Beruflich Dokumente

Kultur Dokumente

Cellulose Extraction Thimbles

Hochgeladen von

Samj18Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cellulose Extraction Thimbles

Hochgeladen von

Samj18Copyright:

Verfügbare Formate

The Jayme-Wise and diglyme-HCl methods for extracting cellulose from plant material for stable-isotope analysis differ

considerably in ease of use, with the latter requiring significantly less time and specialized equipment. However, the diglyme-HCl method leaves a small lignin residue in the crude cellulose that may affect stable-isotope values, whereas -cellulose produced by the Jayme-Wise method is relatively pure. We examined whether adding a bleaching step to the diglyme-HCl method could produce cellulose of comparable purity to -cellulose by comparing the yield, percent carbon, and carbon (13C) and oxygen (18O) stable isotope ratios of the two celluloses. We tested each method on the wood of five species that differ in ease of delignification, Eucalyptus maculata Hook., E. botryoides Sm., E. resinifera Sm.,Pinus pinaster Ait. and Callitris glaucophylla J. Thompson & L.A.S. Johnson, as well as the foliage of C. glaucophylla. For hardwoods such as the eucalypts, the diglyme-HCl method without bleaching produced cellulose with 13C and 18O ratios similar to -cellulose. For the softwood, C. glaucophylla, 3 h of bleaching with acidified chlorite following treatment with diglyme-HCl produced cellulose with 13C and 18O ratios similar to -cellulose. Bleached and unbleached crude celluloses and -cellulose of P. pinaster were similar in 18O, but not 13C. Both types of crude cellulose produced from the foliage of C. glaucophylla had significantly different isotope ratios from -cellulose. Overall, the diglyme-HCl method, with or without bleaching, appears to be a simple, fast method for extracting -cellulose from hardwoods for stable-isotope analyses, but its suitability for softwoods and foliage needs to be evaluated depending on the species.

Cellulose Extraction Thimbles

Home | Specialty Products | Extraction Thimbles | Cellulose Extraction Thimbles

High Performance Cellulose Extraction Thimbles

Cellulose extraction thimbles are produced from high-quality alpha cellulose cotton linter and have excellent mechanical strength and retention. Standard single thickness thimbles have a wall thickness of approximately 1 mm (10.0 m nominal particle

retention). Double thickness thimbles have a wall thickness of approximately 2 mm (6.0 m nominal particle retention) for applications where higher retention and increased wet or dry strength, or rigidity are required. The high purity of the materials ensures reliable and reproducible analytical results.

Standard Cellulose Extraction Thimbles

Thimbles of type 603 are made from high-quality cellulose and 603 g thimbles are made from borosilicate glass fibers with an inorganic binder. For all automated extraction apparatus in common use, Whatman offers thimbles whose dimensions are matched exactly to those of the thimble holders to ensure optimal fit.

Thimble size selection guide

Thimble sizes should be selected carefully to fit extractors correctly. The different sizes represent the established practice of showing the internal diameter and overall length of the thimble in millimeters. Therefore, an extra allowance for wall thickness should be made when calculating external diameters. The thimble should pass through the narrower end of the upper extractor socket, allowing 1 to 2 mm clearance, and be 5 to 10 mm above the level of the top of the siphon tube.

http://docs.google.com/viewer?a=v&q=cache:4ziZD-RrYcJ:jestec.taylors.edu.my/Vol%25204%2520Issue%25201%2520March%252009/Vol_4_1_5768_Yan_Yan.pdf+cellulose+extraction+methods&hl=en&gl=us&pid=bl&srcid=ADGEESgQL3OZFx910fGGa LQ2t3J5RoWmhhGpiOojSi-EwvWx2tmYculYaOj5c8olrUcznXQFhsWZroE_aBNj_Dp2rCxBBhOSq23P2RKbDa3QJyqKJrDGNnIcLd38r945KzN9GUSp0a_&sig=AHIEtbSpX7-RdBV7aVHopxVeF3xlCNzZPQ

