Beruflich Dokumente

Kultur Dokumente

Starting Systems for Gas Turbine Engines

Hochgeladen von

Cameron KingOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Starting Systems for Gas Turbine Engines

Hochgeladen von

Cameron KingCopyright:

Verfügbare Formate

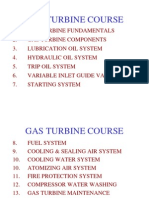

The Gas Turbine Engine: Starting Systems

Although the Gas Turbine Engine is one of the most complicated machines ever engineered by man, the concept is actually fairly simple. Air is drawn into a compressor through an air intake, fuel is burned in a combustion chamber, the hot gas drives the turbine and the exhaust leaves the engine through a nozzle. The turbine, which is directly coupled to the compressor, provides the power to compress the air; the gas leaving the nozzle provides the thrust to propel the aircraft. The Jet Engine works in a self-sustaining cycle; to stop it, the fuel supply is simply cut. Interestingly, when the engine starts, there is a minimal rotational speed to achieve so that the turbine can power the compressor. The starting procedure is basically always the same: a source of power provides the high torque needed to rotate the compressor and the turbine up to a speed at which adequate air passes into the combustion system. There are several types of starting systems and they are used in accordance with engine and aircraft requirements.

The Starting Cycle.

Starting Procedure (extract from a three crew B727)

Starting Methods

Electric: This method consists in driving the engine with a direct current (D.C.) electric motor. It is coupled to the engine through a reduction gear and ratchet mechanism, or clutch, which automatically disengages after the engine has reached the self-sustaining speed.

The electrical supply may be of a high or low voltage and is passed through a system of relays and resistances to allow the full voltage to be progressively built up as the starter gains speed.

Cartridge: This starting system is usually used on military engines since it provides a quick independent method of starting. The starter motor is basically a small impulse-type turbine that is driven by high velocity gases from a burning cartridge. The power output of the turbine is passed through a reduction gear and an automatic disconnect mechanism to rotate the engine.

Iso-propyl-nitrate: This starting system provides a high power output and gives rapid starting characteristics. It is the liquid fuel version of the Cartridge one. In this instance, high-pressure gases, resulting from the combustion of iso-propylnitrate, rotate the turbine. The fuel is sprayed into a combustion chamber, which forms part of the starter, where it is electrically ignited by a high-energy ignition system. A pump supplies the fuel to the combustion chamber from a storage tank and an air pump scavenges the starter combustion chamber of fumes before each start.

Air: This starting system is light, simple and economical to operate so it is used on most commercial and some military jet engines. Like the other systems, the air starter drives a turbine, which transmits power to the engine through a reduction gear and a clutch. But, unlike the other systems, the energy used by the starter is external: indeed the turbine is rotated by air taken from a ground supply, an auxiliary power unit (A.P.U.) or as cross-feed from a running engine. When an external supply of air is not available, a combustor starter is fitted to the engine to provide the air required by the air starter. This unit has a small combustion chamber into which high pressure air, from an aircraft-mounted storage bottle, and fuel, from the engine fuel system, are introduced. The fuel/air mixture is ignited in the combustion chamber and the resultant gas is directed onto the turbine of the air starter. However, some turbo-jet engines are not fitted with starter motors at all, but direct the air obtained from an external source, or from an engine that is running,

Gas turbine: This starter consists of a small, compact gas turbine engine, usually featuring a turbine-driven centrifugal compressor, a reverse flow combustion system and a mechanically independent free-power turbine which drives the engine. To initiate this starter, it is fitted with its own starter electric motor.

These are the most used methods of starting Gas Turbine Engines. Each has its own merits and is appropriate to a particular engine and aircraft in a particular situation.

