Beruflich Dokumente

Kultur Dokumente

Electrosteel Castings International Expansion

Hochgeladen von

Sumit SrivastavaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Electrosteel Castings International Expansion

Hochgeladen von

Sumit SrivastavaCopyright:

Verfügbare Formate

International Marketing

Electrosteel Castings Ltd. Case

Submitted To

Prof. Anuj Sharma

Submitted By:

Sumit Srivastava Roll No. 10DM186 Section: M2

Q1. What are the key success factors for Electrosteel? Is international Expansion a good idea? Ans) Key Success Factors which lead to the success of Electrosteel are: 1. Biggest producer of CIP and DIP: Being the biggest producer of CIP and DIP in the domestic market, they have a well established brand in India. 2. Operational Cost is very Low: In India operational cost is very low and the skilled labour is available at very cheap cost 3. Policies that protect Local industry: Indian policies, politics, bureaucracy, tax structure made it difficult for foreign companies to invest in Indian market and thus provide competitive edge to local companies. 4. Huge market: The market for Electrosteel was huge not only in India but also in International market. As they were the best amongst the production of DIP and CIP pipes they had a huge market available in front of them to cover. 5. Well planned manufacturing, production and finishing line: Setting up a plant in Kardah, near Kolkata offer them infrastructure support of the existing CIP and the services of the existing staff. It also provides simplified Management control and engineering support. Yes, they should go for International expansion, because of following reasons: 1. International expansion will offer them strong opportunities for continued growth. 2. It will help them in building Electrosteel as a global brand and thus will help in translating it as a Global competitor. It will also help them in setting up their operation in foreign countries and thus they can effectively learn and use the technologies of different countries. 3. As domestic market is stagnation, extending operation to international market would be a better choice to stay in business. 4. In India small players are emerging and after few year they can be a potential tough competitors to Electrosteel.

Q2.What is your evaluation of the opportunities to expand either in Vietnam or France? Ans) Opportunities to expand in Vietnam can be explained by discussing its Pros and cons. Pros Being close to India transportation cost will be saved First mover advantage in gaining the market share Increase support for Vietnam Govt. Premium was offered to local suppliers by international agencies for the initial set up of industry Incentive of 3.1 million given by the Vietnamese Government CMCs offer to purchase DIP for other projects on contractual basis also provides more opportunities for growth Cons No proper infrastructure especially road, Transport facilities, scarcity of electricity and water supply. Bureaucratic political system may cause problem while setting up the industry

Opportunities to expand in France by discussing its pros and cons: Pros Large markets in France, Germany and fastest growing market in Spain will help in gaining market share By even setting up industry in one EU nation the company will be recognized as local supplier for the all EU nations and thus will adhere to the same laws and regulations everywhere Stable Political and bureaucratic environment Source of funding is easy. Cons High labour costs as compared to Indian and other markets (10 times higher than that of India and Vietnam) Fall in Demand in many countries (50% in UK) will also slow down the growth of the company

Language barrier is also present as most people do not prefer speaking English. Presence of competitors like Saint Gobain.

Q3. As Das, what is your recommendation going forward? How would you implement your plan? Ans) Company should go for expansion in Vietnam market. Initially they should set up a finishing line in Vietnam and should do casting and other production in the Kardah plant. It will cut down their cost and will help in knowing about the market conditions. Later on they can shift their casting and finishing line facilities in Vietnam. Reasons as to why only finishing line should be set up initially: 1. Since the sales forecast would be difficult it is better to start with the finishing line 2. Foreign funding requirement is less. 3. Transportation savings up to 10% if only finishing line is started there as raw iron is almost equal to 90% of casting irons weight.

Das könnte Ihnen auch gefallen

- Business Transfer Agreement - TemplateDokument26 SeitenBusiness Transfer Agreement - TemplateJignesh PatelNoch keine Bewertungen

- Advanced Accounting Vol.-IDokument792 SeitenAdvanced Accounting Vol.-ISaibhumi80% (5)

- Declaration of Good Faith - F WD 97 03Dokument1 SeiteDeclaration of Good Faith - F WD 97 03colimatrade100% (3)

- ANDTBF 04 (Presentation)Dokument23 SeitenANDTBF 04 (Presentation)izmitlimonNoch keine Bewertungen

- CRCMP 1Dokument4 SeitenCRCMP 1bukugendangNoch keine Bewertungen

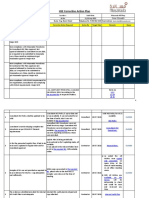

- HSE Corrective Action PlanDokument10 SeitenHSE Corrective Action PlansaqibNoch keine Bewertungen

