Beruflich Dokumente

Kultur Dokumente

MXD2020E

Hochgeladen von

api-3695729Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MXD2020E

Hochgeladen von

api-3695729Copyright:

Verfügbare Formate

Ultra Low Noise, Low offset Drift ±1 g Dual

Axis Accelerometer with Digital Outputs

MXD2020E/F

Sck Internal Temperature

FEATURES (optional) Oscillator Sensor

TOUT

Resolution better than 1 mg at 1 Hz

Dual axis accelerometer fabricated on a monolithic CMOS IC Voltage

VREF

Reference

RoHS compliant CLK

On-chip mixed mode signal processing Continous

50,000 g shock survival rating Heater

Control

Self Test

17 Hz bandwidth

3.00V to 5.25V single supply operation X axis

Low Pass

DOUTX

Small (5mm x 5mm x 2mm) surface mount package Filter

Continuous self-test

Factory Adjust

Independent axis programmability (special order) Offset & Gain

APPLICATIONS Y axis

Low Pass

Filter

DOUTY

Automotive – Vehicle Security/Active Suspension/ABS 2-AXIS

Headlight Angle Control/Tilt Sensing SENSOR

Security – Gas Line/Elevator/Fatigue Sensing VDD Gnd VDA

Office Equipment – Computer Peripherals/PDA’s/Cell Phones

Gaming – Joystick/RF Interface/Menu Selection/Tilt Sensing

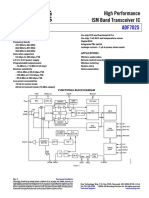

MXD2020E/F FUNCTIONAL BLOCK DIAGRAM

Projectors - Leveling and Keystoning

White Goods – Spin/Vibration Control

GENERAL DESCRIPTION

The MXD2020E/F is an ultra low noise and low cost, dual The typical noise floor is 0.2mg / Hz allowing signals

axis accelerometer built on a standard, submicron CMOS below 1mg to be resolved at 1 Hz bandwidth. The

process. The MXD2020E/F measures acceleration with a MXD2020E/F is available in a LCC surface mount package

full-scale range of ± 1 g and a sensitivity of 20%/g @5V at (5mm x 5mm x 2mm height). It is hermetically sealed and

25°C. It can measure both dynamic acceleration (e.g., operational over a -40°C to +105°C temperature range.

vibration) and static acceleration (e.g., gravity). The

MXD2020E/F design is based on heat convection and Due to the standard CMOS structure of the MXD2020E/F,

requires no solid proof mass. This eliminates stiction and additional circuitry can easily be incorporated into custom

particle problems associated with competitive devices and versions for high volume applications. Contact the factory

provides shock survival up to 50,000 g, leading to for more information.

significantly lower failure rates and lower losses due to

handling during assembly.

The MXD2020E/F provides two digital outputs. The

outputs are digital signals with duty cycles (ratio of pulse

width to period) that are proportional to acceleration. The

duty cycles outputs can be directly interfaced to a micro-

processor.

©MEMSIC, Inc.

Information furnished by MEMSIC is believed to be accurate and reliable.

However, no responsibility is assumed by MEMSIC for its use, nor for any 800 Turnpike St., Suite 202, North Andover, MA01845, USA

infringements of patents or other rights of third parties, which may result from Tel: +1 978 738 0900 Fax: + 978 738 0196

its use. No license is granted by implication or otherwise under any patent or www.memsic.com

patent rights of MEMSIC

MEMSIC MXD2020E/F Rev H Page 1 of 8 2/26/2007

MXD2020E/F SPECIFICATIONS (Measurements @ 25°C, Acceleration = 0g unless otherwise noted, VDD, VDA =

5.0V unless otherwise specified)

