Beruflich Dokumente

Kultur Dokumente

1 4

Hochgeladen von

vvineetOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 4

Hochgeladen von

vvineetCopyright:

Verfügbare Formate

Achieve PredictabIe

ExceIIence

Integrate Lean 5ix 5igma vith

GIobaI 5ervices 5ourcing

y Arvinder Monty 5ingh

5enior Vice President

Lean 5ix 5igma and Transitions

Copyright 2007 by Genpact. All rights reserved.

Contents

Introduction. 1

Lean.Six.Sigma-Global.Sourcing.Interplay. 2

Strategic.Assessment..Laying.the.Foundation. 3

Quick.Hits. 4

Work.Transfer..Sowing.the.Seeds.of.Success. 5

Risk.Identifcation.and.Mitigation. 6

Training. 8

Case.Study:.Lean.Six.Sigma.Enables.Rapid.Process.Transition. 9

Process.Stabilization. 10

Case.Study:.Lean.Six.Sigma.Project.Reduces.Invoice.Backlog. 11

Continuous.Improvements . 12

Case.Study:.Paying.on.Time.Delivers.$13.Million.. 16

Breakthrough.to.Best-in-Class. 17

Case.Study:.Better.Payment.Terms.Saves.$63.Million. 18

Conclusion . 19

1 Achieve.Predictable.Excellence

The global outsourcing of business processes delivers exponential cost, effciency, core

competency, and innovation benefts to buy-side organizations. Mature buyers adopt

global sourcing as a cost reduction strategy, but move on to enhancing shareholder

value through higher margins, new revenue streams, and penetrating new markets to

name a few.

Some buyers gain more from global souring than others, but the most successful

organizations implement global sourcing with clinical precision. Fundamentally,

success depends on:

> Knowing what and when to outsource

> Risk identifcation and mitigation

> Managing expectations

> Flawless execution

> Continued business impact through process excellence

The key to global sourcing success is total control of the program. Customers and

suppliers control sourcing initiatives using tools such as the Capability Maturity Model

or Balanced Scorecard, depending on the process.

We at Genpact feel that Lean Six Sigma is the best way to manage global sourcing

of business processes. The Lean Six Sigma based transition structure helps to

achieve fawless migration and continuously improve processes by reducing

variation. Eventually Lean Six Sigma drives outsourced processes to best-in-class.

2 Achieve.Predictable.Excellence

Lean 5ix 5igma GIobaI 5ourcing InterpIay

Genpact leverages Lean Six Sigma to divide a global sourcing initiative to clearly

demarked phases that include:

> Strategic Process Assessment

> Onsite Re-engineering

> Work Transfer

> Process Stabilization

> Continuous Improvements

> Transform to Best-in-Class

Adherence to the Lean Six Sigma discipline of measurement solves unique issues

such as identifying the wrong process for outsourcing, poor expectation management,

and a lack of visibility into the process among others. Not using Lean Six Sigma on

the other hand can result in a loss of process control and also an inability to achieve

outsourcing goals.

Lean Six Sigma Roadmap to Process Excellence

L

e

v

e

l

o

f

I

m

p

r

o

v

e

m

e

n

t

Phase I Phase II Phase III

Voice of the Customer

Strategic

Assessment

Work

Transfer

Process

Stabilization

Continuous

Improvement

Best in

Class

3 Achieve.Predictable.Excellence

Strategic.Assessment..Laying.the.Foundation.

Strategic assessment enables companies to decide what to outsource and when to

outsource. Mature companies use this phase to build a strategic outsourcing plan,

which blueprints their outsourcing journey. The next steps in this phase include:

> Get customer buy-in and ownership

> Understand customer expectations

> Build a plan to smoothly outsource

> Defne service levels

> Build timelines for processes to be outsourced

> Jointly organize and commit resources

> Understand process start and stop points to

defne project boundaries

> Understand the current process and process map

Lean Six Sigma also stencils processes and compares them to benchmark processes.

The process handoffs, workfow, value stream, and technology are understood and

documented to enable the creation of a wing-to-wing process map.

Genpact uses the assessment phase to capture process deviations and gaps, spot

waste, assess the potential to decouple processes, and mitigate issues that can affect

the global sourcing initiative.

