Beruflich Dokumente

Kultur Dokumente

Banlaw Sales Brochures BPM Nozzle

Hochgeladen von

api-3752216Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Banlaw Sales Brochures BPM Nozzle

Hochgeladen von

api-3752216Copyright:

Verfügbare Formate

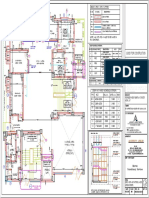

Hydrocarbon management specialists www.banlaw.

com

INTRODUCING

The New Banlaw "Lightweight" Quick-Fill Nozzle

Setting The Standard for Refuelling Nozzles

Lightweight in Handling - Heavyweight in Performance.

With Banlaw's proven reliability in the field, the new lightweight,

ergonomically designed nozzle in conjunction with;FuelTrack™

Fuel & Oil Monitoring Systems and the FillSafe™ Electronic

Zero Tank Pressure Refuelling System, refuelling has become

Safer and more Cost effective than ever before!

Hydrocarbon management specialists

Hydrocarbon management specialists www.banlaw.com

If you're not already using a Banlaw Refuelling Nozzle,

now is the time to take advantage of these benefits:

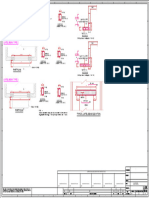

• High Flow Rates - 170 to 800 LPM capability

B F

• Light Weight - 11% Saving on Previous

J Models and 17% Saving when used

600

with the new Alloy Swivel! 550

D if f e r e n t ia l P r e s s u r e ( k P a )

N

500

O

C E G

•D Ergonomically HDesigned - Balanced,

SI

easier to

450 operate, even under

IS

SM

AN

high pump pressures 400

TR

350

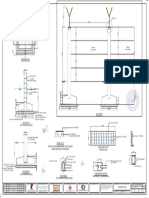

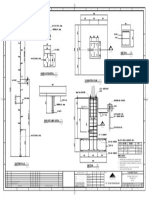

Nozzle Receiver

• Proven Technology

A

and Reliability - The Banlaw

300

250

Dry Break automatic cut-off

AN

KC

AS

E

CR L IC

system eliminates fuel spills, ensuring a cleaner and 200

safer working environment. HY

DR

AU

150

The FillSafe™ Electronic zero tank pressure refuelling100system ensures refuelling can

now be conducted with minimal risk. 50

0

25 50 75 100 125 150 175 200 225 250 275 300

Flowrate (LPM)

* DATA OBTAINED USING ISO68 HYDRAULIC OIL @ 40-45ºC. IMPORTANT: DIFFERENTIAL

Nozzle & Receiver Connected PRESSURE WILL VARY HANDLING A FLUID WITH A DIFFERENT VISCOSITY.

DATA INDICATES FLUID FLOW FROM NOZZLE TO RECEIVER. RESULTS MAY VARY SLIGHTLY

UNDER REVERSE FLOW.

TESTS CONDUCTED BY CCI ENGINEERING, NEWCASTLE, AUSTRALIA DURING APRIL 2004.

Hydraulic Crankcase Transmission Coolant

Fitting Type

Receiver Nozzle Receiver Nozzle Receiver Nozzle Receiver Nozzle

Part Number BPLR6DN BPLN6DB BPLR4CB PLN4BB BPLR3CB BPLN4CB BPLR1BN BPLN1BN

Safe Working Pressure - - - 6.75 979 - - 6.5 943

- 5.0 725 - 6.5 943 -

MPa - PSI

Burst Pressure - - 20.0 2901 26.0 3771 27.0 3916 26.0 3771

MPa - PSI

Safe Working Pressure 4.5MPa (653 psi) 7.0MPa (1015 psi) 8.75MPa (1269 psi) 6.0MPa (870 psi)

Nozzle/Receiver Coupled

Dimensions mm.

