Beruflich Dokumente

Kultur Dokumente

Pti1000 Esd5100 Series

Hochgeladen von

Ramon Thales DomeniconiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pti1000 Esd5100 Series

Hochgeladen von

Ramon Thales DomeniconiCopyright:

Verfügbare Formate

ENGINE GOVERNING SYSTEM

ESD5100 Series Speed Control Unit

Auxiliary Accessory Input 10 Amp Drive Circuit Inputs for Accessories

G A C

OVERNORS MERICA ORP.

Simple Installation and Adjustment Isochronous, Droop, & Variable Speed Operation Adjustable PID Idle Speed Circuit INTRODUCTION

The ESD5100 Series electronic speed device is designed to control engine speed with fast and precise response to transient load changes. This closed loop control, when connected to a proportional electric actuator and supplied with a magnetic speed sensor signal, will control a wide variety of engines in an isochronous or droop mode. It is designed for high reliability and built ruggedly to withstand the engine environment. Simplicity of installation and adjustment was foremost in the design. Non-interacting performance controls allow near optimum response to be easily obtained. Other features include adjustable droop and idle operation, inputs for accessories used in multi-engine or special applications, protection against reverse battery voltage, transient voltages, accidental short circuit of the actuator and fail safe design in the event of loss of speed sensor signal or battery supply.

DESCRIPTION

Engine speed information for the speed control unit is usually received from a magnetic speed sensor. Any other signal-generating device may be used provided that the generated frequency is proportional to engine speed and meets the voltage input and frequency range specification. The speed sensor is typically mounted in close proximity to an engine driven ferrous gear, usually the engine ring gear. As the teeth of the gear pass the magnetic sensor, a signal is generated which is proportional to engine speed. Signal strength must be within the range of the input amplifier. An amplitude of 0.5 to 50 volts RMS is required to allow the unit to function within its design specifications. The speed signal is applied to Terminals C and D on the ESDs. Between these terminals there is an input impedance of over 33,000 . Terminal D is internally connected to Terminal E, battery negative. Only one end of the cable shield should be connected. When a speed sensor signal is received by the ESD, the signal is amplified and shaped by an internal circuit to provide an analog speed signal. If the speed sensor monitor does not detect a speed sensor signal, the output circuit on the ESD will turn off all current to the actuator. A summing circuit receives the speed sensor signal along

with the speed adjust set point input. The speed range has a ratio of 9:1 and is adjusted with by the 25-turn SPEED potentiometer. The output from the summing circuit is the input to the dynamic control section of the speed control unit. The dynamic control circuit, of which the GAIN and STABILITY adjustments are part of, has a control function that will provide isochronous and stable performance for most engine types and fuel systems. The ESDs circuit is influenced by the GAIN and STABILITY performance adjustments. The governor system sensitivity is increased with clockwise relation of the GAIN adjustment. The GAIN adjustment has a range of 33:1. The STABILITY adjustment, when advanced clockwise, increases the time rate of response of the governor system to match the various time constants of a wide variety of engines. The ESD is a PID device, the D, derivative portion can be varied when required. (See instability section in PIB1000.) During the engine cranking cycle, the actuator becomes fully energized and moves to the maximum fuel position. The actuator will remain in this state during engine cranking and acceleration. While the engine is at steady load, the actuator will be energized with sufficient current to maintain the governor speed set point. The output circuit provides switching current at a frequency of about 500 Hz. to drive the actuator. Since the switching frequency is well beyond the natural frequency of the actuator, there is no visible motion of the actuator output shaft.

Governors America Corp., 720 Silver Street Agawam, MA 01001 phone: 413.786.5600 fax: 413.789.7736 www.governors-america.com info@governors-america.com

