Beruflich Dokumente

Kultur Dokumente

PT NDT Procedure

Hochgeladen von

Mohamed AbubackerOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PT NDT Procedure

Hochgeladen von

Mohamed AbubackerCopyright:

Verfügbare Formate

Owner: KPIC

Costumer: Namvaran

Stack-4201

namvaran Consulting Engineers

Managers

Location: Kermanshah- Iran

Document No.: SEC-PJ045-ST-IFP-0008-1

K.P.I.C.

SEC-Project No.: PJ045

Liquid Penetrant test procedure

Purchaser & Owner:

Purchaser review and comment shall not be assumed to indicate either responsibility or liability f or accuracy and completenes of this document or to alter any contractual terms and conditions. Item Numbers: S-4201 Purchasers Disposition No Comments Comments as Noted Rejected

Date

Name

Initial

SDRL Code A 60

Purchase Order No. I-41D1-B213-01

Document No.

Rev.

SEC-PJ045-ST-IFP-0008-1 02

02 01 Rev.

02.08.2004 20.06.2004 Issue Date

COMMENT AS NOTE ISSUED FOR COMMENT

DESCRIPTION

M.Z H.H

PRD. BY

M.Z M.Z

CHKD. BY

M.S.KH M.S.KH

APPR. BY

DISCIPLINE

Quality Assurance System P.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 1 of 4

Contents 1- Procedure to be used 2- Technique 3- Per-examination cleaning & Drying 4- Liquid Penetrant Application 5- Method of Removing excess penetrant 6- Developer Application 7- Evaluation of L.P. Examination 8- Post Cleaning 9- Personnel Qualification 10- Acceptance Standard 11- Attachment (Examination Report)

Quality Assurance System P.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 1 of 4

Liquid Penetrant Examination Procedure

1- Procedure to be used for Examination of beveling of parts shop header welds. Reference standard: ASME V Div .1 Article1 & 6 latest version ASME VIII Div.1 (Edition 2001) Appendix 8 latest version 2- Technique: Color contrast penetrant, using solvent removable penetrant. 3- Per-Examination Cleaning & Drying: The surface to be examined shall be clean & free of grease, flux spatter, rust oil, that might interfere with the penetration of liquid. Also the surface must be dried by proper method such as heating or using clean clothes in case of moisture or wet surface. The proper solvent for degreasing is Magnaflux-SKC-S or equivalent. 4- Liquid Penetrant Application Type of dye penetrant: Visible penetrant examination method. (Magnaflux- Al06C or equivalent.) Application: By thoroughly and uniformly spraying on the part to be examined penetration time: The minimum penetration time shall be as recommended table T-672 in ASME sec.v , Article 6 or as qualified by demonstration for specific application Temperature of surface: 10-52C 5- Method of Removing Excess Penetrant: Removing will be perform by special solvent and clean clothes. (MagnafluxSKC-S or equivalent.) Solvent shall not be spray directly to the weld. 6- Developer Application: The developer shall be applied as soon as possible after PENETRANT removal. Type of developer: (Mangnaflux-SKD-S2 or equivalent) Application: by spraying 7- Evaluation of L.P. Examination: Interpretation shall be done after 5 minutes of applying the developer and not over 15 minutes. All relevant indications shall be recorded and evaluated as per ASME sec. VIII Div. 1 appendix 8, Repair shall preformed under supervision of inspector. Attached form will be used for examination report. 8- Post Cleaning: After evaluation of L.P. examination the remaining material to be removed by proper solvent or water and clean clothes.

Quality Assurance System P.T. Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 1 of 4

9- Personal Qualification: Liquid Penetrant examination will be performed and result will be evaluated by technicians qualified and certified as level II for dye PENETRANT method. Personnel shall be qualified in accordance to SNT-TC-1A of American society for Non-Destructive testing, or trained and examined personnel. 10- Acceptance Standard: The acceptance standard for above mentioned method will be according to ASME VIII Div.1 appendix 8, or water and lean clothes. 11- Attachment For issuance of examination report.

