Beruflich Dokumente

Kultur Dokumente

Hydro Forming BASICS

Hochgeladen von

sushil.vgiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydro Forming BASICS

Hochgeladen von

sushil.vgiCopyright:

Verfügbare Formate

HYDRO FORMING

1. INTRODUCTION

Hydro forming is a relatively new process, which uses water pressure to form complex shapes from sheet or tube material. Design studies suggest that automobiles can be made much lighter by using hydro formed components made of steel. Structural strength and stiffness can be improved and the tooling costs reduced because several components can be consolidated into one hydro formed part. As the automobile industry strives to make car lighter, stronger and more fuel efficient, it will continue to drive hydro forming applications. Some automobile parts such as structural chassis, instrument panel beam, engine cradles and radiator closures are becoming standard hydro formed parts.

The capability of hydro forming can be more fully used to create complicated parts. Using a single hydro formed item to replace several individual parts eliminate welding, holes, punching etc... Hydro forming simplifies assembly and reduce inventory.

The process is quite simple - a blank with a closed-form, such as a cylinder, is internally pressurized using fluid. The fluid is frequently water. The applied pressure is usually in the range 80-450 MPa. Its resultant plastic expansion is confined in a die of the desired shape.

HYDRO FORMING

Fig. Equipment for hydro forming

Hydro forming equipment consists of a hydraulic hydro forming press, pressure intensifiers, hydro form water system, and a hydro forming unit

Fig. Hydro formed components

HYDRO FORMING

Fig . Hydro formed automobile Component

fig . Hydro formed bellows, beginning with cylinders

Fig. Hydro formed handle bar

fig. Hydro formed T-junction

HYDRO FORMING

Fig. The high pressure hydro forming machine in Use at British Steel

HYDRO FORMING 2. METHODS OF HYDRO FORMING

There are two types of Hydro forming 1. Tube Hydro forming 2. Sheet Hydro forming

Sheet hydro forming converts the irregular shaped material into a finished and uniform thickness sheet. The tube hydro forming process is used to form parts in materials such as steel tubes and aluminum extrusions by applying hydraulic pressure.

2.1. TUBE HYDRO FORMING

HYDRO FORMING

Tube hydro forming is a kind of soft-tool forming technology and developed rapidly in the past decades. For taking tubes as processing blanks and liquid as flexible punch, it is more suitable for manufacturing special tubular components, such as different kinds of hollow shafts, discharge pipe of automobile & aeroplanes, sectional pipes etc.. Tubes were placed in the die and sealed on the end. Then under the co-action of compressive axial force and internal pressure, it is forced to deform from elastic stage to plastic stage. With the increasing of the applied load, the deformation increased correspondingly. Finally, under the extremely high pressure, the tube assumed the internal contour of the die precisely. In tube hydro forming, a cylinder is pressurized internally with 80 to 450 MPa pressure by a fluid like water. Compared with traditional processing technology, tube hydro forming always manufactures components at one step. So it can enhance part quality, such as tighter tolerance and increase rigidity, and lower production costs and reduction in production cycle. In this method the tube is placed in die and as press clamps the die valves, low pressure fluid is introduced into tube to pre form it. One the maximum clamping pressure is achieved, the fluid pressure inside the tube is increased so that tube bulges to take internal shape of the die. Simultaneously additional cylinders axially compress the tube to prevent thinning and brushing swing expansion. It is possible that some parts of the component thin excessively during hydro forming. This can sometimes be rectified, in the case of tube hydro forming, by applying axial pressure to feed material into the bulges, thereby reducing bulging.

HYDRO FORMING

Fig. Schematic illustration of the hydro forming of a bulge in a tube

fig. Tube Hydro Forming

HYDRO FORMING 2.11. TUBE HYDRO FORMING PROCESS The hydro forming process varies slightly depending on the component, but heres a general look at the overall procedure. 1. First, a computer-controlled machine cuts a length of straight metal tubing, also called a blank, to the proper size and feeds it into a machine, where it is prebent into the approximate contour of the finished part.