MXD2020E/F

Parameter Conditions Min Typ Max Units

SENSOR INPUT Each Axis

Measurement Range1 ±1.0 g

Nonlinearity Best fit straight line 0.5 1.0 % of FS

Alignment Error2 ±1.0 degrees

Transverse Sensitivity3 ±2.0 %

SENSITIVITY Each Axis

DOUTX and DOUTY @5.0V supply 19.0 20.0 21.0 % Duty

Cycle/g

Change over Temperature (uncompensated)4 Δ from 25°C, at –40°C +120 %

Δ from 25°C, at +105°C -55 %

Change over Temperature (compensated) 4 Δ from 25°C, –40°C to +105°C <3.0 %

ZERO g BIAS LEVEL Each Axis

0 g Offset5 -0.1 0.00 +0.1 g

0 g Duty Cycle5 48 50 52 % Duty Cycle

0 g Offset over Temperature Δ from 25°C ±0.4 mg/°C

Δbased on 20%/g ±0.008 % / °C

PWM output Frequency For MXD2020EL only 97 100 103 Hz

MXD2020E 95 100 105 Hz

MXD2020F 380 400 420 Hz

NOISE PERFORMANCE

mg/ Hz

Noise Density, rms 0.2 0.4

FREQUENCY RESPONSE

3dB Bandwidth 15 17 19 Hz

TEMPERATURE OUTPUT

Tout Voltage 1.15 1.25 1.35 V

Sensitivity 4.6 5.0 5.4 mV/°K

VOLTAGE REFERENCE OUTPUT

VRef output @3.0V-5.25V supply 2.4 2.5 2.65 V

Change over Temperature 0.1 mV/°C

Current Drive Capability Source 100 μA

SELF TEST

Continuous Voltage at DOUTX, DOUTY under @5.0V Supply, output rails to

Failure supply voltage 5.0 V

Continuous Voltage at DOUTX, DOUTY under @3.0V Supply, output rails to

Failure supply voltage 3.0 V

DOUTX and DOUTY OUTPUTS

Normal Output Range Output High 4.8 V

Output Low 0.2 V

Current Source or sink, @ 3.0V-5.25V supply 100 μA

Rise/Fall Time 3.0 to 5.0V Supply 90 100 110 nS

Turn-on Time @5.0V Supply 160 mS

@3.0V Supply 300 mS

POWER SUPPLY

Operating Voltage Range 3.0 5.25 V

Supply Current @ 5.0V 2.7 3.3 4.1 mA

Supply Current @ 3.0V 3.2 4.0 4.8 mA

TEMPERATURE RANGE

Operating Range -40 +105 °C

NOTES 5

1 The device operates over a 3.0V to 5.25V supply range. Please note that

Guaranteed by measurement of initial offset and sensitivity.

2 sensitivity and zero g bias level will be slightly different at 3.0V operation. For

Alignment error is specified as the angle between the true and indicated

devices to be operated at 3.0V in production they can be trimmed at the factory

axis of sensitivity.

3 specifically for this lower supply voltage operation, in which case the sensitivity and

Transverse sensitivity is the algebraic sum of the alignment and the inherent

zero g bias level specifications on this page will be met. Please contact the factory

sensitivity errors

4 for specially trimmed devices for low supply voltage operation.

The sensitivity change over temperature for thermal accelerometers is based on 6

Output settled to within ±17mg.

variations in heat transfer that are governed by the laws of physics and it is highly

consistent from device to device. Please refer to the section in this data sheet titled

“Compensation for the Change of Sensitivity over Temperature” for more

information.

MEMSIC MXD2020E/F Rev H Page 2 of 8 2/26/2007

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VDD, VDA) ………………...-0.5 to +7.0V

Storage Temperature ……….…………-65°C to +150°C

Acceleration ……………………………………..50,000 g

*Stresses above those listed under Absolute Maximum Ratings may cause permanent

damage to the device. This is a stress rating only; the functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Package Characteristics

Package θJA θJC Device Weight

LCC-8 110°C/W 22°C/W < 1 gram

Ordering Guide THEORY OF OPERATION

Model Package Style Digital The MEMSIC device is a complete dual-axis acceleration

Output measurement system fabricated on a monolithic CMOS IC

MXD2020EL LCC8 RoHS compliant 100 Hz process. The device operation is based on heat transfer by

MXD2020EF LCC8, Pb-free 100Hz natural convection and operates like other accelerometers

RoHS compliant having a proof mass except it is a gas in the MEMSIC

MXD2020FL LCC8 RoHS compliant 400 Hz sensor.

MXD2020FF LCC8, Pb-free 400Hz

RoHS compliant A single heat source, centered in the silicon chip is

suspended across a cavity. Equally spaced

All parts are shipped in tape and reel packaging. aluminum/polysilicon thermopiles (groups of

Caution thermocouples) are located equidistantly on all four sides of

ESD (electrostatic discharge) sensitive device. the heat source (dual axis). Under zero acceleration, a

temperature gradient is symmetrical about the heat source,

8 so that the temperature is the same at all four thermopiles,

causing them to output the same voltage.

1 7

X +g

M E M S IC

Acceleration in any direction will disturb the temperature

2 6

profile, due to free convection heat transfer, causing it to be

3 5

asymmetrical. The temperature, and hence voltage output

of the four thermopiles will then be different. The

4 differential voltage at the thermopile outputs is directly

proportional to the acceleration. There are two identical

Y +g

acceleration signal paths on the accelerometer, one to

Top View measure acceleration in the x-axis and one to measure

acceleration in the y-axis. Please visit the MEMSIC

Note: The MEMSIC logo’s arrow indicates the +X sensing website at www.memsic.com for a picture/graphic

direction of the device. The +Y sensing direction is rotated description of the free convection heat transfer principle.

90° away from the +X direction.

Small circle indicates pin one (1).

