Beruflich Dokumente

Kultur Dokumente

Springs (Compatibility Mode)

Hochgeladen von

srwickedsunnyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Springs (Compatibility Mode)

Hochgeladen von

srwickedsunnyCopyright:

Verfügbare Formate

I/C: KALLURI VINAYAK

Springs

A mechanical spring is an elastic member

(generally metal) whose primary function is to

deflect under load and then to recover its original

shape and position when the load is released.

Used for efficient storage and release of energy Used for efficient storage and release of energy

Strength and flexibility are two essential

requirements of spring design.

Spring Types

1. Helical springs (Tension / Compression)

2. Torsion spring

3. Leaf springs

4. Spiral spring

5. Belleville Springs

Leaf spring

5. Belleville Springs

Helical springs

Torsion spring

Spiral spring

Belleville Spring

Stresses in Helical Springs

( )

2 3 2 3

max

4 8 4 2 / 16

2 /

d

F

d

FD

d

F

d

FD

A

F

J

Tr

FD T

+ = + = + =

=

inside

inside

Spring Index and shear stress correction factor

d

D

C =

If we define the spring index to be as follows:

Then the foregone expression for maximum shear stress

can be expressed as:

3 2 3

max

8 4 8

d

FD

K

d

F

d

FD

s

= + =

3 2 3

d d d

Where K

s

is called as the shear stress correction factor and

serves to correct the shear stress estimated from the torsion

alone for the direct shear. Here K

s

is

C

C

K

s

2

1 2 +

=

For the standard springs, C ranges between 6 and 12.

Curvature effect in fatigue loading

Only in fatigue loading, the curvature of the wire

introduces more shear stress than estimated above

Hence that expression for maximum shear stress

needs correction.

Many factors have been suggested for correction.

Prominent are Wahl factor (K ) and Bergstrasser Prominent are Wahl factor (K

w

) and Bergstrasser

factor (K

B

).

These must replace K

s

when incorporated.

Curvature effect in fatigue loading: Wahl factor and

Bergstrasser factor

2 4 615 . 0 1 4 + C C

Static Loading, only effect of direct shear:

C

C

K

s

2

1 2 +

=

Fatigue Loading, effect of both direct shear and curvature:

Wahl factor (K

w

) or Bergstrasser factor (K

B

) is used

3 4

2 4 615 . 0

4 4

1 4

+

= +

=

C

C

K or

C C

C

K

B w

Fatigue Loading, effect of only curvature:

( )

( )( ) 1 2 3 4

2 4 2

+

+

= =

C C

C C

K

K

K

s

B

c

Deflection and Stiffness:

a a

a

Gd

FDN

Gd

N FD

F

U

y

d A d J DN l FD T

Gd

DN F

Gd

N D F

AG

l F

GJ

l T

U

2 4

3

2 4

2

2

4

3 2 2 2

4 8

: theorem second s o' Castiglian

. 4 / ; 32 / ; ; 2 /

2 4

2 2

+ =

=

= = = =

+ = + =

Q

a

a a

N D

Gd

y

F

k

Gd

N FD

C Gd

N FD

y

Gd Gd F

y

3

4

4

3

2 4

3

2 4

8

8

2

1

1

8

D/d, C index spring g Introducin

= =

\

|

+ =

=

+ =

=

Manufacturing processing at the ends and effect on total

coils

Compression Springs

Compression Springs

Formulas for the Dimensional Characteristics of Compression-Springs

Table 101

If interested:

For a thorough discussion and development of these relations, refer

Cyril Samonov, Computer-Aided Design of Helical Compression Springs,

ASME paper No. 80-DET-69, 1980.

SPRING MATERIALS

Music wire, Oil-tempered wire, Hard drawn wire, Chrome-

vanadium wire and Chrome-silicon wire

m

ut

d

A

S = strength, tensile Minimum

Use Table 10-4 for A and m.

Table 104

SPRING MATERIALS

Table 105

Mechanical Properties of Some Spring Wires

SPRING MATERIALS

Unless otherwise specified, use MSS criterion for static design for springs

because the primary loading nature is shear.

