Beruflich Dokumente

Kultur Dokumente

Horizontal Drilling Operations

Hochgeladen von

M Khalid KamranOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Horizontal Drilling Operations

Hochgeladen von

M Khalid KamranCopyright:

Verfügbare Formate

4B-1 The Lease Pumpers Handbook Chapter 4 Understanding the Oil Well Section B DRILLING OPERATIONS No two wells

are alike, even if they are located near each other and are drilled into the same oil-bearing formation. Many variables may enter into the drilling process. People, equipment, procedures, and many other factors affect the drilling operation and can contribute to problems with the completed well. The outcomes of the drilling procedure will forever influence the production of the well. This section provides information to assist the lease pumper in understanding the nature of the drilling operation. B-1. Contracting the Well to Be Drilled. When a contract to drill an oil well is signed, many conditions and agreements are included. The drilling rig contractor will have agreed to drill a well to a specified depth. The conditions for payment are included. The contract payment may be based on the time on the location, a set sum of money, or by the foot. Most wells are contracted by the foot, but the contract is likely to make allowances for unforeseen problems and nondrilling activities, such as time spent allowing the casing cement to set. While the drilling rig is moving in to prepare for drilling, this is referred to as move in and rig up (MIRU). Most drilling today is done with a jackknife rig that can be moved to the well location and raised in just a few sections rather than the built-in-place derricks that were once used. Personnel involved during drilling include: The tool pusher. The drilling company provides a supervisor for the rig while the well is being drilled. At one time, this individual was called a tool pusher. Today, more and more rig crews include petroleum engineers, the terms drilling engineer, production engineer, and similar titles have become popular. To avoid implying that the position must be held by an engineer, this manual uses the term tool pusher. The tool pusher is generally in charge of the drilling rig and is in charge of every moving part of the rig. The tool pusher purchases rig supplies and supervises the drilling procedures and rig personnel. Radios and cellular telephones have made communications so easy that the tool pusher may be in charge of two or more rigs at one time and may not always be present on a specific site. Because of the critical nature of this type of supervision for around-the-clock drilling operations, the tool pusher is often provided with a small mobile home on the well site to remain at the drilling operation for days at a time in the event of problems. The driller. The driller is directly in charge of the drilling four- or five-person rig crew and generally operates the draw works, the system of cables and pulleys used to run pipe into the hole and to pull pipe from the well. Normally, the driller will have worked

4B-2 all of the positions on the rig crew over a period of years and is, thus, very experienced. When a large drilling rig is being moved, all four drilling crews are supporting the rig move. The driller may perform the tool pushers duties when the latter is off. The derrick worker. The derrick worker works high above the floor when the pipe is being pulled or run during regular operations. This position is commonly referred to as a derrick man. On most modern rigs, sections of drill pipe are held vertically in a rack along side the derrick awaiting to be added to the drilling string as the bit works its way deeper into the ground. One of the duties of the derrick worker is to handle pipe that is added to or removed from the drill string. Pipe is added as the drill bit cuts deeper into the ground. Pipe is removed as the drill string is pulled from the ground once the drilling is complete or to replace the bit or to deal with a drilling problem. The pipe is raised and lowered with elevators. The pipe is stored between fingers in the rack next to a platform referred to as a monkey board. When the rig is drilling, the derrick worker supervises and assists the two floor workers in maintaining the cleanliness of the rig. The derrick worker generally supervises and assists in equipment repairs and often catches and labels the mud samples. The derrick worker may also operate the draw works to provide the driller with time to fill out reports and perform other duties. This also gives the derrick worker experience in driller duties to prepare for a possible promotion. The floor workers. There are two floor workers on the rig floor while pulling and running pipe. These personnel are also referred to as floor hands or roughnecks. The more experienced individual is usually referred to as the lead and operates the lead tong. The second person on the floor operates the back-up tong and may be referred to as the back-up. The floor workers are generally the least experienced members of the crew. Motor man. If the rig has a five-person crew, the fifth individual may be called the motor worker or motor man. In this situation, either the motor worker or the derrick worker may have the most experience and relieve the driller during vacation. The motor worker may also be assigned the duty of catching drilling samples. Company representative. The senior member of the crew, such as the tool pusher, or another person will serve as the official representative of the oil operator. With a small oil company, this may actually be the owner of the company. The company is paying the full cost of drilling the new well and owns it when it is completed. The company representative oversees every aspect of the operation from building the road to being sure that the casing is available when it is needed to the delivery and installation of the wellhead and Christmas tree. In most cases, the company representative makes the final decisions concerning most of the formation tests. B-2. Drilling the Well. When the drilling rig is moved onto the lease to begin drilling a new well, the lease pumper, as an employee of the operating company, may have responsibilities related to the operation. Most drilling rigs have suitable steel mud pits, and the operating