Cellulose is widely used in many aspect and industries such as food industry, pharmaceutical, paint, polymers, and many more. Due to the increasing demand

in the market, studies and work to produce cellulose are still rapidly developing. In this work, liquid phase oxidation was used to extract cellulose from palm kernel cake to separate hemicellulose, cellulose and lignin. The method is basically a two-step process. Palm kernel cake was pretreated in hot water at 180C and followed by liquid oxidation process with 30% H2O2 at 60C at atmospheric pressure. The process parameters are hot water treatment time, ratio of palm kernel cake to H2O2, liquid oxidation reaction temperature and time. Analysis of the process parameters on production cellulose from palm kernel cake was performed by using Response Surface Methodology. The recovered cellulose was further characterized by Fourier Transform Infrared (FTIR). Through the hot water treatment, hemicellulose in the palm kernel cake was successfully recovered as saccharides and thus leaving lignin and cellulose. Lignin was converted to water soluble compounds in liquid oxidation step which contains small molecular weight fatty acid as HCOOH and CH3COOH and almost pure cellulose was recovered.

Keywords: Hemicellulose, Lignin, Hot water treatment, Response surface methodology

Das könnte Ihnen auch gefallen

- Standard methods for the examination of water and sewageVon EverandStandard methods for the examination of water and sewageNoch keine Bewertungen

- 2-74-1343890128-Gen Engg - Ijget - Development - T Karthik - UnpaidDokument18 Seiten2-74-1343890128-Gen Engg - Ijget - Development - T Karthik - UnpaidAnonymous Pt7NHkat9Noch keine Bewertungen

- Tappi 280 Extractivos AcetonaDokument3 SeitenTappi 280 Extractivos AcetonaAna HostaledNoch keine Bewertungen

- A Comprehensive Study of Different TypesDokument18 SeitenA Comprehensive Study of Different TypesDiego JavierNoch keine Bewertungen

- Pet Flake Conversion 2Dokument26 SeitenPet Flake Conversion 2James NgNoch keine Bewertungen

- Seminar Paper CharacteristicDokument7 SeitenSeminar Paper CharacteristicSiti Khadijah HubadillahNoch keine Bewertungen

- AcrylamideDokument13 SeitenAcrylamideronking84100% (1)

- A Green Biorefinery Platform For Cost-Effective Nanocellulose Production Investigation of Hydrodynamic Properties and Biodegradability of Thin FilDokument10 SeitenA Green Biorefinery Platform For Cost-Effective Nanocellulose Production Investigation of Hydrodynamic Properties and Biodegradability of Thin FilYi PeiNoch keine Bewertungen

- CHEMIMECHANICAL PULPING OF COTTON STALKS SoakingDokument19 SeitenCHEMIMECHANICAL PULPING OF COTTON STALKS SoakingBlue BlazeNoch keine Bewertungen

- Eco Friendly Extraction and Characterization of Cellulose From Oil Plam Empty Fruit BunchesDokument12 SeitenEco Friendly Extraction and Characterization of Cellulose From Oil Plam Empty Fruit BunchesJair Fajrdo LopezNoch keine Bewertungen

- Teacher Preparation Notes On Plastic Identification LabDokument5 SeitenTeacher Preparation Notes On Plastic Identification LabUniq ManjuNoch keine Bewertungen

- Synthetic Bioplastics From Cassava SkinDokument20 SeitenSynthetic Bioplastics From Cassava SkinlisaNoch keine Bewertungen

- GAMA Article Prf1Dokument6 SeitenGAMA Article Prf1gunjanbanasthaliNoch keine Bewertungen

- The Feasibility of Jackfruit Peeling As Binder To Whiteware Plastic Mass (Revised Chapter 1,2,3)Dokument26 SeitenThe Feasibility of Jackfruit Peeling As Binder To Whiteware Plastic Mass (Revised Chapter 1,2,3)Joshua PicartNoch keine Bewertungen

- Mechanical Properties of Coir Fiber Reinforced Polyester CompositesDokument5 SeitenMechanical Properties of Coir Fiber Reinforced Polyester CompositesDias DiasNoch keine Bewertungen

- Production of Bioplastic From Cassava Peel With Different Concentrations of Glycerol and Caco As FillerDokument9 SeitenProduction of Bioplastic From Cassava Peel With Different Concentrations of Glycerol and Caco As Fillerqueen ann toledoNoch keine Bewertungen

- La Celloidin Methodo ConDokument7 SeitenLa Celloidin Methodo ConramongonzaNoch keine Bewertungen

- Bartolome 2021 IOP Conf. Ser. Earth Environ. Sci. 633 012002Dokument9 SeitenBartolome 2021 IOP Conf. Ser. Earth Environ. Sci. 633 012002Ajay lokhandeNoch keine Bewertungen