Table 106

Maximum Allowable Torsional Stresses for Helical Compression Springs

in Static Applications

Set removal or presetting

Is a process used in the manufacture of compression

springs to induce useful residual stresses

The spring is made to a longer free length than required and

then is compressed beyond the elastic limit by 30% of the

length

When the spring tries spring back, the plastic strain induced

opposes the same resulting in residual stress being set up

that are opposite in direction to the working stresses

Hence the springs behave stronger in service

Set removal must NOT be used for springs used in fatigue

loading

Critical Frequency of Helical Springs: Surging

Spring surge or surging of springs is the problem

and it is similar to the wave propagating in water

If one end of springs is held stationary and other

end is disturbed, the springs vibrates violently

Failure resulting from the resonance inherent in

surging is found to be purely due to torsional surging is found to be purely due to torsional

shear and occurs at 45

o

to the wire axis.

The governing equation for spring surging is the

wave equation:

2

2

2 2

2

t

u

kgl

W

y

u

|

|

\

|

=

Here, u is the displacement, k is the spring stiffness, l is the length of the

spring, g is the acceleration due to gravity, Wis the weight of the active part

of the spring

Contd.

The solution to this differential equation give the natural frequency of

vibration:

W

kg

m =

W

kg m

f

2

=

m = harmonic number

2 2 2

DN d d

( )( )

weight Specific

4 4

2 2 2

=

= = =

a

a

DN d

DN

d

AL W

The fundamental frequency, for m=1, should be from 15 to 20 times the

forcing frequency to avoid the resonance and hence in turn the surging of

the spring

Redesign to effect this normally involves increasing k or decreasing the W

STABILITY:

A compression spring is stable if it does not buckle under the

load

(

(

|

|

\

|

=

2 / 1

2

'

2

'

1 0

1 1

eff

cr

C

C L y

D

L

eff

0

=

( ) G E

E

C

=

2

'

1

( )

E G

G E

C

+

=

2

2

2

'

2

( )

2 / 1

0

2

'

2

2

2

1

(

< >

E G

G E D

L

C

eff

For absolute stability and buckling not to occur,

Slenderness ratio

Elastic constants

End -condition constants () for helical compression springs

Table 102, page 522

Helical Compression Spring Design for Static Service

A helical coil spring force-deflection characteristic

is ideally linear.

For very small deflections, and near closure,

nonlinear behavior begins as the number of active

turns diminishes as coils begin to touch.

The springs operating point to the central 75 The springs operating point to the central 75

percent of the curve between no load, F = 0, and

closure, F = F

s

.

F

s

= (1 + )F

max

Helical Compression Spring Design for Static Service

In addition to the relationships and material

properties for springs, the recommended design

conditions are:

Spring index range : 6 C 12

No of active turns range : 3 Na 15 No of active turns range : 3 Na 15

Robust linearity : 0.15

Factor of safety at closure : n

s

1.2

4

cost) material (relative - fom merit, of figure The

2 2

D N d

t

=

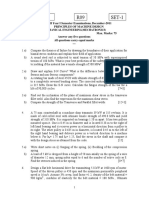

Helical coil compression spring design for static loading.

From Table A-28; 1051

A music wire helical compression spring is needed to

support an 89 N load after being compressed 50.8 mm.

Because of assembly considerations the solid height

cannot exceed 25.4 mm and the free length cannot be

more than 101.6 mm. Design the spring.

Springs are almost always subject to fatigue loading.

Automotive engine valves are supported by compression

springs that are subjected to millions of cycles of

operation without failure.

Shot peening is used to improve the fatigue strength of

Design for Fatigue Load:

Shot peening is used to improve the fatigue strength of

dynamically loaded springs. Shot peening can increase

the torsional fatigue strength by 20 percent or more.

Springs are designed for infinite life based on

Zimmerlis data.

Zimmerlis Data: Shot Peening

A cold working process used to produce a compressive

residual stress layer and modify mechanical properties of

metals

Entails impacting a surface with shot (round metallic,

glass or ceramic particles of 1/64 inch diameter) with glass or ceramic particles of 1/64 inch diameter) with

force sufficient to create plastic deformation

Zimmerlis Data:

The best data on the torsional endurance limits of spring steels are

those reported by Zimmerli and discovered the surprising fact that

size, material, and tensile strength have no effect on the endurance

limits (infinite life only) of spring steels in sizes under 10 mm.