Das könnte Ihnen auch gefallen

- Function: Gas Turbine Description of Components Compressor Bearing HousingDokument23 SeitenFunction: Gas Turbine Description of Components Compressor Bearing HousingMohammad Jahangir AlamNoch keine Bewertungen

- Impulse and Reaction Blading of Gas TurbinesDokument4 SeitenImpulse and Reaction Blading of Gas Turbinesapi-271354682100% (3)

- Basic GT EngineDokument22 SeitenBasic GT EngineabuhurairamunirNoch keine Bewertungen

- Gas Turbine Performance by Rainer KurzDokument16 SeitenGas Turbine Performance by Rainer KurzSulzerRuudNoch keine Bewertungen

- EPS GT Base PrinciplesDokument32 SeitenEPS GT Base PrinciplescdbeardsallNoch keine Bewertungen

- Axial Flow CompressorDokument50 SeitenAxial Flow CompressorSunil Panwar100% (1)

- Design of Turbine Blade: Chapter 1 IntroductionDokument15 SeitenDesign of Turbine Blade: Chapter 1 IntroductionKailash Chauhan100% (1)

- 1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesDokument8 Seiten1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesArgenomSaubiNoch keine Bewertungen

- What Is Turbine?: TypesDokument9 SeitenWhat Is Turbine?: TypesNimra sattar100% (1)

- Pengetahuan Dasar Turbine Gas Tipe Taurus 60 Solar TurbineDokument27 SeitenPengetahuan Dasar Turbine Gas Tipe Taurus 60 Solar TurbineNizar ZulmiNoch keine Bewertungen

- Gas Turbine NotesDokument21 SeitenGas Turbine NotesJohn BlackburnNoch keine Bewertungen

- V005t15a001 88 GT 150Dokument13 SeitenV005t15a001 88 GT 150Antonio CilindroNoch keine Bewertungen

- Jet PropulsionDokument40 SeitenJet PropulsionDileep Kumar Manjhi100% (1)

- Gas Turbine SpecificationDokument94 SeitenGas Turbine SpecificationAbRoxNoch keine Bewertungen

- SGT-600 GT PowerGen ENDokument4 SeitenSGT-600 GT PowerGen ENBehnamayoubzadehNoch keine Bewertungen

- GEA34130 AeroderivativeGT - Whitepaper - R6Dokument10 SeitenGEA34130 AeroderivativeGT - Whitepaper - R6Cecilia CabreraNoch keine Bewertungen

- GE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuideDokument35 SeitenGE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuidesppramNoch keine Bewertungen

- Gas Turbine Introduction and Auxiliary SystemsDokument80 SeitenGas Turbine Introduction and Auxiliary SystemsYahya Faiez WaqqadNoch keine Bewertungen

- Gas Engine FundamentalsDokument13 SeitenGas Engine Fundamentalsherdin56Noch keine Bewertungen

- Gas Turbine Compressor WashingDokument8 SeitenGas Turbine Compressor Washingwolf_ns100% (1)

- Compressor WashingDokument5 SeitenCompressor Washingsamil68Noch keine Bewertungen

- Single Multi Shaft TurbinesDokument1 SeiteSingle Multi Shaft TurbinesmsshahenterNoch keine Bewertungen

- Gas TurbineDokument6 SeitenGas TurbineJusy BinguraNoch keine Bewertungen

- Steam Turbine PDFDokument2 SeitenSteam Turbine PDFeselcosacNoch keine Bewertungen

- GEA18457ADokument20 SeitenGEA18457AEdGouramiNoch keine Bewertungen

- Gas Turbine SlideDokument212 SeitenGas Turbine SlideMuhd RizzuwanNoch keine Bewertungen

- Gas TurbineDokument5 SeitenGas TurbineAbdul BasitNoch keine Bewertungen

- Sealing in TurbomachineryDokument62 SeitenSealing in Turbomachineryjparmar100% (1)

- A Plant Supplier and Market Overview SIEMENSDokument33 SeitenA Plant Supplier and Market Overview SIEMENSKenneth Castelo GilerNoch keine Bewertungen

- Omml 0495 06 Loadgear ADokument532 SeitenOmml 0495 06 Loadgear APhong leNoch keine Bewertungen

- Poster SGT-2000E Series - Nov16Dokument1 SeitePoster SGT-2000E Series - Nov16nasr305Noch keine Bewertungen

- GE Frame 9E Turbine Stator and Rotor ConstructionDokument14 SeitenGE Frame 9E Turbine Stator and Rotor ConstructionArashNoch keine Bewertungen

- Multi-Stage Steam Turbines: Proven Reliability and EfficiencyDokument8 SeitenMulti-Stage Steam Turbines: Proven Reliability and EfficiencyAlfredo Velasquez100% (1)

- TSL Fr5001 1st Stage BucketsDokument1 SeiteTSL Fr5001 1st Stage BucketsthanarajtnbNoch keine Bewertungen

