Beruflich Dokumente

Kultur Dokumente

Guide Molding Comparison

Hochgeladen von

Akshay KumarOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Guide Molding Comparison

Hochgeladen von

Akshay KumarCopyright:

Verfügbare Formate

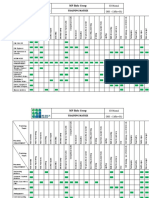

Pentz Cast Solutions Aluminum Casting: Molding Process Comparisons

Benefits/Limitations Process

Automated Precision Green Sand Molding

(See Terms & Concepts for more detailed descriptions of process) Superior performance at any volume. Extremely efficient, flexible and cost effective. Utilizes automated system for building and handling the green sand molds used to cast parts. Pentz has a PLC-controlled state-of-theart Sinto FBO II automated molding system capable of: 16x20 mold sizes 2 minute tool changes 30 second mold cycles The most versatile casting process. Produces castings with high strength and complex shapes in all sizes with excellent finish. Utilizes manually formed green sand molds to make castings. Economical solution for many castings applications. Excellent for producing parts that require high strength and pressure tight/vacuum tight sealing characteristics. Utilizes chemically bonded dry sand to form molds used to cast parts.

Typical Part Size

1 oz. to 25 lbs.

Typical Surface Finish

(RMS) Industry 250-1000 Pentz 200-400

Min. Draft Req.

1 - 3

Typical Linear Tolerances

(as cast) Industry Norm .030 up to 6. Over 6 add an additional .003/in. Pentz Typical .020 up to 6. Over 6 add an additional .002/in.

Typical Tooling Cost

Without Cores $2,000 - $5,000 With Cores $4,000 - $7,000

Typical Volume

1-2,000,000 / year Automated, efficient and effective at any volume

Manual Precision Green Sand Molding

1 oz. to several tons

Industry 250-1000 Pentz 125-400

- 3

Industry Norm .030 up to 6. Over 6 add an additional .003/in. Pentz Typical .020 up to 6. Over 6 add an additional .002/in. Industry Norm .030 up to 6. Over 6 add an additional .003/in. Pentz Typical .020 up to 6. Over 6 add an additional .002/in. Industry Norm .015 up to 3.875. Add an additional .020 up to 15.15 Pentz Typical .012 up to 3.875. Add an additional .017 up to 15.15 Industry Norm .004 up to 1 Over 1 add an additional .0015/in. up to 12 Industry Norm .005 up to 1 Over 1 add an additional .005/in. Industry Norm .001

Without Cores $800 - $4,000 With Cores $4,000 - $8,000

1-100,000 / year Any Volume

Precision Dry Sand Molding (AKA No Bake, Airset, Cold Box CO2, etc.) Permanent Mold

1 oz. to several tons

Industry 250-750 Pentz 200-500

- 3

Without Cores $800 - $4,000 With Cores $4,000 - $8,000

1-100,000 / year Any Volume

Produces very high-density castings that are pressure tight and have excellent structural characteristics. Parts are cast repeatably from the same cast iron mold. A mold typically lasts the life of the product.

1 oz. to 100 lbs.

Industry 150-750 Pentz 100-500

2 - 10

Without Cores $5,000 $40,000 With Cores $15,000 - $70,000

2,000 / year minimum Medium to High Volume

Die Casting

Casting forms in steel dies. Well suited for nonstructural components.

<1 oz. to 35 Ibs.

Industry 32-63

1 - 3

$10,000 - $400,000

5,000 minimum High Volume

Investment Casting (Lost Wax)

Casting formed in a ceramic No Industry No $3,000 - $10,000 Under 1000 mold. Generally used for minimum 10-85 Minimum small, intricate parts to Low Volume requiring very high 20 lbs. dimensional stability. Cut aluminum from billet 1 oz. Industry No $1,000 - $3,000 5 or less Hog Out using CNC program. to 20-60 Minimum (Includes program Typically used for one-off 100 lbs. & fixture costs) Low Volume prototypes. Does not look or perform like actual casting. Note: The above industry comparison depends on the casting supplier, metals, tool design, and casting design. Actual part and tooling costs vary significantly based on size, complexity, and tolerances required.