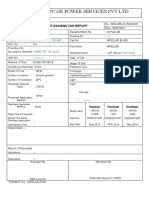

Quality Assurance System P.T. Procedure

Plate Applicable Code & Procedure Material Surgace Preparation Type Penetrant Application Temperature Grinding Color Contrast Brushing C Water - Washable Penetrates Removal Post - Emulsifying Penetrates Solvent - Removable Penetrates Item No. Joint No. Defect Type Dimension (mm) Evaluation A R Remove A R Project No.:

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 1 of 4

Stage of Examination ASME V Prepared Edge As Welded Machining Fluorescent Spraying Penetrant Time Minutes Dry Developer Developing Wet Developer Recharged Yes No Fin - exam A R After P.W.H. After Hydro. Test Others Others

Judgment Inspector Signature

Satisfactory Operator AAC

Unsatisfactory CLIENT

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- NDTDokument38 SeitenNDTNishant B MayekarNoch keine Bewertungen

- MEENA Internation NDT TrainingDokument45 SeitenMEENA Internation NDT Trainingahmzahid100% (1)

- Helium Leak Testing DubaiDokument32 SeitenHelium Leak Testing DubaiAbhijitNoch keine Bewertungen

- PT ReportDokument49 SeitenPT ReportRajesh Owaiyar100% (1)

- Experienced NDT engineer CVDokument6 SeitenExperienced NDT engineer CVTrung Tinh HoNoch keine Bewertungen

- Nde ProceduresDokument66 SeitenNde Proceduressoumaya yahyaouiNoch keine Bewertungen

- VISUAL TESTING PROCEDURE FOR WELDDokument4 SeitenVISUAL TESTING PROCEDURE FOR WELDCoralSun CravensickNoch keine Bewertungen

- 12 MT ProcedureDokument17 Seiten12 MT ProcedureThân KhaNoch keine Bewertungen

- Scan Plan (PAUT) For Taper Joints and K WeldsDokument4 SeitenScan Plan (PAUT) For Taper Joints and K WeldsRamakrishnan AmbiSubbiahNoch keine Bewertungen

- Visible Penetrant Examination Using The Water-Washable ProcessDokument6 SeitenVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANoch keine Bewertungen

- UT Personnel Mockup ProcedureDokument19 SeitenUT Personnel Mockup ProcedureIksan Adityo Mulyo100% (1)

- Procedure For Ferrit TestingDokument11 SeitenProcedure For Ferrit TestingKarrar TalibNoch keine Bewertungen

- Liquid Penetrant Examination ProcedureDokument15 SeitenLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- Welding Inspection Consumables PDFDokument28 SeitenWelding Inspection Consumables PDFJoseph PeterNoch keine Bewertungen

- 4) RT-EQ-P-03 - Control of NDT Equipments and ConsumablesDokument6 Seiten4) RT-EQ-P-03 - Control of NDT Equipments and ConsumablesMOHD AZMIL AMIN BIN MOHAMAD STUDENT100% (1)

- D-p5-Bv-pd-011 - Iris, Issue 01, Rev 00 - Internal Rotary Inspection SystemDokument11 SeitenD-p5-Bv-pd-011 - Iris, Issue 01, Rev 00 - Internal Rotary Inspection SystemThinh NguyenNoch keine Bewertungen

- NDE NDT Inspection BrochureDokument16 SeitenNDE NDT Inspection BrochureEngr Arfan Ali DhamrahoNoch keine Bewertungen

- MT Form Asme PDFDokument1 SeiteMT Form Asme PDFTrung Tinh HoNoch keine Bewertungen

- DPTDokument12 SeitenDPTAMIT SHAH100% (2)

- Weld DiscontinuityDokument61 SeitenWeld DiscontinuityEKKACHAI PRABNAKORN0% (1)

- Saudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorDokument1 SeiteSaudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorSiddiqui Abdul Khaliq100% (1)

- Internal RT Procedure Spread IIDokument4 SeitenInternal RT Procedure Spread IIravi00098100% (1)

- OCS Engineering & Construction Visual Inspection ReportDokument1 SeiteOCS Engineering & Construction Visual Inspection ReportvinothNoch keine Bewertungen

