Beruflich Dokumente

Kultur Dokumente

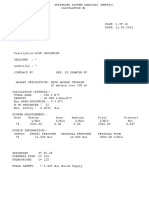

Sprinkler System Maintenance

Hochgeladen von

Rey ObiasOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sprinkler System Maintenance

Hochgeladen von

Rey ObiasCopyright:

Verfügbare Formate

Sprinkler Systems 2-1. General.

This chapter provides the minimum requirements for the routine inspection, testing, and maintenance of sprinkler systems. Table 2-1 shall be used to determine the maximum required frequencies for inspection, testing, and maintenance. Exception. Valves and fire department connections shall be inspected, tested, and maintained in accordance with chapter 9. 2-1.1 the inspection, testing, and maintenance of the automatic sprinkler systems can involve or result in a system that is out of service. The procedures outlined in chapter 11 shall be followed where such impairment to protection occurs. 2-1.2n Notification to supervisory service. To avoid false is alarms where a supervisory service is provided, the alarm receiving facility always shall be notified by the owner or designated representative as follows: a) Before conducting any test or procedure that could result in the activation of an alarm, and b) After such test or procedures are concluded. 2-1.3 Records. Records shall be maintained according to section 1-8 2-2 Inspection 2-2.1 sprinklers 2-2.1.1 sprinklers shall be inspected from the floor level annually. Sprinklers shall be free of corrosion, foreign materials, paint, and physical damage and shall be installed in the proper orientation (upright, pendent, or sidewall). Any sprinkler shall be replaced that is painted, corroded, damaged, loaded, or in the improper orientation. Exception No 1. Sprinklers installed in concealed spaces such as above suspended ceilings shall not require inspection. Exception No. 2 sprinklers installed in areas that are inaccessible for safety considerations due to Process operations shall be inspected during each scheduled shutdown. 2-2.1.2 unacceptable obstructions to spray patterns shall be corrected. 2-2.1.3 the supply of spare sprinklers shall be inspected annually for the following: a) The proper number and type of sprinklers b) A sprinkler wrench for each type of sprinkler

2-2.2 Pipe and Fittings. Sprinkler type and fittings shall be inspected annually from the floor level. Pipe and fittings shall be in good condition and free of mechanical damage, leakage, corrosion, and misalignment. Sprinkler piping shall not be subjected to external loads by materials either resting on the pipe or hung from the pipe. Exception No. 1 pipe and fittings installed in concealed such as above suspended ceilings shall not require inspection. Exception no. 2 pipe installed in areas that are inaccessible for safety considerations due to process operations shall be inspected during each scheduled shutdown. 2-2.3 Hangers and seismic braces. Sprinkler pipe hangers and seismic braces shall be inspected annually from the floor level. Hangers and seismic braces shall not be damage or loose. Hangers and seismic braces that are damaged or loose shall be replaced or refastened. Exception No. 1 hangers and seismic braces installed in concealed spaces such as above suspended ceilings shall not require inspection. Exception No. 2 hangers installed in areas that are in accessible for safety considerations due to process operation shall be inspected during each scheduled shutdown. 2-2.4 Gauges 2-2.4.1 Gauges on wet-pipe sprinkler system shall be inspected monthly to ensure that they are in good condition and that normal water supply pressure is being maintained. 2-2.4.2 gauges on dry, pre action and deluge systems shall be inspected weekly to ensure that normal air and water pressures are being maintained. 2-2.6 Alarm Devices. Alarm devices shall be inspected quarterly to verify that they are free of physical damage. 2-3 Testing 2-3.1 Sprinklers. Where sprinklers have been in service for 50 years, they shall be replaced or representative samples from one or more sample areas shall be submitted to a reorganized testing laboratory accessible to the authority having jurisdiction for field service testing. Test procedures shall be repeated at 10 year intervals. Exception No.1 fast response sprinklers that have been in service for 20 years shall be tested. they shall be retested at 0 year intervals.