Unpeened springs were tested from a minimum torsional stress of

138 MPa to a maximum of 620 MPa and peened springs in the range

138 MPa to 930 MPa . The corresponding endurance strength

components for infinite life were found to be components for infinite life were found to be

ut sy ut ut su

sm sa

sm sa

S S S or S S

MPa S MPa S

Peened

MPa S MPa S

Unpeened

557 . 0 35 . 0 67 . 0

534 398

:

379 241

:

=

= =

= =

Design for Fatigue Loading Based on Zimmerlis

Data

criterion. failure fatigue a apply then and

, , , , , , , ,

min max su sy e m a m a

S or S S F F find given F F

min max min max

2 2

F F

F and

F F

F

m a

+

=

=

3 3

8 8

2 2

d

D F

K and

d

D F

K

F and F

m

W m

a

W a

m a

= =

= =

Zimmerlis Data (Gerber criteria)

su

sm

sa

se

su

sm

se

sa

line load given for cordinate tion Inter

S

S

-

S

S

S

S

S

S

|

|

\

|

= =

|

|

\

|

+

2

2

sec

1

1

limit endurance the find Then

S

sa

and S

sm

are from

Zimmerlis data.

S

su

= 0.67S

ut

Factor of Safety,

a

sa

f

S

n

=

m

a

sm

sa

ut

se

se

su

sa

F

F

S

S

r

rS

S

S

S r

S

= =

(

(

|

|

\

|

+ + =

2

2 2

2

1 1

2

Refer Table 6-7 ; page 307

Zimmerlis Data (Goodman criteria)

su

sm

sa

se

su

sm

se

sa

line load given for cordinate tion Inter

S

S

-

S

S

S

S

S

S

|

|

\

|

= =

|

|

\

|

+

sec

1

1

limit endurance the find Then

S

sa

and S

sm

are from

Zimmerlis data.

S

su

= 0.67S

ut

Factor of Safety,

a

sa

f

S

n

=

m

a

sm

sa

se su

su se

sa

F

F

S

S

r

S rS

S rS

S

line load given for cordinate tion Inter

= =

+

=

sec

Refer Table 6-6 ; page 307

Zimmerlis Data (ASME- Elliptic criteria)

sy

sm

sa

se

sy

sm

se

sa

line load given for cordinate tion Inter

S

S

-

S

S

S

S

S

S

|

|

\

|

= =

|

|

\

|

+

|

|

\

|

2

2

2

sec

1

1

limit endurance the find Then

S

sa

and S

sm

are from

Zimmerlis data.

S

su

= is to calculated

from Table 10-5

page 526

Factor of Safety,

a

sa

f

S

n

=

m

a

sm

sa

sy se

sy se

sa

F

F

S

S

r

S r S

S S r

S

line load given for cordinate tion Inter

= =

(

(

+

=

2 2 2

2 2 2

sec

Refer Table 6-8 ; page 308

Tension/ Extension springs: end preparation

Combined axial tension and

bending stress at A

Only

torsion at

B

Side

views

Tension /Extension springs:

Improved design

views

Analysis of stresses in tension springs

( )

( )

( )

( ) d

r

C

C C

C C

K

K

d d

D

K F

A

A

A A

1

1

1 1

1

2

1

2 3

2

,

1 4

1 4

by given curvature, for factor correction strss Bending

4 16

moment bending tension axial combined to due A at stress tensile maximum The

=

=

=

(

+ =

( )

( )

( )

( )

( ) d

r

C

C

C

K

K

d

FD

K

B

B

B B

2

2

2

2

3

2

,

4 4

1 4

by given curvature, for factor correction strss Torsional

8

by given is B at stress shear torsional maximum The

=

=

=

=

Extension spring

F

A

B

( )

( )

( ) d

r

C

C C

C C

K

d d

D

K F

A

A A

1

1

1 1

1

2

1

2 3

2

,

1 4

1 4

4 16

=

=

(

+ =

( )

d

FD

K

B B

3

8

=

Stress is to be computed at three locations

C

( )

( )

( ) d

r

C

C

C

K

d

B

2

2

2

2

2

,

4 4

1 4

=

=

3 4

2 4

8

3

+

=

=

C

C

K

d

FD

K

B

B C

INITIAL TENSION IN CLOSE-WOUND TENSION SPRINGS

When extension springs are made with coils in contact with

one another, they are said to be close-wound.

Spring manufacturers prefer some initial tension in close-

wound springs in order to hold the free length more

accurately.

( ) ( ) ( )

E

G

N N coils of number Active

d N C d N d D L

ky F F

b a

b b o

i

+ =

+ = + + =

+ =

,

1 2 1 2 : length Free

No of body coils

INITIAL TENSION IN CLOSE-WOUND TENSION SPRINGS:

The initial tension in an extension spring is created in the

winding process by twisting the wire as it is wound onto

the mandrel.