- Welcome SpeechDokument5 SeitenWelcome SpeechSabiaha Sarwar Dept. of EST ,JUSTNoch keine Bewertungen

- The Effect of Glutaraldehyde As Crosslinking Agent in The Sweet Potato StarchChitosan Membrane For Pervaporation MethodDokument6 SeitenThe Effect of Glutaraldehyde As Crosslinking Agent in The Sweet Potato StarchChitosan Membrane For Pervaporation MethodInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- DMGS_SSK_13350 PlagiDokument7 SeitenDMGS_SSK_13350 PlagiARUP PAULNoch keine Bewertungen

- 14 1Dokument5 Seiten14 1Mark Bryan ToribioNoch keine Bewertungen

- Textile Scouring OptimizationDokument7 SeitenTextile Scouring OptimizationGizem D.Noch keine Bewertungen

- Research Institute of Industrial Technology, Gyeongsang National UniversityDokument6 SeitenResearch Institute of Industrial Technology, Gyeongsang National UniversityAndrianNoch keine Bewertungen

- Eco-Friendly Disperse Dyeing and Functional Finishing of Nylon 6 Using Supercritical Carbon DioxideDokument15 SeitenEco-Friendly Disperse Dyeing and Functional Finishing of Nylon 6 Using Supercritical Carbon DioxideGoh Kae HorngNoch keine Bewertungen

- A Comparison Between Highly Depithed and Conventionally Depithed Bagasse PulpDokument7 SeitenA Comparison Between Highly Depithed and Conventionally Depithed Bagasse PulpAlphonse SambranoNoch keine Bewertungen

- Suaduang 2019Dokument7 SeitenSuaduang 2019Feyza Igra Harda PutraNoch keine Bewertungen

- Emissions and ControlsDokument7 SeitenEmissions and ControlsDrVishwanatha HNNoch keine Bewertungen

- Good Manufacturing Practice For The Handling of AcetateDokument9 SeitenGood Manufacturing Practice For The Handling of Acetateherna_reyesNoch keine Bewertungen

- Dissolving Pulps by Oxidation of The Cellulosic Fraction of Lignocellulosic WasteDokument9 SeitenDissolving Pulps by Oxidation of The Cellulosic Fraction of Lignocellulosic WasteAlyssa LapeñaNoch keine Bewertungen

- 10 Owoeye Et AlDokument12 Seiten10 Owoeye Et Alnermeen ahmedNoch keine Bewertungen

- Composites: Part B: Yicheng Du, Tongfei Wu, Ning Yan, Mark T. Kortschot, Ramin FarnoodDokument7 SeitenComposites: Part B: Yicheng Du, Tongfei Wu, Ning Yan, Mark T. Kortschot, Ramin FarnoodWaleed ShakilNoch keine Bewertungen

- AnthraciteDokument3 SeitenAnthracitepradeepkumar5683Noch keine Bewertungen

- Pulp and Paper Glossary DefinitionsDokument88 SeitenPulp and Paper Glossary Definitionsandhie68Noch keine Bewertungen

- IPPTA 173-69-73 Effect of BrokeDokument5 SeitenIPPTA 173-69-73 Effect of BrokeBastian Richard SitohangNoch keine Bewertungen

- Graphene membranes for solvent dehydrationDokument3 SeitenGraphene membranes for solvent dehydrationFarida TaniaNoch keine Bewertungen

- Continuous masterbatch fiber production processDokument2 SeitenContinuous masterbatch fiber production processkeyur1109Noch keine Bewertungen

- Textile DyesDokument5 SeitenTextile Dyesapi-27596299Noch keine Bewertungen

- Recycling Glass Fibers (M6)Dokument2 SeitenRecycling Glass Fibers (M6)SureshKumar DevulapallyNoch keine Bewertungen

- Dyes RemovalDokument28 SeitenDyes RemovalHamayoun MahmoodNoch keine Bewertungen

- Purification of Dilactide through Melt CrystallizationDokument4 SeitenPurification of Dilactide through Melt CrystallizationRaj SolankiNoch keine Bewertungen

- Sample Preparation Techniques in BiochemistryDokument16 SeitenSample Preparation Techniques in BiochemistryFenny Aulia SugianaNoch keine Bewertungen

- Bagasse and Its ApplicationDokument8 SeitenBagasse and Its Applicationnurul'ain haniyun mohamad fodziNoch keine Bewertungen

