Beruflich Dokumente

Kultur Dokumente

Bitumen Brochure PAVING GRADE-1

Hochgeladen von

Charith LiyanageOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bitumen Brochure PAVING GRADE-1

Hochgeladen von

Charith LiyanageCopyright:

Verfügbare Formate

Paving Grade Bitumen

Bitumen Classifications

Most high performing roads in Australia are built and maintained using bitumen because it is durable and has exceptional waterproofing and adhesive properties. Bitumens used in road construction and maintenance are refined and blended to meet strict road engineering requirements and industry specifications. Paving grade bitumens are categorised according to viscosity (degree of fluidity) gradings. The higher the grade, the stiffer the bitumen.

Class 170, Class 320, Class 600

Road Construction and Maintenance Applications

Quality Assurance

BP Bitumen is recognised nationally for its proven track record in delivering products of consistently high quality. Every day our products perform under the most diverse and demanding road conditions in Australia. This is attributable to a combination of our unique product technology, comprehensive quality assurance programs, operational efficiency and sophisticated production processes all supported by our highly skilled and experienced staff. We maintain an in-house national technical centre which focuses on R&D, as well as providing technical expertise and support to our customers. Our team of technical specialists is dedicated to ensuring our products are thoroughly tested at every stage from the selection of crude oil at the start of the production process, right through to delivery. Our product stewardship and rigorous quality management practices reflect our commitment to delivering the highest quality products that perform on the road. Our commitment to quality is recognised by our accreditation to Australian Standard AS/NZS 9001.

BP Bitumen Class 170

Class 170 is widely used in sprayed sealing and light asphalt applications to provide durability and fatigue resistance. It is also used to manufacture cutback bitumens, bitumen emulsions and modified bitumens.

BP Bitumen Class 320

Class 320 is most commonly used to manufacture asphalt mixes. Due to its higher viscosity, stiffer asphalt mixes can be produced to improve resistance to shoving and other problems associated with higher temperature and traffic loads.

BP Bitumen Class 600

Class 600 is primarily used to manufacture extra heavyduty asphalt pavements that need to endure substantial traffic loadings.

Storage & Handling

The storage of bitumens for prolonged periods at elevated temperatures should be avoided as quality may be adversely affected. As a general rule, bitumen should be stored at the lowest temperature that enables practical use. For normal operations, such as blending and transferring liquid bitumen, temperatures of 10C to 40C above the minimum pumping temperature are recommended. Storage & Handling Temperature Recommendations

Applications

The table below shows typical applications for paving grade bitumens: Applications Bitumen Class Class 170 Class 320 Class 600 Sprayed Sealing Light Asphalt Medium Heavy Heavy

Extra

BP Bitumen BP Bitumen BP Bitumen Class 170 Class 320 Class 600 Storage for 135 145C up to 30 days Storage for 155 165C up to 14 days Storage for 170 180C up to 7 days Maximum 190C temperature Minimum 135C pumping temperature 135 145C 155 165C 170 180C 190C 145C 135 145C 155 165C 170 180C 190C 155C

AS2008 Class 170, Class 320 & Class 600 grades

Application Temperature Recommendations BP Bitumen BP Bitumen BP Bitumen Class 170 Class 320 Class 600 Asphalt mixing Asphalt compaction Sprayed sealing 150 160C 135 150C 175 185C 155 165C 140 155C 180 190C 165 175C 150 165C N/A

Typical Characteristics

Property Typical Value BP Bitumen BP Bitumen BP Bitumen Class 170 Class 320 Class 600 Viscosity at 60C, Pa.s Viscosity at 135C, Pa.s Viscosity at 60C after RTFO, Pa.s Penetration at 25C, dmm Flashpoint, C Viscosity of residue at 60C % of original Density at 15C, kg/m3 170 0.40 320 0.53 600 0.80

Specification

BP Bitumen Class 170, Class 320 and Class 600 bitumens are manufactured to comply with the requirments of Australian Standard AS2008 Residual bitumens for pavements.

300 70 360 180

640 46 360 200

1300 27 360 215

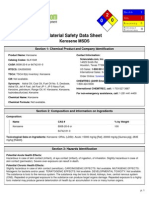

Health & Safety

To ensure hot bitumen is used in a safe and efficient manner the following safety precautions must be followed: Wear suitable personal protective equipment (PPE) at all times. Full skin protection is required to avoid accidental burns when transferring or handling hot bitumen. Always prevent contact between water and hot bitumen by checking the contents of the previous load before loading bituminous products into tankers and by following procedures to avoid violent boil-over of tanks. Avoid exposure to fumes by standing back on the gantry or upwind until the vapours have dispersed. Minimise bitumen fume by heating bitumen and asphalt products to the recommended temperatures. Minimise the use of diesel when cleaning equipment as this contributes to the bitumen fume. For a full description of hazards associated with the use of bitumen, please refer to the appropriate material safety data sheet (MSDS) available on the BP Bitumen website.