In order to understand processes and the risks of migrating them, the Lean Six Sigma

methodology uses face-to-face interviews with process experts at the customer

site. Questionnaires are used to understand pain points of processes and focus on

exceptions in the value chain. Based on this exercise, Genpact presents the customer

with a plan to outsource which includes:

> Processes divided up by stages

> Optimum talent count and cost

> Potential productivity gains

> Risk mitigation strategies

> Recommendations to maximize

return on investment

4 Achieve.Predictable.Excellence

Quick.Hits

In the strategic assessment and work transfer phases, buyers get quick

benefts by using Lean. Lean quickly identifes and eliminates waste,

thereby improving productivity.

Failure Modes and Effects Analysis (FMEA), a commonly used tool for instance,

delivers quick hits by analyzing potential problems in the initial outsourcing phases

when it is easier to take actions to overcome these issues. FMEA proactively identifes

potential failure modes and their effect on the process. This facilitates the teams to

put together an action plan well in advance.

Benchmarking and quality function deployment (QFD) are other tools that provide

quick hits. Benchmarking compares processes to be outsourced with best-in-class

processes to identify gaps and map scalable improvement ideas. QFD also helps

outsourcing vendors and their customers to build critical process characteristics from

the viewpoints of the customers, external markets, and technology. This enables

Genpact to prioritize and focus on the key metrics as per the customer.

Lean Six Sigma improvements give immediate results during the initial stages

of global sourcing, but more importantly, it sets up the process to move to the

continuous improvement and best-in-class phases.

5 Achieve.Predictable.Excellence

Work.Transfer..Sowing.the.Seeds.of.Success

Work transfer is the make or break stage of global sourcing and also the point where

buyers and providers sow the seeds of future success.

Several outsourcing projects fail or face tough hurdles as providers and customers do not

identify the risks inherent in outsourcing processes. This often happens when the process

handoffs are not clearly understood and how its decoupling affects the workfow.

Lean Six Sigma measures and analyzes the complete process chain prior to outsourcing

to identify and mitigate risks upfront. The performance of the processes touched by

outsourcing is measured, after a robust data collection exercise. The data is used to

determine defects and decide on metrics for future process tracking.

Next, the data collected and newly developed process maps are analyzed to determine

root causes of defects and identify areas for improvement. Genpact identifes gaps

between current performance and goal performance, captures sources of variation,

and prioritizes opportunities to improve.

Work Transfer

Strategic

Assessment

Feasibility

Analysis

Transition

Work Transfer

Service

Delivery

D

e

f

i

n

e

M

e

a

s

u

r

e

A

n

a

l

y

z

e

C

o

n

t

r

o

l

I

m

p

r

o

v

e

PLANNING EXECUTION OPERATIONS

6 Achieve.Predictable.Excellence

Risk.Identifcation.and.Mitigation

At this stage, tools such as Feasibility & Risk Analysis as well as Failure Modes &

Effects Analysis (FMEA) identify the specifc processes for outsourcing. In the feasibility

analysis, Genpact uses Lean Six Sigma to score a process on several criteria to

determine outsourcing feasibility. The criteria used are:

> Ability to decouple

> Baseline processes to measure future performance against current

> Manual intensity of the process

> Expected savings from outsourcing

> Direct contact with customer

> Process standardization level

> Process capability

> Language requirement

In assessing outsourcing risks, Lean Six Sigma examines:

> Knowledge transfer and retention

> Skill availability

> IT/ Communication requirements

> Process complexity

> Buyers openness to change

> Profciency in language

> Legal aspects

Risk Assessment & Control

Function

Part/Process

Failure Mode

Causes

Occurrence

(1-10)

RPN

Risk Priority Number

RPN = SxOxD = 1 to 1000

Controls

Detectability

(1-10)

Effects

Severity

(1-10)

7 Achieve.Predictable.Excellence

A low score on risk and high score on feasibility make a process suitable for

outsourcing. For instance in outsourcing an F&A process for a large pharmaceutical

company Genpact found high feasibility but a couple of high risk areas in

communication and peoples aspects. The risks were then mitigated through robust

knowledge transfer and effective communication within the buyers organization.

Genpact also conducts FMEA to identify failure factors in process transition and builds

a preventive plan. For instance, applying FMEA to an F&A process, Genpact examines

causes of failure such as:

> Incorrect data entry or delay in data set up

> Customer dissatisfaction and rework

> Long response times or lack of data cross referencing

> Lack of existing control such as performance

standards or supervision

Based on the FMEA results Genpact recommends a course of action prior to

shipping the process. The goal of the work transfer phase is to eliminate

disruption to client operations on outsourcing.

