Beruflich Dokumente

Kultur Dokumente

Design - CAD Models From Sketches

Hochgeladen von

Saurav SinghOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design - CAD Models From Sketches

Hochgeladen von

Saurav SinghCopyright:

Verfügbare Formate

41

Development of CAD models from sketches: a case study for automotive applications

R Vignesh, R Suganthan, and K Prakasan* Department of Production Engineering, PSG College of Technology, Peelamedu, Coimbatore, India The manuscript was received on 6 April 2006 and was accepted after revision for publication on 2 August 2006. DOI: 10.1243/09544070JAUTO331

Abstract: Today products are designed not only for their functional requirements but also for aesthetics. In the automotive industries, styling has become a major part of the design process with class-A surfaces. Class-A surfaces are freeform surfaces with a continuous curvature. The process of engineering any component or system begins by generating a concept that actually describes the product in terms of its form, function, and t. Concept sketches help the designers to arrive quickly and easily at a stage where a satisfactory design can be specied for detailed design. These concept sketches can be used for development of the digital concept design and analysis of the curves and surfaces. Software such as Alias exists and thus can be used with suitable hardware for sketching the concept of the car body on a computer screen. In this paper a systematic procedure is discussed for generating class-A surfaces from the images of concept sketches which are manually prepared on paper. These images are imported into the sketch tracer module of CATIA V5. A designer can use the image as the reference and produce a digital sketch by tracing the image using CATIA V5 software without adding any special hardware. Later, interrogation of these surfaces for improved aesthetics can be attempted. This method will be useful for the users of CATIA V5 to improve their design practices and skills. Keywords: concept sketches, clay modelling, class-A surface, reection lines, isophotes

1 INTRODUCTION Product styling is carried out to create visual attractiveness in products. Styling is widely accepted as an important way to add value to a product without changing its technical performance. As new product quality rankings converge, styling is emerging as a key dierentiator for consumers. The role of styling is to create fresh and exciting design concepts that are not just contemporary but trend setting as well. Styling enhances the visual appeal of the vehicles and at the same time develops innovative designs and components for customers. Today, not only are products designed considering the functionality but also special considerations are given to their aesthetics which can produce a desire in a persons mind to own that product. This is the

* Corresponding author: Department of Production Engineering, PSG College of Technology, Peelamedu, Coimbatore, Tamil Nadu, 641 004, India. email: prakasan_psg@redimail.com

reason for the evolution of class-A surfaces and their importance. Class-A surfaces are those aesthetic freeform surfaces that are visible to us and that have an optimal aesthetic shape and high surface quality. Restyling of existing products is frequently performed in the automotive industries, since engineers usually prefer the evolution of a product to a complete redesign. Customer feedback, client assistance suggestions, and market directives usually inuence the decision on redesign or restyling of a product. However, quite often product modications are less expensive than the development of a new product. A traditional car development process involves the development of many handmade rendering sketches in order to oer a vision of the models look. From these sketches, a few are selected and, by pasting the four views of a constrained drawing on the wall, which are made on a 1 : 10 scale, the scaled-down clay model is developed. One scaled-down clay model is nalized and the model is scanned using three-dimensional scanners. Then a 1 : 1 clay model

Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

JAUTO331 IMechE 2007

42

R Vignesh, R Suganthan, and K Prakasan

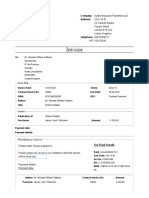

of the nalized sketch is developed. In this phase all the changes require much time. A comparison between concept development and styling by the conventional method and the approach based on computer aided design (CAD) is provided in Fig. 1. The objective of this work is to present a case in which the images of manually prepared conceptual sketches are used in CATIA V5 software to trace the curves for developing CAD models and surface interrogation. An attempt is also made to compare a surface that is not checked for curvature continuity and a surface checked for curvature continuity for their aesthetics and appearance. The approach used here can reveal the discontinuity in the surface which is dicult to notice otherwise although both are created in the same software. The procedure adopted here can be practised by the users of CATIA V5 to improve their innovations. A sketch on paper by an artist is made use of in this procedure. This appears

to be a novel approach. From the experience of the present authors it was found that awareness of the capability of CATIA V5 for surface interrogation is limited among users.

