Beruflich Dokumente

Kultur Dokumente

1 Materials

Hochgeladen von

api-3699282Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 Materials

Hochgeladen von

api-3699282Copyright:

Verfügbare Formate

Sulzer cast materials

Corresponding materials standards Nominal chemical composition Guaranteed mechanical properties

Internal code PRE* Tensile General properties and examples of applications

Number code EN Hardness

Item EN 10283 USA ASTM C Cr Ni Mo Cu N strength Elongation %

10283 HB

[N/mm2]

Martensitic cast steels

A precipitation hardening grade with good strength properties and corrosion and wear

4Е G-X 5 CrNiCu 16 4 1.4525 А 747-99 СВ7Сu-2 0,07 14,0-15,5 4,5-5,5 2,5-3,2 1205 5 400 resistance. Used for pump components.

Austenitic cast steels (solution heat treated)

Improved resistance to hot sulphuric and organic acids due to a high molybdenum content.

4G C-X 5 CrNiMo 19 11 3 1.4412 А 743-98а CG-3M 0,03 18,0-21,0 9,0-13,0 3,0-4,0 30,8 520 25 160 Molybdenum increases the pitting resistance of steel.

43 C-X 4 NiCrCuMo 30 20 4 1.4527 А 743-98а CN-7M 0,07 19,0-22,0 27,5-30,5 2,0-3,0 3,0-4,0 30 425 35 140 A grade for castings where resistance to sulphuric acid is essential.

Excellent corrosion resistance. Nitrogen also gives very good resistance to pitting and crevice

4U AVESTA 654SMO 1.4652 UNS S32654 0,025 23,0-25,0 21,0-23,0 7,1-7,5 0,3-0,7 0,4-0,55 56 600 35 220 corrosion. Resistant to hot acids with high chloride content. Used in sea water applications,

phosphoric acid slurries, and in the liquids containing halides.

Duplex steels (austenitic-ferritic, solution heat treated)

Steel with better tensile and yield strength and better machinability than austenitic steels. Use

41 G-X 2 CrNiMoN 25 6 3 1.4468 А-890-99 3А 0,06 24,0-27,0 4,0-6,0 1,75-2,5 0,15-0,25 34,5 655 25 230 for various equipment in the chemical and metallurgical industries.

Similar grade to the previous one. The copper content improves corrosion resistance in e. g.

4L G-X 2 CrNiMoN 25 6 3 3 1.4517 А-890-99 1А 0,04 24,0-26,5 4,75-6,0 1,75-2,25 2,75-3,25 0,1-0,25 35,6 690 16 250 weak sulphuric acid solutions. Molybdenum improves general corrosion resistance.

The best resistance against pitting corrosion among duplex steels. High molybdenum content

4T G-X 2 CrNiMoN 26 7 4 1.4469 А-890-99 5А 0,03 24,0-26,0 6,0-8,0 4,0-5,0 0,1-0,3 43,1 690 18 250 guarantees excellent resistance in sulphuric and phosphoric acids with halides content. High

hardness improves wear resistance.

Nickel alloys (solution heat treated)

High Cr and Mo contents make the alloy suitable for reducing and oxidizing and otherwise

4J 2.4697 А-494-00 CW-6M 0,07 17,0-20,0 balance 17,0-20,0 495 25 180 severely corroding conditions. Good resistance to sulphuric acid, and also to hydrochloric acid

up to concentration of app.. 10%.

Wear resistant cast irons EN 12513

High-chromium white cast iron for wear resistant pumps. The high chromium content

А532-93а Class III Type

5B EN-GJN-HV600 (xCr23) EN-JN-3049 2,0-3,0 23,0-30,0 max 2,5 max 3,0 max 1,2 600 guarantees reasonable corrosion resistance. Well suited for wearing applications in alkaline

A conditions.

*PRE [Pitting Resistance Equivalent] indicates resistance against pitting and crevice forms of corrosion. PRE is calculated from sum of most important alloying elements by formula:

PRE=Cr%+3,3xMo%+16xN%

Das könnte Ihnen auch gefallen

- Cladding & Overlay - Ni InstituteDokument24 SeitenCladding & Overlay - Ni Institutesajid aslamNoch keine Bewertungen

- Senior Welding Inspector Guide BookDokument327 SeitenSenior Welding Inspector Guide Bookpalani22100% (4)

- EthanolDokument8 SeitenEthanolapi-3699282Noch keine Bewertungen

- Chiksan Original Swivel Joints: A Complete Line of Swivel Joints For Drilling, Production, and Well ServicingDokument16 SeitenChiksan Original Swivel Joints: A Complete Line of Swivel Joints For Drilling, Production, and Well Servicingger80Noch keine Bewertungen

- Microsoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFDokument56 SeitenMicrosoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFamitNoch keine Bewertungen

- Material InspectionDokument39 SeitenMaterial Inspectionkrisman f siregarNoch keine Bewertungen

- EZUGWU - Key Improvements in The Machining of Difficult-To-cut Aerospace SuperalloysDokument15 SeitenEZUGWU - Key Improvements in The Machining of Difficult-To-cut Aerospace SuperalloysLuis Fillipe Lopes TorresNoch keine Bewertungen

- Duplex Stainless Steel WeldingDokument25 SeitenDuplex Stainless Steel WeldingcfcshakerNoch keine Bewertungen

- Ultimate Guide To Cast Iron WeldingDokument16 SeitenUltimate Guide To Cast Iron WeldingMohamedNoch keine Bewertungen

- 06 Fire Water Piping Welding ProcedureDokument10 Seiten06 Fire Water Piping Welding ProcedureAkhilesh Kumar100% (1)

- MCM AllDokument7 SeitenMCM AllPalanisamy RajaNoch keine Bewertungen

- 226 PDFDokument16 Seiten226 PDFDwijendra60% (10)

- Corrosion Resistant A890 SulzerDokument6 SeitenCorrosion Resistant A890 SulzerwkfilhoNoch keine Bewertungen

- API 571 Quick ReviewDokument32 SeitenAPI 571 Quick ReviewMahmoud Hagag100% (1)

- Design of A Three-Storey Commercial Building: I. Description of The StructureDokument8 SeitenDesign of A Three-Storey Commercial Building: I. Description of The StructureShōya Ishida100% (1)

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDokument2 SeitenAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNoch keine Bewertungen

- GSG PicturesDokument13 SeitenGSG Picturesapi-3699282Noch keine Bewertungen

- Ahlstar Process PumpsDokument15 SeitenAhlstar Process Pumpsapi-3699282100% (3)

- Steel PropertiesDokument22 SeitenSteel PropertiesMOHD SALMANNoch keine Bewertungen

- Submerged Arc TechnologyDokument11 SeitenSubmerged Arc TechnologymerlonicolaNoch keine Bewertungen

- Bamboo As Construction MaterialDokument27 SeitenBamboo As Construction Material38 Anirudha PachoreNoch keine Bewertungen

- MetallurgyDokument41 SeitenMetallurgyLakshmi Narayan100% (2)

- Hardness Test of WeldsDokument4 SeitenHardness Test of Weldsjose_sebastian_2Noch keine Bewertungen

- Sulfidic Corrosion in Refineries - A ReviewDokument13 SeitenSulfidic Corrosion in Refineries - A Reviewrogerh44Noch keine Bewertungen

- Cast Materials: Sulzer PumpsDokument6 SeitenCast Materials: Sulzer PumpsElmey Bin JulkeplyNoch keine Bewertungen

- Materials Castings E00510 SulzerDokument5 SeitenMaterials Castings E00510 SulzerAmir SafdarNoch keine Bewertungen

- SULZER CastMaterials - E00510Dokument5 SeitenSULZER CastMaterials - E00510nhirpara1Noch keine Bewertungen

- Alloy Key Features: Information SourceDokument1 SeiteAlloy Key Features: Information Sourceunknown unexplainedNoch keine Bewertungen

- Alloy 6moDokument2 SeitenAlloy 6moAndre SodaNoch keine Bewertungen

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Dokument2 SeitenAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNoch keine Bewertungen

- Rust and Acid-Resistant Steels, Ferritic-AusteniticDokument3 SeitenRust and Acid-Resistant Steels, Ferritic-AusteniticKiranNoch keine Bewertungen

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDokument2 SeitenStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNoch keine Bewertungen

- Cu ZN 05Dokument2 SeitenCu ZN 05wjjt6chgtmNoch keine Bewertungen

- Dev Corrosion Abrasion Resisitant Overlay MenonCook 012415 PDFDokument19 SeitenDev Corrosion Abrasion Resisitant Overlay MenonCook 012415 PDFunknown1711Noch keine Bewertungen

- 25CR20NIDokument2 Seiten25CR20NIShariq KhanNoch keine Bewertungen

- Hard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1Dokument1 SeiteHard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1convmech enggNoch keine Bewertungen

- Structural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanDokument153 SeitenStructural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanJohn Philip Neri BesedillasNoch keine Bewertungen

- Material - (1 4462)Dokument2 SeitenMaterial - (1 4462)Ashutosh PathakNoch keine Bewertungen

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDokument3 SeitenSuper Duplex Stainless Steel: Excellent Engineering SolutionsshyamNoch keine Bewertungen

