. Make sure that this front plate (white shiny metal plate in front of the cutter) is 4 to 7 mm lower then the top of the lower conveyor belt. To do this you might have to open the assembly of the front plate in cutter, and re-shape the stand of this front plate create enough space is beneath the front plate so that the conveyor takes easy position (Pulley has a curvature). Maintain 8 mm of horizontal distcnce between the belt and the front plate, for the smooth movement of the belt.

You might need another front plate on top of the existing front plate (unlikely, only if last part of the fiber jumps out of machine during cutting), should you need that , the minimum recommended distance between the existing and the new front plate should be 50 mm. Make a temporary welding between the legs of chopper and feeder to join them good, The gap between the conveyors can be adjusted to certain extent ( 40 mm ) if needed, based on the type of copra fiber that you feed, although this is adjusted after lots of trials, you may want to change that again ( do that only when absolute necessary needs a lot of adjustment once touched )

The Chain mechanism makes it a positive displacement type of conveyors, if the chain makes too much of cutting noise, loosen the chain a little, and if the sprokets override the chain tighten the same, (chain loosening or tightening is a bit sensitive, with very small change, the effect is in magnitudes)

There are two rollers, the first one is to break the hardness of the fiber, and the second one is to flatten the fiber curve. While adjusting Maintain a height difference of approx 10 mm between the first and the second roller, first being higher.

Variator: This is an electronic device, to control the speed of the conveyor belt. The set direction is reverse, and recommended speed on the LED is between 20 and 30, however initial trials without fiber can be taken at lower speeds. Feed: The feed to the feeder is manual, an operator

shall feed fibers into the hopper one after another, he can place two or three together depending on the size, however, do not overload the hopper with fiber, else the conveyor will choke. After a while through experience, the operator

will arrive at the optimum capacity of feed.

If the cutter is also supplied with the speed adjusting device, a balance is to be arrived at while changing the speed of both the motors for the optimum capacity and the performance of these machines.

In case of choking of fiber in between the conveyors, STOP the machine immediately, reverse the direction of conveyor by a button on variator, reduce the speed manually., remove the fiber, change the direction to the original and start again.

The variator will return to the pre-set condition, once the machine is switched on afresh, should need to make the recording of the new settings, take the following steps: 1. Make the desired changes 2. Press the ENTER button on the panel. 3. switch off the variator 4. Switch on again Once the trial are over, weld the feeder to the chopper firmly, paint in the desired color. Cut the top safety cover of cutter to fit with the new conditions, make sure that the machine is working smoothly (make movement of cutter wheel by hand). Fix the safety cover back to its place. Spares: There are spares supplied along with this machine, like belt joints, extra belt length, sprokets, extra master joints for the chain, and extra chain, nut sand bolts etc. It is highly recommended to keep them at a safe place as they are specific to this machine and may hamper production if not replaced timely.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Starting SystemDokument34 SeitenStarting SystemGetachew Tikue100% (2)

- 1953 3 AudioDokument76 Seiten1953 3 Audiokimbalsummers801100% (1)

- Lumel Current TransformersDokument32 SeitenLumel Current TransformersMihai BuzzNoch keine Bewertungen

- Bioactive Glass Cosmetics UsesDokument2 SeitenBioactive Glass Cosmetics UsesagdalineroNoch keine Bewertungen

- 12V 40ah (10hr) : Shenzhen Center Power Tech - Co.LtdDokument2 Seiten12V 40ah (10hr) : Shenzhen Center Power Tech - Co.LtdPhuoc “Felix” PhanNoch keine Bewertungen

- ANGEN - En006 B Restricted Earth Fault ProtectionDokument5 SeitenANGEN - En006 B Restricted Earth Fault ProtectionAlejandro Mira EstradaNoch keine Bewertungen

- Dynamini Series Adhesive Supply UnitDokument2 SeitenDynamini Series Adhesive Supply UnitITWDynatecNoch keine Bewertungen

- SynchrocouplerDokument6 SeitenSynchrocouplerMandark0009Noch keine Bewertungen

- Hot Runner ControllerDokument13 SeitenHot Runner ControllerNguyễn Hùng CườngNoch keine Bewertungen

- MS1000B 100JA Application Note PDFDokument9 SeitenMS1000B 100JA Application Note PDFHoracio Dorantes ReyesNoch keine Bewertungen

- Service Manual Audio Car Philips CEM250-55Dokument32 SeitenService Manual Audio Car Philips CEM250-55Alexandre Pereira NunesNoch keine Bewertungen

- Sens Battery ChargerDokument17 SeitenSens Battery ChargervjNoch keine Bewertungen

- Low-Power and Fast Full Adder by Exploring New and Gates: XOR XnorDokument13 SeitenLow-Power and Fast Full Adder by Exploring New and Gates: XOR XnorvishwasNoch keine Bewertungen

- Oil Burner Controls Type BHO 64 and LOA 44 - DanfossDokument12 SeitenOil Burner Controls Type BHO 64 and LOA 44 - Danfossr_cristiNoch keine Bewertungen

- GPIO Initialization For ARM MicroprocessorDokument25 SeitenGPIO Initialization For ARM MicroprocessorCristian Santana RodriguezNoch keine Bewertungen

- Ga B75M D3H - R11Dokument32 SeitenGa B75M D3H - R11Đorđe ĐukićNoch keine Bewertungen

- Positive, Zero, Negative Sequence of AlternatorDokument3 SeitenPositive, Zero, Negative Sequence of AlternatorJeya KannanNoch keine Bewertungen

- LCD DMF 50316NB FW 5Dokument17 SeitenLCD DMF 50316NB FW 5technicahmettNoch keine Bewertungen

- TB9300 User GuideDokument5 SeitenTB9300 User Guidelee.tetleie1675Noch keine Bewertungen

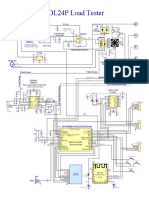

- DL24P Schematic DiagramDokument1 SeiteDL24P Schematic DiagramLAN JR HOUSE0% (1)

- Piezas de Recambio para Los Sistemas de Inyección de Combustible CATERPILLAR, CUMMINS, CAVDokument78 SeitenPiezas de Recambio para Los Sistemas de Inyección de Combustible CATERPILLAR, CUMMINS, CAVMiguel Ángel Gil PérezNoch keine Bewertungen

- 5g Technology Seminar ReportDokument28 Seiten5g Technology Seminar Reportankit20750% (1)

- Marantz SR 4500 BrochureDokument4 SeitenMarantz SR 4500 BrochureAnandNoch keine Bewertungen

- Musical Curiosities in The Temples of South IndiaDokument159 SeitenMusical Curiosities in The Temples of South IndiaMiguel CoponNoch keine Bewertungen

- Proline Promass 80 Operating InstructionsDokument130 SeitenProline Promass 80 Operating InstructionsOgnjen DrljanNoch keine Bewertungen

- SLC Wiring Manual-51253Dokument80 SeitenSLC Wiring Manual-51253teum3250% (8)

- Alternating CurrentDokument36 SeitenAlternating Currentkapil100% (1)

- CF-31UFLAXxM FirstAid BaseManualDokument33 SeitenCF-31UFLAXxM FirstAid BaseManualtuftiejaneNoch keine Bewertungen

- Keyence Infrared Temperature Sensors BrochureDokument14 SeitenKeyence Infrared Temperature Sensors BrochureAlfin AhsanNoch keine Bewertungen