8 Achieve.Predictable.Excellence

Training

The work transfer phase also includes knowledge transfer where provider employees

are trained on the customers industry, domain & process skills. This phase includes

identifying training material, creating a training plan, building a standard operations

procedure and validating the resultant documentation with the customers subject

matter experts. These subject matter experts usually train future trainers onsite,

who then train associates at the process delivery center. The performance of the team

being trained is continuously monitored through a training process tracking plan

and dashboards.

Global sourcing can succeed only if vendors are able to quickly assimilate and retain

knowledge. This is proving to be increasingly diffcult given the high attrition rates in

the global sourcing industry. Genpact uses Lean Six Sigma in its people practices to

retain talent by hiring right, training right and rewarding right. As a result, Genpacts

retention rates are at twice the industry level.

During work transfer, the mutually agreed upon process metrics are validated, issue

escalation, resolution paths, and communication plans are fnalized, and the IT plan is

implemented. Genpact also fnalizes the business continuity plan at this stage.

Finally by using Lean Six Sigma in the work transfer phase both the customer and

provider clearly understand:

> The process to be outsourced

> Its links to other processes

> Commitments needed

> Expectations

9 Achieve.Predictable.Excellence

c

a

s

e

s

t

u

d

y

Lean.Six.Sigma.Enables.Rapid.Process.Transition

A leading UK-based global health and care provider wanting greater scalability

decided to move 10 processes from an existing service provider to Genpact.

The processes, involving 176 associates, had to be transitioned to India in a very

short time of two months.

The use of Lean Six Sigma right upfront at the request for proposal stage and

simultaneous implementation of the solution identifcation and transition stages

enabled rapid process migration. This transition was front loaded to ensure

customer satisfaction, seamless operations post transition and reduced time in

knowledge transfer. The steps taken in this direction were:

> Commencing remote knowledge transfer with offshore team

> Anticipatory visa clearance for potential trainees traveling to UK

> On the job training to Genpact associates

> Creation of IT alternatives

> Customer and Genpact trainers created training manuals/standard operating

procedures well in advance

> Validation of customer data to:

n Create baselines

n Defne service level agreements

n Understand critical performance metrics

n Set expectations

Genpact also created a business process management system which tracks:

> Transaction level productivity

> Daily agent productivity

> Processes and errors

> Trends through dashboards

Business.Impact. .

Genpact transitioned all the 10 process in less than two months and exceeded

customer expectations on 80 of the 88 metrics focused on productivity, accuracy

and turnaround times. Less than six months after commencing the engagement

Genpact processes 10% more claims.

10 Achieve.Predictable.Excellence

Pocess.Stabilization

To stabilize the outsourced process, Lean Six Sigma ensures that

improvements are kept on the new course by preventing a relapse.

An ongoing monitoring plan is developed, documented, and

implemented. Vendors such as Genpact have institutionalized Lean

Six Sigma improvements by modifying systems and structures that

pertain to staffng, training, and incentives.

The stabilization stage, similar to Business Process Management, uses

software tools to:

> Enable process execution

> Monitor process execution

> Analyze process and people performance

> Make process changes in real-time

> Upskilling of people on regular basis

The frst step of process stabilization is the pilot phase. Here Lean Six

Sigma validates in actual application the measurement system on

process inputs that cause or control a problem in output. This ensures

that Genpact can successfully manage the outsourced process, that

the IT systems are in place and that the process documentation is

working. Genpact also analyzes key sources of variation and tests the

offshore site readiness and business continuity.

The second area pertains to determining process capability of

the offshore site by confrming statistically that set goals are met

and defects monitored. Finally, process control is rolled out by

implementing a control plan to remediate identifed defects. The

implemented process and control plan are handed over to the

process owner. On successful implementation of the pilot plan the

outsourced process goes into full production phase. A quality team

monitors the outsourced process until it is stabilized. The metrics are

continuously monitored after process stabilization to prevent relapse

and identify opportunities to improve the process to best-in-class.

