Beruflich Dokumente

Kultur Dokumente

Genius Shock

Hochgeladen von

Rob. Van WaesOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Genius Shock

Hochgeladen von

Rob. Van WaesCopyright:

Verfügbare Formate

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 2

The Scott Genius Shock should be adjusted exactly to the current rider for reaching maximum safety and fun while riding. All adjustments should be done at the local dealer or following this manual.

OWNERS MANUAL

Content

> Traction Control-Functions > Picture of the Genius Shock and Remote Control Lever > Basic Set-Up of the Remote Control > Recommended Tools for the Shock Set-Up > Set-Up of Positive Air Chamber > Set-Up of Negative Air Chamber > Set-Up of Rebound > More Details about Shock Set-Up > Maintenance / Service Guide > Important > Warranty P. 02 P. 03 P. 04 P. 05 P. 06/07 P. 06/07 P. 08 P. 08 P. 09 P. 10/11 P. 12/19

00-01

The basic set-up of the Scott Genius Shock is easy and can be done within a few minutes.

OWNERS MANUAL

SCOTT BICYCLES

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 4

OWNERS MANUAL

Traction Control-Functions Picture of the Genius Shock and Remote Control Lever

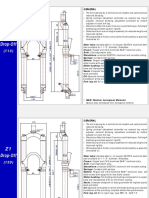

The heart of the TC-System is the newly developed and innovative Scott Genius Shock, offering three functions which make this system possible. By using the remote lever you can choose between following functions: 1. ALL TRAVEL MODE: full travel of 125mm (Genius MC) resp. 90mm (Genius RC / Genius Contessa). 2. TRACTION MODE: by reducing the air volume inside the shock the travel of the shock will be reduced to around 60%, the characteristic of the air spring gets harder. This results in climbing without bobbing and offers still optimum traction of the rear wheel. 3. LOCK OUT MODE: the shock is locked, climbing on asphalt roads is now possible without any power loss. Simultaneously a blow-off-system prevents the shock being damaged in case the rider did not open the system while crossing obstacles. In the drawing of the shock and remote lever, shown below, you will see the parts indicated with numbers which will be used in the manual for the adjustment and set-up. [2] [3]

OWNERS MANUAL

S1 S2 S3 S4 S5 S6 S7 S8 S9

Upper Shock Bolt Lower Shock Bolt Piggy-Back Shock Housing Rebound-Screw Positive Chamber Valve Negative Chamber Valve Cable Fixation Screw Lock Out Lever

S10 S11 S12 L1 L2 L3 L4

Cable Clamping Screw Traction Mode Lever Shock Piston Remote Lever Remote Control Cable Tension Screw Allen Screw

You will find following positions on the remote lever: [1]

2 S7 1

S1

S9 S8 S6 L3 L2

S4

S3

Position lockout S12 S5 All travel S2 Traction Control-Functions Genius Shock S10 S11

L4 L1

Traction mode

Remote Lever

02-03

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 6

OWNERS MANUAL

Basic Set-Up of the Remote Control

1. Put the remote lever (L1) to position lock-out. [1] 5. When putting now the remote lever to position All Travel the cable clamping screw will pull the traction mode lever downward and the shock will offer now the full travel. [5] Please clean regularly after riding off-road the shock piston (S12) and all other parts in motion of the shock with a soft and wet cloth to prevent from excessive wear and tear.

Please note

Recommended Tools for the Shock Set-Up

For the set-up of the shock we recommend to use the tools listed below: - a shock pump with a scale up to 20 bars/300 psi with a special air valve connector preventing from air getting away while removing the pump from the shock valve and granting exact air pressure. -Therefore we recommend the Scott Shock Pump which you can order at your local Scott-Dealer with parts number 15.1.834.208.0.000 - the SAG-Boy on the back of this manual

2. Fix the remote control cable (L2) with the cable fixation screw (S8) using a 3mm allen key (tightening torque: 3 Nm) on the lock out lever (S9). [3]

6. Check now the set-up for perfect function of remote lever and shock. 3. Put the remote lever now to position Traction Mode. [1] 7. In case you want to fine-tune the brake-away power of the remote lever, you can do this by using a 2mm allen key and by turning the allen screw (L4). In case you want to readjust the tension of the remote control cable you can do this by using the tension screw (L3). [6]