A 124 110.5 97 91.5

B 89.5 76.5 68 64

• Tough

C Ø- Made from 62

Steel and Aluminium, 55

NOT plastic. 50 46

Thread D (female) 1¼” BSP 1” BSP 1” BSP 1” BSP

• Thread

Increased

E (male) Productivity

1¼” BSP - With a 2" (nom)

1” BSP bore Banlaw has 1”

theBSPhighest flow rate¾” BSP

F 79 75.5 67.5 63

capability,

ØG

improving refuelling

56 times andachieving

50 reduced vehicle46downtime. A choice 41of

5 shut-off

ØH pressure settings

37 in addition to up31.5to 4 receiver settings,28ensures a solution 24

J 22 21 21 20

to even the most demanding refueling applications.

• Superior

• Specifications

Safe Working Pressure (SWP)

Customer Support - our accredited Distributor and Repairer network

• Part No. Description

Standard Fitting: BPLR6DN

offerRecommended

- Maximum prompt andWorkingfactual technical advice and product support worldwide. Our stringent

Pressure. NPT Hose Tail: add suffix ‘N’ to Part No. e.g. BP64N

Burstselection process ensures only specialist people

Pressure (BP) represent

Receiver and Dustthe

Capsuperior

Assembly:range

BP64&Cof or BP64N&C

- Minimum Pressure at which fitting will suffer failure.

Banlaw products and services.

Seal Material - either Viton or HNBR

Receiver Dust Cap alone: BPLR6-C

Call your Authorised Banlaw Distributor:

Call for a full consultation

Banlaw Pipeline Pty. Ltd.

17 Strathmore Road

Caves Beach NSW 2281

Australia

Telephone +61 (0)2 49724777

Fax. +61 (0)2 49714910

Website: www.banlaw.com Please Note: Use only Banlaw factory replacement parts.

Email: sales@banlaw.com.au

Non-genuine parts may cause equipment failure or malfunction,

ABN 88 062 044 071 and invalidate factory warranty.

hydrocarbonmanagement

Hydrocarbon managementspecialists

specialists

Das könnte Ihnen auch gefallen

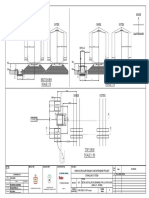

- Preliminary: D C B ADokument1 SeitePreliminary: D C B APatrick O'TooleNoch keine Bewertungen

- Anchor Bolt DetailsDokument1 SeiteAnchor Bolt Detailsk sulekhNoch keine Bewertungen

- Porur - Raised FloorDokument3 SeitenPorur - Raised Floortarha.buddyNoch keine Bewertungen

- Technical Submittal 400A RectifierDokument3 SeitenTechnical Submittal 400A Rectifierarshad mehmoodNoch keine Bewertungen

- 18wattamp PDFDokument1 Seite18wattamp PDFleolamiaNoch keine Bewertungen

- Eagleburgmann Part3Dokument1 SeiteEagleburgmann Part3ONURNoch keine Bewertungen

- Detail Section 2: Reflected Ground Ceiling Plan 1 A4 Reflected Second Ceiling Plan 2 A4Dokument1 SeiteDetail Section 2: Reflected Ground Ceiling Plan 1 A4 Reflected Second Ceiling Plan 2 A4JAN WESLEY MORIDONoch keine Bewertungen

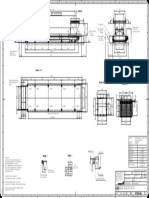

- Changing 2 Officials 2: Removable Lifting Eyes at Low Level 6500mm C CDokument1 SeiteChanging 2 Officials 2: Removable Lifting Eyes at Low Level 6500mm C CFoVihoangNoch keine Bewertungen

- 10 Ø STIRRUPS at 200 C/C-b4 C Span L A Spacing (MM) SL - NO. Location Bar Mkd. Shape Dia. (MM) Nos. BARDokument1 Seite10 Ø STIRRUPS at 200 C/C-b4 C Span L A Spacing (MM) SL - NO. Location Bar Mkd. Shape Dia. (MM) Nos. BARआशीष खोखरNoch keine Bewertungen