Process Stabilization

Stabilization

Monitor performance

by trend analysis

Enable zero surprise

operations through

communication

Six Sigma / Lean driven

process improvements

Create Process Mission

Document Process

Document CTQs

Identify & Segment

Improvements

Create Performance

Management System

Transition

Data Collection Plan

Transition

Performance Monitoring

Develop Dashboards

Improve Process

11 Achieve.Predictable.Excellence

c

a

s

e

s

t

u

d

y

Lean.Six.Sigma.Project.Reduces.Invoice.Backlog

After outsourcing, a $1.5 billion water technologies company continued to face

a huge backlog of invoices. The outsourcing team working on the accounts

payment process could not create appropriate accruals to close the general ledger

on time. The Genpact Lean Six Sigma team examined the process map of both

upstream and downstream processes and found the following root causes:

> The invoice amount to be booked could not be seen until the end of the year

> Productivity variance in team members

> Lack of prioritization as queued invoice details were not visible

Genpact fxed the IT system to enable viewing of invoice amount. The ability to

view the invoice enabled associates to prioritize them. Several approvals and email

responses were automated to speed up the process. All approval and rejection

notices were consolidated in a single repository for easy access. Genpact rolled

out a training plan to improve productivity of team members.

The result was a reduction in backlog from 5538 invoices to 1290.

12 Achieve.Predictable.Excellence

Continuous.Improvements.

The discipline of Lean Six Sigma must be a way of life and not just a set of discrete

green belt or black belt projects that aim to better Sigma levels and control them.

True disciples of Lean Six Sigma do not treat process stabilizations as a goal but just

another step towards continuous improvements.

Lean Six Sigma tools such as the Voice of Customer, CTQ metrics combined with

structured communication, ensures that customer expectations and value delivered are

always visible. Not only do the Lean Six Sigma tools assist the vendor in proving value,

but the buyers too are able to convey the benefts of outsourcing in their organizations.

Betters Y Factors

Productivity

Business Impact

Speed,

Customer acquisition

Retention

Control, Improve X factors

Accuracy

Minimum touch points

Analysis time

Review Rigor

Business Knowledge

Timely delivery

Uniform process steps

Reach a new level

of process efficiency

13 Achieve.Predictable.Excellence

The Voice of Customer loop runs through and ties continuous improvement and

breakthrough phases to understand customer needs and changing market conditions

that require process changes. The main tool used to get customer feedback is Net

Promoter Score (NPS). NPS measures Genpact through its customers eyes. Using

a model developed by Fred Reichheld at Bain, NPS tracks promoters who are

enthusiastic and recommend Genpact, passives who are satisfed but may not

recommend and detractors who are unhappy.

NPS Overview

Standard means to compare

customer satisfaction levels

across Biz / Processes

Proactive method of Identifying

potential concern areas

Helps capture feedback

from across the cross section

of Process Owners

W

h

a

t

i

s

N

P

S

?

Web based tool that helps to

gather data from Customers

about their Needs & Requirements

14 Achieve.Predictable.Excellence

Genpact listens attentively to customers, acts on feedback to convert passives

and detractors to promoters, resulting in an increase in NPS scores. Recent NPS

scores also improved due to process improvements, meeting CTQs/CPS and

effective communication.

A key philosophy at Genpact is to generate good profts for customers and shun bad

profts. Good profts are earned by increasing value to customer, but bad profts are

generated by increasing prices to the detriment of the customer.

Research shows that average frms are in the 5 to 10 percent NPS range, which means

that promoters are slightly higher than detractors. Several companies have negative

NPS. But past and current fast-growing companies such as Amazon, eBay, Costco,

and Dell have NPS ratings in the range of 4080%. Genpact has achieved an overall

NPS score of 55% in the frst half of 2006.

15 Achieve.Predictable.Excellence

Work Transfer

Process moved for

Measuring NPS

Process moved for

Measuring NPS

Database dump taken

for processes to be

measured

Upload completed

data on eVoC Site

Rollout the

questionnaire

scorecard to Clients

(Respondents)

Inform RM / Ops for

info. and follow-up

Filled-in Scorecard

received?

Reports Generated:

Satisfaction level by

CEO

RM every account

SDO

AVP portfolio wise

G

e

n

p

a

c

t

O

p

e

r

a

t

i

o

n

s

/

Q

u

a

l

i

t

y

C

e

n

t

r

a

l

V

O

C

T

e

a

m

R

M

R

e

s

p

o

n

d

e

n

t

G

e

n

p

a

c

t

C

l

i

e

n

t

Track details on response

from clients. Publish age

response report by CoE

Close VoC survey after

4 weeks. Publish VOC

reports on performance

Send Reminders every

week for two weeks

Respondent names

& email Ids added

Final Verification of

Respondent Details

Follow-up with

respondents for

participation

Continue online

tracking on eVOC site

for responses

Access eVOC site and

fill up the scorecard

and comments

Y

N

16 Achieve.Predictable.Excellence

c

a

s

e

s

t

u

d

y

Paying.on.Time.Delivers.$13.Million.