When the spring is completed and removed from the

mandrel, the initial tension is locked in because the spring

cannot get any shorter.

( )

MPa

C

e

C

i

|

\

|

=

5 . 6

3

4 9 . 6

231

is, stress torsional d uncorrecte of range Preferred

105 . 0

PROBLEM

A hard-drawn steel wire extension spring has a

wire diameter of 0.9 mm, an outside coil

diameter of 6 mm, hook radii of r

1

=2.55 mm

and r

2

= 2.1 mm, and an initial tension of 5 N.

The number of body turns is 12.17. From the

given information: given information:

(a) Determine the physical parameters of the spring

(b) Check the initial preload stress conditions

(c) Find the factors of safety under a static 24 N

load.

Solution:

( ) ( )

( )( )

mm N

Gd

k

turns

E

G

N N

C C K

d D C

mm d OD D

b a

B

/ 885 . 3

9 . 0 10 79

57 . 12

10 198

10 79

17 . 12

254 . 1 3 4 / 2 4

67 . 5 9 . 0 / 1 . 5 /

1 . 5 9 . 0 6

4

3 4

3

3

=

= =

=

+ = + =

= + =

= = =

= = =

( )( )

( ) ( )

( ) ( ) ( ) ( )( )

mm y L L

mm

k

F F

y

mm d N d D L

mm N

N D

Gd

k

o

i

b o

a

14 . 25 89 . 4 25 . 20

89 . 4

885 . 3

5 24

25 . 20 9 . 0 1 17 . 12 9 . 0 1 . 5 2 1 2

/ 885 . 3

57 . 12 1 . 5 8

9 . 0 10 79

8

1 1

1

1

3 3

= + = + =

=

=

= + + = + + =

=

= =

( )

( )( )

( )

( )

| |

( ) range. preferred in the not is It . 1 . 102 7 . 24 8 . 126

5 . 151 7 . 24 8 . 126

5 . 6

3 67 . 5

4 9 . 6

231

07 . 89

9 . 0

1 . 5 5 8 8

is stress initial d uncorrecte The

min

67 . 5 * 105 . 0 max

3 3

MPa

MPa

e

MPa

d

D F

i

i

i

uncorr

i

= =

= + =

|

\

|

+ =

= = =

( )( )

( )

15 . 536

9 . 0

1 . 5 24 8

254 . 1

8

3 3

1

1

= = =

B

MPa

d

D F

K

( )

( )

( )

526 . 1

15 . 536

55 . 818

S

55 . 818 1819 45 . 0 S 45 . 0 S

1819

9 . 0

1783

d

A

S

9 . 0

1

sy

ut sy

190 . 0 m

ut

3 3

1

= = =

= = =

= = =

s

B

n

MPa

MPa

d

Contd.

( )

( )

( )

( )

( ) ( )

( )

( ) ( )

( )

( )

25 . 1364

25 . 1364 1819 75 . 0 S 75 . 0 S

, 1021

9 . 0

4

9 . 0

1 . 5 16

15 . 1 24

15 . 1

1 67 . 5 67 . 5 * 4

1 67 . 5 67 . 5 4

1 4

1 4

67 . 5

d

D

d

2r

C

is A at bending hook end in the situation The

ut y

2 3

1

2

1 1

1

2

1

1

1

= = =

=

(

+ =

=

=

= = = =

A

A

S

MPa

MPa

C C

C C

K

C

( )

( )

( )

( )

( )

( )

( ) ( )

( )

( ) 595 . 1

513

55 . 818

, 513

9 . 0

1 . 5 24 20 . 1 8

2 . 1

4 66 . 4 4

1 66 . 4 4

4 4

1 4

66 . 4

9 . 0

9 . 0 1 . 5

d

2r

is B at hook - end in situation The

336 . 1

1021

25 . 1364

3

1

2

2

2

2

1

= = = =

=

=

=

= =

= = =

B

y

B

B

A

y

A

y

n MPa

C

C

K

d

d D

C

S

n

Close wound like helical coil

extension spring

Negligible initial tension

The ends connect a force at a

distance from coil axis to apply a

torque

Wound with a pitch that just

separates the body coils to avoid

TORSION SPRINGS:

separates the body coils to avoid

intercoil friction.