2-3.1.2 A representative sample of sprinklers shall consist of a minimum of not less than four sprinklers or one percent of the number of sprinklers per individual sprinkler sample, whichever is greater. 2-3.1.3 Where one sprinkler within a representative sample fails to meet the test requirement, all sprinklers represented by the sample shall be replaced. 2-3.2 Gauges. Gauges shall be replaced e every 5 years or tested every 5 year by comparison with a calibrated gauge. Gauges not accurate to within 3 percent of the full scale shall be recalibrated or replaced. 2-3.3 Alarm devices. Waterflow alarm devices including but not limited to mechanical Water motor gongs, vane type water flow devices, and pressure switches that provide audible or visual signals shall be tested quarterly. 2-3.3.1 Testing the waterflow alarm on wet pipe systems shall be accomplished by opening the inspectors test connection. 2-3.3.2 Testing the waterflow alarm on the dry pipe, preaction, or deluge systems shall be accomplished by using the bypass connection. 2-4 Maintenance. 2-4.1 Sprinklers. 2-4.1.1 Replacement sprinklers shall have the proper characteristics for the application intended. These include: a) Style; b) Orifice size and K factor; c) Temperature rating; d) Coating if any; e) Deflector type (e.g., upright, pendent, sidewall); f) Design requirements. 2-4.1.3 Special and quick response sprinklers . special and quick response sprinklers as defined by NFPA 13, Standard for the installation of sprinkler Systems, shall be replaced with sprinklers of the same make, model, orifice, size temperature, range and thermal response characteristics, and k factor. Exception . if the special or quick response sprinkler is no longer manufactured, a special quick response sprinkler with comparable performance characteristics shall be installed 2-4.1.4 A supply of spare sprinklers (never less than 6) shall be stored in a cabinet on the premises for replacement purposes. The stock of spare sprinkler shall be proportionally representative of the types and temperature ratings of the system

sprinklers. A minimum of two sprinklers of each type and temperature ratings installed shall be provided. The cabinet shall be so located that it will not be exposed to moisture, dust, corrosion, or a temperature exceeding 100 F(38 C). 2-4.1.5 The stock of spare sprinklers shall be as follows: a) For protected facilities having not over 300 sprinklers- not less than 6 sprinklers b) For protected facilities having 300 to 1000 sprinklers- not less than 24 c) For protected facilities having over 1000 sprinklers- not less than 24 sprinklers. 2-4.1.6 A special sprinkler wrench(es) shall be provided and kept in the cabinet to be used in the removal and installation of sprinklers. A sprinkler wrenches shall be provided for each type of sprinkler installed. 2-4.1.7 Sprinklers protecting spray coating areas shall be protected using plastic bags having maximum thickness of .003 in. (0.076 mm) or with small paper bags. Coverings shall be replaced when deposits or residue accumulate. 2-4.1.8 Sprinklers shall not be altered in any respect or have any type of ornamentation, paint, or coatings applied after shipment from the place of manufacture. 2-4.1.9 Sprinklers and automatic spray nozzles used for protecting commercial type cooking equipment and ventilating systems shall be replaced annually. Exceptions. Where automatic bulb type sprinklers or spray nozzles are used and annual examination shows no build up of grease or other material on the sprinklers or spray nozzles, such sprinklers and spray nozzles shall not be required to be replaced.

Das könnte Ihnen auch gefallen

- ANSUL Aircraft HangarsDokument8 SeitenANSUL Aircraft Hangarsاحمد الجزار2007100% (1)

- Water SprayDokument2 SeitenWater SpraySaba SamankanNoch keine Bewertungen

- Sprinkler Protection For High Bay and Automated Storage in Warehouse Type Storage FacilitiesDokument11 SeitenSprinkler Protection For High Bay and Automated Storage in Warehouse Type Storage FacilitiesJose Gregorio Prada RodriguezNoch keine Bewertungen

- Fire Protection Foam Systems CatalogDokument52 SeitenFire Protection Foam Systems CatalogAhrian BenaNoch keine Bewertungen

- Documentation AnsulDokument40 SeitenDocumentation AnsulkdsessionsNoch keine Bewertungen