Corporations not paying on time do not get the best pricing from suppliers.

Suppliers often provide discounts for timely payments and levy penal interest for

delays. A global customer was losing more than 11% in discounts on invoices due

to delayed payments. The delays also created friction in the supplier relationship.

Using the Lean Six Sigma toolroot cause analysisGenpact tracked the

problem to:

> Not basing invoice prioritization on payment terms

> Inadequate training of AP team across sites

> Infrequent information updating on system

Solution

Genpact developed a tool with prioritization logic that was derived from

payment terms. The suspense report on the IT system was updated more

frequently and to prevent a productivity drop due to increased updating,

Genpact digitized several activities. Genpact is also training the AP team

across multiple sites

Business.Impact.

Performance Metric Pre-Genpact 2005 Post-Genpact 2006

Discount lost (%) 11.1 <3

Discount lost ($) $2 million $700k

Beneft to Client Impact to bottom-line is $1.3 million

17 Achieve.Predictable.Excellence

Breakthrough.to.Best-in-Class

Breakthroughs are achieved due to the best practices followed by outsourcing

vendors. Working with multiple clients give outsourcing providers access to best in

class processes over and above which they have extensive experience in improving

processes. These two strengths enable them to drive processes to best-in-class.

Genpact has achieved several breakthroughs for its customers:

> Higher revenues

> Reduced accounts receivables

> On time payables to get better pricing

> Productivity increases

> Penetrating new markets

18 Achieve.Predictable.Excellence

c

a

s

e

s

t

u

d

y

Better.Payment.Terms.Saves.$63.Million

Genpacts learning from its multiple customers helps to quickly identify problems

in specifc processes. Since Genpact has eliminated several defects for a range

of customers, each new instance of the same defect is fxed in less time. When

a global media frms account payables faced accuracy and controllership issues

Genpact quickly identifed the problems as:

> Duplicate payments

> Varied vendor payment terms

> Slow system response

Genpact used Lean Six Sigma to improve accuracy, productivity, and payment

terms by:

> Finding root causes for inaccuracy and retraining resources

> Daily audits to track duplicate payments

> Using templates to improve system response

> Reducing variance in payment terms by:

n Analyzing payment history

n Balances

n Terms of contract

Business.Impact

> $63 million savings from improved payment terms

> Accuracy up to 99% from 94%

> Zero duplicate payments from 1%

> Transactional productivity of 18%

> 43% more invoices processed

19 Achieve.Predictable.Excellence

Conclusion

Several organizations implement global sourcing without Lean Six Sigma. Some of

them have been successful and some have failed. In most cases, not integrating

Lean Six Sigma to your global sourcing initiative can lead to waste and rework. It can

also result in an inability to quantify the benefts of global sourcing and statistically

measure continuous improvements. Sometimes emerging risks are not highlighted

early enough, which can disrupt operational fow.

Without Lean Six Sigma, buyers may be able to sense the benefts of global sourcing,

but will fnd it diffcult to explicitly prove that outsourcing benefted the organization.

Lean Six Sigmas data-driven discipline and its structured communication methodology

solves the problem.

Lean Six Sigma is the DNA of Genpact. Its embedded in everything that Genpact

does, both internally and for external customers. It is a culture inherited from

Genpacts parent, GE, and necessary to successfully leverage Lean Six Sigma.

Genpact has over 400 black belts, master black belts, and quality leaders. It also

has over 2,000 certifed greenbelts and 150 lean coaches. Genpact usually runs

about 400 Six Sigma projects and over 2,400 lean projects. Genpacts Lean

Six Sigma discipline delivers industrial strength processes to customers.