4. Fix the cable clamping screw (S10) using a 2mm allen key (tightening torque 2.5Nm) about 0.5mm above the traction mode lever (S11). [4]

0.5 mm

2 mm allen keg

04-05

OWNERS MANUAL

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 8

OWNERS MANUAL

Set-Up of Positive Air Chamber IMPORTANT: For all adjustments of the air spring the lockout lever has to be in position all travel

The positive air chamber contains the air-spring you sit-on while riding. [7] To adjust the air pressure of the positive chamber of the Scott Genius Shock please refer to the following instruction: 1. Remove the valve cap of the black valve (S6) located on the Piggy-Back (S3). 2. Mount the shock pump with its adaptor on the valve 3. Pump the recommended pressure into the Piggy-Back. On the housing of the Piggy-Back you will find a table showing in the black colored areas the recommended air pressure of the positive chamber according to the riders weight. 4. When you reached the needed pressure remove the pump and put the valve cap on the valve. The negative air chamber contains the air-spring influencing the brake-away and characteristic while absorbing shocks. A too high brake-away can cause an non-secure and uncomfortable ride. [8] To adjust the air pressure of the negative chamber of the Scott Genius Shock please refer to the following instruction: 1. Remove the cap of the silver valve (S7) located on the shock housing (S4). 2. Mount the shock pump with its adaptor on the valve. 3. Pump the recommended pressure into the shock housing. On the housing of the piggy-back you will find a table showing in the silver colored areas the recommended air pressure of the negative chamber according to the riders weight. 4. When you reached the needed pressure remove the pump and put the valve cap on the valve.

Set-Up of Negative Air Chamber

We recommend to make sure that the pressure balance between positive and negative chamber follows the recommendations shown on the piggy-back. Not doing so may cause a loss in performance or comfort or may result in damage of the shock. To check the adjustment, please follow as shown below: 1. Sit on the bike, put your feet on the pedal. [9] 2. Ask a second person, to put the color beam of the SAG-Boy, recommended for your bike model, aside the eye-to-eye distance of the shock bolts. 3. If the distance between the bolts is corresponding to the length of the color beam, the air pressure is matching to your weight 4. If the distance between the bolts is shorter than the length of the color beam, the air pressure of the positive chamber is too high and should be carefully reduced by using the bleed knob of the shock pump until the measures are corresponding. [10] 5. If the distance between the bolts is longer than the length of the color beam, the air pressure of the positive chamber is too low and should be increased by using the shock pump until the measures are corresponding.

After adjusting positive and negative chamber according to the riders weight you can double check by using the SAG-Boy, which is on the back of the manual, if the SAG (negative travel) is well adjusted.

The negative travel is important when crossing grooves or holes on the trail. If the bike is well adjusted the rear wheel and the swingarm will roll through the groove without the mainframe moving. The SAG should be 15-20% of the travel for race oriented riders and 20-25% of the travel for comfort oriented riders. The SAG-Boy indicates the recommended eye-to-eye distance of the shock bolts of the different Genius models.

10

Positive Air Chamber

Negative Air Chamber

06-07

OWNERS MANUAL

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 10

OWNERS MANUAL

Set-Up of Rebound More Details about Shock Set-Up Maintenance / Service Guide

OWNERS MANUAL

By using the red rebound screw (S5) you can adjust the rebound step by step.

www.scottusa.com In addition you can download this tuning program on your pc.

Please refer to the following instruction: Ride your bike off a sidewalk (remain in the saddle) and check how many times it bounces. 1. If it bounces 1-2 times, the set up is good. 2. If it bounces more than 3 times the rebound is too fast. Turn the screw 1-2 clicks clockwise. 3. If it does not bounce the rebound is too slow. Turn the screw 1-2 clicks counter clockwise. [11]

For maintenance and service please refer to the following table:

Maintenance period

11

New

Every ride

Every 8 hours

Every 40 hours

Every 1000 hours / min. 1 x year

Check of air pressure Check of rebound Clean shock bushings, check for tear and wear, grease Change of oil/inspection at Scott Shock Service Clean shock housing Clean Lockout mechanism

Rebound Knob

08-09

Rebound describes the speed the shock comes back to its original length after absorbing an obstacle.