- GRADE 302: Element Content (%)Dokument3 SeitenGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Cu ZN 15Dokument2 SeitenCu ZN 15wjjt6chgtmNoch keine Bewertungen

- Technology Properties and Applications of Niobium Carbide Reinforced Steel and Iron AlloysDokument31 SeitenTechnology Properties and Applications of Niobium Carbide Reinforced Steel and Iron AlloysDaniel NavarroNoch keine Bewertungen

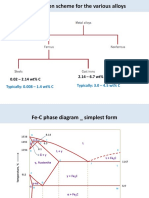

- Classification Scheme For The Various Alloys: 0.02 - 2.14 WT% C 2.14 - 6.7 WT% CDokument19 SeitenClassification Scheme For The Various Alloys: 0.02 - 2.14 WT% C 2.14 - 6.7 WT% CAlex HalesNoch keine Bewertungen

- Aero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196Dokument2 SeitenAero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196jayalakshmivinothNoch keine Bewertungen

- Stellite 6 - ERCoCrADokument2 SeitenStellite 6 - ERCoCrAtilakthakar1Noch keine Bewertungen

- VDM Alloy 926 Cronifer 1925 Hmo: Material Data Sheet No. 5002 February 2003 EditionDokument12 SeitenVDM Alloy 926 Cronifer 1925 Hmo: Material Data Sheet No. 5002 February 2003 Editionrohitshukla23Noch keine Bewertungen

- 1Dokument4 Seiten1Anonymous 6MI1wMNoch keine Bewertungen

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDokument3 SeitenStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNoch keine Bewertungen

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDokument1 SeiteBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNoch keine Bewertungen

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Dokument3 SeitenAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNoch keine Bewertungen

- Aalco Metals LTD Stainless Steel 14021 Bar 311Dokument2 SeitenAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNoch keine Bewertungen

- High Performance Austenitic Welded Stainless Tubular ProductDokument2 SeitenHigh Performance Austenitic Welded Stainless Tubular ProductGuido RuizNoch keine Bewertungen

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Dokument8 SeitenWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaNoch keine Bewertungen

- Montanstahl Duplex-WebDokument5 SeitenMontanstahl Duplex-WebXavierNoch keine Bewertungen

- Equivalência de Ñ FerrososDokument6 SeitenEquivalência de Ñ FerrososEriton SobralNoch keine Bewertungen

- Data Sheet A-10: Alloy TypeDokument3 SeitenData Sheet A-10: Alloy Typemohamed AdelNoch keine Bewertungen

- 444 Data Sheet PDFDokument2 Seiten444 Data Sheet PDFamitavjhaNoch keine Bewertungen

- Ch-07 SteelsDokument20 SeitenCh-07 SteelsKHUSHI JAINNoch keine Bewertungen

- 409 Data BulletinDokument12 Seiten409 Data BulletinWilliam PaivaNoch keine Bewertungen

- Specification Sheet: 2205: (UNS S32205/S31803)Dokument2 SeitenSpecification Sheet: 2205: (UNS S32205/S31803)Haytham MohamedNoch keine Bewertungen

- Article Pump Engineer Aluminium Bronze enDokument3 SeitenArticle Pump Engineer Aluminium Bronze enSatrio Agung WijonarkoNoch keine Bewertungen

- Cu ZN 20Dokument2 SeitenCu ZN 20wjjt6chgtmNoch keine Bewertungen

- TGN-PE-01 Hardness Testing of Welds PDFDokument6 SeitenTGN-PE-01 Hardness Testing of Welds PDFTeoTyJayNoch keine Bewertungen

- 2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeDokument13 Seiten2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeGonzalo MazaNoch keine Bewertungen

- Technical Data: Blue SheetDokument9 SeitenTechnical Data: Blue SheetforuzzNoch keine Bewertungen

- 409 Stainless Steel PDFDokument2 Seiten409 Stainless Steel PDFDang Thanh TuanNoch keine Bewertungen

- Pre-Treatments of Iron or Steel For Reducing Risk of Hydrogen EmbrittlementDokument3 SeitenPre-Treatments of Iron or Steel For Reducing Risk of Hydrogen EmbrittlementDanZel DanNoch keine Bewertungen

- Steel SpecificationsDokument4 SeitenSteel Specificationsgaurav tiwariNoch keine Bewertungen

- Section 12 - Welding Consumables - Low Alloy SteelsDokument68 SeitenSection 12 - Welding Consumables - Low Alloy SteelsFriedrich SchwimNoch keine Bewertungen

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokument1 SeiteThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiNoch keine Bewertungen