- 57 PQRDokument13 Seiten57 PQRAbdul Tri Hamdani HamdaniNoch keine Bewertungen

- MT ReportDokument1 SeiteMT ReportBauyrzhanNoch keine Bewertungen

- Magnetic Particle Examination: DateDokument2 SeitenMagnetic Particle Examination: DateAbhishek SharmaNoch keine Bewertungen

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDokument2 SeitenNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNoch keine Bewertungen

- NDT For WeldersDokument66 SeitenNDT For WelderssameeraNoch keine Bewertungen

- Info Sheet Iris Inspection of TubesDokument2 SeitenInfo Sheet Iris Inspection of TubesCepi Sindang KamulanNoch keine Bewertungen

- Pws Convention PresentationDokument93 SeitenPws Convention Presentationbenj100% (1)

- Cp16 Issue Renewal and Recertification of PCN Levels 1 & 2 CertificatesDokument19 SeitenCp16 Issue Renewal and Recertification of PCN Levels 1 & 2 Certificatesndt_inspectorNoch keine Bewertungen

- PTS-1012 - RA Hardness Test ReportDokument1 SeitePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNoch keine Bewertungen

- 15 - Nde Rev 011Dokument32 Seiten15 - Nde Rev 011Adnan RanaNoch keine Bewertungen

- Report - Form - MT - PT - RT - Ut - Cal - 2015Dokument9 SeitenReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlNoch keine Bewertungen

- LPT Written ProcedureDokument8 SeitenLPT Written ProcedureManikantaSumanthNoch keine Bewertungen

- 5111FA-Assessment Report-Shell & Roof Rev.1Dokument14 Seiten5111FA-Assessment Report-Shell & Roof Rev.1Hosam AhmedNoch keine Bewertungen

- Welding Variable Calculator AS1554.1Dokument2 SeitenWelding Variable Calculator AS1554.1Alin TomozeiNoch keine Bewertungen

- Techno NDT Services: Ultrasonic Flaw Detection ReportDokument1 SeiteTechno NDT Services: Ultrasonic Flaw Detection Reportram dreamsNoch keine Bewertungen

- D-p5-Bv-pd-004 - Utt, Issue 01, Rev 00 - Ultrasonic Thickness TestingDokument14 SeitenD-p5-Bv-pd-004 - Utt, Issue 01, Rev 00 - Ultrasonic Thickness TestingThinh NguyenNoch keine Bewertungen

- NDT Application FormDokument4 SeitenNDT Application FormAhmed Shaban KotbNoch keine Bewertungen

- DPT ProcedureDokument4 SeitenDPT ProcedureRohit Attri100% (1)

- Radiographic Report SummaryDokument4 SeitenRadiographic Report SummaryTuấn ĐậuNoch keine Bewertungen

- AITIS Company ProfileDokument7 SeitenAITIS Company ProfileassurendranNoch keine Bewertungen

- RADIOGRAPHIC TEST PROCEDURE (RT Procedure)Dokument17 SeitenRADIOGRAPHIC TEST PROCEDURE (RT Procedure)Senthil Kumaran100% (1)

- Holiday Detector ProcedureDokument2 SeitenHoliday Detector ProcedurenathgsurendraNoch keine Bewertungen

- Pmi Solution Report FormDokument1 SeitePmi Solution Report FormqaqcpipemanNoch keine Bewertungen

- Epz NCS RT 02Dokument1 SeiteEpz NCS RT 02Mijanur RahmanNoch keine Bewertungen

- Pt. Astar Testing & InspectionDokument2 SeitenPt. Astar Testing & InspectionSASINoch keine Bewertungen

- Quality Control Procedure for Hardness TestingDokument7 SeitenQuality Control Procedure for Hardness TestingPinto Carlos100% (2)

- Holiday Detection ProcedureDokument4 SeitenHoliday Detection Proceduregst ajah100% (1)

- Reviewed UT Procedure 10-12-2016Dokument18 SeitenReviewed UT Procedure 10-12-2016Muhammad Maulana100% (1)