4B-3 company may have constructed an earth mud pit with a plastic liner to receive the excess fluids and the drilling cuttings. Although most rigs will have from two to four steel pits, the very first pit will have a shale shaker mounted on top to allow the drilling mud to fall through the screens. The formation cuttings slide down the vibrating inclined screen and fall over the side and directly into the earth mud pit. When the hole is finished, it will take several weeks or even months before the mud will dry out enough for the cuttings in the pit to be leveled out on the location. As soon as the rig shuts down, the landowner will expect the lease pumper to maintain a clean, well-fenced pit capable of protecting livestock from harm. Sometimes fence will have to be installed as soon as the drilling starts. B-3. Downhole Measurements. The lease pumper is also likely to be responsible for maintaining the well records. One of the most important set of records is the downhole measurements. These measurements record the dimensions of every section of pipe used in the well. Downhole diameters are important in order to know the sizes of tools, pumps, etc. that will pass through the pipe, as well as couplings and other components required to complete the installation. Casing is a name applied to any pipe that is cemented into place. The moveable strings of pipe inside the fixed casing that can be easily pulled and run back in when working the well over are called tubing. Casing and tubing are always measured by outside diameter. If the same pipe is used on the surface, it is called line pipe and is measured by inside diameter. Casing, tubing, and line pipe do not necessarily refer to the design of the pipe. The purpose of the pipe or where it is used is what determines its name. Downhole lengths must be known in order to accurately determine the depth of the well, the location of the perforations, and other features vital to good production. As the well is drilled, distances are measured from the top of the kelly bushing (KB), which is the sliding bushing that sits in the top of the rotary table on the drilling rig

Figure 1. A tri-cone drilling bit. The lease pumper is likely to be responsible for looking out for the landowners interests during the drilling operation, especially if the drilling is contracted. If the mud pit is not properly fenced, the land owners cattle may try to get into the pit to get a drink of water. Occasionally, lost circulation materials are added, and the livestock are attracted to them. The livestock may also try to eat greasy rags, plastic, and other trash that blows away from the rig.

4B-4 floor. The KB allows the drill kelly to slide down through it while the pipe is rotating and the hole is being drilled. The abbreviation KB will appear somewhere on the drilling report records to indicate that this is the initial point from which all downhole measurements are made. All measurements are made to onehundredth of a foot. Instead of using inches, each foot is divided into ten parts, and each tenth of a foot is divided into ten parts. Thus, 106 is equal to 10 and one-half feet or 10.50. All rig tapes use this system of measurement, making it easier to add lengths. For example, three lengths of pipe are 199, 203/32, and 204-5/16, respectively, when measured with a conventional steel tape. Using hundredths of a foot, the same measurements would be 19.77, 20.09, and 20.36. These are numbers that can be handled by a conventional calculator. As the well is completed, everything that goes downhole, such as tubing, rods, and pumps, is measured in the hundredths of a foot. After the casing pipe has been set (cemented permanently in the hole) and the braiden head or wellhead has been installed, the distance from the top of the wellhead up to the top of the kelly bushing is measured and then subtracted from all drilling records so that well records are accurate once the drilling rig is gone. B-4. The Surface String of Casing. Much of the water that people drink comes from underground reservoirs of fresh water. Protecting the fresh water zones is one of the most important considerations when drilling a new well. The bottom of the string of surface casing must extend well below the fresh water zones. The surface hole is also drilled deep enough to pass through any loose materials until stable rock has been encountered before the surface pipe is set or cemented into place. Before the surface casing is made up or run in the hole, it is carefully measured and inspected. The couplings may also be welded to prevent future leaks. Centralizers and scratchers are installed on the pipe. The centralizers (Figure 2) are bow-shaped strips of steel that will hold the pipe in the center of the hole away from the walls. This permits cement to be forced up through the hole on the outside of the pipe to form a good cement bond.