1.04

1.04

1.04

For further information, please contact us:

Web www.bpbitumen.com.au E-mail bpbitumenaustralia@bp.com Technical Helpline 1800 24 88 66 (FREECALL) National Office 55 Toll Drive, Altona North, VIC 3025 Telephone (03) 8368 8700 Facsimile (03) 8368 8701

The information provided in this Guide is of a general nature and should only be used as a guide. Please contact BP Bitumen staff to ensure you have access to the most current information and for advice relating to any particular circumstances. BP Australia Pty Ltd (BP) makes no warranty as to the completeness or accuracy of the information provided and, to the fullest extent permitted by applicable law, BP and its subsidiaries are not liable for any costs, loss or damage incurred in connection with use of the information provided in this Guide. The material contained in this Guide is protected by copyright. BP, Olexobit, Multibit, Aquabit and the Helios Design are registered trade marks of BP p.l.c. and licensed to BP Australia Pty Ltd for use in Australia. BP Australia Pty Ltd ABN 53 004 085 616, Melbourne Central, 360 Elizabeth Street, Melbourne 3000, Australia. Printed November 2008.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Industry 4.0: Industrial Revolutions and Future ViewDokument5 SeitenIndustry 4.0: Industrial Revolutions and Future ViewCharith LiyanageNoch keine Bewertungen

- Industry 4.0. DelloiteDokument32 SeitenIndustry 4.0. Delloitemihai.banicaNoch keine Bewertungen

- Measurement of Consumer Ethnocentrism of Slovak Consumers: Janka - Petrovicova@umb - SKDokument12 SeitenMeasurement of Consumer Ethnocentrism of Slovak Consumers: Janka - Petrovicova@umb - SKCharith LiyanageNoch keine Bewertungen

- 270Dokument3 Seiten270Charith LiyanageNoch keine Bewertungen

- A Solid Oxide Fuel CellDokument4 SeitenA Solid Oxide Fuel Cellbayman66Noch keine Bewertungen

- Msds - Auto I.T KeroseneDokument6 SeitenMsds - Auto I.T KeroseneCharith LiyanageNoch keine Bewertungen

- OBOR and Sri Lanka's Economic DevelopmentDokument4 SeitenOBOR and Sri Lanka's Economic DevelopmentCharith LiyanageNoch keine Bewertungen

- Wef Gitr Full ReportDokument307 SeitenWef Gitr Full ReportShakir AbdullahNoch keine Bewertungen

- Information 03 00036 PDFDokument32 SeitenInformation 03 00036 PDFCharith LiyanageNoch keine Bewertungen

- MP 18Dokument10 SeitenMP 18Charith LiyanageNoch keine Bewertungen

- 12 803 263 Coating For Metal ContainersDokument16 Seiten12 803 263 Coating For Metal ContainersCharith LiyanageNoch keine Bewertungen

- Bituminous PaintDokument9 SeitenBituminous PaintCharith LiyanageNoch keine Bewertungen

- Beneficiation and Evaluation of Mutaka KaolinDokument7 SeitenBeneficiation and Evaluation of Mutaka KaolinCharith LiyanageNoch keine Bewertungen

- CutbackDokument22 SeitenCutbackShabbir AliNoch keine Bewertungen

- 12 803 263 Coating For Metal ContainersDokument16 Seiten12 803 263 Coating For Metal ContainersCharith LiyanageNoch keine Bewertungen

- Web Docs - Cat 2 - 15 October 2013 - 040 1857 13 PDFDokument170 SeitenWeb Docs - Cat 2 - 15 October 2013 - 040 1857 13 PDFCharith LiyanageNoch keine Bewertungen

- Economic Geology of Sri LankaDokument21 SeitenEconomic Geology of Sri LankaCharith LiyanageNoch keine Bewertungen

- CoconutOil 2Dokument112 SeitenCoconutOil 2kavindaousl1Noch keine Bewertungen

- CeramicDokument41 SeitenCeramicCharith LiyanageNoch keine Bewertungen

- Sri Lanka Energy Balance 2007Dokument89 SeitenSri Lanka Energy Balance 2007jbmune6683Noch keine Bewertungen

- A Comparative Study For Pre and Post War Performance of Colombo Stock Exchange (CSE)Dokument13 SeitenA Comparative Study For Pre and Post War Performance of Colombo Stock Exchange (CSE)Charith LiyanageNoch keine Bewertungen

- Brochure Ball Mills en 1Dokument16 SeitenBrochure Ball Mills en 1Charith Liyanage100% (1)

- Dining EtiquetteDokument15 SeitenDining EtiquetteShruti JoshiNoch keine Bewertungen

- Ball-Mill 1Dokument4 SeitenBall-Mill 1Charith LiyanageNoch keine Bewertungen

- Meshaal Jasem M AlshammaryDokument234 SeitenMeshaal Jasem M AlshammaryCharith LiyanageNoch keine Bewertungen

- Coconut Oil-WorldDokument4 SeitenCoconut Oil-WorldCharith LiyanageNoch keine Bewertungen

- The Coconut Development AuthorityDokument7 SeitenThe Coconut Development AuthorityCharith LiyanageNoch keine Bewertungen