- Radiography Acceptance Criteria As Per B 31.3Dokument2 SeitenRadiography Acceptance Criteria As Per B 31.3mohamedNoch keine Bewertungen

- Ultrasonic Test Report: Before AfterDokument7 SeitenUltrasonic Test Report: Before AfterMenad SalahNoch keine Bewertungen

- Welder Performace Qualification Report 2014..Dokument132 SeitenWelder Performace Qualification Report 2014..Kayra Riri ChirulNoch keine Bewertungen

- API 1104 Welding Defect GuideDokument48 SeitenAPI 1104 Welding Defect GuidesbmmlaNoch keine Bewertungen

- STS QAC SOP 006 Repair Procedure For Stainless SteelDokument5 SeitenSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNoch keine Bewertungen

- IRTS Pulsed Eddy Current Testing Work ProcedureDokument10 SeitenIRTS Pulsed Eddy Current Testing Work ProcedurePeterNoch keine Bewertungen

- D-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingDokument18 SeitenD-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingThinh NguyenNoch keine Bewertungen

- PT Procedure GeneralDokument9 SeitenPT Procedure Generalvsnaiduqc100% (1)

- CodeDokument3 SeitenCodeMohamed AbubackerNoch keine Bewertungen

- Ladder PDFDokument12 SeitenLadder PDFmalisolangiNoch keine Bewertungen

- Difference Between Process Flow and Piping and Instrument DiagramDokument1 SeiteDifference Between Process Flow and Piping and Instrument DiagramMohamed AbubackerNoch keine Bewertungen

- CodeDokument1 SeiteCodeMohamed AbubackerNoch keine Bewertungen

- Transcript - Creating A CSharp WPF ApplicationDokument3 SeitenTranscript - Creating A CSharp WPF ApplicationMohamed AbubackerNoch keine Bewertungen

- Lader SafetyDokument8 SeitenLader SafetyMohamed AbubackerNoch keine Bewertungen

- Sofa SetDokument1 SeiteSofa SetMohamed AbubackerNoch keine Bewertungen

- Turn Off Win DeffenderDokument1 SeiteTurn Off Win DeffenderMohamed AbubackerNoch keine Bewertungen

- Samsung Galaxy Tab 2 P3110 Tips and TricksDokument18 SeitenSamsung Galaxy Tab 2 P3110 Tips and TricksMohamed AbubackerNoch keine Bewertungen

- 2011 AddendaDokument9 Seiten2011 AddendaMrityunjoy BanerjeeNoch keine Bewertungen

- PL HT Dcu1 BHB Zusatz 133218 00 GBDokument4 SeitenPL HT Dcu1 BHB Zusatz 133218 00 GBMohamed AbubackerNoch keine Bewertungen

- Piping SpecificationsDokument10 SeitenPiping SpecificationssmithallenNoch keine Bewertungen

- The History and Importance of Impact TestingDokument15 SeitenThe History and Importance of Impact TestingsusanwebNoch keine Bewertungen

- Plant Layout-Pipe RackDokument24 SeitenPlant Layout-Pipe RackSouparna DuttaNoch keine Bewertungen

- PT NDT ProcedureDokument5 SeitenPT NDT ProcedureMohamed AbubackerNoch keine Bewertungen

- Stick Electrode Welding GuideDokument44 SeitenStick Electrode Welding GuideTrajan AureliusNoch keine Bewertungen

- No Exim Organisation ListingDokument21 SeitenNo Exim Organisation ListingVivek PatilNoch keine Bewertungen

- Sahpra Biosimilars Medicines GuidanceDokument30 SeitenSahpra Biosimilars Medicines GuidancevinayNoch keine Bewertungen

- LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetDokument1 SeiteLNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetWang MbaoNoch keine Bewertungen

- NTUGIGRIP - UK Ner CelikDokument7 SeitenNTUGIGRIP - UK Ner CelikAnte KovacicNoch keine Bewertungen

- AnaChem Titrimetry 3Dokument6 SeitenAnaChem Titrimetry 3Jei HernandezNoch keine Bewertungen

- International As: CHEMISTRY (9620)Dokument24 SeitenInternational As: CHEMISTRY (9620)SIHAN CHENNoch keine Bewertungen

