Beruflich Dokumente

Kultur Dokumente

Wireless Control of Irrigation System

Hochgeladen von

Adharsh RsOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wireless Control of Irrigation System

Hochgeladen von

Adharsh RsCopyright:

Verfügbare Formate

80

FAER

FAER

81

7. WIRELESS CONTROL OF IRRIGATION SYSTEM OPERATING FROM 3 INDUCTION MOTOR FED BY 1 SUPPLY

COLLEGE : MEENAKSHI SUNDARARAJAN ENGINEERING COLLEGE, CHENNAI ELECTRICAL AND ELECTRONICS U. DEEPA N. SANDEEP PRANAVAMOORTHY B

Operation of a three phase motor pump using single phase supply Automation of communication irrigation system using wireless

BRANCH : GUIDE : STUDENTS :

INTRODUCTION There have not been any significant technological advancements being made in agricultural sector as compared to other sectors. Irrigation system needs to be monitored on a regular basis. The first aim of the project is to reduce the wastage by automating the entire irrigation system. The three-phase supply system in now available worldwide, except perhaps in some rural areas where only a single phase supply is available. The second aim of our project is to tackle this issue, thereby enabling the operation of these pumps even in the absence of three phase supply. PROBLEM DEFINITION The moisture content of the field is not monitored and it is manually observed by the farmers which are prone to errors. DESIGN AND IMPLEMENTATION The technical details of the project contain block diagram, circuit connections and detailed explanation of various components used. The analysis is split into two parts Automation of communication. irrigation system using wireless

The water or moisture sensor is placed in the field which continuously senses the moisture content in the field. The output of the sensor is transmitted wirelessly using a zigbee module. Another zigbee module at the receiving end receives these transmitted signals and gives it as an input to the main micro-controller which is the control unit. This main micro-controller is programmed to perform the various functions. First, the opening/closing of the shutters is controlled by the main micro-controller depending on the sensor output. Secondly, once all the fields are irrigated to the optimum level a signal is sent to switch off the motor thereby stopping the water supply. Thirdly, the main microcontroller sends all the details of the operations being performed in the field to the farmers mobile using GSM. The farmer can operate the field either in manual mode or in automatic mode. In the manual mode the farmer will wirelessly control the on/off of the motor and the shutters irrespective of the sensor output. In automated mode, the operation is based on the sensor output as explained above. The picture of the hardware model of irrigation part is given below:

Field 1

Motorola Scholar Programme : 2008-09 Motorola Scholar Programme : 2008-09

82

FAER

FAER

83

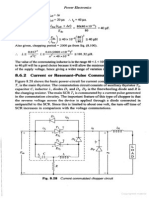

Main control unit and GSM module OPERATION: Single-phase motors are the most common form in the lower horse-power ranges, but they become uneconomical for ratings above about 0.5kW and therefore an increasing tendency to use standard three-phase motors supplied from single-phase supply if the three-phase supply is not available.

third winding is connected to the line through a fixed and variable capacitor, both being parallel to each other. The capacitance of the variable capacitor is varied electronically with the help of an IGBT connected in series with the capacitor. The duty cycle of the IGBT is varied continuously with respect to motor speed as follows. The speed of the motor is obtained using a tachometer. The frequency pulses are tapped out from the tachometer and given to a frequency to voltage converter. The voltage level which is proportional to the frequency is given as the reference input to the comparator whose other input is the saw tooth waveform. The pwm pulse obtained is given as the gate pulse to the IGBT. Hence as the speed varies the voltage level and hence the duty cycle of the IGBT varies thereby varying the net capacitor value. This continuous variation of capacitance with respect to speed maintains minimum unbalance between the three phases of the induction motor. An opto-coupler is used in order to isolate the low voltage electronic circuit from power circuit.