- Speedtronic Mark VI Turbine Control System: GE Power SystemsDokument22 SeitenSpeedtronic Mark VI Turbine Control System: GE Power SystemsAli AlhukkeyNoch keine Bewertungen

- MHPS Jac GTDokument7 SeitenMHPS Jac GTkp pkNoch keine Bewertungen

- SGT-A05 (Industrial 501) Service Solutions: Engineered Solutions To Enhance Engine OperabilityDokument16 SeitenSGT-A05 (Industrial 501) Service Solutions: Engineered Solutions To Enhance Engine OperabilityEduleofNoch keine Bewertungen

- Gas Turbine Performance: by Rainer KurzDokument16 SeitenGas Turbine Performance: by Rainer Kurzthryee100% (1)

- Gasturbine-Maintenance and OperationDokument117 SeitenGasturbine-Maintenance and OperationervikranthNoch keine Bewertungen

- Borsecope Inspection PDFDokument9 SeitenBorsecope Inspection PDFahmedNoch keine Bewertungen

- Report Gas TurbineDokument17 SeitenReport Gas TurbineBookMaggotNoch keine Bewertungen

- GT24/GT26 Operation Training Module: Jacking Oil SystemDokument15 SeitenGT24/GT26 Operation Training Module: Jacking Oil SystemAli HegaigNoch keine Bewertungen

- Turbine Blades: Terry Andersen Nathan StastnyDokument21 SeitenTurbine Blades: Terry Andersen Nathan StastnyIrteza HossainNoch keine Bewertungen

- Gas Turbine Terminology.Dokument7 SeitenGas Turbine Terminology.chahrazed bngNoch keine Bewertungen

- Gas Turbine BookDokument246 SeitenGas Turbine Bookmpus0% (1)

- LM2500 16th Stage Bleed Manifold KitDokument2 SeitenLM2500 16th Stage Bleed Manifold KitDenis JimenezNoch keine Bewertungen

- Gas Turbine CourseDokument54 SeitenGas Turbine CourseMgn San100% (1)

- Gas Turbine Disc Stress CalculationsDokument3 SeitenGas Turbine Disc Stress CalculationsKishore MylavarapuNoch keine Bewertungen

- Advantages of Aeroderivatives IAGT 206 - Final - PaperDokument15 SeitenAdvantages of Aeroderivatives IAGT 206 - Final - PapermvanzijpNoch keine Bewertungen

- Microturbines Generate Power from WWTP BiogasDokument2 SeitenMicroturbines Generate Power from WWTP BiogasKwang Je LeeNoch keine Bewertungen

- 7FA Upgrade Combustion HardwareDokument2 Seiten7FA Upgrade Combustion Hardwaresauerbach1Noch keine Bewertungen

- BSIDokument112 SeitenBSIaliNoch keine Bewertungen

- Turbine & Fan Blades from Jet EnginesDokument7 SeitenTurbine & Fan Blades from Jet EnginescanilkumarrichithaNoch keine Bewertungen

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionVon EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionNoch keine Bewertungen

- Electric StarterDokument3 SeitenElectric StarterDio BrandoNoch keine Bewertungen

- Types of Jet Engines: 6.1 TurbojetDokument20 SeitenTypes of Jet Engines: 6.1 Turbojetapi-376777497Noch keine Bewertungen

- Super ChargingDokument23 SeitenSuper Charginghirenbabaji100% (2)

- Aircraft Systems: PowerplantDokument4 SeitenAircraft Systems: PowerplantHanz EspirituNoch keine Bewertungen

- Super ChargingDokument24 SeitenSuper ChargingGagan KaushikNoch keine Bewertungen

- Working Principle Gas Turbine and Combined Cycles, Auxiliary SystemsDokument27 SeitenWorking Principle Gas Turbine and Combined Cycles, Auxiliary SystemsRey Danielle Navea100% (2)

- Border Security Using Wireless Integrated Network Sensors (WINS)Dokument18 SeitenBorder Security Using Wireless Integrated Network Sensors (WINS)Pradeep CheekatlaNoch keine Bewertungen

- SVCE Seminar Report Format (FINAL)Dokument6 SeitenSVCE Seminar Report Format (FINAL)Vinod KumarNoch keine Bewertungen

- What Is Canal LiningDokument6 SeitenWhat Is Canal LiningFiaz GujjarNoch keine Bewertungen