www.pentzcastsolutions.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- RFIADokument11 SeitenRFIAMary Joy TorresNoch keine Bewertungen

- Price List Grand I10 Nios DT 01.05.2022Dokument1 SeitePrice List Grand I10 Nios DT 01.05.2022VijayNoch keine Bewertungen

- AIA Design Development Deliverable ListDokument8 SeitenAIA Design Development Deliverable Listpeterhwilliams100% (1)

- GPS Navigator: ModelDokument99 SeitenGPS Navigator: ModelMain UddinNoch keine Bewertungen

- Comp7 - Answer Key - Dec. Exam - 1st SetDokument2 SeitenComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaNoch keine Bewertungen

- Network 18Dokument44 SeitenNetwork 18Ashok ThakurNoch keine Bewertungen

- Introduction To The Philosophy of Science First PartDokument138 SeitenIntroduction To The Philosophy of Science First PartChandra Sekhar Sahu100% (1)

- Culinary History and Nouvelle CuisineDokument4 SeitenCulinary History and Nouvelle CuisineARPITA BHUNIANoch keine Bewertungen

- MP Birla Group: Training MatrixDokument3 SeitenMP Birla Group: Training MatrixAprilia kusumaNoch keine Bewertungen

- User Manual ConsoleDokument45 SeitenUser Manual Consoledhana0809Noch keine Bewertungen

- Connorized Classical CatalogDokument37 SeitenConnorized Classical CatalogPablo Olea RodríguezNoch keine Bewertungen

- Water Demand Fire Flow Calculation Hydraulic ModelingDokument110 SeitenWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNoch keine Bewertungen

- Civil Engineering Set 2Dokument13 SeitenCivil Engineering Set 2Dev ThakurNoch keine Bewertungen

- Doctors Appointment - 4!14!17 Acid RefluxDokument11 SeitenDoctors Appointment - 4!14!17 Acid RefluxRay Edwin Anderson IIINoch keine Bewertungen

- CH 01Dokument24 SeitenCH 01Gabriel FlorêncioNoch keine Bewertungen

- Plant Seedling Classification Using CNNDokument12 SeitenPlant Seedling Classification Using CNNYugal Joshi0% (1)

- Mtech Geotechnical Engineering 2016Dokument48 SeitenMtech Geotechnical Engineering 2016Venkatesh ThumatiNoch keine Bewertungen

- B. WoolworthsDokument5 SeitenB. WoolworthsNjabulo Shakes NtuliNoch keine Bewertungen

- Kalpana ChawlaDokument5 SeitenKalpana Chawlanoor.md100% (2)

- Common Sense Renewed R. C. ChristianDokument276 SeitenCommon Sense Renewed R. C. Christianwarhed76100% (3)

- Descent of Darwin - Theosophy WatchDokument17 SeitenDescent of Darwin - Theosophy Watchjorge_lazaro_6Noch keine Bewertungen

- Axminster CarpetDokument19 SeitenAxminster Carpetrohit sinhaNoch keine Bewertungen

- FM200 Clean Agent System Installation GuideDokument6 SeitenFM200 Clean Agent System Installation Guidehazro lizwan halimNoch keine Bewertungen

- The Indonesian Food Processing Industry (Final)Dokument48 SeitenThe Indonesian Food Processing Industry (Final)patalnoNoch keine Bewertungen

- Technical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Dokument56 SeitenTechnical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Im Chinith100% (1)

- World Ranking For Industrial Trucks DHF 2015Dokument2 SeitenWorld Ranking For Industrial Trucks DHF 2015MA TotalforkliftNoch keine Bewertungen

- Actividad 3.1B-Xport-Model-Exercises-SCMDokument5 SeitenActividad 3.1B-Xport-Model-Exercises-SCMDante Rivera SalinasNoch keine Bewertungen

- Contact Details For Medical Schools by PostcodeDokument13 SeitenContact Details For Medical Schools by PostcodeHeena R ModiNoch keine Bewertungen

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENDokument2 SeitenData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasNoch keine Bewertungen

- ADAMHAND8A4Dokument11 SeitenADAMHAND8A4Elker José Camargo100% (1)