The phase and neutral of the single phase supply are given to the two windings of the three phase induction motor. The

Motorola Scholar Programme : 2008-09 Motorola Scholar Programme : 2008-09

84 TESTING

FAER

FAER

85

Steady state current minimized Less maintenance cost More economical Better efficiency

In the automation part the reference of the comparator of the moisture sensor is set to 4.54V. When the field is dry, the sensor produces an voltage of 4.81V and hence the comparator output will be high. The sensor gives an output voltage of 3.2V during wet condition and the comparator output will be at zero volts. This output is converted to serial data with the microcontroller for Zigbee transmission. After Zigbee transmission, the GSM module either transmits or receives messages as per the mode of operation. The tacho generator is coupled with the motor to get the desired speed. This gives the frequency pulses as output. There is a digital tachometer connected to this which reads the motor speed. These frequency pulses obtained are spike waveforms.This output from the tacho generator is amplified and fed to the frequency to voltage converter to get appropriate voltage for the corresponding speed of motor. As the pulses obtained are very less in magnitude, an amplifier circuit is used and then it is converted to voltage pulses. The output voltage thus obtained is about 2V. The output obtained from the F to V converter is fed to the inverter LM 358 so that the voltage varies in direct proportion to frequency. The magnitude remains same (2V). The DC voltage output got from the F to V converter and inverter circuit acts as the reference and cuts the saw tooth waveform to get the PWM output. These PWM pulses are fed to the base of the IGBT and hence switching of the IGBT is controlled by the PWM output. This in turn controls the net capacitance of the circuit. ADVANTAGES No centrifugal switch Less harmonics No zero current switching

Motorola Scholar Programme : 2008-09

Frequency pulses

Input to IGBT gate APPLICATIONS Woodworking machines

Motorola Scholar Programme : 2008-09

86 Ice cream mixture and compressor Agricultural Horticulture LIKELY PROBLEMS THAT MAY BE ENCOUNTERED

FAER

FAER

87

the automation of the irrigation system is highly feasible so that the irrigation can be done even without the presence of farmer. REFERENCES Three-phase induction motor operating from single-phase supply with an electronically controlled capacitor - By Nabil.A.Ahmed Department of Electrical and Electronics Engineering, Assiut University, Assiut 71516, Egypt. Received 27 October 2003; received in revised form 26 May 2004; accepted 20 June 2004. Published in Science Direct, Electric Power Systems Research 73 (2005) 121-128 A Text book of Electrical Technology - By B.L.Theraja and A.K.Theraja Volume II AC and DC machines, S.Chand publications, reprint 2007. AT89C52 data sheet LM2917 datasheet LM3524 datasheet Zigbee user guide GSM user guide

Water level sensors should be placed in appropriate place such that there is uniform distribution of water all over the area, else the water level sensors might give a wrong output. The ratings of the capacitors are decided based on the impedance of the circuit: - If the capacitors are not designed properly the capacitors may even burst. As high voltage capacitors are used the switch should be capable of withstanding the high voltage surges produced hence care should be taken while deciding the rating of the IGBT. CONCLUSION The design and implementation of a controlled capacitor for a three-phase induction motor operating from single phase supply has been presented by using a fixed capacitor in series with an electronic switch. The proposed system eliminates the use of mechanical or centrifugal switches which is located inside the motor. This avoids the possibility of the switch failure and leads to less operational and maintenance cost and improves the system reliability. The optimum effective capacitor value can be on-line adjusted at any operating speed by periodically changing the duty cycle of the controlled switch to achieve minimum unbalance in phase voltages or any other optimization criteria to improve the motor performance at different speeds. With the output obtained from the hardware module, it can be inferred that

*~*~*

Motorola Scholar Programme : 2008-09

Motorola Scholar Programme : 2008-09

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Blue ChipDokument16 SeitenThe Blue ChipVanitsa Droguett100% (1)

- A Study of ReptiliansDokument23 SeitenA Study of ReptiliansRed Young100% (1)

- AI Learning ResourcesDokument6 SeitenAI Learning Resourcesrip asawNoch keine Bewertungen

- Blooms Taxonomy For Mathematics ChartDokument1 SeiteBlooms Taxonomy For Mathematics ChartRiza Bedoy100% (3)

- Detailed Lesson Plan in MathematicsDokument5 SeitenDetailed Lesson Plan in MathematicsJssy May71% (17)

- The Servant LeadershipDokument7 SeitenThe Servant Leadershipnavkar_centreforskills100% (1)

- SSC SSC Prasar Bharati Executive Exam 2013 Question Papers IDokument18 SeitenSSC SSC Prasar Bharati Executive Exam 2013 Question Papers IAdharsh RsNoch keine Bewertungen

- Current Commutation ChopperDokument6 SeitenCurrent Commutation ChopperAdharsh RsNoch keine Bewertungen

- Insulated-Gate Bipolar Transistor (IGBT) Inverter With Vector ModulationDokument27 SeitenInsulated-Gate Bipolar Transistor (IGBT) Inverter With Vector ModulationAdharsh RsNoch keine Bewertungen