Figure 2. A casing centralizer.

4B-5 Then scratchers (Figure 3) are put on the pipe to scrape the drilling mud off the walls of the hole. This allows the cement to bond to the pipe and to the walls of the hole. The caked-on drilling mud is removed from the walls of the hole by raising and lowering the pipe several times to scrape it loose. As cement is pumped down into the hole through the casing and out the bottom, it rises toward the surface outside the casing to form a good cement bond completely around the pipe all the way to the surface. When the well is plugged, the pipe is left in place. Occasionally, in deep wells, a tapered string of casing is installed, consisting of strings of casing with successively smaller diameters. This is done because of economics or physical limits of the casing string. First, a relatively large casing is set that reaches from the surface and part of the way down the hole toward the reservoir. Then a slightly smaller bit and string of drill pipe is used. A casing hanger is installed at the bottom of each string of casing to allow the next size of pipe to be lowered through that section before it is securely attached and cemented into place. As the casing is run, it may be periodically filled with drilling mud to keep it from collapsing from the excessive external pressure. This is referred to as floating the pipe in. B-6. Drill Stem Tests and Drilling Breaks. One of the most important decisions that the drilling supervisor makes is determining what to do when a drilling break occurs. A drilling break is a sudden increase in the rate at which the bit cuts through the earth and it indicates that the formation is more porous. A porous layer may contain hydrocarbons, such as crude oil or natural gas. By taking into consideration how fast the mud pump is operating, the distance to the bottom of the well, and the volume of the space outside of the drill pipe, the crew can calculate how long it will be before cuttings from the drilling break zone reach the surface. When the cuttings from the zone the drilling break occurred in arrive, the person catching samples will test the cuttings under an ultraviolet light or black light. Should crude oil be present, the sample will glow under the black light. High mud pressures may prevent a good sample from reaching the surface, and the

Figure 3. Scratchers used to remove from the walls of the hole. B-5. Intermediate Strings of Casing. Some oil wells will be deep enough that a second string of pipe is cemented into the hole above the production reservoir. This string is often installed to correct adverse hole conditions such as sloughing, heaving, high-pressure gas, or lost circulation zones. Each time a string of casing is added, a smaller bit is used, small enough to go inside the new casing and drill out the bottom, usually down to the reservoir.

4B-6 solution might be to run a drill stem test. In this test, the drill pipe takes the place of the tubing string. The production company decides if the test is to be run. The rig must stop drilling new hole until the test is over, and an hourly rate may used until drilling begins again. Allowances are made in the contract to provide time to run pipe and cement it into position. When the rig stops drilling to run pipe, the lease operator will pay by the hour, or some other appropriate amount to compensate for rig expense during the time spent running casing, cementing, and waiting on the cement to set and get hard. The time while the cement sets is referred to as WOC or waiting on cement on the drilling report. During this time, the rig crew is busy cleaning the rig floor, rearranging the drill pipe on the racks, and getting a smaller drill bit ready to begin drilling again. The new drilling bit will be considerably smaller than the previous bit because the drill bit and pipe must be small enough to go through the casing to reach the bottom or cemented pipe and drill beyond it to extend the depth of the hole toward the oil reservoir. B-7. Keeping the Hole Full Gauge and the Packed Hole Assembly. The bit wears in diameter as well as tooth sharpness as the hole is drilled. As the bit diameter shrinks, so does the hole diameter. To overcome this problem, a reamer is run right behind the bit. A series of rolling cones rotate as the bit is turned and these cones ream the hole slightly larger. Reaming the hole one time is usually sufficient. The bit also wears on the shoulders, and, without a reamer, when the crew pulls the drill pipe to run a new bit, the new bit will have trouble getting back to bottom.

