Beruflich Dokumente

Kultur Dokumente

Assembly Drawing Example A0002

Hochgeladen von

Dudeboy NauticOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Assembly Drawing Example A0002

Hochgeladen von

Dudeboy NauticCopyright:

Verfügbare Formate

8

ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

APPLIED KINETICS STANDARD IS TO INCLUDE FASTENERS WITH BALLONS. CUSTOMER OPTION TO OMIT FASTENER BALOOONS OR FASTENERS AND FASTENER BALOONS TO SAVE ON PROJECT HOURS

F

11 31/32"

30

30

QTY. 1 1 2 1 1 1 1 1 2 1 2 2 1 1 1 1 1 4 4 2 1 2 2 2 3 4 4 2 4 2 1

PART NO. / CAT NO. DESCRIPTION AK0002M0020 CLAMP ARM AK0002M0021 CLAMP ARM LINK AK0002M0022 CYLINDER LINK ARM AK0002M0023 SPINE AK0002M0024 CYLINDER TRUNION AK0002M0025 MOUNTING PLATE TYPE 1 AK0002M0026 JAW AK0002M0027 CYLINDER LINK SPACER AK0002M0028 PIVOT PIN AK0002M0029 MOUNTING PLATE SPACER AK0002M0030 KEY AK0002M0031 PIVOT PIN AK0002M0032 MOUNTING PLATE TYPE 2 157 206 ADVU-50-120-A-P-A -SHORT-STROKE CYLINDER SUA-50 CLEVIS MOUNT CL-815-GSB GRIPPER SWIVEL BODY CL-8-RGF SWIVEL CONTACT GRIPPER 3\8x1\2x3\8 FLANGED BRONZE BUSHING 3\4x7\8x1\2 FLANGED BRONZE BUSHING 1\2x5\8x1\2 FLANGED BRONZE BUSHING 1\2-13 UNC ALLOY STL NUT GR 5 1\4-20 UNC x 2 3\8 ALLOY STL SHCS GR5 1\4 STL LOCKWASHER 1\4-20 UNC ALLOY STL NUT GR 5 1\4 x 2 L STL DOWEL PIN #6 STL LOCKWASHER #6-32 UNC x 1\2 ALLOY STL SHCS GR5 3\8 x 2 1\2 L STL DOWEL PIN 1\4-20 UNC x 3\4 ALLOY STL FHCS GR5 #10-32 UNF x 3\8 ALLOY STL SET SCR - CUP PT M12x1.75 MET ALLOY STL HEX JAM NUT CL8.8

MATERIAL / MANUFACTURER AISI C1018 CRS FB 6061-T6 AL FB AISI C1018 CRS FB 6016-T6 AL FB AISI C1018 CRS RND 6016-T6 AL FB AISI A2 TOOL STEEL 6061-T6 AL FB STD DOWEL PIN 6016-T6 AL FB AISI C1018 CRS FB AISI A2 TS DRILL ROD 6016-T6 AL FB FESTO FESTO CARR-LANE CARR-LANE ANY ANY ANY ANY ANY ANY ANY ANY ANY ANY ANY ANY ANY SUPPLIED WITH FESTO CYL

2 3/4" 4 9 2 18

21 15 1

D

18 16 9

17 14 .44 WHEN CYLINDER ROD FULLY RETRACTED AND POSITION SET 7

28 13 11/32"

13 25 6 10

6

C

31

26 5 29 28

20 3 28 NOTE: BACK OFF CYLINDER ROD 1/2 TURN ONCE CONTACT IS MADE BETWEEN ITEM #1 & #4 THEN TIGHTEN JAM NUT, ITEM #31. 22

B

24 19 23

25

11

27

27

11

12

26

12

NOTE: QTY. 2 AS SHOWN QTY. 2 MIRROR IMAGE TO SHOWN

ZONE NOTES REV. DESCRIPTION DATE BY

SolidWorks

MAINTENANCE / REBUILDING LEGEND FOLLOW SPECIFIC ASSEMBLY PROCEDURE LUBRICATION POINT, GREASE REQUIRED LUBRICATION POINT, OIL REQUIRED SPECIAL ADHESIVES OR SEALANTS SHOULD BE USED OIL LEVEL FASTENER(S) REQUIRING SPECIAL ATTENTION TO APPLIED TORQUE PART WHICH REQUIRES PERIODIC REPLACEMENT

THIRD ANGLE PROJECTION ENGINEER DRAWN DATE DWG. SCALE CLIENT DO NOT SCALE DRAWING NO MANUAL CHANGES

METRIC REFERENCE DIMENSIONS ARE INDICATED IN SQUARE PARENTHESIS [METRIC]

DIMENSIONS SHOWN IN ROUND PARENTHESIS ARE FOR REFERENCE ONLY (REF.)