- Plan Reflected Ceiling Plan: Kinnera 22181551022 22181551022 Sem. VIIDokument1 SeitePlan Reflected Ceiling Plan: Kinnera 22181551022 22181551022 Sem. VIIkinneraNoch keine Bewertungen

- Hospital PlumbingDokument1 SeiteHospital PlumbingGrace Orilla RavarraNoch keine Bewertungen

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDokument1 SeiteYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNoch keine Bewertungen

- EN-02, PANEL Fan & Feeding (EMY-301681-01) - 05Dokument1 SeiteEN-02, PANEL Fan & Feeding (EMY-301681-01) - 05M Arifur RahmanNoch keine Bewertungen

- Boundary Wall (Final)Dokument1 SeiteBoundary Wall (Final)Engineering CivilMantra100% (1)

- Structural S 1 PDFDokument1 SeiteStructural S 1 PDFIbbe CaguiatNoch keine Bewertungen

- GA Drawing Rev.06Dokument1 SeiteGA Drawing Rev.06Adi PurnomoNoch keine Bewertungen

- Bsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightDokument1 SeiteBsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightdharuNoch keine Bewertungen

- Detail 4-Lintel 4Dokument1 SeiteDetail 4-Lintel 4Manoj JaiswalNoch keine Bewertungen

- A101 - Reinforcement Detail of Column & Footing Modify 23-06-22Dokument1 SeiteA101 - Reinforcement Detail of Column & Footing Modify 23-06-22avdesh7777Noch keine Bewertungen

- Deg PDB PanelDokument1 SeiteDeg PDB PanelHarshad prajapatiNoch keine Bewertungen

- Ick Work - Partition Layout (Ground Floor)Dokument1 SeiteIck Work - Partition Layout (Ground Floor)Shubham PokhriyalNoch keine Bewertungen

- AFL Substation SolutionsDokument12 SeitenAFL Substation SolutionsManali PrajapatiNoch keine Bewertungen

- Bega Betex - Cylinders NSSS NSLS NSCS NSHS enDokument4 SeitenBega Betex - Cylinders NSSS NSLS NSCS NSHS enAndresNoch keine Bewertungen

- R. Ganti Laki - Laki 0.00: KM/WC WanitaDokument1 SeiteR. Ganti Laki - Laki 0.00: KM/WC WanitaRahman NdablegNoch keine Bewertungen

- Service Road: Karnataka BorderDokument1 SeiteService Road: Karnataka BorderPraveen CyssanNoch keine Bewertungen

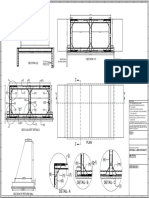

- Septic Tank 16.08.19-ModelDokument1 SeiteSeptic Tank 16.08.19-ModelAnindit MajumderNoch keine Bewertungen

- Reflected Ceiling Plan: Section Aa'Dokument1 SeiteReflected Ceiling Plan: Section Aa'dimple balsaraNoch keine Bewertungen

- Toilet DetailsDokument1 SeiteToilet DetailsKINNERA V G SNoch keine Bewertungen

- BMRCL 32M 001Dokument1 SeiteBMRCL 32M 001DOMNoch keine Bewertungen

- PDF 32m Span Shop DwgsDokument11 SeitenPDF 32m Span Shop DwgsDOMNoch keine Bewertungen

- S-4 Detail & ScheduleDokument1 SeiteS-4 Detail & SchedulearjayymerleNoch keine Bewertungen

- Detail HH With LOC Panel (INS - DYN) - On 07-04-2020-A34C-LCDokument1 SeiteDetail HH With LOC Panel (INS - DYN) - On 07-04-2020-A34C-LCThaung MyintNoch keine Bewertungen

- Plumbing and Electrical CompilationDokument8 SeitenPlumbing and Electrical CompilationEDRICK ESPARRAGUERRANoch keine Bewertungen