- Faculty of Engineering and Computing Sciences: Annexure-IDokument2 SeitenFaculty of Engineering and Computing Sciences: Annexure-IAkshay MehtaNoch keine Bewertungen

- Pending Exception RDokument17 SeitenPending Exception Rsyafri maryonoNoch keine Bewertungen

- Zeeman Effect ExplainedDokument10 SeitenZeeman Effect ExplainedSayyed SalmanNoch keine Bewertungen

- Materi Welding Defect IIDokument64 SeitenMateri Welding Defect IIsmartz inspectionNoch keine Bewertungen

- Check List For Overall Piping Plot PlanDokument3 SeitenCheck List For Overall Piping Plot PlankamleshyadavmoneyNoch keine Bewertungen

- M4 4 Synthetic Surface Modeling Bezier and Bspline PatchesDokument40 SeitenM4 4 Synthetic Surface Modeling Bezier and Bspline PatchesNANDULA GOUTHAM SAINoch keine Bewertungen

- AS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingDokument3 SeitenAS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingThylaneNoch keine Bewertungen

- Experiment No 02Dokument5 SeitenExperiment No 02Farhan AliNoch keine Bewertungen

- Axial Piston Pump Series PV: Variable DisplacementDokument32 SeitenAxial Piston Pump Series PV: Variable DisplacementGyanaranjan NayakNoch keine Bewertungen

- SOP's For All Digital Marketing ActivitesDokument3 SeitenSOP's For All Digital Marketing ActivitesSavijeet Singh50% (2)

- Physics Investigatory Project Class 12 CbseDokument20 SeitenPhysics Investigatory Project Class 12 Cbsesyed50% (6)

- Basic Engineering Correlation Calculus v3 001Dokument3 SeitenBasic Engineering Correlation Calculus v3 001Ska doosh100% (1)

- CS610 Final Term Past Papers Mega FileDokument35 SeitenCS610 Final Term Past Papers Mega Filehowtoplaygames38Noch keine Bewertungen

- GH Chap 78 - Insulin, Glucagon and DMDokument16 SeitenGH Chap 78 - Insulin, Glucagon and DMShellz2428Noch keine Bewertungen

- PI ControllerDokument5 SeitenPI Controllerdanuega1Noch keine Bewertungen

- A Greener, Biocatalytic Benzoin Synthesis: Kenyon College - CHEM 234 - Organic Chemistry Lab IIDokument2 SeitenA Greener, Biocatalytic Benzoin Synthesis: Kenyon College - CHEM 234 - Organic Chemistry Lab IINicalyn BolanteNoch keine Bewertungen

- IGCSE Chemistry TEST YOUR SELF CHAPTER 4Dokument12 SeitenIGCSE Chemistry TEST YOUR SELF CHAPTER 4Nguyễn Việt Huy RoyNoch keine Bewertungen

- B483B483M 13e1Dokument10 SeitenB483B483M 13e1Mohamad ZandiNoch keine Bewertungen

- KUKA Sim 30 Installation enDokument49 SeitenKUKA Sim 30 Installation enRégis Naydo0% (1)

- PLC Omron BasicDokument19 SeitenPLC Omron BasicnorbipmmNoch keine Bewertungen

- Clients Class Workbook v5.1 CBTDokument192 SeitenClients Class Workbook v5.1 CBTmich0pNoch keine Bewertungen

- 93C66 Microwire EepromDokument13 Seiten93C66 Microwire EepromadrianramonNoch keine Bewertungen

- MSC Thesis Final Version Stephan de HoopDokument92 SeitenMSC Thesis Final Version Stephan de HoopSanjay singhNoch keine Bewertungen

- (Altium Tutorial) PCB Symbol Naming ConventionDokument7 Seiten(Altium Tutorial) PCB Symbol Naming ConventionDefne AktemizNoch keine Bewertungen

- Philippine Electronics Code - Volume 1Dokument28 SeitenPhilippine Electronics Code - Volume 1Ishimaru Thor100% (1)

- Astm-e855 Изгиб МеталлаDokument8 SeitenAstm-e855 Изгиб МеталлаАлесь БуяковNoch keine Bewertungen

- Stator Generator EolianDokument40 SeitenStator Generator EolianCatalin BordeiNoch keine Bewertungen