Arvinder Monty Singh is Senior Vice President

of Lean Six Sigma and Transitions. He can be

reached at arvinder.singh@genpact.com.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

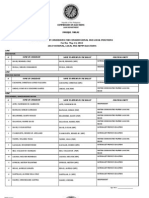

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsDokument2 SeitenCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsNoch keine Bewertungen

- Strategic Management: Cross-FunctionalDokument2 SeitenStrategic Management: Cross-Functionalirfan ullah khanNoch keine Bewertungen

- Strategies in Corporate Level Strategy and Industry Attractiveness MatrixDokument25 SeitenStrategies in Corporate Level Strategy and Industry Attractiveness MatrixAndreanAlamsahNoch keine Bewertungen

- Seattle City Council Letter To Mayor DurkanDokument8 SeitenSeattle City Council Letter To Mayor DurkanKING 5 NewsNoch keine Bewertungen

- Studiu de Caz: PRICEWATERHOUSECOOPERSDokument4 SeitenStudiu de Caz: PRICEWATERHOUSECOOPERSFlorin BălunăNoch keine Bewertungen

- Exec. Order 03-19 - BDRRMCDokument7 SeitenExec. Order 03-19 - BDRRMCnorie garcesNoch keine Bewertungen

- Anoop Mohan: Tel: +971 4 3553581 Mob: +971 563131245 Dubai, U A EDokument2 SeitenAnoop Mohan: Tel: +971 4 3553581 Mob: +971 563131245 Dubai, U A ENoushad N HamsaNoch keine Bewertungen

- RPO Requisition Approval and Sourcing FlowchartDokument5 SeitenRPO Requisition Approval and Sourcing FlowchartShaishav TodiNoch keine Bewertungen

- SWOT Analysis of JHM Consolidation BerhadDokument3 SeitenSWOT Analysis of JHM Consolidation BerhadkoghillahNoch keine Bewertungen

- Strategic Role of HRDokument7 SeitenStrategic Role of HRArchana PandaNoch keine Bewertungen

- Push Vs Pull SystemDokument3 SeitenPush Vs Pull SystemSenthil KumarNoch keine Bewertungen

- 208 - Everyday Vocabulary Elections TestDokument4 Seiten208 - Everyday Vocabulary Elections TestNhung NguyễnNoch keine Bewertungen

- 3529202Dokument4 Seiten3529202HarishNoch keine Bewertungen

- Total Quality Management Toyota: Presented byDokument25 SeitenTotal Quality Management Toyota: Presented bybugsbugsNoch keine Bewertungen

- MDDokument2 SeitenMDraghuyNoch keine Bewertungen

- Reaction Paper (PCOS Machines)Dokument2 SeitenReaction Paper (PCOS Machines)Aya BeltranNoch keine Bewertungen

- Introduction of Supply Chain ManagementDokument36 SeitenIntroduction of Supply Chain ManagementMuhammad FaizanNoch keine Bewertungen

- The Supply Chain of The IKEA CompanyDokument3 SeitenThe Supply Chain of The IKEA CompanyAndrea Chiappe Restrepo100% (1)

- Balingayan Voters ListDokument42 SeitenBalingayan Voters ListAngelika CalingasanNoch keine Bewertungen

- Democracy ExplainedDokument46 SeitenDemocracy ExplainedNirmal BhowmickNoch keine Bewertungen

- Talavera, Nueva EcijaDokument2 SeitenTalavera, Nueva EcijaSunStar Philippine NewsNoch keine Bewertungen

- Introduction To Value Stream MappingDokument33 SeitenIntroduction To Value Stream MappingbradleyjtennantNoch keine Bewertungen

- IT Project Management - Chapter 3 Project Estimating Techniques and ToolsDokument73 SeitenIT Project Management - Chapter 3 Project Estimating Techniques and ToolsZeeshan BhattiNoch keine Bewertungen

- Could Demand-Driven MRP Be The Solution We Have Been Looking ForDokument7 SeitenCould Demand-Driven MRP Be The Solution We Have Been Looking Forclemen_angNoch keine Bewertungen

- RFIDokument5 SeitenRFIAvinash Aglawe100% (1)

- Manu ChandariaDokument16 SeitenManu ChandariaMohamed AladdinNoch keine Bewertungen

- E-Business Strategy Planning and ImplementationDokument27 SeitenE-Business Strategy Planning and ImplementationWall JohnNoch keine Bewertungen

- IIMM ISO Supplement 2015Dokument32 SeitenIIMM ISO Supplement 2015dpamplona_nevilleclarke67% (3)

- MGMT Directive 11045 Protection of Classified National Security Information Accountability Control and StorageDokument24 SeitenMGMT Directive 11045 Protection of Classified National Security Information Accountability Control and StoragecharlenecleoeibenNoch keine Bewertungen

- City Clerk Recommendations of Municipal Elections Reform Commission (CF 13-1364)Dokument38 SeitenCity Clerk Recommendations of Municipal Elections Reform Commission (CF 13-1364)Southern California Public RadioNoch keine Bewertungen