- 2022 CSU PlinthDokument6 Seiten2022 CSU PlinthLoo KlNoch keine Bewertungen

- Pump House-1Dokument1 SeitePump House-1Raghwendra SinghNoch keine Bewertungen

- WZR KFSH Icu r01 Sheet A900 WZR KFSH TF SD Etd Enlarged Toilet Details TF 11Dokument1 SeiteWZR KFSH Icu r01 Sheet A900 WZR KFSH TF SD Etd Enlarged Toilet Details TF 11ezeyadahNoch keine Bewertungen

- Joint Details of MCWDokument1 SeiteJoint Details of MCWVijay SinghNoch keine Bewertungen

- Manhole DetailsDokument1 SeiteManhole DetailsJanakiram GoudNoch keine Bewertungen

- 18m HIN OCT 101 300 S355JRDokument1 Seite18m HIN OCT 101 300 S355JRbibinbibinNoch keine Bewertungen

- 2ND PartDokument1 Seite2ND PartKELVIN TECHNOLOGIESNoch keine Bewertungen

- Gad 2Dokument1 SeiteGad 2Aerotide InfrastructuresNoch keine Bewertungen

- OMSHS4-R-SNWPCL-SN - SL - 4909 - Electrical Pole Layout Plan Rev A AFCDokument1 SeiteOMSHS4-R-SNWPCL-SN - SL - 4909 - Electrical Pole Layout Plan Rev A AFCshihabNoch keine Bewertungen

- 3BHK Revise Toilet-T3 Tile DetailDokument1 Seite3BHK Revise Toilet-T3 Tile Detailabdul quadirNoch keine Bewertungen

- CombinepdfDokument3 SeitenCombinepdfNitinNoch keine Bewertungen

- Precast Segmental Pile DesignDokument1 SeitePrecast Segmental Pile DesigncivixxNoch keine Bewertungen

- C-452, ALPHA I Sanction PDFDokument1 SeiteC-452, ALPHA I Sanction PDFRishu DevNoch keine Bewertungen

- Section X-X SCALE 1:20Dokument1 SeiteSection X-X SCALE 1:20Prabhat BaralNoch keine Bewertungen

- Type I Public Toilet Sanitary Installation-Layout3Dokument1 SeiteType I Public Toilet Sanitary Installation-Layout3Seid MuhammedNoch keine Bewertungen

- Belt Drive LH: Projectionsmeth.1 ISO5456-2Dokument1 SeiteBelt Drive LH: Projectionsmeth.1 ISO5456-2Traian SerbanNoch keine Bewertungen

- Solar - 5in 1out ACDB GADokument1 SeiteSolar - 5in 1out ACDB GAmukeshNoch keine Bewertungen

- For Stirrups & Ties 135° Bend: Development Length of Standard Hooked BarsDokument1 SeiteFor Stirrups & Ties 135° Bend: Development Length of Standard Hooked BarsLhewiz BrionesNoch keine Bewertungen

- Vie Pc01 STN DWG MP Ppa 01109 0Dokument1 SeiteVie Pc01 STN DWG MP Ppa 01109 0Ashish BhartiNoch keine Bewertungen

- Construction Drawing: Domestic Water Storage TankDokument1 SeiteConstruction Drawing: Domestic Water Storage TankrajavelNoch keine Bewertungen

- Telecommunication Tower Design & Implementation Technical SpecificationDokument30 SeitenTelecommunication Tower Design & Implementation Technical SpecificationJohn MelvinNoch keine Bewertungen

- Mewar - Polytex - Anchorbolt - Plan - & Ga Details - R2 - 2024.01.30-14Dokument1 SeiteMewar - Polytex - Anchorbolt - Plan - & Ga Details - R2 - 2024.01.30-14Cosine PowerNoch keine Bewertungen

- Municipality of Pamplona: Details Sign BoardDokument1 SeiteMunicipality of Pamplona: Details Sign BoardArmand Mikhail TempladoNoch keine Bewertungen