- United Coconut Planters Bank, Petitioner, vs. Spouses Samuel and Odette Beluso, RespondentsDokument3 SeitenUnited Coconut Planters Bank, Petitioner, vs. Spouses Samuel and Odette Beluso, RespondentsPam RamosNoch keine Bewertungen

- Case 2Dokument3 SeitenCase 2Banta EdmondNoch keine Bewertungen

- CESIM Decision-Making GuideDokument37 SeitenCESIM Decision-Making GuideDhawal Panchal100% (1)

- Sunil Pandey Electrosteel CastingsDokument4 SeitenSunil Pandey Electrosteel CastingsSunil PandeyNoch keine Bewertungen

- Electro Steel Castings: Presented by Pooja Harish Devika AlexDokument13 SeitenElectro Steel Castings: Presented by Pooja Harish Devika AlexShashank Varma100% (1)

- Electrosteel Case: Manufacturing Strategy - MG 635Dokument4 SeitenElectrosteel Case: Manufacturing Strategy - MG 635Prashant LandgeNoch keine Bewertungen

- Hariyali Kissan Bazaar: & Mahindra SubhlabhDokument90 SeitenHariyali Kissan Bazaar: & Mahindra SubhlabhJamal ShahidNoch keine Bewertungen

- Strategic Analysis of Ti Cycles IndiaDokument6 SeitenStrategic Analysis of Ti Cycles Indiamonk0062006Noch keine Bewertungen

- SAP-LAP Framework for Holistic Management InquiryDokument11 SeitenSAP-LAP Framework for Holistic Management Inquiryvijchoudhary16Noch keine Bewertungen

- Marketing Dossier - 2019-20 PDFDokument49 SeitenMarketing Dossier - 2019-20 PDFpriya100% (1)

- Airtel Service Centre Physical Environment StudyDokument3 SeitenAirtel Service Centre Physical Environment StudydacchuNoch keine Bewertungen

- Alfa NetworkDokument8 SeitenAlfa Networkvinaygada67% (3)

- How Tata Steel aligns its 7 internal factors for successDokument43 SeitenHow Tata Steel aligns its 7 internal factors for successmuralimadhavaregurigupthaNoch keine Bewertungen

- Electrical Equipment Industry 2020Dokument2 SeitenElectrical Equipment Industry 2020Ipsita Bhattacharjee100% (1)

- Marketing Strategies and Consumer Response of English Newspapers in PuneDokument17 SeitenMarketing Strategies and Consumer Response of English Newspapers in PuneRubi Ragini kumariNoch keine Bewertungen

- M&MDokument8 SeitenM&MIIMnotes100% (1)

- Clariant Corporation Case Analysis Focusing on Marketing and Sales StrategiesDokument16 SeitenClariant Corporation Case Analysis Focusing on Marketing and Sales Strategieshunnygoyal0% (1)

- Xylo Case StudyDokument7 SeitenXylo Case StudyKalpesh TailorNoch keine Bewertungen

- ABC - Activity Based CostingDokument15 SeitenABC - Activity Based CostingjpereztmpNoch keine Bewertungen

- Task 03: Data Analysis: House Pricing Vs Incinerator InstallationDokument10 SeitenTask 03: Data Analysis: House Pricing Vs Incinerator InstallationKAJAL KUMARINoch keine Bewertungen

- Sarthak Patil SIP TASKSDokument9 SeitenSarthak Patil SIP TASKSSarthak PatilNoch keine Bewertungen

- IMC Group-10, Surf Excel, Daag Acche HainDokument17 SeitenIMC Group-10, Surf Excel, Daag Acche HainAnanya AgrawalNoch keine Bewertungen

- Global Logistics AssignmentDokument3 SeitenGlobal Logistics AssignmentSara KiranNoch keine Bewertungen

- Kanpur ConfectionariesDokument11 SeitenKanpur Confectionariesarvind1289Noch keine Bewertungen

- Tata IndicaDokument15 SeitenTata IndicaGaurav ShahareNoch keine Bewertungen

- "CRM System For Spicejet and Business Cycle": Submitted byDokument11 Seiten"CRM System For Spicejet and Business Cycle": Submitted byKiran KarkiNoch keine Bewertungen

- Group 4 SGVS Case Study - CA1Dokument5 SeitenGroup 4 SGVS Case Study - CA1Yash ChaudharyNoch keine Bewertungen

- V Guard Case Assignment 2Dokument4 SeitenV Guard Case Assignment 2RohitSuryaNoch keine Bewertungen

- Capturing The Value of Supplementary ServicesDokument4 SeitenCapturing The Value of Supplementary ServicesnikhilkabadiNoch keine Bewertungen