AKNC AKNC 2000.08.11 1:2

20

A

19

Applied Kinetics

Professional Engineering and Design Services

CUSTOMER PROJECT

AAA AUTOMATION SERVICES 1234

A1 CASTING COMPANY BELL HOUSING DEGATE

PERIODIC TENSIONING REQUIRED

CLIENT PROJ. NUM.

GRIPPER CLAMP SUB-ASSEMBLY HOUSING GRIPPER

TOTAL QTY.

RECOMMENDED OIL LEVEL

SIZE

SHEET OF

1 1

APPLIED KINETICS PROJECT CODE

AK0002

1

DRAWING NUMBER

A0002

REV.

A0

Das könnte Ihnen auch gefallen

- Production Drawing & Pracctice Lab ManualDokument23 SeitenProduction Drawing & Pracctice Lab ManualVenkateswar Reddy Mallepally88% (8)

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionVon EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNoch keine Bewertungen

- Chapter 6 - Assembly DrawingsDokument87 SeitenChapter 6 - Assembly DrawingsAnonymous ohCM2ktv100% (1)

- ME113 Wk10&11 Ch08Dokument128 SeitenME113 Wk10&11 Ch08Atthapol YuyaNoch keine Bewertungen

- Engineering Drawing Notes BDokument50 SeitenEngineering Drawing Notes BAchinNoch keine Bewertungen

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsVon EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNoch keine Bewertungen

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Von EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Bewertung: 4.5 von 5 Sternen4.5/5 (5)

- Lesson 6. Welding SymbolsDokument37 SeitenLesson 6. Welding SymbolsJay-r MiñozaNoch keine Bewertungen

- Shop Data - Fitting Layout For HVACDokument2 SeitenShop Data - Fitting Layout For HVACDaniel AustinNoch keine Bewertungen

- Model Machine DrawingDokument15 SeitenModel Machine Drawingசெல்வ குமார்Noch keine Bewertungen

- Conventional Practice in Section ViewDokument29 SeitenConventional Practice in Section ViewmadhuNoch keine Bewertungen

- The Basics of Applying Bend FunctionsDokument18 SeitenThe Basics of Applying Bend Functionssssf-dobojNoch keine Bewertungen

- Assembly Drawings Balloons Parts ListsDokument23 SeitenAssembly Drawings Balloons Parts ListsJonoyJetticsZêrcõnSmith100% (1)

- Autodesk Inventor - Optimized Weldment Design and DocumentationDokument4 SeitenAutodesk Inventor - Optimized Weldment Design and DocumentationNdianabasi Udonkang100% (1)

- Metal Cutting PDFDokument92 SeitenMetal Cutting PDFJagadishchandrabose KondamudiNoch keine Bewertungen

- What Are Bend Allowance, Bend Deduction and K-FactorDokument11 SeitenWhat Are Bend Allowance, Bend Deduction and K-Factoritsme5616Noch keine Bewertungen

- c15 Catia v5r17Dokument76 Seitenc15 Catia v5r17Shubham HarleNoch keine Bewertungen

- Engineering Drawings Practice PDFDokument27 SeitenEngineering Drawings Practice PDFSuriyakumar SundaramNoch keine Bewertungen

- Engineering DrawingDokument1 SeiteEngineering DrawingDreamtech PressNoch keine Bewertungen

- Roller Metal Bender Version: 2019-01 Tilen ThalerDokument26 SeitenRoller Metal Bender Version: 2019-01 Tilen ThalerLuis BaracchiNoch keine Bewertungen

- K-Factor - SheetMetal PDFDokument2 SeitenK-Factor - SheetMetal PDFsunilbholNoch keine Bewertungen

- Welding Drafting Manual-AustraliaDokument15 SeitenWelding Drafting Manual-AustraliamohanumaNoch keine Bewertungen

- HMT Mandrel Bending 101Dokument80 SeitenHMT Mandrel Bending 101zaiofracassadoNoch keine Bewertungen

- DEMONSTRATION - Const. of A HelixDokument2 SeitenDEMONSTRATION - Const. of A HelixNitin B maskeNoch keine Bewertungen

- Thread EngagementDokument15 SeitenThread Engagementsumeetsaini88Noch keine Bewertungen