- Specifications:: Produced by An Autodesk Student VersionDokument1 SeiteSpecifications:: Produced by An Autodesk Student VersionBharani MadamanchiNoch keine Bewertungen

- PB 950 A WB: The Netherlands Tel.: (+31) 854 868 200 Palfinger Boats BV Pasteurdijk 8 3846 BS HarderwijkDokument1 SeitePB 950 A WB: The Netherlands Tel.: (+31) 854 868 200 Palfinger Boats BV Pasteurdijk 8 3846 BS HarderwijkAhmet GelişliNoch keine Bewertungen

- BOX CULVERT 2 X 4 X 3-ModelDokument1 SeiteBOX CULVERT 2 X 4 X 3-ModelketanNoch keine Bewertungen

- Technical Bulletins TB - Quick-Fill Tank VentsDokument13 SeitenTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216Noch keine Bewertungen

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDokument11 SeitenBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- PhoneList (FirstName)Dokument35 SeitenPhoneList (FirstName)api-3752216100% (3)

- Wiggins Vents Info Wiggins VentsDokument2 SeitenWiggins Vents Info Wiggins Ventsapi-3752216Noch keine Bewertungen

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemDokument3 SeitenScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Risk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3Dokument39 SeitenRisk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3api-3752216100% (1)

- Fast Fill Couplers FF Coupling Price List-06Dokument1 SeiteFast Fill Couplers FF Coupling Price List-06api-3752216Noch keine Bewertungen

- Fast Fill Couplers LC Hi-Flow FlyerDokument3 SeitenFast Fill Couplers LC Hi-Flow Flyerapi-3752216Noch keine Bewertungen

- Breakaway Valve TB - AUS4W-50 Break-Away ValveDokument2 SeitenBreakaway Valve TB - AUS4W-50 Break-Away Valveapi-3752216Noch keine Bewertungen

- Cross Reference Info Banlaw Cross RefrenceDokument45 SeitenCross Reference Info Banlaw Cross Refrenceapi-3752216Noch keine Bewertungen

- BPM800 BPM800 - Rev 1Dokument16 SeitenBPM800 BPM800 - Rev 1api-3752216Noch keine Bewertungen

- Banlaw Sales Brochures FuelTrackTM System OverviewDokument4 SeitenBanlaw Sales Brochures FuelTrackTM System Overviewapi-3752216Noch keine Bewertungen

- BPM800 BPM800 Repair - Rev 1Dokument7 SeitenBPM800 BPM800 Repair - Rev 1api-3752216Noch keine Bewertungen

- Banlaw Sales Brochures FuelTrack Presentation (Full)Dokument24 SeitenBanlaw Sales Brochures FuelTrack Presentation (Full)api-3752216Noch keine Bewertungen

- BPM800 BPM Vs BAM - Rev 1Dokument3 SeitenBPM800 BPM Vs BAM - Rev 1api-3752216Noch keine Bewertungen

- Banlaw Sales Brochures FuelTrack Presentation (Full)Dokument24 SeitenBanlaw Sales Brochures FuelTrack Presentation (Full)api-3752216Noch keine Bewertungen

- NKT-2022-5735 C OGCCC Katalog - Vereinheitlichung 2022-RZ-ANSICHTDokument32 SeitenNKT-2022-5735 C OGCCC Katalog - Vereinheitlichung 2022-RZ-ANSICHTAmir IbrahimNoch keine Bewertungen

- Astra AllDokument192 SeitenAstra Allmnbvqwert33% (3)

- Lighting Lighting: Tempo LED FloodlightDokument2 SeitenLighting Lighting: Tempo LED FloodlightALBERTO HURTADONoch keine Bewertungen

- WeighSouth Standard Bench Scale Instruction ManualDokument19 SeitenWeighSouth Standard Bench Scale Instruction Manualmoises castroNoch keine Bewertungen

- Design and Implementation of Simple As Possible Computer (SAP-1)Dokument52 SeitenDesign and Implementation of Simple As Possible Computer (SAP-1)Muhammad Anas 484-FET/BSEE/F18Noch keine Bewertungen

