Beruflich Dokumente

Kultur Dokumente

SkyJacker Dodge DTBA27 Install Manual

Hochgeladen von

lilfrogerCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SkyJacker Dodge DTBA27 Install Manual

Hochgeladen von

lilfrogerCopyright:

Verfügbare Formate

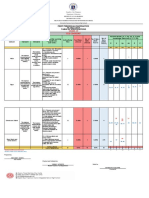

94-01 Dodge 1/2, 3/4 and 1 Ton Heavy Duty Adjustable Track Bar Designed for Vehicles w/ 4-7

Lift Part # DTBA27 * Please read all instructions thoroughly before attempting installation.

1. Park the vehicle on flat level ground. Set the emergency brake and block the tires. Remove the factory track bar. The factory track bar attaches to the passenger side axle and the driver side frame rail. 2. Locate the cross-member that runs underneath engine oil pan. This will be the mounting location for the new track bar relocation bracket. Drill out the existing brake line retainer hole on rear of cross-member. Drill all the way through cross-member using 1/2 drill bit. Install 1/2 x 2 1/2 fine thread bolt, special half-washer, and Stover nut. Drill from backside to front off cross-member. The half-washer will lock the bolt in place. (See Photo # 1). Locate factory hole on bottom passenger side of cross-member. This hole will need to be drilled all the way through with 1/2 drill bit. Install bracket to the new hole using 1/2 x 2 1/4 fine thread bolt, Stover nut and flat washer. Washer will only be used on the nut side of bolt. Install new 18x70mm bolt with washers and selflocking nut. This bolt will go through new bracket into factory track bar mount. Tighten all bolts so that inside hole on the bottom can be marked and drilled. Once marked, drill a 1/2 hole up through the cross member. (See Photo # 2).To protect the oil pan when drilling, place a small piece of cardboard in between the cross member and pan. Install new 1/2 x 2 1/2 bolt with washer and Stover nut. Once again, flat washer will not be used on bottom side of bracket. Tighten all bolts on track bar bracket. Important Note: On diesel models the oil pan is much closer to the cross member. It may be necessary to cut off the threads on the bolt to allow for clearance.

Photo #1

Photo #2

I-DTBA27 5-03

Pg 1

3. Remove tie rod from passenger side. This will allow access to track bar mount on passenger side. Using the template from page #3 as a guide cut out sway bar bracket on passenger side of axle.(See Photo #3). Install new grease fitting, sleeve, and polyurethane bushings into track bar. Be sure to grease bushings prior to installation. Place step down spacers into each side of rod end. Install track bar with rod end at the axle end. The track bar will attach to the axle using new Allen head bolt supplied. (See Photo #4). Install upper end of track bar using cam bolt, cam bolt washer and Stover nut supplied. (See Photo #5).Cam bolt will install from the front and go through to the back using cam washer and stover nut on the back side. Torque to 159 Ft. Lbs. At this time reinstall passenger side tie rod. IMPORTANT NOTE: Adjustment should always be made at the cam bolt on the upper bracket to center the axle. If needed then make further adjustments at the rod end at the axle. At no time should there be more than 1/2 of thread showing past the Jam Nut. The Skyjacker Heavy Duty track bar is designed to fit 4-7 lift heights. Install with the rod end screwed all the way in. Adjust the cam bolt at the frame to that the head of the bolt is closest to the driver side. Once installed, measure the axle to see if it is centered. This can be done by measuring the tires to see if one tire sticks out of the fender well more than the other. If the axle is still pushed out to the passenger side, (1/4 is acceptable), measure the difference. Then cut half of that amount off the threaded end of the track bar. Be sure to place masking tape around track bar where it will be cut before cutting so that powder coat does not chip. Example: The tire is sticking out 1 further on the passenger side than on the driver side. You would then cut 1/2 off the threaded end of the track bar. Do Not Under any circumstances cut more than 1/2 off of the track bar! Reinstall bar and adjust the cam bolt to set the axle center. Be sure that jam nut is tightened after the track bar is installed. Final settings should be made by a qualified alignment shop.

