Beruflich Dokumente

Kultur Dokumente

Marie Curie Poster Presentation (Gideon Susman)

Hochgeladen von

Oriane RokegemOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Marie Curie Poster Presentation (Gideon Susman)

Hochgeladen von

Oriane RokegemCopyright:

Verfügbare Formate

Using Phase Change Materials to Reduce Energy Consumption in Buildings

The E ng ineering Doctorate (Eng D) in Environmental Technolog y

Four year course in which the student is based in industry, conducting a research project that is beneficial to the sponsor company. R esearch must focus on sustainable technologies. Initially a very general topic is defined and then focused onto a specific research question. Two journal papers must be published, and fourteen weeks worth of courses passed, in order to qualify for the doctorate.

G eneral Abs tract

The aim of this research is to increase the us e of phase change materials in the built environment and thereby reduce the overall energy consumption and ass ociated carbon emissions of buildings. The research began with the general aim of identifying ways in which energy storage could be used to reduce a buildings carbon emissions. E nergy storage can lead to carbon emiss ion reductions in three ways: R eduction in energy demand, increas ed energy efficiency and increased use of intermittent renewables. E nergy storage systems are broken down into electricity storage, which results from restricted conversion, and thermal storage, which results from restricted flow. Thermal storage is further broken down into passive and active storage. P has e change materials have applications in both pass ive and active systems. There are s everal opportunities for research into using latent thermal storage in the built environment. The most promising areas for research in latent thermal energy systems are: Improvements in the heat transfer between the space and the P C M , optimisation of exis ting P C M -based s ystems and demonstration of certain systems efficacy through testing of occupied buildings or simulation.

Technical Abs tract (Focus on Phas e C hang e Materials )

The destructive consequences of climate change and the resulting requirement to reduce carbon emissions is generally accepted. P hase change materials have a large number of potential active and passive applications for managing, and therefore saving energy, in the built environment. However, so far only a limited number of P C M installations have emerged. This is due to; the ignorance and risk-aversion of designers, the cost of the systems and s ome current technical limitations. This E ngD will focus on one or more of these factors in order to increase utilisation of latent heat storage systems. Ignorance and risk aversion can be combated through reliable demonstrations of efficacy in occupied buildings or with simulation. The cost of systems can be reduced in various ways including container removal through shape-stabilisation. The technical limitations of low cycle-life and fire risk, can be overcome through selection of organic P C M s and appropriate mitigation techniques, respectively. Heat transfer may be enhanced through the following: Addition of highly conductive particles, fibres or expanded graphite; promotion of convection currents in the liquid phase when melting; addition of conductive fins or increasing the number of heat exchange loops in active systems.

R esearch E ngineer: G ideon S usman B ackground: M S c in S ustainable E nergy Technologies and M anagement. B S c in P hysics and P hilosophy. Academic S upervisors: D r M aria Kolokotroni & D r C hang-ying Zhao (B runel University) Industrial S upervisor: D r Andrew C ripps (B uro Happold E ngineers Ltd)

1. Why is reduced energ y cons umption important?

R educing energy consumption in any system will reduce running costs and lower carbon emissions. With the causes and damaging effects of climate change firmly established, developing more ways to reduce carbon emissions is of paramount importance. In E urope over 40% of energy used, and the consequent C O 2 emitted, results from energy consumed by building services. R educing this energy load will have a dramatic impact on E uropean energy consumption.

6. Phas e C hang e Materials : Pas s ive Applications C ateg ories of E nerg y S torag e Technolog y and Media for the B uilt Environment

An obvious comparison for P C M s in pass ive applications is that of sensible thermal mass. B oth can absorb excess heat from a space and release it when temperatures fall. As a result, both can reduce minimum and maximum temperatures and both can reduce heating and cooling loads but due to the fact that P C M s absorb and emit heat at one temperature, or transition zone, there is a much greater potential for steadying internal temperatures around the thermal comfort zone. Added to this, they have an energy density an order of magnitude higher than sensible storage materials , which makes them smaller, lighter and easier to install. P C M s therefore have a great potential for effectively tracking thermal comfort conditions. The different types of pass ive applications researched are numerous. Included are: Wallboards: E asily retro-fitted boards that moderate temperatures and reduce cooling load. C ommercially available in the form of the D upont E nergain panel. S hutters: S olar radiation that is absorbed by the P C M shutters is emitted to the room at night when the s hutters are closed. Not commercially available. B uilding B locks: B locks impregnated with P C M can increase the thermal mass of a building significantly. Not commercially available. Floor Heating: B y incorporating P C M s into floors, the heating load resulting from solar gains can be delayed by several hours. Not commercially available. C eiling B oards: These boards can perform the same function as wall boards but have the advantage of being placed at the hottest part of the room. Not commercially available. A ir C onditioning: B y flowing air passed solid P C M blocks, the air temperature can be reduced to comfortable levels. C ommerically available as C oolD eck with P C M from C limator. Trombe Walls: Walls that are located behind south facing windows to absorb solar radiation and reduce heating load. P C M trombe walls are lighter and smaller than their concrete counterparts. Not commercially available.