- Explosionado de Partes: - Mini SplitDokument6 SeitenExplosionado de Partes: - Mini SplitAldair Contreras MataNoch keine Bewertungen

- Marzocchi MX Comp Technical Instructions 2006Dokument27 SeitenMarzocchi MX Comp Technical Instructions 2006alexkyrNoch keine Bewertungen

- Rincian Estimasi Instalasi CCTV CabangDokument11 SeitenRincian Estimasi Instalasi CCTV CabangAhmad AstajibNoch keine Bewertungen

- PBB Spec ChartDokument1 SeitePBB Spec ChartSamson Rajan BabuNoch keine Bewertungen

- Oštrač BoreraDokument59 SeitenOštrač BoreradinoNoch keine Bewertungen

- Usf 73 A1Dokument2 SeitenUsf 73 A1A.HassanNoch keine Bewertungen

- Form STODokument1 SeiteForm STOMuhammad FarhanNoch keine Bewertungen

- Short Circuit inDokument1 SeiteShort Circuit inKartino Surodipo100% (4)

- 742RDokument19 Seiten742Rj31ocNoch keine Bewertungen

- TachAdapter Instructions (Black) Rev 5Dokument18 SeitenTachAdapter Instructions (Black) Rev 5Ismael Vega100% (1)

- R&M ControlMaster PDFDokument6 SeitenR&M ControlMaster PDFUongNoch keine Bewertungen

- Star 36 - Star 36D - Star 41 - Star 41D - Star 41F: Motore 1, Engine 1, Moteur 1, Motor 1Dokument22 SeitenStar 36 - Star 36D - Star 41 - Star 41D - Star 41F: Motore 1, Engine 1, Moteur 1, Motor 1Vitor FreitasNoch keine Bewertungen

- M4000 Product Line Application Note: M4140:02: Hardware RequirementsDokument12 SeitenM4000 Product Line Application Note: M4140:02: Hardware Requirementsupt vadodara100% (1)

- MS171 MS181 MS211 Service ManualDokument102 SeitenMS171 MS181 MS211 Service Manuallucian0757% (7)

- S-40 (From Serial Number S4003-7001 To S4015-21540) PN. 89721Dokument384 SeitenS-40 (From Serial Number S4003-7001 To S4015-21540) PN. 89721albert michaelNoch keine Bewertungen

- Air Inlet ServomotorDokument1 SeiteAir Inlet Servomotorhidakota hidakotaNoch keine Bewertungen

- CBC 9Dokument120 SeitenCBC 9mukesh lachhwaniNoch keine Bewertungen

- Mounting Instructions For Danfoss Compressors: Refrigeration and Air ConditioningDokument16 SeitenMounting Instructions For Danfoss Compressors: Refrigeration and Air Conditioningbogdan208Noch keine Bewertungen

- Brosur Transmax Helical Gear TRDokument200 SeitenBrosur Transmax Helical Gear TRbangpaiNoch keine Bewertungen

- Bulletin 136Dokument39 SeitenBulletin 136Константин ГусевNoch keine Bewertungen

- SG Eq4Dokument1 SeiteSG Eq4tungdohmeNoch keine Bewertungen

- IoT Based Distribution Transformer Health Monitoring SystemDokument8 SeitenIoT Based Distribution Transformer Health Monitoring SystemIJRASETPublicationsNoch keine Bewertungen

- Comparison of PSFB and FB-LLC For High Power DCDCDokument49 SeitenComparison of PSFB and FB-LLC For High Power DCDCNhật Đào QuốcNoch keine Bewertungen

- 2 SK 170Dokument5 Seiten2 SK 170vdăduicăNoch keine Bewertungen

- High Pressure Cast Steel: Sempell Dewrance Parallel Slide Gate ValvesDokument20 SeitenHigh Pressure Cast Steel: Sempell Dewrance Parallel Slide Gate ValvesbagusNoch keine Bewertungen