- Online Deal Aggregator Provides Savings & AnalyticsDokument10 SeitenOnline Deal Aggregator Provides Savings & Analyticsbikash_kediaNoch keine Bewertungen

- Big Bazaar Strategic AnalysisDokument16 SeitenBig Bazaar Strategic Analysisprakashprabum0% (1)

- Ease My TripDokument17 SeitenEase My TripLijoy MathewNoch keine Bewertungen

- Case Kimura KK MM1Dokument8 SeitenCase Kimura KK MM1Anuj YadavNoch keine Bewertungen

- By: Loy Lobo Aapa Angchekar Priyanka BendaleDokument45 SeitenBy: Loy Lobo Aapa Angchekar Priyanka BendaleLoy LoboNoch keine Bewertungen

- IdDokument4 SeitenIddheivayani kNoch keine Bewertungen

- MDCM's IT Objectives and Project PortfolioDokument4 SeitenMDCM's IT Objectives and Project PortfolioSabyasachi SahuNoch keine Bewertungen

- FLATPEBBLEDokument9 SeitenFLATPEBBLERasika Dhiman100% (1)

- Benefice Limited - Team 5Dokument16 SeitenBenefice Limited - Team 5DEMINoch keine Bewertungen

- Infosys Case - GRP No 3 - Assignment 2Dokument11 SeitenInfosys Case - GRP No 3 - Assignment 2harsh510% (1)

- Strat FDDokument6 SeitenStrat FDSaatwick MathurNoch keine Bewertungen

- ITC E Choupal PPT FinalDokument37 SeitenITC E Choupal PPT Finalvishal4181Noch keine Bewertungen

- The Dabbawala System: On Time Delivery Every Time: Group - 02Dokument9 SeitenThe Dabbawala System: On Time Delivery Every Time: Group - 02Saumya GautamNoch keine Bewertungen

- Leadership in TCS: 1. Motivating Yourself Will Motivate EmployeesDokument5 SeitenLeadership in TCS: 1. Motivating Yourself Will Motivate EmployeesPrem GauravNoch keine Bewertungen

- Group 6 Vora-and-CompanyDokument9 SeitenGroup 6 Vora-and-CompanyAkanksha SinhaNoch keine Bewertungen

- Vora and CompanyDokument9 SeitenVora and CompanyAditya SaxenaNoch keine Bewertungen

- Metabical Case SolutionDokument8 SeitenMetabical Case SolutionShelton Nazareth0% (1)

- Does IT Payoff Strategies of Two Banking GiantsDokument10 SeitenDoes IT Payoff Strategies of Two Banking GiantsMohit Gupta100% (1)

- 21 Chap - Module 3 - Brand PositioningDokument7 Seiten21 Chap - Module 3 - Brand PositioningraisehellNoch keine Bewertungen

- Red Lobster Assignment FULLDokument16 SeitenRed Lobster Assignment FULLSabrina FazalNoch keine Bewertungen

- CRM of Shopper's StopDokument5 SeitenCRM of Shopper's StopSheik Nazaar0% (1)

- E Commerce JabongDokument24 SeitenE Commerce JabongRabiba Zia100% (1)

- D MartDokument16 SeitenD MartVijay KumarNoch keine Bewertungen

- CRM Strategy and Outlook Group AnalysisDokument7 SeitenCRM Strategy and Outlook Group Analysistanya singhNoch keine Bewertungen

- An Internship Report On: Organization Study atDokument18 SeitenAn Internship Report On: Organization Study atKiran BabuNoch keine Bewertungen

- Sakshee Sheetal Suchita Geetanjali Deepali RohitDokument18 SeitenSakshee Sheetal Suchita Geetanjali Deepali Rohitsheetalsamant100% (1)

- Sales and Distribution Management CourseDokument8 SeitenSales and Distribution Management CourseSaurabh KadamNoch keine Bewertungen

- Challenges Faced by Kirana StoresDokument9 SeitenChallenges Faced by Kirana StoresAnand Vinod Kumar100% (1)

- Summer Internship Report in Market ResearchDokument34 SeitenSummer Internship Report in Market ResearchGaurav MukherjeeNoch keine Bewertungen

- Prithvi Electricals B2B Motor StrategyDokument4 SeitenPrithvi Electricals B2B Motor StrategyOishik BanerjiNoch keine Bewertungen

- HS 700 Applied Economics: (Course Presentation)Dokument18 SeitenHS 700 Applied Economics: (Course Presentation)ash_1982Noch keine Bewertungen