2. Next, the blank is inserted into the die, which is pumped full of highly pressurized water.

3. The water fills the blank, which conforms to the die walls. The water shapes the blank into the desired form.

4. At the same time, the machine compresses the ends of the blank, which eliminates thin spots on the outer wall of the blank, and prevents wrinkling on the inner wall, as well.

5. The component is then removed from the hydro forming press, the ends are trimmed and mounting holes are pierced with lasers and cutting torches.

Step 1

HYDRO FORMING

Step 2

Step 3

Step 4

HYDRO FORMING

10

2.12. HOW CAN TUBE HYDRO FORMING BENEFIT

HYDRO FORMING THE AUTO MANUFACTURER

1. Increased strength to weight ratios 2. Improved stiffness torsion and bending rigidly 3. Improvement in NHV Factor 4. Incorporation of hole punching, slot making, embosses swing hydro

11

forming process.

5. Reduction in number of manufacturing stages, hence tooling. 6. Reduction in welding, hence distortion and subsequent heat treatment. 7. Reduction in production cost 8. Reduced floor area

2.2. SHEET HYDRO FORMING

HYDRO FORMING Sheet hydro forming involves forming of sheet with application of fluid pressure. During the sheet hydro forming process, the hydraulic pressure varies in the range equal to or less than 100 MPa A sheet metal blank informed by hydraulic counter pressure generated by punch drawing sheet into pressurized water chambers. The water pressure effectively punches the sheet firmly against punch to form required shape.

12

The major advantage of fluid forming is increased drawing ratio. The process take place in two stages performed during one press stroke. The sheet is performed by applying low fluid pressure while it is clamped firmly by a blank holder pressure. Performing achieves on evenly distributed strengthening in the component center. In next step fluid pressure increased gradually and blank holder pressure is controlled relative to sheet reformation.

HYDRO FORMING

13

Fig. Sheet hydro forming

2.21. NEW CONCEPT IN SHEET HYDRO FORMING

HYDRO FORMING Double Sheet Hydro Forming

14

Structural component with closed components are formed by this process. Some advantages of this process are:Integration of more parts, further reduction of components & thus steps. Stiffness increase and reduction in overall spring back due to closed box section & continuous weld section. A complete component is made in one single hydro forming step, with only top and bottom die.

Fig. Double sheet hydro forming

HYDRO FORMING

15

2.22. THE APPLICATION SPECTRUM

1. There are numerous automotive components well suited to hydro forming of sheets. 2. This is especially true in area of outer skin with its extreme demand of surface quality and dimensional accuracy. 3. Longer outer skin parts for passenger cars, utility vehicles and truck such as goods, doors and tender as well as complex structural components can be formed. 4. 5. Low capital cost. Fewer and simpler dies. Better NHV (noise, vibration and harshness factors) factors.

6. Reduction in weight. 7. High process capability. 8. Reduction in cost of component.

Fig. Schematic View of Advantages

HYDRO FORMING

16

3. FORMING LIMIT DIAGRAM

During hydro forming process failure occurs due to thinning, this is due to the excessive deformation in a given region. A quick and economical analysis of deformation in a forged part is analyzed from forming limit diagram. The ability to detect point to point variation in strain distribution generally requires circle diameter between 2.5 to 5 mm. The sheet is then deformed, converting circles in to ellipse, and the distorted pattern is then measured and evaluated. Regions where the area has expanded are locations of sheet thinning Regions where area has contracted have undergone sheet thickening. Using the ellipse on the deformed grid, the major (Strains in the direction of larger radius) and associated minor strains (Strains perpendicular to the major) can be determined for variety of locations and values can be plotted on the forming limit diagram. If both major and minor strains are positive deformation is known as stretching, and thinning will possible.