1

ISO 9001 CERTIFIED

Switching the output transistors reduces its internal power dissipation for efficient power control. The output circuit can provide current up to 10 Amps continuous at 25C for 12 and 24 VDC battery systems. The actuator responds to the average current to position the engine fuel control lever. In standard operation, the ESDs performance is isochronous. Droop governing can be selected by connecting Terminals K and L and the percent of droop governing can be varied with the DROOP adjustment control. Connecting Terminals G and H can increase the droop range. The ESD has several performance and protection features, which enhance the governor system. A speed anticipation circuit minimizes speed overshoot on engine startup or when large increments

of load are applied to the engine. Engine idle speed can be remotely selected and is adjustable. The ESD5100 Series can accept accessory inputs (i.e., GACs Load Sharing Modules & Synchroners) to achieve variable speed operation and multi-engine control. Protection against reverse battery voltage and transient voltages is provided. The design is fail safe in the event of loss of speed sensor signal or battery supply. The ESD5100 Series speed control unit is compatible with GOVERNORS AMERICA CORP. proportional electric actuators (except the 2001 Series) as well as those from other manufacturers.

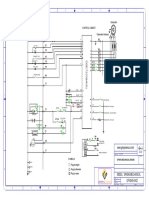

DIAGRAM 1 SYSTEM WIRING AND OUTLINE

5.00 (127)

LEAD CIRCUIT JUMPER

SELECTION CHART

Model

esd5111 esd5111h esd5111t esd5119

CharaCteristiCs

Standard Unit Hard Potted Temperature Compensated EFC Reverse Acting EFC Forward Acting/Light Force EFC Forward Action/Light Force/Temperature Compensated Soft Coupling Option/Speed Detection Circuit Soft Coupling Option/Hard Potted 4-20 mA Output Soft Coupling Option/Expanded Range to 10.5K Hz Expanded Adjustable Speed Range

SPEED CONTROL UNIT MODEL: ESD51xx

S/N :

MADE IN AGAWAM, MA U.S.A.

GA C

OVERNORS MERICA ORP.

ESD5131, ESD5131H, and ESD5151 only

SPEED GAIN STABILITY DROOP

E1

E7

E6

1 OFF LEAD CIRCUIT ON

ON 2 SOFT COUPLING OFF

5.00 (127)

CAUTION

E2

E3

ENGINE SPEED CONTROL

COMPONENT. WHEN INSTALLING OR SERVICING REFER TO PRODUCT PUBLICATION.

esd5120

DEAD TIME COMPENSATION JUMPER

PICK-UP - + ACTUATOR BATTERY

IDLE

AUX 10V

esd5120t esd5131

A B C D E F GH J K L MN P

0.27 (6,8)

OPTIONAL ACTUATOR CABLE SHIELDING TO MEET CE DIRECTIVE

esd5131h esd5150

ACCESSORY POWER SUPPLY

*

ACTUATOR MAGNETIC PICK-UP

_ +

S1

CW

ACCESSORY INPUT

esd5151 esd5159

ADD JUMPER TO INCREASE DROOP RANGE

GROUND REFERENCE

IDLE

SPEED TRIM

ISOCHRONOUS DROOP

EXTERNAL SELECTOR SWITCH (NOT REQUIRED FOR SINGLE SPEED ISOCHRONOUS OPERATION)

BATTERY

FUSE 15A MAX

SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER WIRING OF ACTUATOR BASED ON BATTERY VOLTAGE

SPECIfICATIONS

reliaBility Vibration...............................................................1G, 20-100 Hz Testing..................................................................100% Functionally Tested environMental Ambient Operating Temperature Range......-40 to +185F (-40 to +85C) Relative Humidity........up to 95% All Surface Finishes.........................Fungus proof and corrosion resistance RoHS Regulation...........................................................................Compliant inPut PoWer DC Supply...........................................12 or 24 20% VDC Battery Systems (Transient and Reverse Voltage Protected) Polarity......................................................Negative Ground (case isolated) Power Consumption......................................100 mA (No actuator current) Speed Signal Range..................................................................0.5 50 VAC Actuator Current Range @ 77F (25C)........................10 Amps continuous CoMPlianCe / standards Agency...........................................................................CE Requirements