- Melaka Refineary Vib ProposalDokument6 SeitenMelaka Refineary Vib ProposalZul Hilmi LihinNoch keine Bewertungen

- HydraulicDokument8 SeitenHydraulicOsama OmayerNoch keine Bewertungen

- 15 Foam MakerDokument8 Seiten15 Foam MakerMatthew BennettNoch keine Bewertungen

- Section 15310 Fire Protection PipingDokument8 SeitenSection 15310 Fire Protection PipingkdpmansiNoch keine Bewertungen

- PN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingDokument5 SeitenPN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingKadiri OlanrewajuNoch keine Bewertungen

- Foam Proportioning - Diesel Tank-Data Book-1 PDFDokument207 SeitenFoam Proportioning - Diesel Tank-Data Book-1 PDFMaycol SanchezNoch keine Bewertungen

- Sizing Your Grease Trap or InterceptorDokument3 SeitenSizing Your Grease Trap or InterceptorMike Mor'zNoch keine Bewertungen

- Sprinklers PDFDokument43 SeitenSprinklers PDFpil7194Noch keine Bewertungen

- Fire Sprinkler For Non-Storage Facilities PPT Presentation PDFDokument62 SeitenFire Sprinkler For Non-Storage Facilities PPT Presentation PDFMickoAngeloRamirezAquino100% (2)

- Selecting A Fire PumpDokument24 SeitenSelecting A Fire PumpCelsoRapi50% (2)

- Sidewall SprinklerDokument6 SeitenSidewall SprinklerAhrian BenaNoch keine Bewertungen

- Fire Water Tank Design RequirementsDokument23 SeitenFire Water Tank Design RequirementsWaseem Siddique100% (1)

- Preaction System ManualDokument64 SeitenPreaction System ManualAhmed Mohamed Rashed100% (1)

- Maintenance ManualDokument17 SeitenMaintenance ManualSean ChanNoch keine Bewertungen

- Foam Chamber Data SheetDokument6 SeitenFoam Chamber Data Sheetadilmomin45Noch keine Bewertungen

- Fire FightingDokument50 SeitenFire FightingJagadeesh KandasamyNoch keine Bewertungen

- Sprinkler and SystmesDokument4 SeitenSprinkler and SystmesridwanNoch keine Bewertungen

- Sample of Nfpa Hydraulic CalculationDokument14 SeitenSample of Nfpa Hydraulic Calculationzasza100% (1)

- Sprinkler System ComponentsDokument68 SeitenSprinkler System Componentsjosediaz141Noch keine Bewertungen

- Break TanksDokument3 SeitenBreak TanksReza Khaje100% (1)

- Procedure For Inspection and Sterilisation of Water Storage TanksDokument4 SeitenProcedure For Inspection and Sterilisation of Water Storage TanksMuhammad Hussain BilalNoch keine Bewertungen

- AED Design Requirements - Jockey Pumps - Mar09Dokument5 SeitenAED Design Requirements - Jockey Pumps - Mar09rogel_gana100% (1)

- Mechanical Plan Evaluation and Review OutlineDokument11 SeitenMechanical Plan Evaluation and Review OutlineEngelbert CasanovaNoch keine Bewertungen

- Fire Hydrant SpecsDokument14 SeitenFire Hydrant SpecsGie Mak100% (2)

- 04-Sprinkler SystemDokument32 Seiten04-Sprinkler SystemRavi100% (1)

- Fixed or Semi Fixed Foam...Dokument35 SeitenFixed or Semi Fixed Foam...carybe69100% (1)

- 3844-Internal Fire Hydrants and HoseDokument22 Seiten3844-Internal Fire Hydrants and HoseSOMU_61100% (1)

- Water Spray SystemDokument5 SeitenWater Spray SystemNguyenThanhdungNoch keine Bewertungen

- SECTION 15340 Water Spray Fixed Systems Rev 0Dokument28 SeitenSECTION 15340 Water Spray Fixed Systems Rev 0Basil OguakaNoch keine Bewertungen