The wire in the torsion spring is

in bending

Free

End

Free

end

location

Back

angle

Angular

rotation,

proportio

-nal to Fl

TORSION SPRING

Fixed

End

location

angle

For all positions of the moving end + = = constant.

turns partial ; body turns

integer

360

integer

= =

+ = + =

p b

p

o

b

N N

N N

Bending Stress :

The bending stress can be expressed as

2 2

1 4 1 4

' '

C C

K and

C C

K

factor correction stress is K where

I

Mc

K

+

=

=

=

3

3

32

,

32

) 1 ( 4

1 4

) 1 ( 4

1 4

d

Fl

K is equation bending the

d

c

I

and Fl M ng Substituti

unity than less also and K than less always is K

C C

C C

K and

C C

C C

K

i

i o

o i

=

= =

+

+

=

=

Torsional stiffness:

( )

radians

E d

Ml

d E

Fl

EI

Fl

l

y

e

4 4

2 2

3

64

64 / 3 3

: deflection End

= = = =

The end deflection is bending of a cantilever beam whereas The end deflection is bending of a cantilever beam whereas

the coils undergo bending action under M = Fl requiring

application of Castigliano theorem.

Strain energy in bending,

=

EI

dx M

U

2

2

b b

c

DN DN

c

E d

MDN

E d

FlDN

d I

EI

dx Fl

EI

dx l F

F F

U

l

b b

4 4

4

0

2

0

2 2

64 64

64 /

2

= =

=

|

|

\

|

=

|

|

\

|

The Force F will deflect through a distance l

Torsional stiffness

( ) ( )

a t e b a e

b

b

t

e e c t

N

E d

MD

N N N

D

l l

N

Defining

D

l l

N

E d

MD

E d

Ml

E d

Ml

E d

MDN

E d E d

4

2 1

2 1

4 4

2

4

1

4

2 1

64

; ,

3

3

64

3

64

3

64 64

(rad), deflection angular total The

= + =

+

=

|

\

|

+

+ = + + =

+ + =

Stiffness expressions in torque/radian units:

b c

c

DN

E d M

k

64

4

= =

( )

2 1

4

64

3

l l

E d M

k

e

e

+

= =

Stiffness values in torque/turn values (i.e 2 rad /turn) :

a t

s

DN

E d M

k

64

4

= =

2

4

'

= =

E d M

k 2

4

'

= =

E d M

k

( )

2

3

4

'

= =

E d M

k

Torsional stiffness

2

64

'

'

= =

a t

s

DN

E d M

k

2

64

'

'

= =

b c

c

DN

E d M

k

( )

2

64

3

2 1

'

'

+

= =

l l

E d M

k

e

e

a t

s

DN

E d M

k

8 . 10

4

'

'

= =

b c

c

DN

E d M

k

8 . 10

4

'

'

= =

( )

2 1

4

'

'

8 . 10

3

l l

E d M

k

e

e

+

= =

Tests show that the effect of friction between the coils is such that the

constant 10.2 (i.e 64/2) should be increased to 10.8

Torsion spring supported on round bar or pin:

c b

b

N

D N

D

+

= n deformatio after and before balance volume from , '

'

When the load is applied to a torsion spring, the spring winds up, causing

a decrease in the inside diameter of the coil body.

Ensure that the inside diameter of the coil never becomes equal to or less

than the diameter of the pin, in which case loss of spring function would

ensue

The helix diameter of the coil D becomes

( ) ( ) | |

b

'

c b

c b

N D A N D' A

N

= +

+

( )

pin

pin c

b

pin

c b

b

pin pin i

D d D

D d

N

D d

N

D N

D d D D D

+ +

=

+

= = =

'

1

'

'

The new inside diameter D

i

= D d makes the diametral clearance

between the body coil and the pin of diameter D

p

Design of Torsion Springs for Strength:

Static strength

m

ut

d

A

S =

Table 106

First column entries in Table 106 can be divided by 0.577 (from distortion-

energy theory) to give

Das könnte Ihnen auch gefallen

- FT 155-Am-2, C-5Dokument11 SeitenFT 155-Am-2, C-5Matheus Mariano0% (1)

- Exoskeleton Chairless ChairDokument31 SeitenExoskeleton Chairless ChairNithin PradeepNoch keine Bewertungen

- Pen Holder PaperDokument6 SeitenPen Holder Paperapi-273074304Noch keine Bewertungen

- Plastic Vs Elastic DeformationDokument2 SeitenPlastic Vs Elastic DeformationRCNoch keine Bewertungen

- CAD Drawing M1911ADokument59 SeitenCAD Drawing M1911AAngela Uselton100% (1)