Figure 4. A reamer used to maintain hole diameter as the bit wears.

4B-7 B-8. Drilling a Straight Hole. It is not generally possible to drill a straight hole from the surface all the way to the oil reservoir. Factors such as the density of the formation, uneven wear on the bit, flexing of the drill pipe, and other conditions may result in the hole becoming deviated off true vertical depth (TVD). Generally, the hole is still usable for oil production. Drilling the hole involves a continuous series of decisions to adjust the drilling technique to obtain the best results. Considerations include obtaining a good, usable hole, getting good performance and life from the bit, and making good drilling progress. The two principal means of controlling these factors are the rotational speed of the bit and the amount of weight applied. Maximum penetration rate and a straight hole is maintained by varying the amount of drill pipe weight applied to the bit and the r.p.m. of the bit. A good balance of the two must be determined, and that balance may have to be adjusted as conditions, such as the density of the formation or the depth of the hole, change. As the bit encounters formations that are not horizontal, it will have a tendency to climb uphill. To help solve this problem, more drill collars will be run on top of the reamer. Drill collars add weight and make the pipe more rigid. Even the use of collars will not solve all drilling problems. Another common problem is having the bit get stuck in grooves that can develop in the sides of the hole. These grooves, called key seats, are formed as the drill pipe flexes under pressure and rubs the side of the hole. The threaded ends of the drill pipe are known as connections and are larger in diameter than the body or tube of the drill pipe. These connections, being larger in diameter than the rest of the pipe, sometimes become stuck in the key seats, especially when the crew starts pulling the bit out of the hole. Another problem that may develop can be caused by the corkscrew profile of the drilled hole. Because the formations are not of the same density all the way down to the production zone and the bit wears and the drill pipe flexes, the hole rarely goes straight down but instead has a twisted profile like a corkscrew. However, the tubing string tends to hang vertically in the hole, meaning that it is likely to rub against the casing as it comes into contact with the bends in the corkscrew. This contact can lead to holes being worn in the casing and in the tubing. Tubing collars can wear to the point that they fracture, allowing the tubing string to collapse into the well. Methods of addressing some of these problems are addressed in the Well Servicing and Workover section of this handbook.

4B-8

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- ID-Wall Mount Micro Corrector HARDWAREDokument25 SeitenID-Wall Mount Micro Corrector HARDWAREFelix Julio Céspedes SotoNoch keine Bewertungen

- Abb Transfer Şalteri̇Dokument56 SeitenAbb Transfer Şalteri̇AdemEfeNoch keine Bewertungen

- Ficha Tecnica Sistema Proteccion Mecanica y Anticorrosiva 8Dokument3 SeitenFicha Tecnica Sistema Proteccion Mecanica y Anticorrosiva 8Felix Julio Céspedes SotoNoch keine Bewertungen

- Explosive Atmospheres Protection: Main CatalogueDokument44 SeitenExplosive Atmospheres Protection: Main CatalogueFelix Julio Céspedes SotoNoch keine Bewertungen

- Handbook Dresser CorrectorDokument67 SeitenHandbook Dresser CorrectorMarco A VelascoNoch keine Bewertungen

- Abb Ovr Range System Prom - 2011 - 1txh000083c0201Dokument36 SeitenAbb Ovr Range System Prom - 2011 - 1txh000083c0201Felix Julio Céspedes SotoNoch keine Bewertungen

- Al-1400 Al-2300 Al5000Dokument2 SeitenAl-1400 Al-2300 Al5000Felix Julio Céspedes SotoNoch keine Bewertungen

- General Product CatalogDokument24 SeitenGeneral Product CatalogFelix Julio Céspedes SotoNoch keine Bewertungen