Fig. Forming Limit Diagram

HYDRO FORMING 4. HYDRO FORMING PROCESS CONTROL

17

A typical hydro forming system would include a press capable of developing necessary forces to clamp the die valves together when internal pressure acts on fluid; a high pressure water system to intensify water pressure for forming component, looking including aerial cylinder and punches, depending on component and a control system for process monitoring.

Since the entire process of operation takes place inside a closed die, one cannot see what actually happens during forming. Therefore the controller plays a vital role in displaying, monitoring and controlling the different parameters of forming in real time.

HYDRO FORMING

18

Fig: Schematic Diagram of Tube Hydro forming and Process Control

HYDRO FORMING

19

5. HYDRO JOINING

Usually after hydro forming, additional joining operations are required to form assemblies. To reduce manufacturing time and number of process steps, joining operation are being integrated into hydro forming process. This also reduces tool cost. Two approaches to hydro joining are punch riveting hydro clinching.

In punch riveting, pressurized fluid acts on one sheet while a moving punch acts on other sheets from opposite sheet. Punch is moved against rivet and under the fluid counter pressure; it spreads to form a solid, visually attractive joint.

In hydro clinching, high pressure fluid action the punch. The prescribed fluid presses the material to be hydro formed part through a note in sheet to be joined.

HYDRO FORMING

20

6. CONCLUSION

During the last 12 years, general awareness of hydro forming has grown steadily. Although interest in hydro forming is wide ranging, the vast majority of application are in automobile industry.

Hydro Forming is not solution for manufacturing all automotive parts. The benefits of automotive light weight resin and weight reduction achieved by hydro forming can be measured in kilogram. It cannot be applied to every components, one has to study inability of hydro forming the part and the economic and technical payback.

Just like transistor revolutionized the electronic industry, hydro forming has taken the vehicle manufacturing industry a step up to evolutionary ladder, allowing auto component for vehicle. Although hydro forming has not taken off rapidly as it should have, is only matter on time before this technology is absorbed in the industry.

HYDRO FORMING

21

7. REFERENCES

1. The Machinist Journal (October Edition)

2. www.howstuffworks.com

3. www.wiley.com

4. www.thefabricator.com

HYDRO FORMING

22

Das könnte Ihnen auch gefallen

- Manufacturing of GearsDokument47 SeitenManufacturing of GearsMuhammad UmarNoch keine Bewertungen

- Optimization of Plastics Injection Molding ProcessDokument11 SeitenOptimization of Plastics Injection Molding Processfaishal hafizhNoch keine Bewertungen

- Interview QuestionDokument22 SeitenInterview QuestionsugeshNoch keine Bewertungen

- NC CNC Machine ToolDokument50 SeitenNC CNC Machine ToolShoaib MultaniNoch keine Bewertungen

- MP-I - Unit 5 - Sheet Metal WorkingDokument60 SeitenMP-I - Unit 5 - Sheet Metal WorkingTirumala Height Phase-INoch keine Bewertungen

- Deep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnDokument4 SeitenDeep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnbrahimNoch keine Bewertungen

- Report Final - Upsetting of Engine Valves and Parametric Study On Engine ValvesDokument44 SeitenReport Final - Upsetting of Engine Valves and Parametric Study On Engine ValvesAravind Srinivasan100% (1)

- Ejector PinsDokument21 SeitenEjector PinssyazwanmahadzirNoch keine Bewertungen

- Deep DryingDokument83 SeitenDeep DryingYasir HussainNoch keine Bewertungen

- Fit Tolerance For Plastic PartsDokument16 SeitenFit Tolerance For Plastic PartsA_JANNESNoch keine Bewertungen

- Overview Rubber ProcessDokument36 SeitenOverview Rubber ProcessYudoWijayantoNoch keine Bewertungen

- Aluminum Die Casting Process FlowDokument13 SeitenAluminum Die Casting Process FlowPrabish KumarNoch keine Bewertungen