- Practice Final ExamDokument18 SeitenPractice Final ExamAttri BezbaruahNoch keine Bewertungen

- Steel Making Process: Phases, Microstructures & PropertiesDokument65 SeitenSteel Making Process: Phases, Microstructures & PropertiesSunny PatilNoch keine Bewertungen

- 1 s2.0 0360128578900084 MainDokument50 Seiten1 s2.0 0360128578900084 MainJefferson DavidNoch keine Bewertungen

- Clo2 DIY Spreadsheets (MMS - CDS)Dokument1 SeiteClo2 DIY Spreadsheets (MMS - CDS)bagus918Noch keine Bewertungen

- Cell, Microscopy, EpitheliumDokument14 SeitenCell, Microscopy, EpitheliumNICOLE JADE PINEDANoch keine Bewertungen

- Expeirment 1Dokument7 SeitenExpeirment 1Djaimee Joyce NimesNoch keine Bewertungen

- Vacuum Brazing of Alumina To Titanium For Implantable Feedthroughs Using Pure Gold As The Braze MetalDokument7 SeitenVacuum Brazing of Alumina To Titanium For Implantable Feedthroughs Using Pure Gold As The Braze MetalMohammad SiddiquiNoch keine Bewertungen

- Alkaloids: Definition and Classification of AlkaloidsDokument6 SeitenAlkaloids: Definition and Classification of AlkaloidsMai LinhNoch keine Bewertungen

- A Review of Biochar in Anaerobic Digestion To Improve Biogas ProductionDokument12 SeitenA Review of Biochar in Anaerobic Digestion To Improve Biogas ProductionShaik Muntasir ShovonNoch keine Bewertungen

- Chemistry 9th Model PaperDokument3 SeitenChemistry 9th Model PaperHasnain Ahmad KhanNoch keine Bewertungen

- Simple and Sensitive Paper-Based Colorimetric BiosensorDokument9 SeitenSimple and Sensitive Paper-Based Colorimetric BiosensorRitaNoch keine Bewertungen

- Smartcare Damp Proof Ultra PDFDokument2 SeitenSmartcare Damp Proof Ultra PDFramachandran_chem100% (1)

- Dye PenetrantDokument10 SeitenDye PenetrantBunty PereraNoch keine Bewertungen

- FAC 2012 Shah SteviaDokument13 SeitenFAC 2012 Shah SteviaLiền CòisNoch keine Bewertungen

- Drilling Engineer AbubakerDokument20 SeitenDrilling Engineer AbubakerrishibarathiNoch keine Bewertungen

- Epilux 219: Product DescriptionDokument2 SeitenEpilux 219: Product DescriptionMoin AltafNoch keine Bewertungen

- Alpha Amylase and Alpha Glucosidase Inhibitory Effects of Aqueous Stem ExtractDokument10 SeitenAlpha Amylase and Alpha Glucosidase Inhibitory Effects of Aqueous Stem ExtractVincent ReyesNoch keine Bewertungen

- DPT ProcedureDokument3 SeitenDPT ProcedureAmit HasanNoch keine Bewertungen

- ColorBond 4pager XRW NewDokument2 SeitenColorBond 4pager XRW NewGireesh Krishna KadimiNoch keine Bewertungen

- 1.ENERGY SCENARIO-merged PDFDokument188 Seiten1.ENERGY SCENARIO-merged PDFraj walkeNoch keine Bewertungen

- Iso 295 2004Dokument9 SeitenIso 295 2004rtsultanNoch keine Bewertungen

- Fundamentals of Petroleum and Petrochemical Engineering: Uttam Ray ChaudhuriDokument154 SeitenFundamentals of Petroleum and Petrochemical Engineering: Uttam Ray ChaudhuriEmad AliNoch keine Bewertungen

- HP PA11 DatasheetDokument2 SeitenHP PA11 DatasheetErxhan AhmetiNoch keine Bewertungen

- Urine Test Strip AnalysisDokument4 SeitenUrine Test Strip AnalysisAurian TormesNoch keine Bewertungen