7. Phas e C hang e Materials : Active Applications

There are many examples of P C M s being us ed in active applications. These include: S olar A bsorption C ooling: S olar energy may be converted to thermal energy in water, contained by a solar collector. If this energy is then us ed to drive an absorption cycle, coolth is produced which can be used to cool a space. However, because the sun doesnt constantly shine and is not perfectly in phase with cooling loads, thermal energy storage is needed to fill any gaps. This can be provided by P C M s. PC M heat pump system: Using P C M storage, a heat pump system may be reduced in size through more constant operation. S easonal Heat S torage: A large enough P C M store can be used to balance the difference in temperatures between the seasons. This has been researched particularly for greenhouses where constant climatic conditions are desired.

2. How can energ y s torag e help?

E nergy storage can reduce consumption in the following ways: 1. R educing energy demand at the point of us e. E .g. S toring thermal energy in the building fabric for supplementary heating or cooling. 2. Increasing the efficiency of many types of device. E .g. O perating chillers at night to make use of the lower condensing temperatures. 3. Allowing intermittent renewable energy sources to generate a greater proportion of national energy consumption. E .g. Wind power.

Electricity S torag e B atteries Fuel C ells & Hydrogen Flow B atteries

Thermal Energ y S torag e

Active S torag e Ice S torage Hot Water S torage C hilled Water S torage P hase C hange M aterials

Pas s ive S torag e

P hase C hange M aterials S ensible Thermal M ass

(Labourers fit an E nergain panel to the wall of a house.)

Underground Thermal E nergy S torage

3. G eneral Energ y S torag e Theory

E nergy storage is defined as the restricted conversion or flow of energy that confines it to some vessel, or medium, for some period of time. R estricted conversion is achieved through balancing the fundamental physical forces acting in a system. This type of storage is normally used in the storing of electricity. E xamples are: B atteries, in which a balancing of electromagnetic forces is manifested as chemical storage; and pumped hydro storage, in which gravitational potential energy is balanced with the electromagnetic forces which are manifested as the solidity of the reservoir bed and dam. R estricted flow is achieved in two ways. O ne is the insulation of a medium from the surrounding environment. E .g. The lagging on a domestic hot water tank. The second is the utilisation of a medium with large thermal mass and a specified conductivity that has a direct thermal interaction with its local environment. E .g. The stone that makes up the fabric of a church building.

(An upturned C oolD eck cassette with P C M pouches exposed. The cassette would normally be pos itioned in the ceiling void where air is flowed past the P C M pouches and cooled as the P C M melts. It is then ejected to the room from the circular hole in the centre. The P C M solidifies by pas sing cool night time air past it.)

(A schematic design of a P C M heat storage system for a greenhouse. Heat is supplied by flat-plate solar collectors and delivered to the heat storage unit in s ummer. In winter, the heat storage unit discharges its heat to the greenhouse thus maintaining required climatic conditions.)

(Graphical representation the temperature moderation effect of thermal mass.)

8. B arriers to PC M Ins tallation

Notes PCM Type Advantages Disadvantages Examples Butyl Stearate Paraffin C16-C18 Capric-Lauric acid Dimethyl sabacate Polyglycol E600 Paraffin C13-C24 (34%mistric acid +66%Capric acid) 1-Dodecanol Further categorised as paraffins and non-paraffins. No corrosives. Low or no undercooling. Chemical and thermal stability Lower phase change enthalpy. Low thermal conductivity. Inflammability. Paraffin C18 (45-55%) Vinyl Stearate Capric Acid RT 20 (Paraffin from Rubitherm GmBH) RT 26 (Paraffin from Rubitherm GmBH) RT 25 (Paraffin from Rubitherm GmBH) RT 30 (Paraffin from Rubitherm GmBH) RT 27 (Paraffin from Rubitherm GmBH) RT 32 (Paraffin from Rubitherm GmBH) KF.4H2O Mn(NO3)2.6H2O CaCl2.6H2O LiNO3.3H2O NaSO4.10H2O Undercooling. Corrosion. Phase Separation. Phase segregation - lack of thermal stability. Climsel C23 (Salt hydrate from Climator) Climsel C24 (Salt hydrate from Climator) STL 27 (Salt hydrate from Mitsubishi Chemical) S27 (Salt hydrate from Cristopia) TH 29 (Salt hydrate from TEAP) Climsel C32 (Salt hydrate from Climator) 66.6% CaCl2.6H2O + 33.3% MgCl2.6H2O Subject to the disadvantages of their constituents. (These may be organic-organic, organic-inorganic or inorganic-inorganic compositions.) 48% CaCl2 + 4.3% NaCl + 0.4% KCl + 47.3% H2O 47% Ca(NO3)2.4H2O + 53% Mg(NO3)2.6H2O 60% Na(CH3COO).3H2O + 40% CO(NH2)2 Melting Temperature (C) 19 20-22 21 21 22 22-24 24 26 28 27-29 32 22 25 26 28 28 31 18.5 25.8 29 30 32 23 24 Heat of fusion (kJ/kg) 140 152 143 120 127.2 189 147.7 200 244 122 152.7 172 131 232 206 179 130 231 125.9 190.8 296 251 148 216