Pin Description: LCC-8 Package

Pin Name Description I/O

1 TOUT Temperature (Analog Voltage) O

2 DOUTY Y-Axis Acceleration Digital Signal O

3 Gnd Ground I

4 VDA Analog Supply Voltage I

5 DOUTX X-Axis Acceleration Digital Signal O

6 Vref 2.5V Reference Output O

7 Sck Optional External Clock I

8 VDD Digital Supply Voltage I

MEMSIC MXD2020E/F Rev H Page 3 of 8 2/26/2007

COMPENSATION FOR THE CHANGE IN

PIN DESCRIPTIONS SENSITIVITY OVER TEMPERATURE

VDD – This is the supply input for the digital circuits and All thermal accelerometers display the same sensitivity

the sensor heater in the accelerometer. The DC voltage change with temperature. The sensitivity change depends

should be between 3.00 and 5.25 volts. Refer to the section on variations in heat transfer that are governed by the laws

on PCB layout and fabrication suggestions for guidance on of physics. Manufacturing variations do not influence the

external parts and connections recommended. sensitivity change, so there are no unit-to-unit differences

in sensitivity change. The sensitivity change is governed

VDA – This is the power supply input for the analog by the following equation (and shown in Figure 1 in °C):

amplifiers in the accelerometer. Refer to the section on PCB

layout and fabrication suggestions for guidance on external Si x Ti2.90 = Sf x Tf2.90

parts and connections recommended. where Si is the sensitivity at any initial temperature Ti, and

Sf is the sensitivity at any other final temperature Tf with

Gnd – This is the ground pin for the accelerometer. the temperature values in K.

DOUTX – This pin is the digital output of the x-axis 2.5

Sensitivity (normalized)

acceleration sensor. It is factory programmable to 100 Hz 2.0

or 400 Hz. The user should ensure the load impedance is 1.5

sufficiently high as to not source/sink >100μA typical. 1.0

While the sensitivity of this axis has been programmed at 0.5

the factory to be the same as the sensitivity for the y-axis, 0.0

the accelerometer can be programmed for non-equal -40 -20 0 20 40 60 80 100

sensitivities on the x- and y-axes. Contact the factory for Temperature (C)

additional information.

DOUTY – This pin is the digital output of the y-axis Figure 1: Thermal Accelerometer Sensitivity

acceleration sensor. It is factory programmable to 100 Hz

In gaming applications where the game or controller is

or 400 Hz. The user should ensure the load impedance is

typically used in a constant temperature environment,

sufficiently high as to not source/sink >100μA typical.

sensitivity might not need to be compensated in hardware

While the sensitivity of this axis has been programmed at

or software. The compensation for this effect could be

the factory to be the same as the sensitivity for the x-axis,

done instinctively by the game player.

the accelerometer can be programmed for non-equal

sensitivities on the x- and y-axes. Contact the factory for

For applications where sensitivity changes of a few percent

additional information.

are acceptable, the above equation can be approximated

with a linear function. Using a linear approximation, an

TOUT – This pin is the buffered output of the temperature

external circuit that provides a gain adjustment of –0.9%/°C

sensor. The analog voltage at TOUT is an indication of the

would keep the sensitivity within 10% of its room

die temperature. This voltage is useful as a differential

temperature value over a 0°C to +50°C range.

measurement of temperature from ambient and not as an

absolute measurement of temperature. After correlating the

For applications that demand high performance, a low cost

voltage at TOUT to 25°C ambient, the change in this

micro-controller can be used to implement the above

voltage due to changes in the ambient temperature can be

equation. A reference design using a Microchip MCU (p/n

used to compensate for the change over temperature of the

16F873/04-SO) and MEMSIC developed firmware is

accelerometer offset and sensitivity. Please refer to the

available by contacting the factory. With this reference

section on Compensation for the Change in Sensitivity

design, the sensitivity variation over the full temperature

Over Temperature for more information.

range (-40°C to +105°C) can be kept below 3%. Please

visit the MEMSIC web site at www.memsic.com for

Sck – The standard product is delivered with an internal

reference design information on circuits and programs

clock option (800kHz). This pin should be grounded

including look up tables for easily incorporating sensitivity

when operating with the internal clock. An external

compensation.

clock option can be special ordered from the factory

allowing the user to input a clock signal between 400kHz

DISCUSSION OF TILT APPLICATIONS AND

And 1.6MHz

RESOLUTION

Tilt Applications: One of the most popular applications of

Vref – This pin is the output of a reference voltage. It is set

the MEMSIC accelerometer product line is in

at 2.50V typical and has 100μA of drive capability.

tilt/inclination measurement. An accelerometer uses the

MEMSIC MXD2020E/F Rev H Page 4 of 8 2/26/2007

force of gravity as an input to determine the inclination resolution of the measurement. With a simple RC low pass

angle of an object. filter, the rms noise is calculated as follows:

A MEMSIC accelerometer is most sensitive to changes in Noise (mg rms) = Noise(mg/ Hz ) * ( Bandwidth( Hz) *1.6)

position, or tilt, when the accelerometer’s sensitive axis is

perpendicular to the force of gravity, or parallel to the

Earth’s surface. Similarly, when the accelerometer’s axis is The peak-to-peak noise is approximately equal to 6.6 times

parallel to the force of gravity (perpendicular to the Earth’s the rms value (for an average uncertainty of 0.1%).

surface), it is least sensitive to changes in tilt.