In case you want more exact numbers of the shock air pressure than shown on the decal on the piggy-back or youre looking for tuning hints including different shock characteristics of the Genius Shock, please have a look at

Please clean regularly after riding off-road the shock piston (S12) and all other parts in motion of the shock with a soft and wet cloth or if needed with mild soap to prevent from excessive wear and tear.

Please check that the valve caps are always fixed completely on the valves to avoid damages of the valves or inner parts of the shock caused by dust.

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 12

OWNERS MANUAL

Important

OWNERS MANUAL

The Scott Genius Shock is pressurised. Never open, disassemble or rework the shock. Only a qualified and authorized Scott service staff/shock service center should do this.

Scott recommends strongly the use of a torque key to prevent from damages on shock, shock bushings or frame. In addition the shock bolts should be fixed with Loctite medium (blue) to prevent the bolts from getting unscrewed. Damages caused by improper assembly or bad maintenance as mentioned above, are not covered by warranty.

To ship the shock to Scott or the shock service authorized by Scott please contact your local Scott dealer.

To open a shock which is under pressure can be dangerous and may cause injuries!

The Scott Genius Shock always must be adjusted to the riders weight to warrant perfect function. Therefore check before every ride the shock for fitting air pressure.

Once the recommended check up is made by Scott or a shock service authorized by Scott, it is reported in the maintenance schedule at the end of the manual, which will then enable you to claim for warranty within the warranty period.

10-11

Riding a defective or not properly working shock can result in the loss of control over the bike and may cause severe or dangerous injuries!

In case you want to disassemble the shock from the bike for service or other reasons please note the recommended tightening torque of 10Nm for the shock bolts.

The owner of the shock is responsible for the costs of the service.

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 14

FOR SCOTT GENIUS SHOCK

03

Scott warrants its Genius Shock for two years for defects in material and/or workmanship. In addition following parts are not covered by warranty:

Model Year Size Frame

________________________ ________________________ ________________________ ________________________

The warranty period starts with the day of purchase. It is obligatory to give a copy of the bill of purchase together with the shock to Scott. In case the bill can not be shown Scott is free to reject the warranty claim. Following damages are not covered by warranty: - improper use - damages on the piston seals caused by high pressure washers - damages in the surface of the shock or piston caused by cable housings, stones or crashes - any attempts to disassemble the rear shock - changes in technical specifications - oil changes not made at Scott or Shock Service Centers authorized by Scott - neglecting the service and maintenance periods mentioned in the maintenance schedule (please refer to the maintenance schedule listed above in this manual)

- all piston bushings and sliders - the surface of the piston - the fixation bushings - the shock bolts Claims must be made through an authorized Scott dealer. For information regarding the nearest dealer, write or call this company or the national Scott Distributor.

DATE OF PURCHASE

DEALERS SIGNATURE

12-13

- all seals and mud scrapers

OWNERS MANUAL

WARRANTY

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 16

SCOTT SERVICE PLAN

SCOTT SERVICE PLAN

Model Year Size Frame

___________________ ___________________ ___________________ ___________________

Service comment : ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________

Model Year Size Frame

___________________ ___________________ ___________________ ___________________

Service comment : ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________

DATE OF SERVICE

DEALERS SIGNATURE

DATE OF SERVICE

DEALERS SIGNATURE

14-15

OWNERS MANUAL

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 18

SCOTT SERVICE PLAN

SCOTT SERVICE PLAN

Model Year Size Frame

___________________ ___________________ ___________________ ___________________

Service comment : ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________

Model Year Size Frame

___________________ ___________________ ___________________ ___________________

Service comment : ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________

DATE OF SERVICE

DEALERS SIGNATURE

DATE OF SERVICE

DEALERS SIGNATURE

16-17

OWNERS MANUAL

manual Shock 03_ A5 _E

30.09.2003

14:59 Uhr

Seite 20

SCOTT SERVICE PLAN

SCOTT SERVICE PLAN

Model Year Size Frame

___________________ ___________________ ___________________ ___________________

Service comment : ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________

Model Year Size Frame

___________________ ___________________ ___________________ ___________________

Service comment : ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________

DATE OF SERVICE

DEALERS SIGNATURE

DATE OF SERVICE

DEALERS SIGNATURE

18-19

OWNERS MANUAL

Das könnte Ihnen auch gefallen

- Essential Scooter Maintenance for the Absolute BeginnerVon EverandEssential Scooter Maintenance for the Absolute BeginnerNoch keine Bewertungen