10. Looking Forward

The information presented here strongly indicates that thermal energy storage in P C M s can reduce carbon emissions from buildings. The ques tion therefore is: What can be done to increase the likelihood of PC Ms being specified for heating and/or cooling systems? O f the six barriers to installation listed, the cost, the perceived efficacy and the low internal heat transfer are most important. The three others may be dealt with as follows: R isk of leakage through expansion can be mitigated through improved container design and so is subsumed under D evelopment below. C ycle life is effectively infinite for organic P C M s but there is a risk of fire, however, this can be easily mitigated as the flash-point for paraffin is low. S o, three basic approaches for research present themselves: Development improve/optimise operation. For many P C M applications the system is sufficiently complex and under-developed to warrant optimisation studies. The most obvious area for improvement is internal heat transfer as a low rate of internal heat transfer is the dominant limiting factor in any P C M -based systems efficacy. It may well be that the optimal method for increased heat transfer is application dependent and so here lie several opportunities for study. Another opportunity here is to try to find ways to improve the heat transfer between the space and the P C M . Ideally, the moment the temperature in a space rises above the transition temperature of the P C M , the associated excess heat is removed, so that in effect the temperature of the room can never significantly rise above the P C M transition temperature. Further attempts to approach this ideal may be fruitful. 2) Demonstrate efficacy to engineers and architects. With certain systems being shown to be operationally successful and cost-effective, the lack of uptake in P C M technology is likely to be due to ignorance and/ a risk-averse attitude or from building designers. This may be overcome through demonstrations of the success of P C M -based systems. M ost convincingly this would take the form of detailed and reliable studies of occupied buildings. Failing this, a demonstrably reliable simulation would go some way to convincing designers the difficulty here being the reliable modelling of the P C M itself. 3) Reduction in cost. Any design alteration that leads to a reduction in cost (particularly capital costs) would make these systems far more attractive. O ne study of a free-cooling system with P C M located in the ventilation ductwork showed that the P C M itself only cons tituted 17% of the total system cost. C learly then a cost reduction is not seriously limited by raw materials. D evelopments , such as shape-stabilisation with expanded graphite, suggest that an increase in conductivity and a decrease in container cost can be achieved simultaneously.

P C M use is currently limited because of: R isk of leakage through expansion. R isk of fire. Low internal heat transfer rate. Low cycle-life. P erceived efficacy of the system. C ost of the system

9. Improving Heat Trans fer

The great technical limitation on the increased application of P C M s for thermal storage is their low conductivity, es pecially in the liquid phase. For example paraffins have a typical thermal conductivity of 0.21 0.24 W/ mK. This means that the charging or discharging of the P C M is slow which results in an unreactive system that absorbs only a small amount of the excess heat available. The various methods for improving heat transfer are: G reatly increasing the heat exchange surface area to volume ratio. This is the strategy taken by D uP ont in the design of their E nergain panels. The same principle is exploited thermal storage units are filled with many loops of heat exchange pipe to carry the heat exchange fluid (normally water) to as much of the P C M as possible. Adding highly conductive particles, fibres or expanded graphite. The picture opposite shows two blocks of paraffin wax. The one on the left is pure. The one on the right contains 10% expanded graphite which has stabilised the shape and increased conductivity by a factor of 4. Increasing the internal s urface area through the addition of such elements as fins or metal foams. The major drawback here is the additional costs in materials and manufacture. P romoting convection currents to more effectively transfer heat when the substance enters the liquid phase, when heated. The picture opposite shows partly melted paraffin in a finned container liquid in white, solid in black. O ne of the convection currents is indicated some additive dye in the central chamber.