- Asphalt Emulsion TechnologyDokument58 SeitenAsphalt Emulsion Technologyapi-3698973100% (2)

- Satistics On Coconut Oil PalmDokument63 SeitenSatistics On Coconut Oil PalmpasebanjatiNoch keine Bewertungen

- Coconut ProductionDokument14 SeitenCoconut ProductionCharith LiyanageNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Rural Road Works RatesDokument87 SeitenRural Road Works RatesRoopesh Chaudhary100% (1)

- Analyzing road accidents in India's Kanyakumari districtDokument5 SeitenAnalyzing road accidents in India's Kanyakumari districtRhythika rhythiNoch keine Bewertungen

- CHARGING SYSTEM DIAGNOSIS GUIDEDokument61 SeitenCHARGING SYSTEM DIAGNOSIS GUIDEMark100% (1)

- LHB Coaches - Wikipedia, The Free EncyclopediaDokument6 SeitenLHB Coaches - Wikipedia, The Free Encyclopediakasyapreddy100% (1)

- Bacoor City Comprehensive Development PlanDokument12 SeitenBacoor City Comprehensive Development PlanMeliton JuanicoNoch keine Bewertungen

- BMW's 'Company of Ideas' Campaign Targets Creative ClassDokument12 SeitenBMW's 'Company of Ideas' Campaign Targets Creative ClassSachIn JainNoch keine Bewertungen

- ProjectReport On Expressway (Divyanshu Shukla)Dokument30 SeitenProjectReport On Expressway (Divyanshu Shukla)Divyanshu ShuklaNoch keine Bewertungen

- Examen Final - Semana 8 ESP - SEGUNDO BLOQUE - VIRTUAL-INGLES GENERAL 4 - (GRUPO B03)Dokument15 SeitenExamen Final - Semana 8 ESP - SEGUNDO BLOQUE - VIRTUAL-INGLES GENERAL 4 - (GRUPO B03)Luz Andrea Correa ForeroNoch keine Bewertungen

- Rules 7Dokument3 SeitenRules 7coneyquNoch keine Bewertungen

- Traffic Management BLK1 MIDTERMDokument76 SeitenTraffic Management BLK1 MIDTERMALJHON SABINONoch keine Bewertungen

- Waste Management Design GuidelinesDokument40 SeitenWaste Management Design GuidelinesPhilip PhamNoch keine Bewertungen

- Ulolwe Vol 3 No 10Dokument151 SeitenUlolwe Vol 3 No 10MuazNoch keine Bewertungen

- LTRC Capsule 11-3B Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete MixturesDokument2 SeitenLTRC Capsule 11-3B Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete MixtureswalaywanNoch keine Bewertungen

- Water Leakages in Subsurface Facilities: Required Watertightness, Contractual Matters, and Methods of RedevelopmentDokument10 SeitenWater Leakages in Subsurface Facilities: Required Watertightness, Contractual Matters, and Methods of Redevelopmentpujan gurungNoch keine Bewertungen

- Carspotting: The Real Adventures of Irvine Welsh by Sandy MacnairDokument40 SeitenCarspotting: The Real Adventures of Irvine Welsh by Sandy MacnairBlack & White Publishing100% (1)

- List of Consultants to whom work awarded by the NHAI for NHDP Phase IIDokument8 SeitenList of Consultants to whom work awarded by the NHAI for NHDP Phase IISurya Gowtham100% (1)

- Travel Tips To European Countries PDFDokument39 SeitenTravel Tips To European Countries PDFYa SiNoch keine Bewertungen

- Speed and DelayDokument16 SeitenSpeed and DelaySanjay KumarNoch keine Bewertungen

- Chapter One: Smart City SolutionsDokument27 SeitenChapter One: Smart City Solutionssnehal sabnisNoch keine Bewertungen

- Trinity River Trail MapDokument2 SeitenTrinity River Trail Mapjeffclaa100% (1)

- Yeshwanthpura T.T.M.C. - Banashankari T.T.M.C.: 410FA Bus Time Schedule & Line MapDokument4 SeitenYeshwanthpura T.T.M.C. - Banashankari T.T.M.C.: 410FA Bus Time Schedule & Line Mapsamardhan samardhanNoch keine Bewertungen

- MMMDokument6 SeitenMMMAbdelkader DraïNoch keine Bewertungen

- Introduction Main PDFDokument3 SeitenIntroduction Main PDFshubhu11Noch keine Bewertungen

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Dokument31 Seiten14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- Ae 211 PDFDokument15 SeitenAe 211 PDFNestor GalianoNoch keine Bewertungen

- Vice City CheatsDokument4 SeitenVice City Cheatsvarghees prabhu.sNoch keine Bewertungen

- Car Body Components and TerminologyDokument61 SeitenCar Body Components and TerminologyVi JäìNoch keine Bewertungen

- RigaDokument99 SeitenRigaankara271828Noch keine Bewertungen

- Mayor's Transport StrategyDokument14 SeitenMayor's Transport Strategymartinadam82Noch keine Bewertungen

- Company Profile IDDC 2021Dokument24 SeitenCompany Profile IDDC 2021Revi Adikharisma100% (1)