- Time: 03 Hours Maximum Marks: 100 Instructions To CandidatesDokument2 SeitenTime: 03 Hours Maximum Marks: 100 Instructions To CandidatesAa BbNoch keine Bewertungen

- Product Design and DevelopmentDokument14 SeitenProduct Design and Developmentapi-279168957Noch keine Bewertungen

- Product Design and DevelopmentDokument8 SeitenProduct Design and DevelopmentAnonymous d6EtxrtbNoch keine Bewertungen

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDokument28 SeitenBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledCordillera St. JosephNoch keine Bewertungen

- Coil SpringDokument14 SeitenCoil SpringLeti HanajNoch keine Bewertungen

- 3D PrintingDokument18 Seiten3D PrintingkishanNoch keine Bewertungen

- Engineering Design II: Springs I - IntroductionDokument46 SeitenEngineering Design II: Springs I - IntroductionSean ChanNoch keine Bewertungen

- Product Design and DevelopmentDokument16 SeitenProduct Design and DevelopmentTedy ThomasNoch keine Bewertungen

- A Progress Report On Design and Development of MEMS Based SensorDokument3 SeitenA Progress Report On Design and Development of MEMS Based Sensorarun14089Noch keine Bewertungen

- DOME-I Unit 1 - GDokument17 SeitenDOME-I Unit 1 - GGautam GunjanNoch keine Bewertungen

- PHD Sem - 1 Progress PresentationDokument23 SeitenPHD Sem - 1 Progress PresentationsanibubaNoch keine Bewertungen

- How To Take Patent in INDIA FinalDokument19 SeitenHow To Take Patent in INDIA FinalnonsenseatulNoch keine Bewertungen

- Bortole M Design Control Robotic Exoskeleton Gait Rehabilitation Tesis Master PDFDokument95 SeitenBortole M Design Control Robotic Exoskeleton Gait Rehabilitation Tesis Master PDFMuizzuddin RosliNoch keine Bewertungen

- The Third AlternativeDokument2 SeitenThe Third Alternativeislam_hassan8284Noch keine Bewertungen

- ms-11 - Strategic ManagementDokument1 Seitems-11 - Strategic ManagementIGNOU MBA HELPNoch keine Bewertungen

- Operations Management Product Design and Development IDokument11 SeitenOperations Management Product Design and Development IPrateek ChaturvediNoch keine Bewertungen

- Development of Noonee Chairless ChairDokument59 SeitenDevelopment of Noonee Chairless Chairvidyadhar G75% (4)

- Unit 5 - THIN CYLINDER MOSDokument22 SeitenUnit 5 - THIN CYLINDER MOSAsvath GuruNoch keine Bewertungen

- Leading Sustainability Through Re-Integrative Education: You and Higher Education InstitutionsDokument30 SeitenLeading Sustainability Through Re-Integrative Education: You and Higher Education InstitutionsGreatLakesIanNoch keine Bewertungen

- In-Sem: 30 Marks End-Sem: 70 Marks TW: 50 Marks: Theory - 4hr/week Practical - 2hr/weekDokument45 SeitenIn-Sem: 30 Marks End-Sem: 70 Marks TW: 50 Marks: Theory - 4hr/week Practical - 2hr/weekfiramegbNoch keine Bewertungen

- Rack and Pinion Steering DesigningDokument19 SeitenRack and Pinion Steering DesigningAudrian Louven Realubit Sabado0% (2)

- Unit-5 Dimensional Analysis by DR Pramod PachghareDokument23 SeitenUnit-5 Dimensional Analysis by DR Pramod Pachgharepramod100% (1)

- Shaft DesignDokument37 SeitenShaft DesignFarah HumaNoch keine Bewertungen

- Design Exploration - Judd KaiserDokument30 SeitenDesign Exploration - Judd KaiserSangbum KimNoch keine Bewertungen

- Mechanical Design Data BookDokument69 SeitenMechanical Design Data Bookvenugopalmanga100% (1)

- HvpeDokument122 SeitenHvpeAmitNoch keine Bewertungen

- SolidWorks Sustainability ArticleDokument4 SeitenSolidWorks Sustainability ArticleNatarajan RamamoorthyNoch keine Bewertungen

- ArcUri - Organe de Masini OMDokument18 SeitenArcUri - Organe de Masini OMCîrstea BökiNoch keine Bewertungen