Organic

4. Thermal Energ y S torag e

In the UK 41% of C O 2 emissions associated with buildings is due to heating. G lobally 45% of residential and commercial buildings energy demand comes from cooling. It is clear therefore that reducing the energy required for occupants thermal comfort will greatly reduce overall energy consumption. B y controlling the heat flows in a building, through storage, the required energy can be reduced. This is a strong motivation for researching and developing thermal energy storage devices and media. There are two types of thermal energy storage system; active and passive: Active s torag e systems refer to those that are thermally isolated from the environment they are intended to interact with. This requires an intermediate heat transfer fluid to actively transport heat between the storage vessel and the environment. Pas s ive s torag e systems are in direct contact with the environment that they are intended to thermally interact with. There are also two types of thermal energy storage medium, that are commonly used; sensible and latent. An example of s ens ible thermal energ y s torag e media is the solid fabric of a building. E xamples of latent thermal energ y s torag e media are; ice, which can be used for space cooling, or paraffin wax which could be incorporated into the building fabric for passive storage.

Inorganic

Further categorised as salt hydrates and metallics.

Greater phase change enthalpy. Lower cost.

27 27 29 32 25

213 207 188 212 127

Eutectic

A minimummelting composition of two or more components, which melt and freeze congruently.

Subject to the advantages of their constituents. (These may be organic-organic, organic-inorganic or inorganicinorganic compositions.)

26.8

188

30

136

30

200.5

5. Phas e C hang e Materials

In the built environment phase change materials (P C M s) refer to those materials that can be used to usefully store heat through a change of phase from solid to liquid and vice versa. They are generally divided into three types of material as shown in the table below. (This excludes ice storage which has largely different applications .) There are several properties that a P C M should have in order for application in the built environment to be feasible. These are: Appropriate phas e change temperature. High change of enthalpy near temperature of use. High thermal conductivity in liquid and solid phases (but not always.) Low density variation. High density. S mall or no undercooling. C hemical stability. No phase separation. C ompatibility with container materials. Non-toxic, non-flammable, nonpolluting. C heap and abundant.

(A representation of P C M impregnated plaster board.)

G los s ary

A bs orption C ycle - A refrigeration process, driven by heat (not compression) and using two fluids; one refrigerant and one absorbant. A ctive S torage S ys tems - Those systems that are thermally isolated from the environment they are intended to interact with. B atteries - E lectricity storage devices in which chemical energy is converted to electricity through the reaction of electrodes with the electrolytes they are submerged in. B uilding S ervices - The provision of water, lighting, ventilation and temperature control that make a building habitable. C hiller - A device for actively cooling an occupied space.

C ooling - In the context of building services this normally refers to the cooling of an occupied space, as opposed to the cooling of objects. C oolth - The difference in internal energy between a medium and its surroundings, when that medium is cooler than the surroundings. O ften treated as a form of stored energy. C ondens ing Temperature - The temperature to which a refrigerant is cooled upon reaching the condenser in a refrigeration cycle. C ycle Life - The number of times that a storage device can be fully charged and discharged before it degrades significantly in storage capacity. EngD - S ee The E ngineering D octorate in E nvironmental Technology box in the abstract bar. Flow B atteries - E lectricity storage devices in which chemical energy is converted to electricity through the reaction of two liquids on inert electrode surfaces.

Fuel C ells - E lectricity generation devices in which oxygen and hydrogen combine to form water. Heat Pump - A device that effectively converts low temperature heat into higher temperature heat through a vapour compression cycle. Lagging - The insulation surrounding thermal storage devices or pipes. Pas s ive S torage S ys tems - Those systems that are in constant thermal contact with the environment they are intended to interact with. Phas e C hange Material (PC M) - A material that has a solid/ liquid transition temperature/ zone, and high latent heat capacity, such that significant thermal storage can be achieved. Pumped Hydro S torage - An electricity storage system that converts the gravitational potential energy, of an elevated mass of water, when that water is released.