DIGITAL INTERFACE

Table 1 and Figure 2 to help illustrate the output changes in The MXD2020E/F is easily interfaced with low cost

the X- and Y-axes as the unit is tilted from +90° to 0°. microcontroller. For the digital output accelerometer, one

Notice that when one axis has a small change in output per digital input port is required to read one accelerometer

degree of tilt (in mg), the second axis has a large change in output. For the analog output accelerometer, many low cost

output per degree of tilt. The complementary nature of microcontroller are available today that feature integrated

these two signals permits low cost accurate tilt sensing to a/d (analog to digital converters) with resolutions ranging

be achieved with the MEMSIC device (reference from 8 to 12 bits.

application note AN-00MX-007).

In many applications the microcontroller provides an

X

effective approach for the temperature compensation of the

+90 0

sensitivity and the zero g offset. Specific code set, reference

designs, and applications notes are available from the

M E M SIC

gravity factory. The following parameters must be considered in a

00 digital interface:

Y Resolution: smallest detectable change in input acceleration

Top View

Bandwidth: detectable accelerations in a given period of

Figure 2: Accelerometer Position Relative to Gravity time

Acquisition Time: the duration of the measurement of the

acceleration signal

X-Axis Y-Axis

X-Axis

Orientation Change Change DUTY CYCLE DEFINITION

To Earth’s X Output per deg. Y Output per deg. The MXD2020E/F has two PWM duty cycle outputs (x,y).

Surface (g) of tilt (g) of tilt The acceleration is proportional to the ratio T1/T2. The

(deg.) (mg) (mg) zero g output is set to 50% duty cycle and the sensitivity

90 1.000 0.15 0.000 17.45 scale factor is set to 20% duty cycle change per g. These

85 0.996 1.37 0.087 17.37 nominal values are affected by the initial tolerance of the

80 0.985 2.88 0.174 17.16 device including zero g offset error and sensitivity error.

70 0.940 5.86 0.342 16.35

This device is offered from the factory programmed to

60 0.866 8.59 0.500 15.04

45 0.707 12.23 0.707 12.23 either a 10ms period (100 Hz) or a 2.5ms period (400Hz).

30 0.500 15.04 0.866 8.59

20 0.342 16.35 0.940 5.86 T1 Length of the “on” portion of the cycle.

10 0.174 17.16 0.985 2.88 T2 (Period) Length of the total cycle.

5 0.087 17.37 0.996 1.37 Duty Cycle Ratio of the “0n” time (T1) of the cycle to

0 0.000 17.45 1.000 0.15 the total cycle (T2). Defined as T1/T2.

Table 1: Changes in Tilt for X- and Y-Axes Pulse width Time period of the “on” pulse. Defined as

T1.

Resolution: Accelerometers can be used in a wide variety

of low g applications such as tilt and orientation. The T2

device noise floor will vary with the measurement

bandwidth. With the reduction of the bandwidth the noise

floor drops. This will improve the signal to noise ratio of T1

the measurement and resolution. The output noise scales

directly with the square root of the measurement

bandwidth. The maximum amplitude of the noise, its peak- A (g)= (T1/T2 - 0.5)/0.2

At 0g T1=T2

to- peak value, approximately defines the worst case

T2= 2.5ms or 10ms (factory programmable)

Figure 3: Typical output Duty Cycle

MEMSIC MXD2020E/F Rev H Page 5 of 8 2/26/2007

For a more detail discussion of temperature compensation

CHOOSING T2 AND COUNTER FREQUENCY reference MEMSIC application note #AN-00MX-002

DESIGN TRADE-OFFS

The noise level is one determinant of accelerometer Microcontroller

resolution. The second relates to the measurement

Ax I/O

resolution of the counter when decoding the duty cycle MEMSIC

Ay

output. The actual resolution of the acceleration signal is Accel I/O

limited by the time resolution of the counting devices used T

A/D

to decode the duty cycle. The faster the counter clock, the

higher the resolution of the duty cycle and the shorter the

T2 period can be for a given resolution. Table 2 shows Figure 4: Zero g Offset Temperature Compensation Circuit

some of the trade-offs. It is important to note that this is the

resolution due to the microprocessors’ counter. It is COMPENSATION FOR EXTENDING THE

probable that the accelerometer’s noise floor may set the FREQUENCY RESPONSE

lower limit on the resolution. The response of the thermal accelerometer is a function of

the internal gas physical properties, the natural convection

mechanism and the sensor electronics. Since the gas

Counter- properties of MEMSIC's mass produced accelerometer are

MEMSIC Clock Counts Reso- uniform, a digital filter can be used to equally compensate

Sample Rate Per T2 Counts lution

all sensors. The compensating filter does not require

T2 (ms) Rate (MHz) Cycle per g (mg)

adjustment for individual accelerometers. The function of

10.0 100 1.0 10000 2000 0.5

the compensating filter is to apply gain in proportion with

10.0 100 0.5 5000 1000 1.0

2.5 400 1.0 2500 500 2.0

the acceleration changes. The faster the acceleration

2.5 400 0.5 1250 250 4.0

changes occur, the higher the gain that the filter applies.