Photo #3 The above picture shows the removed portion of the lower track bar mount.

Photo #4 Cam Bolt

Photo #5

Pg 2

Track Bar Te Template Track Bar mplate

TOP

Dodge Lower Mount

Once installation is completed, check all bolts and hardware for proper installation. Re-tighten all bolts after the first 100 miles. Torque Specifications 1/2 Fine Thread Bolts - 85-90 ft. lbs. 1/2 Coarse Thread Cam Bolt - 75-80 ft. lbs. 18mmx70mm Bolt - 200 ft. lbs. 5/8 Cam Bolt Coarse Thread - 159 ft. lbs.

*Seat Belts Save Lives, Please Wear Your Seat Belt*

Parts List:

Part# DTB70-B D70TB-10 HD34X34DTB 34RFTJN 3381 TBS2625 ZF316 TJDLB 58X412CAMB 12X212BHFTB CBW412-7D 12X214FTB 12X212FTB 18X70MMB HW316 58STVCTN 12STVFTN 18MMN 12USSW 12SAEW 18MMFW LT100 Description DGE 94-01 7" TRACK BAR-BRKT DGE 94-01 7" TRACK BAR H.DUTY 3/4ROD END/DGE T-BAR 3/4" RIGHT HAND JAM NUT BUSHING DODGE BLK HIGH DUR TRACK BAR SLV,7"DODGE,2.625 ZERK FITTING ALEMITE, 3/16" TJ DRAG LINK BUSHING,1.125" 5/8 X 4 1/2 CAM BOLT 1/2 X 2 1/2 BUTTON HEAD FIN CAM WASHER,58X412CAMB,7"DGE 1/2 X 2 1/4 FINE THD BOLT 1/2 X 2 1/2 FINE THRD BOLT 18 X 70 METRIC BOLT/10.9 HALF WSHR-WLDED FOR DTB45-B 5/8" STOVER COARSE THRD NUT 1/2" STOVER LKNUT, FINE THD 18MM-2.5TPI NYLON LOCKNUT 1/2 USS WASHER 1/2 SAE WASHER 5/8"-A325 FLAT WASHER,PLAIN Loctite 427 1 ML TUBE Qty. 1 1 1 1 2 1 1 2 1 1 1 1 1 1 1 1 3 1 1 2 1 1 Pg 3

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 2012 Ram Truck Owners ManualDokument726 Seiten2012 Ram Truck Owners Manuallilfroger100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- MasterTech DEF Reference BookDokument13 SeitenMasterTech DEF Reference Booklilfroger100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 2012 Ram Diesel Supplement 4thDokument173 Seiten2012 Ram Diesel Supplement 4thlilfroger100% (1)

- 2008 Durango 1stDokument481 Seiten2008 Durango 1stccteo1Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- 2003 NV5600 Service ManualDokument45 Seiten2003 NV5600 Service Manuallilfroger27% (11)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 2012 Ram Cargo Van User GuideDokument132 Seiten2012 Ram Cargo Van User GuidelilfrogerNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 2003 NV3500 Service ManualDokument41 Seiten2003 NV3500 Service Manuallilfroger97% (38)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Dodge G56 Service ManualDokument68 SeitenDodge G56 Service Manuallilfroger93% (15)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 1995 Dakota Service ManualDokument1.430 Seiten1995 Dakota Service Manuallilfroger100% (4)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Dodge Getrag 238 Service ManualDokument72 SeitenDodge Getrag 238 Service Manuallilfroger100% (14)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Dodge 42RLE Service ManualDokument186 SeitenDodge 42RLE Service Manuallilfroger97% (37)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Dodge 45RFE/545RFE Service ManualDokument263 SeitenDodge 45RFE/545RFE Service Manuallilfroger94% (51)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- 01 - A Note On Introduction To E-Commerce - 9march2011Dokument12 Seiten01 - A Note On Introduction To E-Commerce - 9march2011engr_amirNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Five Kingdom ClassificationDokument6 SeitenFive Kingdom ClassificationRonnith NandyNoch keine Bewertungen