- Membranes 12 00910 v2Dokument16 SeitenMembranes 12 00910 v2Thanh Phương NguyễnNoch keine Bewertungen

- Application of Ceramic Membrane As A Pretreatment Digestion of Alcohol-Distillery Wastes in AnaerobicDokument9 SeitenApplication of Ceramic Membrane As A Pretreatment Digestion of Alcohol-Distillery Wastes in AnaerobicPraphulla RaoNoch keine Bewertungen

- Physicomechanical Properties of Agro Waste Filled High Density Polyethylene Bio-CompositesDokument116 SeitenPhysicomechanical Properties of Agro Waste Filled High Density Polyethylene Bio-CompositesIheoma Chukwujike NwuzorNoch keine Bewertungen

- Parameters For Composting Tannery Bovine Hair WasteDokument9 SeitenParameters For Composting Tannery Bovine Hair WasteCleyby DavilaNoch keine Bewertungen

- Non Structural Carbohydrate Variability in Hevea Clones: Conference PaperDokument17 SeitenNon Structural Carbohydrate Variability in Hevea Clones: Conference PaperAntonio Agudelo SánchezNoch keine Bewertungen

- Plastic Recycling ThesisDokument7 SeitenPlastic Recycling Thesisamandabarbergilbert100% (2)

- Towards Coupling Dispersive FinalDokument9 SeitenTowards Coupling Dispersive FinalKadesh Hanah McCarthyNoch keine Bewertungen

- Jurnal 2 KoagulanDokument8 SeitenJurnal 2 KoagulanfauzanNoch keine Bewertungen

- 90-Mechanical and Rheological PPties of Epoxidized Soybean Oil Plasticized PLA 2009Dokument7 Seiten90-Mechanical and Rheological PPties of Epoxidized Soybean Oil Plasticized PLA 2009TOUFIKNoch keine Bewertungen

- Calculating Starch Adhesive SolidsDokument4 SeitenCalculating Starch Adhesive SolidsJosé Luis Pacheco JürgensNoch keine Bewertungen

- ZeoformDokument6 SeitenZeoformRamonaNoch keine Bewertungen

- Composite Sleepers 1Dokument14 SeitenComposite Sleepers 1Suprit MagadumNoch keine Bewertungen

- Biopolymers and Renewable Resources: PartlDokument23 SeitenBiopolymers and Renewable Resources: PartlFlavia Gerjoi BezerraNoch keine Bewertungen

- Utilization of Cocoa Theobroma Cacao L Pod Husk AsDokument10 SeitenUtilization of Cocoa Theobroma Cacao L Pod Husk AsJENNIFER TATIANA PORRAS OLIVEROSNoch keine Bewertungen

- Wolman 2010 - Article - EggWhiteLysozymePurificationWi PDFDokument8 SeitenWolman 2010 - Article - EggWhiteLysozymePurificationWi PDFEmanuelMuruagaNoch keine Bewertungen

- Optimization of Time and Saving Water, Energy Through Using Regulator With Hydrogen Peroxide in Exhaust Bleaching ProcessDokument8 SeitenOptimization of Time and Saving Water, Energy Through Using Regulator With Hydrogen Peroxide in Exhaust Bleaching ProcessDyeing DyeingNoch keine Bewertungen

- Exhibit F - Case 1 - Missouri - Dash Cam Shows Officer Lying About Headlight Not WorkingDokument9 SeitenExhibit F - Case 1 - Missouri - Dash Cam Shows Officer Lying About Headlight Not WorkingSamj18Noch keine Bewertungen

- Letter To Ann G. Montealegrer - NotaryDokument1 SeiteLetter To Ann G. Montealegrer - NotarySamj18Noch keine Bewertungen

- Understanding Your Employer ID Number (EINDokument36 SeitenUnderstanding Your Employer ID Number (EINSamj18100% (1)

- California Contract LawDokument32 SeitenCalifornia Contract LawShelley YeamanNoch keine Bewertungen

- San Mateo County CaseDokument18 SeitenSan Mateo County CaseSamj18Noch keine Bewertungen

- How They List Grantor and Grantee Per DocumentDokument7 SeitenHow They List Grantor and Grantee Per DocumentSamj18100% (1)

- Form A - Information ListDokument3 SeitenForm A - Information ListSamj18Noch keine Bewertungen