Table 2: Trade-Offs Between Microcontroller Counter Rate and For analog output accelerometers, the compensating filter

T2 Period. can be implemented with a circuit involving two op-amps

and some resistors and capacitors. For digital output

COMPENSATION FOR ZERO G OFFSET CHANGE accelerometers, a digital filter is necessary.

OVER TEMPERATURE

The compensation of offset is performed with the following In applications where high frequency accelerations need to

equation: Aoc = A + ( a + b * T + c * T * T) be measured, a DSP (digital signal processor) may be

where Aoc is the offset compensated acceleration, A is the necessary to implement the digital filter. DSP IC’s and

uncompensated acceleration, T is temperature and a, b, c development tools are readily available from major IC

are constants characteristic to each accelerometer. manufacturers.

Computer programs are used to determine these constants.

The constants can be read from and written to the MCU However, if the bandwidth requirement is relatively low

EEPROM via the RS-232. The constants a,b,c are normally (i.e. 100Hz), it is possible to implement a digital frequency

stored in the MCU EEPROM. To determine the values of compensating filter with an 8 bit microcontroller. The

the constants, each accelerometer is taken to three different microcontroller will likely have to be capable of operating

temperatures, preferably evenly spread across the desired at relatively high clock frequencies (20MHz).

temperature span. The zero g bias (A0, A1 and A2) and the

temperatures (T0, T1 and T2) are recorded at each CONVERTING THE DIGITAL OUTPUT TO AN

temperature. The data collected (A0, T0, A1, T1, A2, T2) is ANALOG OUTPUT

used in a quadratic interpolation (or LaGrange polynomial) The PWM output can be easily converted into an analog

to determine a, b and c as follows: output by integration. A simple RC filter can do the

r0 = A0 / ( (T0-T1)*(T0-T2) ) conversion. Note that that the impedance of the circuit

r1 = A1 / ( (T1-T0)*(T1-T2) ) following the integrator must be much higher than the

r2 = A2 / ( (T2-T0)*(T2-T1) ) impedance of the RC filter. Reference figure 5 for an

a = r0 * T1 * T2 + r1 * T0 * T2 + r2 * T0 * T1 example.

b = - r0 * (T1+T2) – r1 * (T0+T2) – r2 *(T0+T1)

c = r0 + r1 + r2

10K

DOUT AOUT

In many cases a computer is used to control the

temperature, communicate with the MCU, and to calculate MEMSIC 1uF

the constants. After calculating the constants, the computer Accel.

downloads the constants to EEPROM.

Figure 5: Converting the digital output to an analog voltage

MEMSIC MXD2020E/F Rev H Page 6 of 8 2/26/2007

TEMPERATURE OUTPUT NOISE REDUCTION

It is recommended that a simple RC low pass filter is used

Power Supply

when measuring the temperature output. Temperature

output is typically a very slow changing signal, so a very

low frequency filter eliminates erroneous readings that may

result from the presence of higher frequency noise. A

simple filter is shown in Figure 6. C1 VDA VDD

0.1uF

MEMSIC

Accelerometer

8.2K

TOUT Filtered TOUT

MEMSIC 0.1uF

Accel.

Figure 7: Power Supply Noise Rejection

Figure 6: Temperature Output Noise Reduction

PCB LAYOUT AND FABRICATION SUGGESTIONS

1. The Sck pin should be grounded to minimize noise.

POWER SUPPLY NOISE REJECTION 2. Liberal use of ceramic bypass capacitors is

One capacitor is recommended for best rejection of power recommended.

supply noise (reference Figure 7 below). The capacitor 3. Robust low inductance ground wiring should be used.

should be located as close as possible to the device supply 4. Care should be taken to ensure there is “thermal

pin (VDD). The capacitor lead length should be as short as symmetry” on the PCB immediately surrounding the

possible, and surface mount capacitor is preferred. For MEMSIC device and that there is no significant heat

typical applications, the capacitor can be ceramic 0.1 μF. source nearby.

5. A metal ground plane should be added directly beneath

the MEMSIC device. The size of the ground plane

should be similar to the MEMSIC device’s footprint

and be as thick as possible.

6. Vias can be added symmetrically around the ground

plane. Vias increase thermal isolation of the device

from the rest of the PCB.