- CESIM CaseDokument8 SeitenCESIM CaseDhawal PanchalNoch keine Bewertungen

- SWOT Analysis of Bangladesh Apparel IndustryDokument7 SeitenSWOT Analysis of Bangladesh Apparel Industrysakhawat hossenNoch keine Bewertungen

- QuestionsDokument1 SeiteQuestionsadipat15Noch keine Bewertungen

- WSJ 14Dokument3 SeitenWSJ 14finbar28Noch keine Bewertungen

- Starbucks International Risks Overall StrategyDokument10 SeitenStarbucks International Risks Overall StrategySumit SrivastavaNoch keine Bewertungen

- Marketing Mix PDFDokument20 SeitenMarketing Mix PDFVikram KumarNoch keine Bewertungen

- Child Labor and Its MoralityDokument18 SeitenChild Labor and Its MoralityJulius BaldivinoNoch keine Bewertungen

- United States Court of Appeals, Eleventh CircuitDokument7 SeitenUnited States Court of Appeals, Eleventh CircuitScribd Government DocsNoch keine Bewertungen

- Before The Securities Appellate Tribunal MumbaiDokument18 SeitenBefore The Securities Appellate Tribunal Mumbainancyg868Noch keine Bewertungen

- ICICI Group AML Policy April 2008 FinalDokument24 SeitenICICI Group AML Policy April 2008 FinalbhaskarlalamNoch keine Bewertungen

- Apega ActDokument148 SeitenApega Actg6933038Noch keine Bewertungen

- CME1Part1 ENDokument149 SeitenCME1Part1 ENyoNoch keine Bewertungen

- JP Morgan - North America Metals & MiningDokument17 SeitenJP Morgan - North America Metals & MiningPT Ujatek BaruNoch keine Bewertungen

- Sir David Arculus Et Al. (2009a) Arculus Review - A Report For The Conservative PartyDokument58 SeitenSir David Arculus Et Al. (2009a) Arculus Review - A Report For The Conservative PartyPiotr WójcickiNoch keine Bewertungen

- Electronic Media and Regulatory LawDokument8 SeitenElectronic Media and Regulatory LawAnamNoch keine Bewertungen

- Securities and Exchange Commission v. Capital Gains Research Bureau, Inc., and Harry F. Schwarzmann, 306 F.2d 606, 2d Cir. (1962)Dokument19 SeitenSecurities and Exchange Commission v. Capital Gains Research Bureau, Inc., and Harry F. Schwarzmann, 306 F.2d 606, 2d Cir. (1962)Scribd Government DocsNoch keine Bewertungen

- ANSI Audit Program Ensures Standards IntegrityDokument5 SeitenANSI Audit Program Ensures Standards Integrityep915197Noch keine Bewertungen

- Chapter 19 - Value Analysis Table of ContentsDokument36 SeitenChapter 19 - Value Analysis Table of ContentsaouadibelgacemNoch keine Bewertungen

- United Interactive™ MOU White LabelDokument3 SeitenUnited Interactive™ MOU White LabelUnited Interactive™Noch keine Bewertungen

- Mayank Kumar - 2024 - ITL Final DraftDokument27 SeitenMayank Kumar - 2024 - ITL Final DraftKinjal KeyaNoch keine Bewertungen

- Consumer Protection Law Presentation SlidesDokument11 SeitenConsumer Protection Law Presentation SlidesUsenathi PhindeloNoch keine Bewertungen

- Contractor safety scoring for selectionDokument9 SeitenContractor safety scoring for selectionmadhusri002Noch keine Bewertungen

- Bank List - Top Banks in The World - AccuityDokument15 SeitenBank List - Top Banks in The World - AccuitySyed MansoorNoch keine Bewertungen

- (Type The Document Title) : Acquisition of Jaguar & Land Rover by Tata MotorsDokument46 Seiten(Type The Document Title) : Acquisition of Jaguar & Land Rover by Tata Motorsravneet050% (2)

- ACC311 Solved Midterm Paper - WWW - Vuattach.ningDokument25 SeitenACC311 Solved Midterm Paper - WWW - Vuattach.ningAwais Choudary100% (1)

- LFC Modeling Framework for Deregulated Power SystemsDokument1 SeiteLFC Modeling Framework for Deregulated Power SystemsEvans EjegiNoch keine Bewertungen

- Your Current Account Statement: Miss Blessing Urhie 94 Tanners Hall Co CarlowDokument2 SeitenYour Current Account Statement: Miss Blessing Urhie 94 Tanners Hall Co CarlowPaula UrhieNoch keine Bewertungen

- EpiPen Stakeholder AnalysisDokument11 SeitenEpiPen Stakeholder Analysis吴茗Noch keine Bewertungen