- Dawg Scooter ManualDokument26 SeitenDawg Scooter ManualStephanie Parker100% (2)

- Manitou ManualDokument6 SeitenManitou Manualtuplow50% (2)

- 3116 Cat Valvuklas Calibre PDFDokument4 Seiten3116 Cat Valvuklas Calibre PDFsergio blandon l100% (1)

- ExpertDokument301 SeitenExpertEngine Tuning Up100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- INDIGODokument25 SeitenINDIGORohitNoch keine Bewertungen

- 2003 Nissan Altima 2.5 Serivce Manual PBDokument8 Seiten2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerNoch keine Bewertungen

- Daikin Presentation - Chiller SystemDokument112 SeitenDaikin Presentation - Chiller Systemlucio ruiz jr100% (1)

- Enlightened Polymer Clay BLAD WebDokument8 SeitenEnlightened Polymer Clay BLAD WebMonika Timári85% (13)

- Technical Standards Training Nov01Dokument83 SeitenTechnical Standards Training Nov01Monish KrishnaNoch keine Bewertungen

- Ecodial Advance Calculation 4.1Dokument33 SeitenEcodial Advance Calculation 4.1Youwan LeeNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Sturmey Archer Hub TechnicalDokument8 SeitenSturmey Archer Hub TechnicalbobnunleyNoch keine Bewertungen

- Valve Lash G3408Dokument9 SeitenValve Lash G3408Djebali MouradNoch keine Bewertungen

- Triaxial TestDokument3 SeitenTriaxial TestkanyisileNoch keine Bewertungen

- Manitou Hyd Pump Repair ManualDokument48 SeitenManitou Hyd Pump Repair ManualArdian Makhmud100% (2)

- SB1208 - ZF As Tronic - Clutch Component LubricationDokument12 SeitenSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNoch keine Bewertungen

- SR Suntour XC Pro Forks Instructions ManualDokument8 SeitenSR Suntour XC Pro Forks Instructions Manual110972ryanNoch keine Bewertungen

- Calibre Valvulas MP8 s34-5116Dokument20 SeitenCalibre Valvulas MP8 s34-5116Jose AGNoch keine Bewertungen

- Minimum Pipe Spacing Chart For Petrochemical & Refinery Plants PDFDokument4 SeitenMinimum Pipe Spacing Chart For Petrochemical & Refinery Plants PDFRamesh KumarNoch keine Bewertungen

- Amine Plant Troubleshooting and OptimizaDokument26 SeitenAmine Plant Troubleshooting and OptimizaHedi Ben MohamedNoch keine Bewertungen

- Camion 789DDokument14 SeitenCamion 789Ddinny blanco rojasNoch keine Bewertungen

- Awc Src3 Manual. 1Dokument5 SeitenAwc Src3 Manual. 1ghionoiucNoch keine Bewertungen

- 5 - GEST 10 362 Edition 4 - Corrosion Behaviour of Carbon Steel in Wet and Dry ChlorineDokument41 Seiten5 - GEST 10 362 Edition 4 - Corrosion Behaviour of Carbon Steel in Wet and Dry ChlorineAdemilson JuniorNoch keine Bewertungen

- Sturmey-Archer AWC-SRC3-MANUAL PDFDokument5 SeitenSturmey-Archer AWC-SRC3-MANUAL PDFtudorbusuiocNoch keine Bewertungen

- Ario User GuideDokument4 SeitenArio User Guideish996Noch keine Bewertungen

- Shock 2007 Epic SJ Enduro ENG Instruction GuideDokument10 SeitenShock 2007 Epic SJ Enduro ENG Instruction Guidelirch5Noch keine Bewertungen

- 2004 Axel Owners ManualDokument2 Seiten2004 Axel Owners ManualJuan Andres FaermanNoch keine Bewertungen

- #30720 2" LIFT KIT - '97 & UP JEEP TJ: Instruction SheetDokument3 Seiten#30720 2" LIFT KIT - '97 & UP JEEP TJ: Instruction SheetClancy Sonter-KelsoNoch keine Bewertungen