MEMSIC MXD2020E/F Rev H Page 7 of 8 2/26/2007

PACKAGE DRAWING

Fig 8: Hermetically Sealed Package Outline

MEMSIC MXD2020E/F Rev H Page 8 of 8 2/26/2007

Das könnte Ihnen auch gefallen

- Ultra Low Noise AccelerometerDokument9 SeitenUltra Low Noise Accelerometerestraj1954Noch keine Bewertungen

- Low Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedDokument11 SeitenLow Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedmhasansharifiNoch keine Bewertungen

- Low Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedDokument1 SeiteLow Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedmhasansharifiNoch keine Bewertungen

- Amplifiers: Model 30S1G6Dokument6 SeitenAmplifiers: Model 30S1G6raj1388Noch keine Bewertungen

- Adxl103 203Dokument16 SeitenAdxl103 203Eduardo Citti Truck CenterNoch keine Bewertungen

- Low Cost Accelerometer With Analog Output: 100 G Single AxisDokument5 SeitenLow Cost Accelerometer With Analog Output: 100 G Single AxispejanssoNoch keine Bewertungen

- Low-Cost With Duty Cycle Output: 2 G Dual-Axis AccelerometerDokument12 SeitenLow-Cost With Duty Cycle Output: 2 G Dual-Axis AccelerometerpraveensahNoch keine Bewertungen

- Miniature Flange Mount Hall Effect Proximity Sensor: DIMENSIONS (In) MM Block DiagramDokument2 SeitenMiniature Flange Mount Hall Effect Proximity Sensor: DIMENSIONS (In) MM Block DiagramsantiagoNoch keine Bewertungen

- Low Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionDokument12 SeitenLow Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionjosmelNoch keine Bewertungen

- Low Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionDokument12 SeitenLow Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionMarlon PerinNoch keine Bewertungen

- 900Mhz Digital Pico Repeater: FeaturesDokument2 Seiten900Mhz Digital Pico Repeater: FeatureszayedNoch keine Bewertungen

- Bosch SensortechDokument2 SeitenBosch SensortechGkou DojkuNoch keine Bewertungen

- Product Data Sheet0900aecd806c4b0eDokument7 SeitenProduct Data Sheet0900aecd806c4b0eAnonymous 8kmJwgcNoch keine Bewertungen

- High Performance FSK/ASK Transceiver IC: Data SheetDokument45 SeitenHigh Performance FSK/ASK Transceiver IC: Data Sheetআশিক পালোয়ানNoch keine Bewertungen

- Product Brief QN8036: High Performance Digital FM Transceiver For Portable DevicesDokument3 SeitenProduct Brief QN8036: High Performance Digital FM Transceiver For Portable Devicesdeena.karan5281Noch keine Bewertungen

- High Performance ISM Band Transceiver IC: Data SheetDokument41 SeitenHigh Performance ISM Band Transceiver IC: Data SheetTuần Hào ĐỗNoch keine Bewertungen

- Obsolete: Low Cost Accelerometers With Digital Output ADXL202/ADXL210Dokument11 SeitenObsolete: Low Cost Accelerometers With Digital Output ADXL202/ADXL210adfumegaNoch keine Bewertungen

- PHOTOSWITCH R Photoelectric Sensors 42BC Long Range Background SuppressionDokument3 SeitenPHOTOSWITCH R Photoelectric Sensors 42BC Long Range Background Suppressiondwi aryantoNoch keine Bewertungen

- CM-FM2-Oxx-CM-FM2D-Oxx-DS-3-0-0Dokument2 SeitenCM-FM2-Oxx-CM-FM2D-Oxx-DS-3-0-0Witto PereNoch keine Bewertungen

- Low Cost, Complete 12-Bit Resolver-to-Digital Converter: CS Is Logic HIDokument12 SeitenLow Cost, Complete 12-Bit Resolver-to-Digital Converter: CS Is Logic HIFrantsiskoNoch keine Bewertungen

- Circuit Note: Fully Automatic High Performance Conductivity Measurement SystemDokument10 SeitenCircuit Note: Fully Automatic High Performance Conductivity Measurement SystemSupolNoch keine Bewertungen

- BHP 900Dokument1 SeiteBHP 900Fanica ColbeaNoch keine Bewertungen

- Unit-3 - Analog Multiplier - AD534Dokument20 SeitenUnit-3 - Analog Multiplier - AD534yp2401553Noch keine Bewertungen

- VX 705Dokument8 SeitenVX 705DimaNoch keine Bewertungen

- LA1136NDokument28 SeitenLA1136NВячеслав ГлушакNoch keine Bewertungen

- lbo-310aDokument1 Seitelbo-310afranciscoNoch keine Bewertungen

- TW28 Datasheet D4en PDFDokument80 SeitenTW28 Datasheet D4en PDFiustinianNoch keine Bewertungen

- 1800Mhz Digital Band Selective Repeater: FeaturesDokument3 Seiten1800Mhz Digital Band Selective Repeater: FeaturesDwi KurniawanNoch keine Bewertungen

- Max 5407Dokument7 SeitenMax 5407agifieldfoxNoch keine Bewertungen

- 200Mhz Cursor Readout Analog Oscilloscope: FeaturesDokument2 Seiten200Mhz Cursor Readout Analog Oscilloscope: Featuresdani385arNoch keine Bewertungen