- Form in MusicDokument8 SeitenForm in MusicAndri KurniawanNoch keine Bewertungen

- Roll ForgingDokument6 SeitenRoll ForgingSaptarshi SinhaNoch keine Bewertungen

- Reaction Injection MoldingDokument8 SeitenReaction Injection MoldingAmeer_Takashim_9385Noch keine Bewertungen

- Flowforming or Metal Spinning (Spin Forming)Dokument2 SeitenFlowforming or Metal Spinning (Spin Forming)ShivajiNoch keine Bewertungen

- Hazardous Area ClassificationDokument36 SeitenHazardous Area Classificationvenkeeku100% (1)

- Sheet Metal Bending-3Dokument15 SeitenSheet Metal Bending-3Sai Sujan100% (1)

- Pump Sizing and SelectionDokument64 SeitenPump Sizing and Selectionsushil.vgiNoch keine Bewertungen

- Piercing DieDokument5 SeitenPiercing DieJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- GB-T 5137.1-2002 Test Methods of Safety Glazing Materials Used On Road Vehicles Part1 Mechanical Properties TestsDokument14 SeitenGB-T 5137.1-2002 Test Methods of Safety Glazing Materials Used On Road Vehicles Part1 Mechanical Properties TestsRandyzhuNoch keine Bewertungen

- Rollvis - Roller Screws - CatalogueDokument74 SeitenRollvis - Roller Screws - Cataloguegoooga299Noch keine Bewertungen

- Drill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsDokument7 SeitenDrill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsSasan AbbasiNoch keine Bewertungen

- Engine Friction PDFDokument24 SeitenEngine Friction PDFsushil.vgiNoch keine Bewertungen

- Injection MoldingDokument25 SeitenInjection MoldingHarshadNoch keine Bewertungen

- Hungr Et Al 2005 - Landslide Travel DistanceDokument30 SeitenHungr Et Al 2005 - Landslide Travel DistanceJosé Ignacio RamírezNoch keine Bewertungen

- Number Patterns and SequencesDokument10 SeitenNumber Patterns and SequencesMohamed Hawash80% (5)

- Evoked Potential Practice Exam - ProProfs QuizDokument23 SeitenEvoked Potential Practice Exam - ProProfs QuizAnonymous 9lmlWQoDm8Noch keine Bewertungen

- Four Bolt Unstiffened End PlateDokument7 SeitenFour Bolt Unstiffened End PlateRnD2013Noch keine Bewertungen

- Measurement of Lines & SurfacesDokument84 SeitenMeasurement of Lines & Surfacessushil.vgiNoch keine Bewertungen

- Lec 6 Extrusion Metal WorkingDokument29 SeitenLec 6 Extrusion Metal WorkingSidra SaeedNoch keine Bewertungen

- Guide to Load Analysis for Durability in Vehicle EngineeringVon EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonBewertung: 4 von 5 Sternen4/5 (1)

- Petrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01Dokument61 SeitenPetrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01luciandu100% (1)

- Astm A394 2008 PDFDokument6 SeitenAstm A394 2008 PDFJavier Ricardo Romero BohorquezNoch keine Bewertungen

- Machine Design Question PaperDokument2 SeitenMachine Design Question Papersushil.vgi100% (1)

- CastingDokument74 SeitenCastingParth Maldhure100% (1)

- Hydro Forming FinalDokument32 SeitenHydro Forming FinalGaurav KatruwarNoch keine Bewertungen

- Hydro FormingDokument22 SeitenHydro FormingNIJIL123Noch keine Bewertungen

- Seminar Report HydroformingDokument11 SeitenSeminar Report HydroformingAnuj Mandloi100% (2)

- Development of Camshaft Machining ProcesDokument6 SeitenDevelopment of Camshaft Machining ProcesAbdul RehmanNoch keine Bewertungen