2 LITERATURE REVIEW To determine the industry practices and surface interrogation techniques for styling, a literature review was carried out and the relevant observations are presented here. Tovey [1] discussed sketching and its role in the concept design of automotives. Automotive designers use sketches to support the styling activity through its two phases of concept design and design development before handing over to the downstream development processes. The importance of computer aided styling over CAD is highlighted. Tovey [2] described the work on sketch mapping as a usable tool and contrasted it with the more conventional direct modelling approach which is seen to have limitations. He also gave a brief description of work in progress on deriving forms directly from sketches. The concept design methodology was also discussed. Suner et al. [3] discussed the use of reection lines and specular highlights for the quality control of car body surfaces. A prototype with a highly reective surface was built and viewed in a cubing room, which has many parallel arranged lights. The reections of the lights are a good measure for surface quality, i.e. for detecting surface curvature discontinuities and for discussing the character of the shape. Hagen et al. [4] presented a detailed survey of surface interrogation methods. Orthotomics are used for convexity tests. Focal surfaces, a new tool for analysing freeform curves and surfaces, are special line congruences that are used to analyse the quality of the surface before sending the data to CNC machines. Hahmann [5] gave a general method for surface interrogation which includes reection lines, isophotes, curvature plots, highlight lines, and isolines. These tools are mainly used in computer graphics and found application in analysing freeform surfaces in CAD. Theisel [6] showed that isophotes and reection lines are dierent tools for surface interrogation. Isophotes were used to identify curvature discontinuities between surfaces, and reection lines were used to measure the quality of the surface.

JAUTO331 IMechE 2007

Fig. 1 Concept development and styling: (a) conventional method and (b) CAD-based approach

Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

Development of CAD models from sketches

43

Monacelli [7] discussed the virtual reality (VR) applications for reducing the time and cost involved in the vehicle development process. VR can help to change the initial concept sketching from a manual method to a digital environment. VR has applications in styling and the designer can visualize the digital model in a better way. Barone [8] explained the need for renovating the traditional styling process to a CAD-based styling process and addressed the diculties faced during the traditional styling process.

3 STYLING OF A CAR BODY A study was carried out on the styling of automotive exteriors because the rst impression that a customer has of a car is the design of the car body. To be competitive in the market, not only is it necessary to have a good design but also it is crucial that the stylists guidelines will be accurately implemented when building the car. The disadvantages with the traditional car development process are the time taken to make changes and the inability of the clay model to create variants of the new product. As the concept model can be seen only at the nal stage of the design process, making changes to the concept model in the nal stages is dicult. The methodology adopted and the step-by-step procedure of the CAD-based development process for the car body using CATIA V5 are explained in Fig. 2. 3.1 Importing concept sketches The input for concept development is sketches. Concept sketches help the designers to arrive quickly and easily at a stage where a satisfactory design can be specied for development of detailed design. The sketches are imported into the sketch tracer module of CATIA V5. They are aligned such that the front view of the car will lie on the front plane. Similarly all the views of the car are aligned to lie on the corresponding plane. The sketches will form a bounding box and the model will lie within the bounding box. Figure 3 shows the aligned concept sketches imported into CATIA V5 using the images (scanned) of manually prepared concept sketches.

Fig. 2 Methodology for CAD-based concept development and styling

Fig. 3 Concept sketches imported into CATIA V5

JAUTO331 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

44

R Vignesh, R Suganthan, and K Prakasan

3.2 Tracing and translating curves Two sketches that will best represent the curve to be generated are selected and curves are traced above the sketch. Both curves will lie on the corresponding plane of sketch. To generate a single curve from the curves traced, an intersection technique is used; the curves traced are extruded and intersected so that the resulting curve will be the required curve for surface generation. If all three sketches represent a curve, then points are plotted in one view and with the other two sketches as references the points are translated such that the points will appear to lie on all three sketches.

The generated sketches are mirrored to generate a group of curves as shown in Fig. 4, which are suitable for generating patches. 3.3 Curve interrogation Good curves will result in good surfaces. Therefore, before generating surfaces the curves are analysed for their quality. Porcupine curvature analysis in CATIA V5 checks for a smooth variation in curvature (plots) throughout the curve. If the curvature variation is smooth, then the curves will result in smooth surfaces. If it is not smooth, then the control points representing the curves are translated so that a smooth variation in curvature is obtained. Figure 5

Fig. 4 Curves for patch generation

Fig. 5 Irregular variations in curvature

Proc. IMechE Vol. 221 Part D: J. Automobile Engineering JAUTO331 IMechE 2007

Development of CAD models from sketches

45

Fig. 6 Smooth variations in curvature

represents an irregular variation in curvature and Fig. 6 shows a smooth variation in curvature. The curvature comb plot will show variation in the magnitude of the radius of curvature. When the magni-

tude of the spikes is small, this indicates a at region on the curve. The magnitude must vary smoothly, or the curve will have sudden peaks and valleys. This is also useful in analysing the continuity between the curves. For curvature continuity it is necessary that there is no step in the curvature comb.