- Datasheet Laurs Router Switch 5702Dokument2 SeitenDatasheet Laurs Router Switch 5702GregNoch keine Bewertungen

- Pg060 - Coaxial RG LSHF Series & 540 Trunk Cable LSHFDokument1 SeitePg060 - Coaxial RG LSHF Series & 540 Trunk Cable LSHFDolyNoch keine Bewertungen

- 50 V Ultra-Low Noise FOC Motor Controller: Features and Benefits DescriptionDokument26 Seiten50 V Ultra-Low Noise FOC Motor Controller: Features and Benefits Descriptionsanthosha rkNoch keine Bewertungen

- ADF7021-NBCPZ ADF7021-NBCPZ. ADF7021-NBCPZ-RL7 Eval - ADF7021-NDB9Z Eval - ADF7021-NDBIZDokument69 SeitenADF7021-NBCPZ ADF7021-NBCPZ. ADF7021-NBCPZ-RL7 Eval - ADF7021-NDB9Z Eval - ADF7021-NDBIZTuần Hào ĐỗNoch keine Bewertungen

- I16v SIP Video Intercom: HighlightsDokument2 SeitenI16v SIP Video Intercom: HighlightsFreddy RodriguezNoch keine Bewertungen

- Lmg1210 200-V, 1.5-A, 3-A Half-Bridge Mosfet and Gan Fet Driver With Adjustable Dead Time For Applications Up To 50 MHZDokument30 SeitenLmg1210 200-V, 1.5-A, 3-A Half-Bridge Mosfet and Gan Fet Driver With Adjustable Dead Time For Applications Up To 50 MHZharshalvikasNoch keine Bewertungen

- 1900Mhz Digital Band Selective Repeater: Mbda-1933Dokument2 Seiten1900Mhz Digital Band Selective Repeater: Mbda-1933thunderNoch keine Bewertungen

- ITechHD HD Series Datasheet Final 4.8.15 OriginalDokument2 SeitenITechHD HD Series Datasheet Final 4.8.15 Originaldekilac896Noch keine Bewertungen

- Dual-Band GSM&DCS Pico Repeater Signal BoosterDokument2 SeitenDual-Band GSM&DCS Pico Repeater Signal Boosterbasil sharyNoch keine Bewertungen

- CQ Amateur Radio 05-2019Dokument116 SeitenCQ Amateur Radio 05-2019testNoch keine Bewertungen

- Auirfz 44 NDokument9 SeitenAuirfz 44 NFrancisco BandresNoch keine Bewertungen

- High Performance, ISM Band, FSK/ASK Transceiver IC: Data SheetDokument47 SeitenHigh Performance, ISM Band, FSK/ASK Transceiver IC: Data SheetSsr ShaNoch keine Bewertungen

- Peralatan PBIDokument2 SeitenPeralatan PBIAchmad Syafii Arifin BandoNoch keine Bewertungen

- Low Cost, Miniature Isolation Amplifiers AD202/AD204: High AccuracyDokument12 SeitenLow Cost, Miniature Isolation Amplifiers AD202/AD204: High AccuracyDiego I. HernándezNoch keine Bewertungen

- Zapd-50w+ RF SplitterDokument1 SeiteZapd-50w+ RF SplitterIan JaredNoch keine Bewertungen

- Scopemeter Test Tools Selection Guide: 190C Color Scopemeter Series 190B Scopemeter Series Fluke 120 SeriesDokument1 SeiteScopemeter Test Tools Selection Guide: 190C Color Scopemeter Series 190B Scopemeter Series Fluke 120 SeriesmehralsmenschNoch keine Bewertungen

- AL6T 66 BsmarTV Solutions GF V1Dokument2 SeitenAL6T 66 BsmarTV Solutions GF V1CarlosAgustoPinedaSanchezNoch keine Bewertungen

- Ad8319 1Dokument19 SeitenAd8319 1Игорь ЛуговскойNoch keine Bewertungen

- DTS Tkda 08-2019 EngDokument2 SeitenDTS Tkda 08-2019 EngErick PerezNoch keine Bewertungen

- Jack RJ - 45, Arco en CDokument5 SeitenJack RJ - 45, Arco en CmrscribdNoch keine Bewertungen

- Ice 2 As 01Dokument24 SeitenIce 2 As 01teleserviceNoch keine Bewertungen

- LT1738Dokument20 SeitenLT1738asminusNoch keine Bewertungen

- Solid State Broadband High Power Amplifier: 2031 - BBS2E3KKODokument3 SeitenSolid State Broadband High Power Amplifier: 2031 - BBS2E3KKOfonpereiraNoch keine Bewertungen

- ACS720 DatasheetDokument30 SeitenACS720 DatasheetRicardo AntunesNoch keine Bewertungen