- Deluge Sprinkler SystemDokument8 SeitenDeluge Sprinkler SystemRaed Al-nomanNoch keine Bewertungen

- 02 - Wet Riser SystemDokument2 Seiten02 - Wet Riser SystemJeghiNoch keine Bewertungen

- Foaming Tendencies of Oil TestsDokument8 SeitenFoaming Tendencies of Oil TestsJustin EvansNoch keine Bewertungen

- For Fire SuppressionDokument28 SeitenFor Fire SuppressionAmjathkhan Shiekusman100% (1)

- Unit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Dokument21 SeitenUnit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Navya chowdaryNoch keine Bewertungen

- Fire Hydrant TestDokument3 SeitenFire Hydrant TesthfrankieNoch keine Bewertungen

- Fire Pump Questions - Churn PressureDokument5 SeitenFire Pump Questions - Churn Pressurenapster386Noch keine Bewertungen

- 3b Domestic Water Meter Installation in Meter Room GuidelinesDokument10 Seiten3b Domestic Water Meter Installation in Meter Room GuidelinesVinish HARIDAS NAIRNoch keine Bewertungen

- FP ManualDokument81 SeitenFP Manualshekharvkate100% (4)

- Nfpa 13 Chapter 1Dokument34 SeitenNfpa 13 Chapter 1hmayordomo100% (1)

- Fire Pump SelectionDokument13 SeitenFire Pump SelectionMarjhel HalligNoch keine Bewertungen

- Fire Protection TanksDokument20 SeitenFire Protection TankssbmmlaNoch keine Bewertungen

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDokument18 SeitenIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaNoch keine Bewertungen

- Multiple Foam Deluge SystemDokument10 SeitenMultiple Foam Deluge SystemTrần VânNoch keine Bewertungen

- Fire Hose Reel SystemDokument7 SeitenFire Hose Reel SystemRedford DonguyaNoch keine Bewertungen

- Fire Pump Pressure SettingsDokument2 SeitenFire Pump Pressure SettingsJhe Inibam100% (1)

- GENT Vigilon Compact ManualDokument32 SeitenGENT Vigilon Compact ManualJun Rey DasigNoch keine Bewertungen

- Fire Fighting - QatarDokument21 SeitenFire Fighting - QatarrajeshjamesNoch keine Bewertungen

- Waterspray MistextinguishingsystemDokument10 SeitenWaterspray MistextinguishingsystemSalley BukhariNoch keine Bewertungen

- Deluge System Definition Working Applications and Advantages With PDFDokument4 SeitenDeluge System Definition Working Applications and Advantages With PDFSiwaNoch keine Bewertungen

- Consulting - Specifying Engineer - NFPA 20 - Fire Pump Design PDFDokument17 SeitenConsulting - Specifying Engineer - NFPA 20 - Fire Pump Design PDFHermi David100% (1)

- Fire Water Hydrant SystemDokument5 SeitenFire Water Hydrant SystemGodwin100% (1)

- Ansul Foam Generator PDFDokument6 SeitenAnsul Foam Generator PDFSuhail EhtishamNoch keine Bewertungen

- Fire Protection - Rev.06Dokument79 SeitenFire Protection - Rev.06Anil MarturiNoch keine Bewertungen

- QCS-2010 Section 19 Part 6 Commissioning of SystemsDokument6 SeitenQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106Noch keine Bewertungen

- Preventive Maintenance PlanDokument16 SeitenPreventive Maintenance PlanAugust Hari0% (1)

- Croner PKE280 H35 Spec SheetDokument2 SeitenCroner PKE280 H35 Spec Sheetvictor hugoNoch keine Bewertungen

- RHS Columnuns Embedded in RC ResearchDokument29 SeitenRHS Columnuns Embedded in RC ResearchErnie Ernie100% (1)

- Fiber Optic CablesDokument24 SeitenFiber Optic CablesARCC2030Noch keine Bewertungen