- руководство по экплуатацииDokument24 Seitenруководство по экплуатацииapi-3699282Noch keine Bewertungen

- Catalog MM 430 enDokument38 SeitenCatalog MM 430 enapi-3699282Noch keine Bewertungen

- руководство по экплуатацииDokument24 Seitenруководство по экплуатацииapi-3699282Noch keine Bewertungen

- Process Performance Motors GB 03-2005 RevADokument164 SeitenProcess Performance Motors GB 03-2005 RevAapi-3699282Noch keine Bewertungen

- Process Performance Motors GB 03-2005 RevADokument164 SeitenProcess Performance Motors GB 03-2005 RevAapi-3699282Noch keine Bewertungen

- LVStdMotorManual DE 12 2004Dokument17 SeitenLVStdMotorManual DE 12 2004api-3699282Noch keine Bewertungen

- Brochure PDokument5 SeitenBrochure Papi-3699282Noch keine Bewertungen

- 12 - Vdmee E69 4Dokument10 Seiten12 - Vdmee E69 4el_tirano_regresa7359100% (1)

- Rodrigo L. Solomon: Address: San Marcos, Camaligan, Camarines Sur Contact Number: 09489259111Dokument2 SeitenRodrigo L. Solomon: Address: San Marcos, Camaligan, Camarines Sur Contact Number: 09489259111Ally CanaveralNoch keine Bewertungen

- Duraloy Technologies, Inc.: 120 Bridge Street Scottdale, PA 15683 USA Tel: 724-887-5100 Fax: 724-887-5224Dokument16 SeitenDuraloy Technologies, Inc.: 120 Bridge Street Scottdale, PA 15683 USA Tel: 724-887-5100 Fax: 724-887-5224gmurdzhevNoch keine Bewertungen

- GL For ContainerDokument61 SeitenGL For ContainerJogi Oscar SinagaNoch keine Bewertungen

- Mumetal Permimphy Supermimphy EngDokument10 SeitenMumetal Permimphy Supermimphy Engvsraju2Noch keine Bewertungen

- Downcomer Nozzle To Drum Welding Procedure: 1.0 ScopeDokument1 SeiteDowncomer Nozzle To Drum Welding Procedure: 1.0 ScopesbmmlaNoch keine Bewertungen

- HMWSSB Godavari Pipe Line ProjectDokument110 SeitenHMWSSB Godavari Pipe Line ProjectSasidhar KatariNoch keine Bewertungen

- ISO 3834 5 Ver EDokument10 SeitenISO 3834 5 Ver ESrinivasa RaghavanNoch keine Bewertungen

- Inox Tester User Manual EP04Dokument36 SeitenInox Tester User Manual EP04Ramon PachecoNoch keine Bewertungen

- 1006 Bronze Gate Valve (Hex. Type) (Screwed) : Salient FeaturesDokument14 Seiten1006 Bronze Gate Valve (Hex. Type) (Screwed) : Salient FeaturesSanket PhatangareNoch keine Bewertungen

- Fassi Marine SerieDokument32 SeitenFassi Marine SerieArnulfo ArriagaNoch keine Bewertungen

- Individual Case Study - Queen Elizabeth's Olympic ParkDokument6 SeitenIndividual Case Study - Queen Elizabeth's Olympic ParkMichael CostaNoch keine Bewertungen

- BS 3701 1964Dokument12 SeitenBS 3701 1964Mohamed FaroukNoch keine Bewertungen

- Ambica Steels Is The Leading Producer of Ingots & Billets in IndiaDokument5 SeitenAmbica Steels Is The Leading Producer of Ingots & Billets in Indiakuldeep SinghNoch keine Bewertungen

- Welding Procedure Specification: (As Per Asme Sec Ix)Dokument1 SeiteWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNoch keine Bewertungen

- AME-26 Rev 1Dokument46 SeitenAME-26 Rev 1Gyanr BNoch keine Bewertungen

- CE 437 - PDF 01 - Intro 01 - Steel - (Design of Steel Structure)Dokument13 SeitenCE 437 - PDF 01 - Intro 01 - Steel - (Design of Steel Structure)Md Mufazzel Hossain ChowdhuryNoch keine Bewertungen

- Iron RecyclingDokument10 SeitenIron RecyclingYousef SailiniNoch keine Bewertungen

- Milling CuttersDokument25 SeitenMilling Cutterspradeep_i19Noch keine Bewertungen

- AMCRPS - PHB - 9thedition - Web PDFDokument448 SeitenAMCRPS - PHB - 9thedition - Web PDFThaungMyintNoch keine Bewertungen

- Megha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedDokument2 SeitenMegha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedABINASH SINGHNoch keine Bewertungen