S olar C ollector - A device that facilitates the heating of a fluid by solar radiation. S us tainable Technologies - Those technologies whose widespread use can be sustained indefinitely without significantly damaging the environment for future generations. Thermal C omfort - The state of mind which expresses satisfaction with the thermal environment. Thermal Mas s - The material in a building that has relatively high specific heat capacity and can therefore regulate temperature. Underground Thermal Energy S torage - The process whereby the ground in the region beneath a building is used for the storage of thermal energy, to be recouped at a later time.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Assignment 01 - Unit 11Dokument8 SeitenAssignment 01 - Unit 11pastpaperscollectorNoch keine Bewertungen

- 360W PV Panel CatalogueDokument2 Seiten360W PV Panel Catalogueblue fluxNoch keine Bewertungen

- Fission Track Dating PDFDokument3 SeitenFission Track Dating PDFzaqiNoch keine Bewertungen

- Units of MeasurementDokument5 SeitenUnits of MeasurementNik FakhiraNoch keine Bewertungen

- Solid State Physics - Eph-104 PDFDokument2 SeitenSolid State Physics - Eph-104 PDFkohli kingNoch keine Bewertungen

- Science 6 DemoDokument8 SeitenScience 6 DemoJenalyn Sumipo100% (2)

- Cooperative Research Centre For Black Coal UtilisationDokument33 SeitenCooperative Research Centre For Black Coal UtilisationRobin IndiaNoch keine Bewertungen

- Cambridge Primary CheckpointDokument24 SeitenCambridge Primary CheckpointAl-Hafiz Bin SajahanNoch keine Bewertungen

- Science-Reviewer TyphoonsDokument10 SeitenScience-Reviewer TyphoonsLaxiava VaniaNoch keine Bewertungen

- Hotel Engineering & MaintenanceDokument2 SeitenHotel Engineering & MaintenanceKamlesh ChouhanNoch keine Bewertungen

- Self Assessment Answers 19 Asal Chem CBDokument3 SeitenSelf Assessment Answers 19 Asal Chem CBRonit KhannaNoch keine Bewertungen

- Pengaruh Low Salinity Waterflooding Dalam Meningkatkan Perolehan Minyak Pada Reservoir Batupasir Dan KarbonatDokument6 SeitenPengaruh Low Salinity Waterflooding Dalam Meningkatkan Perolehan Minyak Pada Reservoir Batupasir Dan KarbonatBella KristianaNoch keine Bewertungen

- Jurnal: Daur LingkunganDokument4 SeitenJurnal: Daur LingkunganAli UsmanNoch keine Bewertungen

- StonesDokument111 SeitenStonesSantosh Kumar MNoch keine Bewertungen

- Generator Capability CurveDokument20 SeitenGenerator Capability CurvegnathblNoch keine Bewertungen

- Added Photos-Final PROJECT REPOR 8sem (1) PDFDokument50 SeitenAdded Photos-Final PROJECT REPOR 8sem (1) PDFravi singhNoch keine Bewertungen

- Not The Latest Sample: Mobile EquipmentDokument12 SeitenNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNoch keine Bewertungen

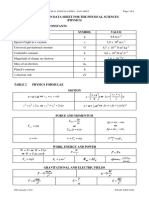

- Physical Sciences Ieb NSC Grade 12 Past Exam Papers 2016 p1 Data SheetDokument2 SeitenPhysical Sciences Ieb NSC Grade 12 Past Exam Papers 2016 p1 Data Sheetoluhlevumisa07Noch keine Bewertungen

- MB4039 HomeworkDokument7 SeitenMB4039 HomeworkSocdal AbdiNoch keine Bewertungen

- Partial Loading Optimal Control - Steam Turbine EffDokument6 SeitenPartial Loading Optimal Control - Steam Turbine EffLTE002Noch keine Bewertungen

- Env Awareness ProblemsDokument2 SeitenEnv Awareness ProblemsPaula FontesNoch keine Bewertungen

- Conversion FactorDokument3 SeitenConversion FactorAniket AngreNoch keine Bewertungen

- Bio F5 - 8.2 Biodiversity DLPDokument19 SeitenBio F5 - 8.2 Biodiversity DLPALAMEL MANZGHAI A/P GANESONNoch keine Bewertungen

- Lecture13 Diffusion NptelDokument13 SeitenLecture13 Diffusion NptelChinar MathurNoch keine Bewertungen

- Periodic Table 150 PDFDokument4 SeitenPeriodic Table 150 PDFT.M.V. AquinoNoch keine Bewertungen

- Force and Pressure PDFDokument11 SeitenForce and Pressure PDFADRIJA MUKHERJEENoch keine Bewertungen

- Notes Volcano NotesDokument42 SeitenNotes Volcano NotestsindelarNoch keine Bewertungen

- BSDS 105 Environmental ManagementDokument7 SeitenBSDS 105 Environmental ManagementEmmanuel M. ChiwaNoch keine Bewertungen

- Inside Our Earth Class 7 MCQs Questions With AnswersDokument5 SeitenInside Our Earth Class 7 MCQs Questions With AnswersKalai Selvi MohanNoch keine Bewertungen

- TF 33 VaporPhaseDesignDokument12 SeitenTF 33 VaporPhaseDesignAdnen GuedriaNoch keine Bewertungen