- Viscoelastic Modeling of Flexible Pavement With Abaqus PDFDokument143 SeitenViscoelastic Modeling of Flexible Pavement With Abaqus PDFcabrel TokamNoch keine Bewertungen

- West Virginia Transporter 2017Dokument16 SeitenWest Virginia Transporter 2017Kyle LangsleyNoch keine Bewertungen

- Work, Kinetic Energy and Potential EnergyDokument28 SeitenWork, Kinetic Energy and Potential EnergyMaey AkimNoch keine Bewertungen

- Company Names and Number UAEDokument35 SeitenCompany Names and Number UAESoju Suresh100% (1)

- Spring Support Used in PipingDokument7 SeitenSpring Support Used in Pipingashish.mathur1Noch keine Bewertungen

- Pmled 6 5K 10a 66Dokument6 SeitenPmled 6 5K 10a 66Eduardo SalgadoNoch keine Bewertungen

- Need and Future of Electronics and Automation inDokument21 SeitenNeed and Future of Electronics and Automation inAjay Kumar VermaNoch keine Bewertungen

- Vsi 52 Dec 2010Dokument4 SeitenVsi 52 Dec 20103LifelinesNoch keine Bewertungen

- Integrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelDokument4 SeitenIntegrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelPavlos Vardoulakis0% (1)

- NIC Components NTC-T SeriesDokument10 SeitenNIC Components NTC-T SeriesNICCompNoch keine Bewertungen

- LECTURE 5 Cor 1Dokument44 SeitenLECTURE 5 Cor 1teamrelax75% (4)

- MSDS - Molecular Sieve 4ADokument4 SeitenMSDS - Molecular Sieve 4AadeliaaaNoch keine Bewertungen

- DASApplicationForm PDFDokument3 SeitenDASApplicationForm PDFEngr.Hamid Ismail CheemaNoch keine Bewertungen

- 2021 Product Catalogue DTH - English - LOWDokument42 Seiten2021 Product Catalogue DTH - English - LOWEmrah MertyürekNoch keine Bewertungen

- Fastner and Tooling Components. Fertrading Group Venezuela.Dokument4 SeitenFastner and Tooling Components. Fertrading Group Venezuela.Renso PiovesanNoch keine Bewertungen

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Dokument2 SeitenDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenNoch keine Bewertungen

- SDFC AdminDokument8 SeitenSDFC AdminYashpal SinghNoch keine Bewertungen

- Electrical Model of Thermal Power PlantDokument81 SeitenElectrical Model of Thermal Power PlantMahesh KumbharNoch keine Bewertungen

- Vibration Diagnosis and CorrectionDokument54 SeitenVibration Diagnosis and Correctionbhanuka2009Noch keine Bewertungen

- Vanguardia, Robert John T - Amte 125L - 1X - Aircraft Fuel Lines (Research)Dokument5 SeitenVanguardia, Robert John T - Amte 125L - 1X - Aircraft Fuel Lines (Research)Robert VanguardiaNoch keine Bewertungen

- Base Plate and Anchor Rod DesignDokument2 SeitenBase Plate and Anchor Rod DesignKannan MurugesanNoch keine Bewertungen

- LCD Monitor DC T201WA 20070521 185801 Service Manual T201Wa V02Dokument59 SeitenLCD Monitor DC T201WA 20070521 185801 Service Manual T201Wa V02cdcdanielNoch keine Bewertungen

- H Molecule. The First Problem They Considered Was The Determination of The Change inDokument2 SeitenH Molecule. The First Problem They Considered Was The Determination of The Change inDesita KamilaNoch keine Bewertungen

- Scania Jenerator DC1372A - 438-487kW PDFDokument2 SeitenScania Jenerator DC1372A - 438-487kW PDFMehmet ErenNoch keine Bewertungen

- SQAP For Pumps 2017Dokument79 SeitenSQAP For Pumps 2017MukeshNoch keine Bewertungen

- 5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop SchematicsDokument46 Seiten5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop Schematicsamier jrs100% (1)

- Chemical BondingDokument27 SeitenChemical BondingSachin Kumar50% (2)