- Parking Brake SystemDokument7 SeitenParking Brake SystemThomas A. EDISSONNoch keine Bewertungen

- Marzocchi 01 Z1 - Dropoff ManualDokument18 SeitenMarzocchi 01 Z1 - Dropoff ManualHarry James BoundenNoch keine Bewertungen

- 3007a Je0m f9q Special FeaturesDokument101 Seiten3007a Je0m f9q Special FeaturesAdam JohnsonNoch keine Bewertungen

- Manual Cadru Scott GamblerDokument9 SeitenManual Cadru Scott GamblerAlvin ZaboloteanuNoch keine Bewertungen

- Crank ShaftDokument6 SeitenCrank ShaftTalal Mohd Al-FannahNoch keine Bewertungen

- 1999 Headshok Fatty SL Owners Manual Supplement enDokument8 Seiten1999 Headshok Fatty SL Owners Manual Supplement enxjcaiNoch keine Bewertungen

- F50LX Cap 03 (Manutenzione)Dokument12 SeitenF50LX Cap 03 (Manutenzione)pivarszkinorbertNoch keine Bewertungen

- JT QB - 1 (Previous Times Questions)Dokument25 SeitenJT QB - 1 (Previous Times Questions)RohitNoch keine Bewertungen

- Goldwing InstructionsDokument5 SeitenGoldwing InstructionsVanadia NohanNoch keine Bewertungen

- Clutch ManualDokument16 SeitenClutch ManualCO BDNoch keine Bewertungen

- MANUAL Mini MotoDokument13 SeitenMANUAL Mini MotoEdgardo ContrerasNoch keine Bewertungen

- 2005-2006 Ario - MC3 - MC3R SVC Guide - Rev - ADokument7 Seiten2005-2006 Ario - MC3 - MC3R SVC Guide - Rev - A_Sjaak_Noch keine Bewertungen

- Tacx Flow ManualDokument17 SeitenTacx Flow Manualfixie1979Noch keine Bewertungen

- Brake System: 1988 Jeep CherokeeDokument22 SeitenBrake System: 1988 Jeep CherokeePreet_Raj_2303Noch keine Bewertungen

- WE4.000 Rev.2 Gunite ASA Pocket GuideDokument8 SeitenWE4.000 Rev.2 Gunite ASA Pocket GuidePrathmeshNoch keine Bewertungen

- Manitou 2001 Magnum Service ManualDokument12 SeitenManitou 2001 Magnum Service ManualEdha AliNoch keine Bewertungen

- Dodge Ram A/C Compressor ClutchDokument7 SeitenDodge Ram A/C Compressor ClutchKkbhuvan KkNoch keine Bewertungen

- Shaft Eyelet External Rebound Adjuster Positive Air Valve (Adapterless)Dokument5 SeitenShaft Eyelet External Rebound Adjuster Positive Air Valve (Adapterless)Will RobinsonNoch keine Bewertungen

- Nubira Timing BeltDokument2 SeitenNubira Timing BeltCicko MickoNoch keine Bewertungen

- Arnott Motorcycle Air Suspension For BaggerDokument9 SeitenArnott Motorcycle Air Suspension For BaggerAntonioPalloneNoch keine Bewertungen

- Cams Andrews 99 Gear-01Dokument4 SeitenCams Andrews 99 Gear-01dsgoodrichNoch keine Bewertungen

- Rear Drum Brakes: Section: 4E2Dokument12 SeitenRear Drum Brakes: Section: 4E2Rafael HernandezNoch keine Bewertungen

- Ajuste de ValvulaDokument4 SeitenAjuste de ValvulaVictor NoschangNoch keine Bewertungen

- NT 855Dokument14 SeitenNT 855Leonardo CoronadoNoch keine Bewertungen

- Alfa Romeo Crosswagon Q4Dokument26 SeitenAlfa Romeo Crosswagon Q4skydvr0% (1)

- 2011 West WR1000 Owners Manual Version - AU 3.1Dokument15 Seiten2011 West WR1000 Owners Manual Version - AU 3.1Gregory Steer100% (1)

- Inter BrakeDokument1 SeiteInter BrakedovlikusNoch keine Bewertungen

- Special Features of The f5r 740 EngineDokument146 SeitenSpecial Features of The f5r 740 EngineBen Van Der MerweNoch keine Bewertungen