- DFMA - Presentation - R3Dokument58 SeitenDFMA - Presentation - R3Er Noor BashaNoch keine Bewertungen

- Chapter 22 Welding Joint Design and SYMBOLSDokument67 SeitenChapter 22 Welding Joint Design and SYMBOLSRiddhi SarvaiyaNoch keine Bewertungen

- Assembly Modeling ProcedureDokument2 SeitenAssembly Modeling ProcedureKailas Sree ChandranNoch keine Bewertungen

- DWG Export IlogicDokument1 SeiteDWG Export Ilogicbekirrrr100% (1)

- Lecture 2 Orthographic ProjectionDokument53 SeitenLecture 2 Orthographic ProjectionANNoch keine Bewertungen

- ME2257 Computer Aided Machine Drawing ManualDokument60 SeitenME2257 Computer Aided Machine Drawing ManualRanjit Rajendran100% (1)

- Engineering Graphics: Course No. 6Dokument12 SeitenEngineering Graphics: Course No. 6vic70r9Noch keine Bewertungen

- Chapter7 Demtol1 - Dimensioning StandardsDokument100 SeitenChapter7 Demtol1 - Dimensioning Standardsapi-265554570Noch keine Bewertungen

- Sheet Metal-Bending Lab PresentationDokument30 SeitenSheet Metal-Bending Lab PresentationHakan BilginNoch keine Bewertungen

- A Review On Springback Effect in Sheet Metal Forming ProcessDokument7 SeitenA Review On Springback Effect in Sheet Metal Forming ProcessantonytechnoNoch keine Bewertungen

- Tumble Jig: Presented by Bharat.k.manvi Reg No: 100926022Dokument29 SeitenTumble Jig: Presented by Bharat.k.manvi Reg No: 100926022Bharat ManviNoch keine Bewertungen

- Smithy & Forging ShopDokument24 SeitenSmithy & Forging Shopashok junapudiNoch keine Bewertungen

- Shaft KeysDokument6 SeitenShaft KeysHashem Mohamed HashemNoch keine Bewertungen

- Design of Single Point Cutting ToolDokument11 SeitenDesign of Single Point Cutting ToolSiddharth DubeyNoch keine Bewertungen

- Engineering Graphics Chapter 6Dokument63 SeitenEngineering Graphics Chapter 6aemychangminNoch keine Bewertungen

- Robots in WeldingDokument12 SeitenRobots in WeldingRehan SharmaNoch keine Bewertungen

- Fundamentals of Joining ProcessesDokument21 SeitenFundamentals of Joining ProcessesNosta Silva100% (1)

- " Welding Fixtures ": Submitted By: Kalpit Kumar 15EBKME040Dokument11 Seiten" Welding Fixtures ": Submitted By: Kalpit Kumar 15EBKME040ksiojiohyui100% (2)

- As In2014ilog 10 ItDokument27 SeitenAs In2014ilog 10 ItmanojlongNoch keine Bewertungen

- Design of Turning FixtureDokument23 SeitenDesign of Turning FixtureDIPAK VINAYAK SHIRBHATE100% (1)

- Part-B1-Petrol Engine Connecting RodDokument5 SeitenPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNoch keine Bewertungen

- MS111 MODULE 6 Techl DrawingDokument189 SeitenMS111 MODULE 6 Techl DrawingMendoza Renz JayNoch keine Bewertungen

- Engineering Graphics (ME-101) - IntroductionDokument68 SeitenEngineering Graphics (ME-101) - IntroductionSUSHIL SUSHILNoch keine Bewertungen

- Assembly Technical Drawing of v12 EngineDokument1 SeiteAssembly Technical Drawing of v12 Engineapi-244817040Noch keine Bewertungen

- Machinist Calc Pro 2UG4088E-BDokument80 SeitenMachinist Calc Pro 2UG4088E-Bbuckeyemarv967100% (2)

- Jigs & FixtureDokument33 SeitenJigs & FixtureramtwinsmeNoch keine Bewertungen

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDokument16 SeitenLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNoch keine Bewertungen

- Computer Aided Machine Drawing Laboratory: Lab ManualDokument31 SeitenComputer Aided Machine Drawing Laboratory: Lab ManualGiridharadhayalanNoch keine Bewertungen

- Engineering Graphics: Course No. 5Dokument13 SeitenEngineering Graphics: Course No. 5vic70r9Noch keine Bewertungen