- Cusip Numbers For RemicsDokument1 SeiteCusip Numbers For RemicsSamj18Noch keine Bewertungen

- Mortgage Fraud - Partial Information Sheet To Complie A Civil ComplaintDokument8 SeitenMortgage Fraud - Partial Information Sheet To Complie A Civil ComplaintSamj18Noch keine Bewertungen

- Subaru Forester ManualsDokument636 SeitenSubaru Forester ManualsMarko JakobovicNoch keine Bewertungen

- MR23002 D Part Submission Warrant PSWDokument1 SeiteMR23002 D Part Submission Warrant PSWRafik FafikNoch keine Bewertungen

- Philippines implements external quality assessment for clinical labsDokument2 SeitenPhilippines implements external quality assessment for clinical labsKimberly PeranteNoch keine Bewertungen

- Bentel J408Dokument64 SeitenBentel J408Bojan MarkovicNoch keine Bewertungen

- Gebauer 2012Dokument26 SeitenGebauer 2012Seán GallagherNoch keine Bewertungen

- Dimensional Data: For Valves and ActuatorsDokument52 SeitenDimensional Data: For Valves and ActuatorsPaulNoch keine Bewertungen

- OilDokument8 SeitenOilwuacbekirNoch keine Bewertungen

- Assessment Formal AssessmentDokument7 SeitenAssessment Formal Assessmentashish33% (3)

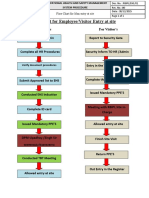

- fLOW CHART FOR WORKER'S ENTRYDokument2 SeitenfLOW CHART FOR WORKER'S ENTRYshamshad ahamedNoch keine Bewertungen

- Frank Wood S Business Accounting 1Dokument13 SeitenFrank Wood S Business Accounting 1Kofi AsaaseNoch keine Bewertungen

- ItilDokument11 SeitenItilNarendar P100% (2)

- Activity No 1 - Hydrocyanic AcidDokument4 SeitenActivity No 1 - Hydrocyanic Acidpharmaebooks100% (2)

- Malaysia's Trade Potential in Colourful AfricaDokument18 SeitenMalaysia's Trade Potential in Colourful AfricaThe MaverickNoch keine Bewertungen

- Health 6 Q 4 WK 6 Module 6 Version 4Dokument16 SeitenHealth 6 Q 4 WK 6 Module 6 Version 4Kassandra BayogosNoch keine Bewertungen

- Thee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDDokument23 SeitenThee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDJuliet AcelNoch keine Bewertungen

- 2020-11 HBG Digital EditionDokument116 Seiten2020-11 HBG Digital EditionHawaii Beverage GuideNoch keine Bewertungen

- Very Easy Toeic Units 7 - 12 (Q1)Dokument39 SeitenVery Easy Toeic Units 7 - 12 (Q1)Minh KhaiNoch keine Bewertungen

- Intake Sheet SampleDokument1 SeiteIntake Sheet SampleRochelleNoch keine Bewertungen

- Classification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialsDokument5 SeitenClassification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialssivaenotesNoch keine Bewertungen

- Analysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Dokument2 SeitenAnalysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Eustache NIJEJENoch keine Bewertungen

- Right To HealthDokument9 SeitenRight To HealthPriya SharmaNoch keine Bewertungen

- Nitric OxideDokument20 SeitenNitric OxideGanesh V GaonkarNoch keine Bewertungen

- Job Satisfaction RRLDokument39 SeitenJob Satisfaction RRLMarie Tiffany100% (1)

- Investigating Population Growth SimulationDokument11 SeitenInvestigating Population Growth Simulationapi-3823725640% (3)

- To The OneDokument8 SeitenTo The OnePizzaCowNoch keine Bewertungen

- 4.5 Cargo DischargingDokument2 Seiten4.5 Cargo DischargingHasan Cosalev100% (1)

- ASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderDokument1 SeiteASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderCatalin BailescuNoch keine Bewertungen

- Puskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListDokument98 SeitenPuskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListLaboratorium PKM 23 IlirNoch keine Bewertungen

- RTG E-One - Manual de Manutenção 41300-41303 (EN)Dokument328 SeitenRTG E-One - Manual de Manutenção 41300-41303 (EN)Conrado Soares100% (1)

- Stress and FilipinosDokument28 SeitenStress and FilipinosDaniel John Arboleda100% (2)