- Ip 178Dokument8 SeitenIp 178oliveira1305Noch keine Bewertungen

- Instruction Manual Garrard 401Dokument21 SeitenInstruction Manual Garrard 401CGWSPAMNoch keine Bewertungen

- Brake SystemDokument106 SeitenBrake SystemfishinmagicianNoch keine Bewertungen

- MANUALE MONO 2012 Rev10 ENDokument11 SeitenMANUALE MONO 2012 Rev10 ENArturoSalviNoch keine Bewertungen

- Rocket Sprocket InstallDokument18 SeitenRocket Sprocket InstallJulio AlarconNoch keine Bewertungen

- Essex Terraplane Six 1933 Owner's Manual of InformationVon EverandEssex Terraplane Six 1933 Owner's Manual of InformationNoch keine Bewertungen

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)Von EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Noch keine Bewertungen

- Wemco Depurator 2003Dokument2 SeitenWemco Depurator 20031mmahoneyNoch keine Bewertungen

- Chapter 1: Overview of Apple Inc 1.1. Introduction To General Information of Apple IncDokument8 SeitenChapter 1: Overview of Apple Inc 1.1. Introduction To General Information of Apple IncLinh LêNoch keine Bewertungen

- A Virtual Exhibition On Food Processing Technology: List of Exhibitors (As of Now)Dokument3 SeitenA Virtual Exhibition On Food Processing Technology: List of Exhibitors (As of Now)DevasyrucNoch keine Bewertungen

- B1ADokument7 SeitenB1ASumantrra Chattopadhyay0% (1)

- Wedi Technical Data Sheet Building Board GB 2016 v1 RZ SCREENDokument3 SeitenWedi Technical Data Sheet Building Board GB 2016 v1 RZ SCREENRui ConceiçãoNoch keine Bewertungen

- HS-901D Technical Data SheetDokument4 SeitenHS-901D Technical Data SheetAji SetiawanNoch keine Bewertungen

- Coek - Info - Acorga Znx50a New Selective Reagent For The SolvenDokument16 SeitenCoek - Info - Acorga Znx50a New Selective Reagent For The SolvenGeorgi SavovNoch keine Bewertungen

- Qualitest Canada BrochureDokument7 SeitenQualitest Canada BrochureBala SingamNoch keine Bewertungen

- Marbled Slipware1 PDFDokument5 SeitenMarbled Slipware1 PDFPilar Vezzani VaillantNoch keine Bewertungen

- Philips - FBH056 057 058 059 PDFDokument5 SeitenPhilips - FBH056 057 058 059 PDFVu Duc DuyNoch keine Bewertungen

- QCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Dokument2 SeitenQCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Ravi TyagiNoch keine Bewertungen

- Q150 R Plus Brochure V1Dokument4 SeitenQ150 R Plus Brochure V1toansNoch keine Bewertungen

- Supporting Information For Thin, Lightweight, Foldable Thermochromic Displays On PaperDokument6 SeitenSupporting Information For Thin, Lightweight, Foldable Thermochromic Displays On PaperDanesh AzNoch keine Bewertungen

- Lime Popping PhenomenonDokument4 SeitenLime Popping PhenomenonFayyaz Ahmad KhanNoch keine Bewertungen

- 19690021129Dokument467 Seiten19690021129Karpincho3Noch keine Bewertungen

- Types and Causes of Cracks in Concrete StructuresDokument11 SeitenTypes and Causes of Cracks in Concrete Structuresraahul_nNoch keine Bewertungen

- M90 01Dokument2 SeitenM90 01DiegoTierradentroNoch keine Bewertungen

- Dual-Phase Steel - WikipediaDokument3 SeitenDual-Phase Steel - WikipediaSandeep PrajapatiNoch keine Bewertungen

- XRAY NT18 Engine Instruction & Safety ManualDokument26 SeitenXRAY NT18 Engine Instruction & Safety ManualAsierReloopNoch keine Bewertungen

- Valassky Piskovec Sharpening StoneDokument17 SeitenValassky Piskovec Sharpening StoneMikail RNoch keine Bewertungen

- Viscosity ReportDokument12 SeitenViscosity ReportBF3nobelNoch keine Bewertungen