- Fine BlankingDokument9 SeitenFine BlankingElaine JohnsonNoch keine Bewertungen

- Formulas CoolersDokument39 SeitenFormulas Coolersbasaca132Noch keine Bewertungen

- Brochure For HPDC ProcessDokument4 SeitenBrochure For HPDC Processramaswamykama786Noch keine Bewertungen

- Hydraulic Symbols: Lines Miscellaneous Units Hydraulic PumpsDokument2 SeitenHydraulic Symbols: Lines Miscellaneous Units Hydraulic PumpsShawn WaltzNoch keine Bewertungen

- Mold Material: H13 P20 Mirror Polish Texture H13 P20Dokument1 SeiteMold Material: H13 P20 Mirror Polish Texture H13 P20Jyoti KaleNoch keine Bewertungen

- Generalitati Mold DesignDokument9 SeitenGeneralitati Mold DesignStefan VladNoch keine Bewertungen

- DFM CH 3Dokument44 SeitenDFM CH 3Trâp A NâtïøñNoch keine Bewertungen

- Metal Process Technology (Meng) : Rolling and Ring Rolling Design of Roll Passes in Shape RollingDokument35 SeitenMetal Process Technology (Meng) : Rolling and Ring Rolling Design of Roll Passes in Shape RollingRavichandran GNoch keine Bewertungen

- Segregation and Compositional Defects in CastingDokument14 SeitenSegregation and Compositional Defects in CastingRupchanda BarmanNoch keine Bewertungen

- Steps Follwed of Procedure of Making DieDokument38 SeitenSteps Follwed of Procedure of Making DieteekamNoch keine Bewertungen

- Misumi Press Die StandardDokument72 SeitenMisumi Press Die StandardthanhvutsmvnNoch keine Bewertungen

- ME 330 Manufacturing Processes Mechanical Assembly: Joining Methods (Cont.)Dokument23 SeitenME 330 Manufacturing Processes Mechanical Assembly: Joining Methods (Cont.)mhafizanNoch keine Bewertungen

- Metal Bending: Bending Is A Manufacturing Process That Produces A V-Shape, U-Shape, or ChannelDokument12 SeitenMetal Bending: Bending Is A Manufacturing Process That Produces A V-Shape, U-Shape, or ChannelMizero AimeNoch keine Bewertungen

- Design Guidelines For Components Die Cast in Creep-Resistant Magnesium Alloys MRI153M and MRI230D PDFDokument6 SeitenDesign Guidelines For Components Die Cast in Creep-Resistant Magnesium Alloys MRI153M and MRI230D PDFKmilo GiraldoNoch keine Bewertungen

- Design & Development of Multi-Evaporative Refrigeration SystemDokument4 SeitenDesign & Development of Multi-Evaporative Refrigeration SystemAnonymous izrFWiQNoch keine Bewertungen

- Moldflow PresentationDokument50 SeitenMoldflow PresentationpatrickNX9420Noch keine Bewertungen

- Deep Drawing Process PDFDokument34 SeitenDeep Drawing Process PDFCADCAM CAENoch keine Bewertungen

- Deep Drawing: Benefits and Industrial ApplicationsDokument3 SeitenDeep Drawing: Benefits and Industrial ApplicationsChandru NatarajanNoch keine Bewertungen

- BrassesDokument7 SeitenBrassesClaudia MmsNoch keine Bewertungen

- Deep Drawing Is One of The Most Crucial and Widely Used Practices of Metal Forming. It IsDokument1 SeiteDeep Drawing Is One of The Most Crucial and Widely Used Practices of Metal Forming. It IsgauravNoch keine Bewertungen

- Sheet Metal-Cup DrawingDokument25 SeitenSheet Metal-Cup DrawingCADTDD100% (1)

- Explosive Forming An OverviewDokument7 SeitenExplosive Forming An OverviewMazurchevici Andrei DănuţNoch keine Bewertungen