- Green ManufacturingDokument18 SeitenGreen ManufacturingFiroz KhanNoch keine Bewertungen

- Bolt Design (1) English PDFDokument3 SeitenBolt Design (1) English PDFAlla EddineNoch keine Bewertungen

- ANSYS 18.2 Mechanical Products UpdateDokument112 SeitenANSYS 18.2 Mechanical Products UpdateAnonymous hprsT3WlP100% (1)

- UHV 3D D2-S4A Und Relationship - Other FeelingsDokument38 SeitenUHV 3D D2-S4A Und Relationship - Other FeelingssatyanandaramNoch keine Bewertungen

- Design Triz Assignment WTF3Dokument15 SeitenDesign Triz Assignment WTF3Firzan HaraziNoch keine Bewertungen

- Unsymmetrical BendingDokument24 SeitenUnsymmetrical BendingAnonymous gO6PtzXa6Noch keine Bewertungen

- Dom Unit 1Dokument41 SeitenDom Unit 1Martin SudhanNoch keine Bewertungen

- Me2303 - Design of Machine ElementsDokument14 SeitenMe2303 - Design of Machine ElementsGowtham RajNoch keine Bewertungen

- IE 443 Lesson 4 Maintainability and Availability AnalysisDokument46 SeitenIE 443 Lesson 4 Maintainability and Availability Analysishamidu athumaniNoch keine Bewertungen

- Bearing ForceDokument2 SeitenBearing ForceJason BakerNoch keine Bewertungen

- Design For SustainabilityDokument16 SeitenDesign For SustainabilityGuangbeng LeeNoch keine Bewertungen

- Chinu - PLMDokument23 SeitenChinu - PLMDharanidhar BeheraNoch keine Bewertungen

- Mechanisms With Lower PairsDokument43 SeitenMechanisms With Lower PairsVincentius NikimNoch keine Bewertungen

- DOME-I Unit 1 - Lec 2Dokument21 SeitenDOME-I Unit 1 - Lec 2Gautam Gunjan100% (1)

- UHV 3D D1-S4 Und Human Being - Self PDFDokument21 SeitenUHV 3D D1-S4 Und Human Being - Self PDFUP BROTHERS100% (1)

- Ansys Advantage Digital Exploration Aa V11 I2Dokument60 SeitenAnsys Advantage Digital Exploration Aa V11 I2david_valdez_83Noch keine Bewertungen

- Chapter 7 Rolling Contact Bearing-2Dokument33 SeitenChapter 7 Rolling Contact Bearing-2Abaziz Mousa OutlawZzNoch keine Bewertungen

- MCMT Unit-IIDokument190 SeitenMCMT Unit-IISai RamNoch keine Bewertungen

- 02 Knuckle JointDokument24 Seiten02 Knuckle JointTeaching ClubNoch keine Bewertungen

- Knuckle Joints DesignDokument10 SeitenKnuckle Joints DesignKvrd Prasad100% (1)

- What Structures Make Up The Back?: CongenitalDokument5 SeitenWhat Structures Make Up The Back?: Congenitalselvi lestariNoch keine Bewertungen

- Spur Gear (Treb)Dokument19 SeitenSpur Gear (Treb)diiivadNoch keine Bewertungen

- Eide PPT Chapter 02Dokument15 SeitenEide PPT Chapter 02Mohammad Abed OmerzadNoch keine Bewertungen

- MSE 451 Composite Materials First Part (. Giks's Conflicted Copy 2016-09-19)Dokument113 SeitenMSE 451 Composite Materials First Part (. Giks's Conflicted Copy 2016-09-19)maxwellNoch keine Bewertungen

- Copper Busbar Joint Volt Drop PDFDokument8 SeitenCopper Busbar Joint Volt Drop PDFANIL KALANoch keine Bewertungen

- Cam Design - HassanDokument65 SeitenCam Design - HassanDanialNoch keine Bewertungen

- 10.mechanica..l SpringsDokument149 Seiten10.mechanica..l SpringsAekkasit SenaartNoch keine Bewertungen

- Theoretical and Applied Fracture Mechanics: Eshwar Kuncham, Subhamoy Sen, Pankaj Kumar, Himanshu PathakDokument16 SeitenTheoretical and Applied Fracture Mechanics: Eshwar Kuncham, Subhamoy Sen, Pankaj Kumar, Himanshu Pathakowais khanNoch keine Bewertungen

- Nimonic Alloy 90Dokument20 SeitenNimonic Alloy 90akashrambharosNoch keine Bewertungen