3.4 Generating surfaces and variants Surfaces are generated from the curves as patches. Figure 7 shows the concept model generated in CATIA V5. The surfaces representing a particular component in a car (e.g. the hood and the top are separate components) are placed in separate open bodies because of the ease in restyling. Figures 8 and 9 show some of the variants generated during the present study.

Fig. 7 Concept model

Fig. 8 Variant: glass top

JAUTO331 IMechE 2007

Fig. 9 Variant: convertible top

Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

46

R Vignesh, R Suganthan, and K Prakasan

3.5 Surface interrogation Surfaces are interrogated for class-A quality. Isophotes and reection lines are the most commonly used tools for surface interrogation. Isophotes are used to identify the discontinuity between surfaces. They highlight the behaviour of the form or shape of a surface when light reects from the surface. This reection of light gives the user an understanding about the curvature discontinuity. This reection should be natural and streamlined and should have uniformity. It is used to identify curvature discontinuities and to locate the dents in surfaces. Curvature discontinuities are represented by discontinuous highlight plots. Figure 10 shows the isophote plot of one of the models. Dents are represented by convergence of the highlight plot at the point of dent. Figure 11 shows the isophote plot on a dent on the surface. Reection lines are used to measure the quality of surfaces. It is the reection of a family of parallel lines on the light plane on the surface. Figure 12 shows the reection line plot on the car surface. 3.6 Rendering Rendering of the models is carred out to improve the visualization aspects of the model. Real-life rendering is mainly performed to make the customers appreciate the look of the nal models. A VR environment is used for visualization and real-life rendering. Figure 13 shows the rendered model generated in CATIA V5.

Fig. 10 Isophote plot

Fig. 11 Isophote plot on a dent surface

Fig. 12 Reection line plot on the surface

Proc. IMechE Vol. 221 Part D: J. Automobile Engineering JAUTO331 IMechE 2007

Development of CAD models from sketches

47

REFERENCES

1 Tovey, M. J., Newman, R. M., and Porter, S. Sketching, concept development and automotive design. Des. Stud., 2003, 24, 135153. 2 Tovey, M. J. Concept design CAD for the automotive Industry. J. Engng Des., 2002, 13, 513. 3 Suner, G., Greiner, G., and Augustiniack, S. Interactive examination of surface quality on car bodies. Computer Aided Des., 2004, 36, 425436. 4 Hagen, H., Hahmann, S., Schreiber, T., Nakajima, Y., Wordenweber, B., and Hollemann-Grundstedt, P. Surface interrogation algorithms. IEEE Computer Graphics Applic., 1992, 12(5), 5360. 5 Hahmann, S. Visualization techniques for surface analysis. In Advanced visualization techniques (Ed. C. Bajaj), 1999, pp. 126 (John Wiley, New York). 6 Theisel, H. Are isophotes and reection lines the same? Computer Aided Geometric Des., 2001, 18, 711722. 7 Monacelli, G. VR applications for reducing time and cost of vehicle development process. In Proceedings of the Eighth International Conference ATA on Vehicle Architectures: Products, Processes and Future Developments, Florence, Italy, May 2003 (Eurographics Association, Switzerland). 8 Barone, M. The process improvement impact on the styling workow of an industrial design company. In Proceedings of the EUROGRAPHICS Workshop on Sketch-Based Interfaces and Modeling, 2004.

Fig. 13 Rendered model

4 CONCLUSIONS This paper tries to provide a systematic approach in developing styles from the images of the manually prepared concept sketches made by an artist with the aid of CATIA V5 software. It also interrogated two surfaces specically to reveal the discontinuities that are present on a surface. If curvature continuity is not satised while designing a surface conventionally, the surface may have discontinuities and aesthetics will have to be improved. This approach is useful for any product development that needs class-A surfacing. The users of CATIA V5 can implement the same technique in their practice without adding any costly hardware.