- Minielcor: Battery Powered Gas Volume Conversion Device With Option of External Power SupplyDokument2 SeitenMinielcor: Battery Powered Gas Volume Conversion Device With Option of External Power SupplyFelix Julio Céspedes SotoNoch keine Bewertungen

- RPM Rotary Gas MetersDokument8 SeitenRPM Rotary Gas MetersFranklin Villca RochaNoch keine Bewertungen

- EAMTB4510 X PDFDokument12 SeitenEAMTB4510 X PDFLuis Durán MirandaNoch keine Bewertungen

- Arreglos CUVWESTX-2Dokument120 SeitenArreglos CUVWESTX-2Felix Julio Céspedes SotoNoch keine Bewertungen

- 1800cpb2 Series Regulators American MeterDokument11 Seiten1800cpb2 Series Regulators American Meterultron2099ultronNoch keine Bewertungen

- Medidores BK g4Dokument2 SeitenMedidores BK g4Daniel MaldonadoNoch keine Bewertungen

- Sect 7Dokument34 SeitenSect 7Ashraf Adel Nashed ZakiNoch keine Bewertungen

- Series 1213B2 Service Regulators: Repair PartsDokument2 SeitenSeries 1213B2 Service Regulators: Repair PartsFelix Julio Céspedes SotoNoch keine Bewertungen

- Al1000 PDFDokument2 SeitenAl1000 PDFdilor19Noch keine Bewertungen

- Taylor Valve Technology, Inc: MC Series Throttling Choke ValveDokument17 SeitenTaylor Valve Technology, Inc: MC Series Throttling Choke ValveFelix Julio Céspedes SotoNoch keine Bewertungen

- TC1625 - Catalog - pgs41-43 Cameron Wills PDFDokument3 SeitenTC1625 - Catalog - pgs41-43 Cameron Wills PDFFelix Julio Céspedes SotoNoch keine Bewertungen

- Putting YOU IN Control OF Your System!: Rbs Series Steam ChokeDokument5 SeitenPutting YOU IN Control OF Your System!: Rbs Series Steam ChokeFelix Julio Céspedes SotoNoch keine Bewertungen

- Gas Lift With Nitrogen Injection Generated in SituDokument10 SeitenGas Lift With Nitrogen Injection Generated in SitutherockstarsunNoch keine Bewertungen

- Nozzle SelectionDokument1 SeiteNozzle SelectionFelix Julio Céspedes SotoNoch keine Bewertungen

- Calificacion de TrepanosDokument1 SeiteCalificacion de TrepanosFelix Julio Céspedes SotoNoch keine Bewertungen

- Ball Valve Technology That Quickly Turns Things Around: CameronDokument4 SeitenBall Valve Technology That Quickly Turns Things Around: CameronLUIS CARLOSNoch keine Bewertungen

- Gas Pipeline HydraulicsDokument59 SeitenGas Pipeline HydraulicsNorazlan Shah MahadiNoch keine Bewertungen

- Internal Corrosion Monitering Systems in Oil & Gas IndustryDokument26 SeitenInternal Corrosion Monitering Systems in Oil & Gas IndustryFelix Julio Céspedes SotoNoch keine Bewertungen

- Floating CasingDokument1 SeiteFloating CasingFelix Julio Céspedes SotoNoch keine Bewertungen

- C 04.a Looking DownholeDokument6 SeitenC 04.a Looking DownholeFelix Julio Céspedes SotoNoch keine Bewertungen

- Types of CorrosionDokument53 SeitenTypes of CorrosionFelix Julio Céspedes Soto100% (3)

- Bos 40Dokument1 SeiteBos 40Andrea CornejoNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Black Powder in PipelineDokument3 SeitenBlack Powder in Pipelinesrlodhi100% (1)

- Mercer Valves PDFDokument16 SeitenMercer Valves PDFJamesTorresPalmaNoch keine Bewertungen

- The Second Term English Language Test NDokument2 SeitenThe Second Term English Language Test NSamra KadouriNoch keine Bewertungen

- Biogas Systems: By: John Megryan B. SamartinoDokument15 SeitenBiogas Systems: By: John Megryan B. SamartinoJohn MegryanNoch keine Bewertungen