- Applying EI Vibration & SBC GuidelinesDokument22 SeitenApplying EI Vibration & SBC GuidelinesvicopipNoch keine Bewertungen

- Simply Gearbox DesignDokument39 SeitenSimply Gearbox DesignJean Pablo Valverde MoraNoch keine Bewertungen

- Cuñas Manuales BJDokument96 SeitenCuñas Manuales BJFerney FonsecaNoch keine Bewertungen

- Fatigue AnalysisDokument26 SeitenFatigue Analysiskaweesa brian100% (1)

- FerrocementDokument25 SeitenFerrocementNandhini NallasamyNoch keine Bewertungen

- Evaluation of Damage Equivalent Factor For Roadway BridgesDokument8 SeitenEvaluation of Damage Equivalent Factor For Roadway Bridgesmonolith80Noch keine Bewertungen

- Crude Oil Pipeline CalculationDokument104 SeitenCrude Oil Pipeline CalculationHendra Yudistira100% (3)

- Part 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDokument45 SeitenPart 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDylkanWingsNoch keine Bewertungen

- Fatigue and Static Crack GrowtDokument14 SeitenFatigue and Static Crack GrowtKay WhiteNoch keine Bewertungen

- PMD ModelDokument8 SeitenPMD ModelDamodara SatyaDeva MadhukarNoch keine Bewertungen

- SHRP2 - S2-R19B-RW-1 Bridges For Service Life Beyond 100 Years - Service Limit State DesignDokument521 SeitenSHRP2 - S2-R19B-RW-1 Bridges For Service Life Beyond 100 Years - Service Limit State DesignKY PengNoch keine Bewertungen

- Aircraft Reciprocating-Engine Failure: An Analysis of Failure in A Complex Engineered SystemDokument269 SeitenAircraft Reciprocating-Engine Failure: An Analysis of Failure in A Complex Engineered SystemJUAN BAEZA PAREDESNoch keine Bewertungen

- Slab On GradeDokument60 SeitenSlab On GradeMANoch keine Bewertungen

- 20ff PDFDokument8 Seiten20ff PDFCaio Fazzioli Tavares100% (1)

- Chapter 3. Failure of MaterialsDokument20 SeitenChapter 3. Failure of MaterialsVishal ShuklaNoch keine Bewertungen

- Shot PeeningDokument19 SeitenShot PeeningchandruNoch keine Bewertungen

- BR 1701 PDFDokument7 SeitenBR 1701 PDFdestiny2bnNoch keine Bewertungen

- PVC O Pipes - Superior PerformanceDokument5 SeitenPVC O Pipes - Superior PerformanceMichaelNoch keine Bewertungen

- Failure Analysis Report - EX1343 Pin Boom Foot FailureDokument6 SeitenFailure Analysis Report - EX1343 Pin Boom Foot Failureputri lestariNoch keine Bewertungen

- 1.1 Gas Turbine EngineDokument21 Seiten1.1 Gas Turbine EngineaarthiNoch keine Bewertungen

- LIFTECH - Container Crane DesignDokument49 SeitenLIFTECH - Container Crane Designaiyubi2100% (1)

- Subsection ZDokument313 SeitenSubsection Zsafeer ahmadNoch keine Bewertungen

- Review On Internal Combustion Engine Vibrations and MountingsDokument12 SeitenReview On Internal Combustion Engine Vibrations and MountingsSanthosh KumarNoch keine Bewertungen

- Design Model For The Fatigue Behaviour of Normal-Strength, High-Strength and Ultra-High-Strength ConcreteDokument11 SeitenDesign Model For The Fatigue Behaviour of Normal-Strength, High-Strength and Ultra-High-Strength Concreteming_zhu10Noch keine Bewertungen

- 8P1. Fatigue Analysis of An Aluminium 2024-T3 Structure With Quality Index K 4.0Dokument4 Seiten8P1. Fatigue Analysis of An Aluminium 2024-T3 Structure With Quality Index K 4.0RGFENoch keine Bewertungen

- HeliCoil Technical Information Shock Vibration FatigueDokument8 SeitenHeliCoil Technical Information Shock Vibration FatigueAce Industrial SuppliesNoch keine Bewertungen

- Soon To A: Reliability of Optical Fibres Impact On Cable DesignDokument6 SeitenSoon To A: Reliability of Optical Fibres Impact On Cable DesignHakimHabibiNoch keine Bewertungen