PerforManCe Isochronous Operation................................................ 0.25 % or better Speed Range /Governor...........................................1K - 7.5K Hz Continuous Speed Drift with Temperature...................................0.5% Typical Idle Adjust CW...........Min. 1200 Hz. Below set speed Idle Adjust CCW.....Min. 4100 Hz. Below set speed Droop Range.....................................................................1 - 5% Regulation Droop Adj. Max. (K-L Jumpered).................875 Hz., 75 Hz. per 1.0 A change Droop Adj. Min. (K-L Jumpered)...................15 Hz., 6 Hz. per 1.0 A change Speed Trim Range...........................................................................200 Hz. Remote Variable Speed Range....................500 - 3.7 kHz. or any part thereof Terminal Sensitivity J..........................................-115 Hz., 15 Hz/Volt @ 5 K Impedance L........................................-735 Hz., 60 Hz/Volt @ 65 K Impedance N........................................-148 Hz., 10 Hz/Volt @ 1 M Impedance P.........................................................10 VDC Supply @ 20 ma Max. PhysiCal Dimensions.......................................................See DIAGRAM 1 Weight............1.2 lb. (0.545 kg) Mounting.........................Any Position, vertical preferred

This document is subject to change without notice. Caution: None of GAC products are flight certified controls including this item. 2 PTI1000 C

Das könnte Ihnen auch gefallen

- Manual Regulador de Velocidade Gac Esd 5111Dokument2 SeitenManual Regulador de Velocidade Gac Esd 5111Paulo Alves100% (2)

- Esd5111 enDokument4 SeitenEsd5111 enRicardo MonteroNoch keine Bewertungen

- Esd5111 enDokument4 SeitenEsd5111 enMahdi Dehghankar100% (1)

- VOLVO Speed Governor ESD 5500E Technical InformationDokument10 SeitenVOLVO Speed Governor ESD 5500E Technical Informationdaniel_ting_1Noch keine Bewertungen

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDokument7 SeitenEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNoch keine Bewertungen

- I Pues D 1000 Series Data SheetDokument3 SeitenI Pues D 1000 Series Data Sheetkhaled kamelNoch keine Bewertungen

- Gac Esd5500Dokument7 SeitenGac Esd5500christramNoch keine Bewertungen

- Manual Regulador de Velocidade Gac Esd 5111 PDFDokument2 SeitenManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- Speed Control GAC ESD5500Dokument8 SeitenSpeed Control GAC ESD5500Manuel Otero80% (5)

- Electronic Governor CatalogDokument26 SeitenElectronic Governor CatalogAung Mh100% (1)

- 2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFDokument13 Seiten2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFSamir KhanNoch keine Bewertungen

- ESD-5500E Series: Analogue Speed GovernorsDokument4 SeitenESD-5500E Series: Analogue Speed GovernorsVasil Stoianov100% (1)

- Ec5000 6-09 PDFDokument5 SeitenEc5000 6-09 PDFAnonymous M0OEZEKoGiNoch keine Bewertungen

- Ec5111 6-09 PDFDokument5 SeitenEc5111 6-09 PDFAnonymous M0OEZEKoGiNoch keine Bewertungen

- Esd-5200 DS en 03.2011 V1.0Dokument4 SeitenEsd-5200 DS en 03.2011 V1.0BryanLeonardoOspinoReinaNoch keine Bewertungen

- 454 GT Series: ID-PWM AC Low Voltage Variable Frequency DrivesDokument12 Seiten454 GT Series: ID-PWM AC Low Voltage Variable Frequency DrivesVicente Orbegoso RodriguezNoch keine Bewertungen

- Ngine Overning Ystems: Generator Frequency Sensing Speed Control UnitDokument6 SeitenNgine Overning Ystems: Generator Frequency Sensing Speed Control Unitjuan narvaezNoch keine Bewertungen

- Regulador Woodward 8290-184Dokument4 SeitenRegulador Woodward 8290-184kinosi100% (1)

- EC5000 Speed ControllerDokument2 SeitenEC5000 Speed ControllerBruno MarianoNoch keine Bewertungen

- What Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputDokument5 SeitenWhat Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputHerman SalimNoch keine Bewertungen

- Avr Newage mx321 PDFDokument4 SeitenAvr Newage mx321 PDFLiya MahagamaNoch keine Bewertungen

- Mx341 Avr Newage StamfordDokument4 SeitenMx341 Avr Newage Stamfordabuzer1981Noch keine Bewertungen