- Ug NX - Cad: Feature Modeling CommandsDokument6 SeitenUg NX - Cad: Feature Modeling CommandsakhilskhilsNoch keine Bewertungen

- How To Calculate The Torsional Stiffness of Rubber Shock MountsDokument4 SeitenHow To Calculate The Torsional Stiffness of Rubber Shock MountsspibluNoch keine Bewertungen

- ThesisDokument18 SeitenThesisTibebu MerideNoch keine Bewertungen

- Sheet Metal WorkingDokument23 SeitenSheet Metal WorkingSujit MishraNoch keine Bewertungen

- Design of Spoon Mold Using Flow Analysis and Higher End Design SoftwareDokument6 SeitenDesign of Spoon Mold Using Flow Analysis and Higher End Design SoftwareashishNoch keine Bewertungen

- CNC Machining Designing For SpeedDokument9 SeitenCNC Machining Designing For SpeedjaimeNoch keine Bewertungen

- Die and Punch AssemblyDokument14 SeitenDie and Punch AssemblyPiyal ChakrabortyNoch keine Bewertungen

- Fluid Flow Through A Piping SystemDokument144 SeitenFluid Flow Through A Piping Systemsushil.vgiNoch keine Bewertungen

- Continuity and Energy EquationsDokument53 SeitenContinuity and Energy Equationssushil.vgiNoch keine Bewertungen

- EMC-3003 Industrial Plants Maintenance LO # 1Dokument21 SeitenEMC-3003 Industrial Plants Maintenance LO # 1sushil.vgiNoch keine Bewertungen

- LO2 - Pressure and Its Measurement For An Incompressible FluidDokument43 SeitenLO2 - Pressure and Its Measurement For An Incompressible Fluidsushil.vgiNoch keine Bewertungen

- LO 4 Handout SLO1,2,3, and 4 All Suboutcome CompleteDokument38 SeitenLO 4 Handout SLO1,2,3, and 4 All Suboutcome Completesushil.vgiNoch keine Bewertungen

- EMC-3003 Industrial Plants Maintenance LO # 1Dokument135 SeitenEMC-3003 Industrial Plants Maintenance LO # 1sushil.vgiNoch keine Bewertungen

- Experiment Inventory: Exploring Charge With Scotch® TapeDokument3 SeitenExperiment Inventory: Exploring Charge With Scotch® Tapesushil.vgiNoch keine Bewertungen

- Faraday - 5 AugustDokument7 SeitenFaraday - 5 Augustsushil.vgiNoch keine Bewertungen

- LO 5 Handout Maintenace Store and CMMS ManagmentDokument14 SeitenLO 5 Handout Maintenace Store and CMMS Managmentsushil.vgiNoch keine Bewertungen

- LO 3 Handout Planning and Scheduling (Chapeter 6, 7)Dokument15 SeitenLO 3 Handout Planning and Scheduling (Chapeter 6, 7)sushil.vgiNoch keine Bewertungen

- Capacitance Cylindrical Capacitor StudentsDokument4 SeitenCapacitance Cylindrical Capacitor Studentssushil.vgiNoch keine Bewertungen

- VGI Aptitude Admission Test 2017: 2x 3 8 X + 4 3 8 x+12 3 2x 3 2x 3Dokument5 SeitenVGI Aptitude Admission Test 2017: 2x 3 8 X + 4 3 8 x+12 3 2x 3 2x 3sushil.vgiNoch keine Bewertungen

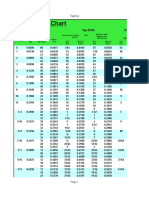

- GATE Toppers Marks Vs RankDokument60 SeitenGATE Toppers Marks Vs Ranksushil.vgiNoch keine Bewertungen