- Visit To Water BankDokument26 SeitenVisit To Water BankMandar Vaman SatheNoch keine Bewertungen

- Natural Gas Engines 2019Dokument428 SeitenNatural Gas Engines 2019Паша Шадрёнкин100% (1)

- Surface Finishing Solutions Using High-Purity AluminumDokument6 SeitenSurface Finishing Solutions Using High-Purity AluminumWK SinnNoch keine Bewertungen

- 9852 2405 01a Transport Simba S7 DDokument2 Seiten9852 2405 01a Transport Simba S7 DHEMER LUIS RIVERANoch keine Bewertungen

- Geothermal DrillingDokument72 SeitenGeothermal DrillingPablo Martínez BerenguerNoch keine Bewertungen

- UhdeDokument16 SeitenUhdeCami CorderoNoch keine Bewertungen

- CoP 02 Policy Standards and Objectives Final 07 - 12 - 2017Dokument25 SeitenCoP 02 Policy Standards and Objectives Final 07 - 12 - 2017qaqc marineryNoch keine Bewertungen

- World Oil Transit Choke PointsDokument10 SeitenWorld Oil Transit Choke PointsBurak KeremNoch keine Bewertungen

- Alternative FuelDokument6 SeitenAlternative FuelKinna VnezhNoch keine Bewertungen

- Co2 Compression at Worlds LargestDokument16 SeitenCo2 Compression at Worlds LargestihllhmNoch keine Bewertungen

- Reservoir Fluids McCain AppendixDokument43 SeitenReservoir Fluids McCain Appendixdefsnds100% (1)

- 6 MarchDokument51 Seiten6 MarchmaritsyaditaaNoch keine Bewertungen

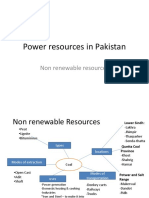

- Power Resources in PakistanDokument28 SeitenPower Resources in PakistanRidwan FaisalNoch keine Bewertungen

- V5 RatioMatic RM0200 Datasheet 110-3 A4 PDFDokument4 SeitenV5 RatioMatic RM0200 Datasheet 110-3 A4 PDFcarlosloucaoNoch keine Bewertungen

- ANovel Designof Liquefied Natural Gas LNGRegasification Power Plant Integratedwith Cryogenic Energy Storage SystemDokument9 SeitenANovel Designof Liquefied Natural Gas LNGRegasification Power Plant Integratedwith Cryogenic Energy Storage SystemTala RamezaniNoch keine Bewertungen

- Staubli Connectors CatalougeDokument28 SeitenStaubli Connectors CatalougeSpark MeditechNoch keine Bewertungen

- Mexico Burgos Basin PresentationDokument18 SeitenMexico Burgos Basin PresentationCarlos PereaNoch keine Bewertungen

- 1.introducing Myanmar Oil & Gas Arena-U Than TunDokument17 Seiten1.introducing Myanmar Oil & Gas Arena-U Than TunRyanLinNoch keine Bewertungen

- Gabriel Valentin ComanescuDokument6 SeitenGabriel Valentin ComanescuGabriel ComanescuNoch keine Bewertungen

- Pemboran 3Dokument74 SeitenPemboran 3Gerald PrakasaNoch keine Bewertungen

- Alternative Fuels1Dokument25 SeitenAlternative Fuels1Sumedh HiwaleNoch keine Bewertungen

- Nigeria Gas Sector ReportDokument138 SeitenNigeria Gas Sector ReportvalentineNoch keine Bewertungen

- Carbon LandscapeDokument137 SeitenCarbon Landscapem_danmNoch keine Bewertungen

- ANYAMESEMDokument29 SeitenANYAMESEMReginald Arthur.Noch keine Bewertungen

- Biomass GasificationDokument23 SeitenBiomass GasificationmysingaporeNoch keine Bewertungen

- F646 CompleteSampleDokument36 SeitenF646 CompleteSampleraj4523Noch keine Bewertungen