- Ad7 710Dokument28 SeitenAd7 710thinh nguyenNoch keine Bewertungen

- ADRF5020Dokument13 SeitenADRF5020Jeong-geun KimNoch keine Bewertungen

- Nexygen Plus 41 User Manual Issue 10Dokument107 SeitenNexygen Plus 41 User Manual Issue 10MARY CARMEN NAVARRETE GUILENNoch keine Bewertungen

- TSXPCX1031Dokument4 SeitenTSXPCX1031Rodrigo Alexis50% (2)

- DICD Tutorial 5Dokument5 SeitenDICD Tutorial 5Pavika Sharma100% (1)

- Implementation of An 8 Floor Control System With A PDFDokument105 SeitenImplementation of An 8 Floor Control System With A PDFtariqNoch keine Bewertungen

- AEIEDokument6 SeitenAEIEarijit_ghosh_18Noch keine Bewertungen

- VU OCW Offline Installation Guide Ver 1.0.0Dokument15 SeitenVU OCW Offline Installation Guide Ver 1.0.0Arif Qureshi0% (1)

- Berkeley Socket API - I: Unit 01.03.01 CS 5220: Computer CommunicationsDokument17 SeitenBerkeley Socket API - I: Unit 01.03.01 CS 5220: Computer CommunicationsViswanath KalannagariNoch keine Bewertungen

- Cisco Unified Contact Center Express Install and Upgrade Guide, Release 11.0Dokument50 SeitenCisco Unified Contact Center Express Install and Upgrade Guide, Release 11.0yuriNoch keine Bewertungen

- Peewee ORM Documentation: Quickstart GuideDokument142 SeitenPeewee ORM Documentation: Quickstart GuidejohnnokiaNoch keine Bewertungen

- Bogar 12000 Book PDF Free PDFDokument3 SeitenBogar 12000 Book PDF Free PDFGanesanNoch keine Bewertungen

- CD4541B - CMOS Programmable TimerDokument19 SeitenCD4541B - CMOS Programmable TimerHugo PerezNoch keine Bewertungen

- Practical List With Solution For Software EngineeringDokument3 SeitenPractical List With Solution For Software EngineeringTIRTHKUMAR SHAHNoch keine Bewertungen

- UNOS On GNS3 Through Qemu: StepsDokument5 SeitenUNOS On GNS3 Through Qemu: StepsYogeshwar Sharma 219467Noch keine Bewertungen

- Ica Lab (135) Iii-IDokument87 SeitenIca Lab (135) Iii-IesesesNoch keine Bewertungen

- DNCMag-201605 Issue24Dokument54 SeitenDNCMag-201605 Issue24pjcdNoch keine Bewertungen

- Caching in Distributed File SystemsDokument56 SeitenCaching in Distributed File SystemsArchana PanwarNoch keine Bewertungen

- PC WORX 6 IEC 61131 ProgrammingDokument442 SeitenPC WORX 6 IEC 61131 ProgrammingAmartuvshin Enkhtur100% (1)

- Components OverviewDokument112 SeitenComponents OverviewJorge MezaNoch keine Bewertungen

- August 2021 Cloud Reseller PricelistDokument1.705 SeitenAugust 2021 Cloud Reseller PricelistjoseNoch keine Bewertungen

- JDBC 1Dokument23 SeitenJDBC 1karanrjoshi2003Noch keine Bewertungen

- Easy-to-Build 5W PLL FM Transmitter KitDokument14 SeitenEasy-to-Build 5W PLL FM Transmitter KitArdhika Dhennis Putra AnandaNoch keine Bewertungen

- Lab Exercise 3 - SniffingDokument4 SeitenLab Exercise 3 - SniffingRyan RobinsonNoch keine Bewertungen

- Logic GatesDokument19 SeitenLogic Gateshabtemariam mollaNoch keine Bewertungen

- Kelvin Hughes VDR BrochureDokument2 SeitenKelvin Hughes VDR BrochureNishant PandyaNoch keine Bewertungen

- XBOX 360 Back up and Burn ToolKit GuideDokument103 SeitenXBOX 360 Back up and Burn ToolKit GuideLeeann TaverasNoch keine Bewertungen

- Survey techniques for injecting and analyzing faults in electronic systemsDokument16 SeitenSurvey techniques for injecting and analyzing faults in electronic systemsMustafamna Al SalamNoch keine Bewertungen

- Cisco VPN Error CodesDokument15 SeitenCisco VPN Error CodesbossfnNoch keine Bewertungen

- COPA1 ST Sem TPDokument422 SeitenCOPA1 ST Sem TPNaveen NarnualNoch keine Bewertungen

- Sicame - MR - Ashok Moni - 22-11799 - Keysight - Daq970a - 16.05.2022Dokument1 SeiteSicame - MR - Ashok Moni - 22-11799 - Keysight - Daq970a - 16.05.2022AshokNoch keine Bewertungen

- GA22-7286-01 System Z Parallel Sysplex RecoveryDokument368 SeitenGA22-7286-01 System Z Parallel Sysplex RecoveryPriya EkambaramNoch keine Bewertungen