JAUTO331 IMechE 2007

Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Baby Layette SetDokument6 SeitenBaby Layette SetvictoriaNoch keine Bewertungen

- Orizon Swordsman Newbie GuideDokument12 SeitenOrizon Swordsman Newbie GuideGigi BecaliNoch keine Bewertungen

- Succeed in English Grammar - Vocabulary 2Dokument1 SeiteSucceed in English Grammar - Vocabulary 2avegaplata1Noch keine Bewertungen

- El Marketing Mix: Estrategia y AplicacionesDokument40 SeitenEl Marketing Mix: Estrategia y AplicacionesNayeli ChoqueNoch keine Bewertungen

- List of Best-Selling Fiction AuthorsDokument5 SeitenList of Best-Selling Fiction AuthorsChenthil KumarNoch keine Bewertungen

- Everyday-Dialogues Sample ESL-Library PDFDokument9 SeitenEveryday-Dialogues Sample ESL-Library PDFRubiel MuñozNoch keine Bewertungen

- Carbothane 134 HB PDSDokument2 SeitenCarbothane 134 HB PDSSamNoch keine Bewertungen

- MFFFreview Mjmrev005Dokument19 SeitenMFFFreview Mjmrev005mohrinerNoch keine Bewertungen

- Holy Mass PDFDokument62 SeitenHoly Mass PDFChelsea RusianaNoch keine Bewertungen

- Landscape Architecture Johor: Services/JHR/Johor-Bahru - Johor BahruDokument10 SeitenLandscape Architecture Johor: Services/JHR/Johor-Bahru - Johor BahrushunmugathasonNoch keine Bewertungen

- Booklet PDFDokument6 SeitenBooklet PDFJossNoch keine Bewertungen

- Pope Joan, by Donna Woolfolk Cross - ExcerptDokument23 SeitenPope Joan, by Donna Woolfolk Cross - ExcerptCrown Publishing Group6% (796)

- (Napoleon Hill) A Lei Do TriunfoDokument5 Seiten(Napoleon Hill) A Lei Do Triunfoanon-86877278% (9)

- Elements of Visual ArtsDokument34 SeitenElements of Visual ArtsGina Sy100% (3)

- Disrupt Yourself Summary: 1-Sentence-Summary: Disrupt Yourself Explains How You Can Harness The Ever-Accelerating PowerDokument4 SeitenDisrupt Yourself Summary: 1-Sentence-Summary: Disrupt Yourself Explains How You Can Harness The Ever-Accelerating PowerHari BabooNoch keine Bewertungen

- Promo Choral High SCH Spec 2014Dokument32 SeitenPromo Choral High SCH Spec 2014Eudo Torres0% (1)

- Hey Soul SisterDokument3 SeitenHey Soul SisterEddieNoch keine Bewertungen

- Marina Bay Sands SingaporeDokument37 SeitenMarina Bay Sands SingaporeGhina Dzakirah Nasution100% (1)

- Sri Sri QuotesDokument28 SeitenSri Sri QuotesAc RaviNoch keine Bewertungen

- Fanny CrosbyDokument15 SeitenFanny CrosbyAdeniyi Adedolapo OLanrewajuNoch keine Bewertungen

- GRAPHIC ORGANIZER of Literature ElementsDokument4 SeitenGRAPHIC ORGANIZER of Literature ElementsJose Abraham Hadi100% (1)

- Hiset Essay WritingDokument8 SeitenHiset Essay WritingKingsNoch keine Bewertungen

- U3 F3970818-ModelDokument1 SeiteU3 F3970818-ModelSobin ThomasNoch keine Bewertungen

- Imp Questions of Ap EamcetDokument8 SeitenImp Questions of Ap EamcetSyed HashirNoch keine Bewertungen

- Henry NeuhausDokument361 SeitenHenry Neuhausmavik100% (3)

- UnpaidDokument2 SeitenUnpaidMike PattisonNoch keine Bewertungen

- Certificado Ul Cuerdas Sterling Rope - 800200Dokument5 SeitenCertificado Ul Cuerdas Sterling Rope - 800200ARISSTANoch keine Bewertungen

- Confessions of My 17Dokument1 SeiteConfessions of My 17Jason BuanNoch keine Bewertungen

- Iteen: Test YourselfDokument32 SeitenIteen: Test YourselfLiliana SilvaNoch keine Bewertungen

- YB1934Dokument404 SeitenYB1934Brendan Paul ValiantNoch keine Bewertungen