- Conveyor Control Using Programmable Logic ControllerDokument7 SeitenConveyor Control Using Programmable Logic ControllerWann RexroNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- War at Sea Clarifications Aug 10Dokument4 SeitenWar at Sea Clarifications Aug 10jdageeNoch keine Bewertungen

- Broiler ProductionDokument13 SeitenBroiler ProductionAlexa Khrystal Eve Gorgod100% (1)

- Lec. 2Dokument22 SeitenLec. 2محمدNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- DxDiag Copy MSIDokument45 SeitenDxDiag Copy MSITạ Anh TuấnNoch keine Bewertungen

- Explore The WorldDokument164 SeitenExplore The WorldEduardo C VanciNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Dokument6 SeitenRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNoch keine Bewertungen

- Protection in Distributed GenerationDokument24 SeitenProtection in Distributed Generationbal krishna dubeyNoch keine Bewertungen

- Rockwell Collins RDRDokument24 SeitenRockwell Collins RDRMatty Torchia100% (5)

- Sample Cross-Complaint For Indemnity For CaliforniaDokument4 SeitenSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Suspend and Resume Calls: Exit PlugDokument4 SeitenSuspend and Resume Calls: Exit PlugrajuNoch keine Bewertungen

- Vedic Maths Edited 2Dokument9 SeitenVedic Maths Edited 2sriram ANoch keine Bewertungen

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDokument1 SeiteLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDNoch keine Bewertungen

- Financial Accounting 1: Chapter 5 Cash and Short Term InvestmentDokument31 SeitenFinancial Accounting 1: Chapter 5 Cash and Short Term InvestmentCabdiraxmaan GeeldoonNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Alpha Sexual Power Vol 1Dokument95 SeitenAlpha Sexual Power Vol 1Joel Lopez100% (1)

- College of Computer Science Software DepartmentDokument4 SeitenCollege of Computer Science Software DepartmentRommel L. DorinNoch keine Bewertungen

- Asan Visa Ae102901499Dokument2 SeitenAsan Visa Ae102901499hardeep ranaNoch keine Bewertungen

- Ae - Centuries Before 1400 Are Listed As Browsable DirectoriesDokument3 SeitenAe - Centuries Before 1400 Are Listed As Browsable DirectoriesPolNeimanNoch keine Bewertungen

- Oracle SOA Suite 11g:buildDokument372 SeitenOracle SOA Suite 11g:buildMohsen Tavakkoli100% (1)

- Mangas PDFDokument14 SeitenMangas PDFluisfer811Noch keine Bewertungen

- 100 20210811 ICOPH 2021 Abstract BookDokument186 Seiten100 20210811 ICOPH 2021 Abstract Bookwafiq alibabaNoch keine Bewertungen

- Bigbazaar PDFDokument14 SeitenBigbazaar PDFazhagu sundaramNoch keine Bewertungen

- Participate in Safe Food Handling Practices SITXFSA002 - PowerpointDokument71 SeitenParticipate in Safe Food Handling Practices SITXFSA002 - PowerpointJuan Diego Pulgarín Henao100% (2)

- PH of Soils: Standard Test Method ForDokument3 SeitenPH of Soils: Standard Test Method ForYizel CastañedaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- CL RouterAndSwitches AE Kn1of3 AnswerDokument19 SeitenCL RouterAndSwitches AE Kn1of3 Answereugene ngNoch keine Bewertungen

- T-Tess Six Educator StandardsDokument1 SeiteT-Tess Six Educator Standardsapi-351054075100% (1)

- Obara BogbeDokument36 SeitenObara BogbeOjubona Aremu Omotiayebi Ifamoriyo0% (1)