- Avr MX321Dokument3 SeitenAvr MX321Ahmad ArpaniNoch keine Bewertungen

- MX321 AVR SPECIFICATION AND ADJUSTMENTDokument4 SeitenMX321 AVR SPECIFICATION AND ADJUSTMENTderickteo5971100% (1)

- Sinpac Cap Start Run Switches CVR - SeriesDokument5 SeitenSinpac Cap Start Run Switches CVR - SeriesstoragebinNoch keine Bewertungen

- Manual Stamford Avr MX342 PDFDokument4 SeitenManual Stamford Avr MX342 PDFSeVictor Rudas CajaNoch keine Bewertungen

- ESD5100 Series Speed Control UnitDokument2 SeitenESD5100 Series Speed Control UnitJaimeCoelloNoch keine Bewertungen

- ISO 9001 CERTIFIED SPEED CONTROL UNIT DOCUMENTDokument2 SeitenISO 9001 CERTIFIED SPEED CONTROL UNIT DOCUMENTajcapetillog100% (2)

- Variador Yanwa AcerosDokument9 SeitenVariador Yanwa Acerosjuan Carlos GonzalezNoch keine Bewertungen

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDokument4 SeitenDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryNoch keine Bewertungen

- Diesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzDokument4 SeitenDiesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzSandro MunizNoch keine Bewertungen

- DG Application AMF / Synchroniser: Conzerv Systems PVT LTDDokument4 SeitenDG Application AMF / Synchroniser: Conzerv Systems PVT LTDjaikolangaraparambilNoch keine Bewertungen

- Sofcon India Pvt. LTD., Lucknow: Vocational Training IN Panel Designing ,& Variable Speed DrivesDokument22 SeitenSofcon India Pvt. LTD., Lucknow: Vocational Training IN Panel Designing ,& Variable Speed Drivesshailendra89Noch keine Bewertungen

- Torsepc 5001TCP Manual 09'29'2003Dokument18 SeitenTorsepc 5001TCP Manual 09'29'2003mahh1234100% (2)

- p11 Engspec Feca Te 106aDokument5 Seitenp11 Engspec Feca Te 106ayounesNoch keine Bewertungen

- Indigenously designed servo voltage stabilizer controllerDokument39 SeitenIndigenously designed servo voltage stabilizer controllershalu29Noch keine Bewertungen

- Vickers Servo ValveDokument28 SeitenVickers Servo ValveHitesh MehtaNoch keine Bewertungen

- Boston Gear Dcx202erp Ratiotrol PDFDokument31 SeitenBoston Gear Dcx202erp Ratiotrol PDFlalo100% (1)

- Rhino Motion Controls: RMCS-1102 v2.0 Micro-Stepping Motor Driver With ENABLE (Max. 50Vdc and 5A Per Phase)Dokument11 SeitenRhino Motion Controls: RMCS-1102 v2.0 Micro-Stepping Motor Driver With ENABLE (Max. 50Vdc and 5A Per Phase)sanjeev kumarNoch keine Bewertungen

- Ref. Spec. - MOV's.Dokument6 SeitenRef. Spec. - MOV's.Shiju Kp.Noch keine Bewertungen

- A1000Dokument8 SeitenA1000monikaNoch keine Bewertungen

- Installation and Maintenance Manual Type SSM Medium Voltage 200 - 7,500 HPDokument120 SeitenInstallation and Maintenance Manual Type SSM Medium Voltage 200 - 7,500 HPHans MortenNoch keine Bewertungen

- What Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputDokument5 SeitenWhat Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputpostNoch keine Bewertungen

- Dieselec Doosan DD-625 KVADokument4 SeitenDieselec Doosan DD-625 KVAJay Tolentino100% (1)

- 10 KvaDokument4 Seiten10 KvaLeonardusHSijabatNoch keine Bewertungen

- Woodward GovernorDokument4 SeitenWoodward GovernorAbhijit Manna100% (1)

- SIMOREG 6RA70 DC MASTER Electronics: Speed Control With CEMF FeedbackDokument15 SeitenSIMOREG 6RA70 DC MASTER Electronics: Speed Control With CEMF FeedbackMancamiaicuru100% (1)

- Sx440, STAMFORD ManualDokument4 SeitenSx440, STAMFORD ManualSarawut PipeNoch keine Bewertungen