- C InterviewDokument2 SeitenC InterviewAdharsh RsNoch keine Bewertungen

- WK307 DC Motor Control RFDokument8 SeitenWK307 DC Motor Control RFVijay T VijuNoch keine Bewertungen

- 2.2.1 Motor Starters...Dokument22 Seiten2.2.1 Motor Starters...Adharsh RsNoch keine Bewertungen

- Load Recognition For Automated Demand Response in MicrogridsDokument6 SeitenLoad Recognition For Automated Demand Response in MicrogridsAdharsh RsNoch keine Bewertungen

- SPE Study Guide For Petroleum Certification ExaminationDokument2 SeitenSPE Study Guide For Petroleum Certification ExaminationXNoch keine Bewertungen

- Solar TimeDokument3 SeitenSolar TimeAkshay Deshpande0% (1)

- Using Keyframe SynfigDokument1 SeiteUsing Keyframe SynfigNdandungNoch keine Bewertungen

- Tabulation of Data and Parts of A Table - Presentation of Data - Everonn - Class-11th CommerceDokument2 SeitenTabulation of Data and Parts of A Table - Presentation of Data - Everonn - Class-11th CommerceMd Shawfiqul IslamNoch keine Bewertungen

- (1997) Process Capability Analysis For Non-Normal Relay Test DataDokument8 Seiten(1997) Process Capability Analysis For Non-Normal Relay Test DataNELSONHUGONoch keine Bewertungen

- 2011 Internship Report RsDokument108 Seiten2011 Internship Report Rschirayus_3Noch keine Bewertungen

- Laws of ReflectionDokument3 SeitenLaws of ReflectionwscienceNoch keine Bewertungen

- Working With DatabaseDokument105 SeitenWorking With DatabaseTara Marie Robinson WhiteNoch keine Bewertungen

- Kcpe Maths Made Familiar QNSDokument96 SeitenKcpe Maths Made Familiar QNSGodwin Ayieko100% (1)

- Bar Coding Tubular ProductsDokument4 SeitenBar Coding Tubular ProductsGusti PanjaitanNoch keine Bewertungen

- Rapport - FEEDBACK INFRA - ODIENNE - V01 - ANGLAISDokument25 SeitenRapport - FEEDBACK INFRA - ODIENNE - V01 - ANGLAISabertoNoch keine Bewertungen

- Lec Verilog TrafficLight SynthesisDokument32 SeitenLec Verilog TrafficLight SynthesisKartikey ManchandaNoch keine Bewertungen

- C++ Functions: Defining A FunctionDokument4 SeitenC++ Functions: Defining A FunctionSourav RoyNoch keine Bewertungen

- 160W002GB Brochure ColormixDokument40 Seiten160W002GB Brochure ColormixPaky PakicNoch keine Bewertungen

- STOCHASTIC FINITE ELEMENT METHOD: Response StatisticsDokument2 SeitenSTOCHASTIC FINITE ELEMENT METHOD: Response StatisticsRocky ABNoch keine Bewertungen

- PSD - Trilok - Kalyan Medicals - June 29, 17 - Business Proposal Ver 1Dokument7 SeitenPSD - Trilok - Kalyan Medicals - June 29, 17 - Business Proposal Ver 1papuNoch keine Bewertungen

- Informatica Certification Prep ListDokument5 SeitenInformatica Certification Prep ListRabindra P.SinghNoch keine Bewertungen

- Voyagers: Game of Flames (Book 2) by Robin WassermanDokument35 SeitenVoyagers: Game of Flames (Book 2) by Robin WassermanRandom House KidsNoch keine Bewertungen

- Classified2018 10 15586115Dokument7 SeitenClassified2018 10 15586115janoosNoch keine Bewertungen

- Borg 2002Dokument16 SeitenBorg 2002Victor Daniel WaasNoch keine Bewertungen

- Soil MechanicsDokument38 SeitenSoil MechanicsAnsh Kushwaha50% (2)

- Speaking B2Dokument2 SeitenSpeaking B2Strafalogea SerbanNoch keine Bewertungen

- HW CFK ModellerDokument7 SeitenHW CFK ModellerKillgusNoch keine Bewertungen

- Finding Herself. KelloggDokument12 SeitenFinding Herself. KelloggMinerva MinasNoch keine Bewertungen