- Lab O2 Projectile Motion (Home Lab Instruction) : All Rights Reserved by Yunsheng QiuDokument15 SeitenLab O2 Projectile Motion (Home Lab Instruction) : All Rights Reserved by Yunsheng Qiusushil.vgiNoch keine Bewertungen

- Gate-2018 Test Series Strength of MaterialsDokument6 SeitenGate-2018 Test Series Strength of Materialssushil.vgiNoch keine Bewertungen

- Practice Problems On Air Conditioning SystemDokument1 SeitePractice Problems On Air Conditioning Systemsushil.vgiNoch keine Bewertungen

- Gate 2018 Test Series: Test No. - Strength of MaterialsDokument1 SeiteGate 2018 Test Series: Test No. - Strength of Materialssushil.vgiNoch keine Bewertungen

- Air RefrigerationDokument10 SeitenAir Refrigerationعبدالله عمرNoch keine Bewertungen

- Ruby On Rails 3 Cheat SheetDokument7 SeitenRuby On Rails 3 Cheat SheetJarosław MedwidNoch keine Bewertungen

- Introducing Small Basic-1 PDFDokument69 SeitenIntroducing Small Basic-1 PDFnilaNoch keine Bewertungen

- Grade 10 CH 6 Assertion Reason QuestionsDokument5 SeitenGrade 10 CH 6 Assertion Reason QuestionsVidhun 8ANoch keine Bewertungen

- Introduction To DatabasesDokument33 SeitenIntroduction To Databases米皮皮Noch keine Bewertungen

- HV Filter Carts 1Dokument2 SeitenHV Filter Carts 1paulpopNoch keine Bewertungen

- Rr410209 High Voltage EngineeringDokument7 SeitenRr410209 High Voltage EngineeringSrinivasa Rao GNoch keine Bewertungen

- ECE ExperimentDokument13 SeitenECE Experimentasm98090% (1)

- W.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)Dokument371 SeitenW.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)El equipo de Genesis ProjectNoch keine Bewertungen

- E5 - Geotextiles TDR - Rev00Dokument2 SeitenE5 - Geotextiles TDR - Rev00Mohd Radzi MustaffaNoch keine Bewertungen

- Math Formula SheetDokument8 SeitenMath Formula SheetHidayah TeacherNoch keine Bewertungen

- Experimental Techniques For Low Temperature Measurements PDFDokument2 SeitenExperimental Techniques For Low Temperature Measurements PDFVanessaNoch keine Bewertungen

- RWC 123 Manoj Prabhakar KaiwartDokument13 SeitenRWC 123 Manoj Prabhakar KaiwartManoj Prabhakar KaiwartNoch keine Bewertungen

- TOFD Dead Zone CalculatorDokument4 SeitenTOFD Dead Zone CalculatorWill SmithNoch keine Bewertungen

- Downloadble Science NotesDokument55 SeitenDownloadble Science NotesJeb PampliegaNoch keine Bewertungen

- Fluid Mech. 2Dokument32 SeitenFluid Mech. 2Leslie Owusu MensahNoch keine Bewertungen

- Basic Use of Datum Plane in Creo ParametricDokument8 SeitenBasic Use of Datum Plane in Creo ParametricKartik BhararaNoch keine Bewertungen

- Coding Assignment 18-WPS OfficeDokument9 SeitenCoding Assignment 18-WPS Officetamj tamjNoch keine Bewertungen

- Data Download CMM366A-4G V1.0 enDokument16 SeitenData Download CMM366A-4G V1.0 enSuramanNoch keine Bewertungen

- ML Observability Build Vs Buy Download Guide 1689038317Dokument31 SeitenML Observability Build Vs Buy Download Guide 1689038317rastrol7Noch keine Bewertungen

- PR100 BrochureDokument28 SeitenPR100 Brochuregus289Noch keine Bewertungen

- PC - Section 1.3 - Worksheet PDFDokument2 SeitenPC - Section 1.3 - Worksheet PDFAnabbNoch keine Bewertungen