- 150-SMC50 Arrancadores Estáticos PDFDokument58 Seiten150-SMC50 Arrancadores Estáticos PDFcamel2003Noch keine Bewertungen

- 2301 Speed ControlDokument4 Seiten2301 Speed ControlCarlos SantosNoch keine Bewertungen

- Hyper Ser DriveDokument10 SeitenHyper Ser DriveRommel100% (1)

- SPM Synchronous Motor ProtectionDokument8 SeitenSPM Synchronous Motor ProtectionImtiazAhmedNoch keine Bewertungen

- As480 Avr Newage StamfordDokument6 SeitenAs480 Avr Newage Stamfordabuzer1981Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- OptimDokument2 SeitenOptimRamon Thales DomeniconiNoch keine Bewertungen

- SMD Single Supply Dual Operational Amplifiers LM358 (KM358Dokument3 SeitenSMD Single Supply Dual Operational Amplifiers LM358 (KM358Ramon Thales DomeniconiNoch keine Bewertungen

- KA431-KA431A-KA431L Programmable Shunt RegulatorDokument12 SeitenKA431-KA431A-KA431L Programmable Shunt Regulatorhamada13Noch keine Bewertungen

- Kipor Diesel Gen Service ManualDokument44 SeitenKipor Diesel Gen Service ManualSteven J Baynes86% (28)

- GP Electronic Wiring DiagramDokument2 SeitenGP Electronic Wiring DiagramRamon Thales DomeniconiNoch keine Bewertungen

- ComAp Electronic Engines Support 04-2016 PDFDokument307 SeitenComAp Electronic Engines Support 04-2016 PDFzalag100% (1)

- Automatic Mains Failure Microprocessor Genset ControllerDokument4 SeitenAutomatic Mains Failure Microprocessor Genset ControllerRamon Thales DomeniconiNoch keine Bewertungen

- GP Mechanical Wiring DiagramDokument2 SeitenGP Mechanical Wiring DiagramRamon Thales Domeniconi100% (1)

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDokument4 SeitenGC315 RENTAL Gensets GC315: Perfect For Groups ofRamon Thales DomeniconiNoch keine Bewertungen

- Easy Gen 3000Dokument56 SeitenEasy Gen 3000Permata Dewa100% (3)

- 5dd6d-Intelilite NT 5 Models Leaflet 2013-11 Cpleilnt PDFDokument6 Seiten5dd6d-Intelilite NT 5 Models Leaflet 2013-11 Cpleilnt PDFRamon Thales DomeniconiNoch keine Bewertungen

- Specification, Controls and Accessories: MX341 Automatic Voltage Regulator (AVR)Dokument40 SeitenSpecification, Controls and Accessories: MX341 Automatic Voltage Regulator (AVR)Ahmed KotbNoch keine Bewertungen

- Application Note: OR ORDokument26 SeitenApplication Note: OR ORRamon Thales DomeniconiNoch keine Bewertungen

- Operator'S Manual: Generating Set and Industrial EnginesDokument86 SeitenOperator'S Manual: Generating Set and Industrial EnginesNasser Ayoub100% (1)

- Tcd2015 IndustrialDokument2 SeitenTcd2015 IndustrialRamon Thales DomeniconiNoch keine Bewertungen

- Dse7520 Installation InstDokument2 SeitenDse7520 Installation InstRamon Thales DomeniconiNoch keine Bewertungen

- Actuadores Woodward Serie LDokument133 SeitenActuadores Woodward Serie LPablo Oscar GrekNoch keine Bewertungen

- IGC700 Series: Ngine Overning YstemsDokument6 SeitenIGC700 Series: Ngine Overning YstemsRamon Thales DomeniconiNoch keine Bewertungen

- VAV CAV Documentation ADokument20 SeitenVAV CAV Documentation AHarish Menon100% (1)

- DND DC No 01 31JAN2013 - Performance Rating and Ranking SystemDokument6 SeitenDND DC No 01 31JAN2013 - Performance Rating and Ranking SystemAbdushaheed Ibn IbrahimNoch keine Bewertungen

- Understanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeDokument1 SeiteUnderstanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeAgus RiyadiNoch keine Bewertungen

- Metco®73F-NS-1 (-2) 10-058 PDFDokument7 SeitenMetco®73F-NS-1 (-2) 10-058 PDF張政雄Noch keine Bewertungen

- The Poem of The Man God Vol 2 by Maria ValtortaDokument8 SeitenThe Poem of The Man God Vol 2 by Maria ValtortaOtieno SteveNoch keine Bewertungen

- Haynes 230 Alloy: Principal FeaturesDokument28 SeitenHaynes 230 Alloy: Principal FeaturesMatheus DominguesNoch keine Bewertungen

- AlbafixwffDokument7 SeitenAlbafixwffjawadbasit0% (1)

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Dokument1 SeiteLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentNoch keine Bewertungen

- Historical Background of Technical WritingDokument10 SeitenHistorical Background of Technical WritingTrina Rose B. RoqueNoch keine Bewertungen

- A1 - QA.L.01 List of Instrument & Test Equipments-NEW 01Dokument1.129 SeitenA1 - QA.L.01 List of Instrument & Test Equipments-NEW 01JKP OperationNoch keine Bewertungen

- Arkaprava Bhattacharya Civil Engineering Portfolio: Email IDDokument9 SeitenArkaprava Bhattacharya Civil Engineering Portfolio: Email IDArkaprava BhattacharyaNoch keine Bewertungen

- CDU Basic Engineering Design BasisDokument12 SeitenCDU Basic Engineering Design BasisSampat100% (2)

- 3UG46161CR20 Datasheet enDokument4 Seiten3UG46161CR20 Datasheet enengmnfNoch keine Bewertungen

- Latihan HitunganDokument9 SeitenLatihan HitunganMuhamad FadilahNoch keine Bewertungen

- Microsoft Dynamics ERP By: Nora Al-MadiDokument15 SeitenMicrosoft Dynamics ERP By: Nora Al-Madivijay_sr2009Noch keine Bewertungen

- Theory Basics - 12 Chromatic Tones PDFDokument2 SeitenTheory Basics - 12 Chromatic Tones PDFPramod Govind SalunkheNoch keine Bewertungen

- Acidente GeradorDokument20 SeitenAcidente GeradorJefferson Leonardo CruzNoch keine Bewertungen

- Perkins 500P PDFDokument5 SeitenPerkins 500P PDFsaleemNoch keine Bewertungen

- My Media Kit AllDokument10 SeitenMy Media Kit Allapi-4725615Noch keine Bewertungen

- Doosan Retrofit ServiceDokument99 SeitenDoosan Retrofit Servicestopless_dalian685Noch keine Bewertungen

- ADJUST FUEL TIMINGDokument3 SeitenADJUST FUEL TIMINGSanjay MadakaNoch keine Bewertungen

- SiemensDokument9 SeitenSiemensGhassen Khalil100% (2)

- Asme Section II A-2 Sa-487 Sa-487mDokument8 SeitenAsme Section II A-2 Sa-487 Sa-487mAnonymous GhPzn1xNoch keine Bewertungen

- List of Classical Music Composers by Era - Wikipedia, The Free EncyclopediaDokument12 SeitenList of Classical Music Composers by Era - Wikipedia, The Free Encyclopediasercast99Noch keine Bewertungen

- Billing 2Dokument6 SeitenBilling 2Diamond Dc100% (6)

- Iso 13485 Medical Devices 2016 PDFDokument12 SeitenIso 13485 Medical Devices 2016 PDFDito PriyambodoNoch keine Bewertungen

- IPR-Trademark Case Laws - CompendiumDokument11 SeitenIPR-Trademark Case Laws - CompendiumShamilee RajkumarNoch keine Bewertungen

- Housing AffordabilityDokument13 SeitenHousing Affordabilityjeanette narioNoch keine Bewertungen

- Clerk Cum Data Entry Operator Recruitment 2018Dokument25 SeitenClerk Cum Data Entry Operator Recruitment 2018Pankaj VermaNoch keine Bewertungen

- Zroute Training Lab v1 0Dokument23 SeitenZroute Training Lab v1 0ChetanNoch keine Bewertungen