- Audit FormatDokument2 SeitenAudit Formatmrajbhar792Noch keine Bewertungen

- Shantilal Shah Engineering College, Bhavnagar: Submission of Proposal For Project/ModelDokument7 SeitenShantilal Shah Engineering College, Bhavnagar: Submission of Proposal For Project/Modelparth patelNoch keine Bewertungen

- Cost Confirmation Table: Final Exams Assignment ModelDokument7 SeitenCost Confirmation Table: Final Exams Assignment ModelJewelyn C. Espares-CioconNoch keine Bewertungen

- The Complete Technology Book On Candle Making & DesignsDokument7 SeitenThe Complete Technology Book On Candle Making & DesignsBala Ratnakar KoneruNoch keine Bewertungen

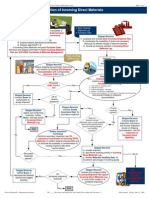

- Receiving and Inspection of Incoming Direct MaterialsDokument1 SeiteReceiving and Inspection of Incoming Direct MaterialssigmasundarNoch keine Bewertungen

- IADC Safety Alert Mud Pumps GDDokument1 SeiteIADC Safety Alert Mud Pumps GDlucas ronaldo coronel mendozaNoch keine Bewertungen

- PDS Gyproc HabitoDokument2 SeitenPDS Gyproc HabitovietNoch keine Bewertungen

- LP-PTG-701002 Inst Spec Rev DDokument79 SeitenLP-PTG-701002 Inst Spec Rev DSyahirul AlimNoch keine Bewertungen

- Webmaster Career Starter 2nd PDFDokument197 SeitenWebmaster Career Starter 2nd PDFSparkWeb SolutionsNoch keine Bewertungen

- Zenith Cooling FanDokument2 SeitenZenith Cooling Fanraza239Noch keine Bewertungen

- Pump & System - October 2011Dokument116 SeitenPump & System - October 2011rajiv_ramachandran100% (1)

- SB Unimax EnglishDokument6 SeitenSB Unimax Englishmohsen_267Noch keine Bewertungen

- Optimization of Cable Insulation Eccentricity by Taguchi Robust DesignDokument6 SeitenOptimization of Cable Insulation Eccentricity by Taguchi Robust Design李庆森Noch keine Bewertungen

- CGD IntroductionDokument48 SeitenCGD IntroductionManav Modi0% (1)

- CODEMagazine 2019 SeptemberOctoberDokument76 SeitenCODEMagazine 2019 SeptemberOctoberAnonymous ze7rq2QKyNoch keine Bewertungen

- Criticism On EDS - 1703029 - ShaurabhDokument2 SeitenCriticism On EDS - 1703029 - Shaurabhsabey22991Noch keine Bewertungen

- Fly The B717-200 User GuideDokument14 SeitenFly The B717-200 User GuideJesús Nieto DomínguezNoch keine Bewertungen

- Project On Mahindra BoleroDokument31 SeitenProject On Mahindra BoleroAnonymous 0jke0i2DPnNoch keine Bewertungen

- RoHS Guide Suppliers Directory Spring SingaporeDokument211 SeitenRoHS Guide Suppliers Directory Spring SingaporeHairulanuar SuliNoch keine Bewertungen

- Rahul ResumeDokument7 SeitenRahul ResumeMohit GautamNoch keine Bewertungen

- Attachment 2 - Asbestos Removal Control Plan (Prac 182) : RiardaDokument3 SeitenAttachment 2 - Asbestos Removal Control Plan (Prac 182) : RiardaadlydhylaNoch keine Bewertungen

- Inkt Cables CabinetsDokument52 SeitenInkt Cables CabinetsvliegenkristofNoch keine Bewertungen

- A320 Oeb N°44 L:G Gear Not Downlocked PDFDokument31 SeitenA320 Oeb N°44 L:G Gear Not Downlocked PDFpilote_a3200% (1)

- Vatluru Auction EstimateDokument15 SeitenVatluru Auction EstimateD.V.Srinivasa RaoNoch keine Bewertungen

- Mysql v5.6Dokument204 SeitenMysql v5.6Adrian LozadaNoch keine Bewertungen

- Singapore Investment News January - March 2011Dokument28 SeitenSingapore Investment News January - March 2011Ani P AlfansoNoch keine Bewertungen

- Basis ManualDokument310 SeitenBasis ManualAnonymous m13yWyGyNoch keine Bewertungen

- DRP Test WorksheetDokument11 SeitenDRP Test Worksheetmahmoud166100% (1)

- Shaker PDFDokument8 SeitenShaker PDFyorf1989Noch keine Bewertungen