Beruflich Dokumente

Kultur Dokumente

Electrocomp

Hochgeladen von

Nikki BoghosianOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Electrocomp

Hochgeladen von

Nikki BoghosianCopyright:

Verfügbare Formate

7-15: Electrocomp LP production mix solutions.

Without additional constraints on production of A/C units and Fans, the following is the corner-point solution. First the following formulas are expressed graphically:

Cornerpoint Analysis

160 140 Number of Fans 120 100 80 60 40 20 0 0 20 40 60 80 100 Number of A/C's Wiring Constraint Drilling Constraint

The cornerpoint is then calculated by solving the equations simultaneously. ( )

The cornerpoints are then (0,0), (0,120), (40,60), and (70,0) and their respective profits are $0, $1800, $1900, and $1750.

(a), With the constraint that the company produce at least 20 A/Cs but not more than 80 fans, the solution would not be affected. Therefore the solution would be 40 A/Cs and 60 Fans. For this solution there would be no slack because it is the optimal solution. (b) With the constraint that the company produce at least 30 A/Cs but not more than 50 fans. Using the corner-point graph again, this constraint shrinks the feasible area to under 50 fans. The new corner-point is calculated using the following formula:

making the new corner points (30,0), (30,50), (45,50), and (70,0), and their respective profits of $750, $1500, $1875, and $1750, therefore the solution would be to produce 45 A/Cs and 50 Fans. The slack would calculated by inputting the data back into the constraints and arriving at 0 hours drilling, 5 hours of wiring, 10 fans, and a surplus of 5 A/Cs. -----------------------------------------------------------------------------------------------------------7-17: For the Outdoor Furniture Corporation with the given constraints the following is the formulas expresses mathematically and graphically:

Outdoor Furniture Company

400 350 300 Benches 250 200 150 100 50 0 0 50 100 150 200 250 Tables Redwood Constraint Labor Constraint

The corner-point is calculated as follows: ( )

The corner-points are therefore (0,0), (0,300), (25,262.5), and (100,0) with respective profits of $0, $2700, $2862.5, and $2000. Therefore the optimal number to produce is 25 Tables and 262.5 Benches. -----------------------------------------------------------------------------------------------------------7-20: Given the constraints of the investments given including $50,000 total average risk being an index of six the constraints can be expressed mathematically as follows:

Solving these two formulas simultaneously would yield ( )

Therefore $20,000 should be invested in petrochemical, $30,000 should be invested in utility, average risk is 6, and the total return on the investment would be $2400 plus $1800 for a total of $4200. 8-2:

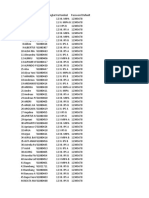

Variable Solution Revenue Constraints Total Funds Municipal Bonds Electronics/Aerospace, Drugs Nursing Home Stock X1 50000 0.053 X2 0 0.068 X3 0 0.049 X4 175000 0.084 X5 25000 0.118

20300 LHS 250000 0 75000 0 RHS 250000 0 0 0

1 0.8 -0.4 -0.5

1 -0.2 0.6

1 -0.2 0.6

1 -0.2 0.6

1 -0.2 -0.4 1

The optimal solution is 50,000 in LA Municipal Bonds, 175,000 in Palmer Drugs, and 25000 in nursing homes.

8-19: The solution to the problem from 8-18 is seen below using solver:

Variable Solution Revenue Constraints Max Beds Max Tests Max Xrays Max Operations X1 61.8181816 285 X2 28.1818184 303

26157.27273 LHS 90 38.60909094 19.00000006 5.63636368 RHS 90 56.6 19 7.67

1 0.3875 0.125 0

1 0.52 0.4 0.2

At the given state of our facilities the optimal use of our facilities can be achieved by adding 62 medical beds and 28 surgical beds. This configuration will generate an additional $26,154 or $9.54M per annum. There will be no empty beds with this configuration however the surgical facilities and test facilities will be under utilized with a surplus capacity of 16 and 2 procedures per day respectively. All other facilities are being used to the fullest extent. I recommend downsizing the labs and surgical staff to optimize revenue.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tektronix P6015a 1000x HV TastkopfDokument74 SeitenTektronix P6015a 1000x HV TastkopfMan CangkulNoch keine Bewertungen

- Semi-Automatic Digital Micro Vickers Hardness Testing Machine (Tester) DVS-1XYDokument8 SeitenSemi-Automatic Digital Micro Vickers Hardness Testing Machine (Tester) DVS-1XY周记伟Noch keine Bewertungen

- User Requirement SpecificationDokument16 SeitenUser Requirement Specificationgigichung1Noch keine Bewertungen

- Connectivity Pack Info System en USDokument226 SeitenConnectivity Pack Info System en USCatCesarNoch keine Bewertungen

- 5G Smart Port Whitepaper enDokument27 Seiten5G Smart Port Whitepaper enWan Zulkifli Wan Idris100% (1)

- Data Quality DMB Ok Dam A BrasilDokument46 SeitenData Quality DMB Ok Dam A BrasilforleviNoch keine Bewertungen

- JMO 2013 Solution Notes: Compiled by Evan ChenDokument8 SeitenJMO 2013 Solution Notes: Compiled by Evan ChenAtakgaNoch keine Bewertungen

- Uenr25330001Dokument8 SeitenUenr25330001William carlos Trujillo cruzNoch keine Bewertungen

- Math Mammoth - 1Dokument113 SeitenMath Mammoth - 1ramjd100% (2)

- Embedded SystemDokument75 SeitenEmbedded SystemDnyaneshwar KarhaleNoch keine Bewertungen

- Aadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryDokument4 SeitenAadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryShankar HirekarNoch keine Bewertungen

- Decision Support SystemDokument6 SeitenDecision Support SystemNaveenNoch keine Bewertungen

- Generic Classes and Methods: A Deeper Look: Java How To Program, 11/eDokument35 SeitenGeneric Classes and Methods: A Deeper Look: Java How To Program, 11/eWilburNoch keine Bewertungen

- StatisticaDokument22 SeitenStatisticaBrenden KramerNoch keine Bewertungen

- 12 PandasDokument21 Seiten12 PandasArshpreet SinghNoch keine Bewertungen

- Advanced SQL7Dokument2 SeitenAdvanced SQL7Denmark Cartagena AsoyNoch keine Bewertungen

- Cognizant 2021 Exam Pattern Round 1:: - Quants - Logical - Verbal - Automata Fix (Code Debugging)Dokument23 SeitenCognizant 2021 Exam Pattern Round 1:: - Quants - Logical - Verbal - Automata Fix (Code Debugging)Ojas DhoneNoch keine Bewertungen

- WF-R8590 R8591 R8593 RevFDokument332 SeitenWF-R8590 R8591 R8593 RevFNicu Muț100% (5)

- User Guide 1531 Clas - 3ag - 21608 - Ahaa - Rkzza - Ed01Dokument338 SeitenUser Guide 1531 Clas - 3ag - 21608 - Ahaa - Rkzza - Ed01iaomsuet100% (2)

- HF G2a Method FixedDokument10 SeitenHF G2a Method FixedHernan OjedaNoch keine Bewertungen

- How To Use Epals To Find A Collaborative Partner ClassroomDokument90 SeitenHow To Use Epals To Find A Collaborative Partner ClassroomRita OatesNoch keine Bewertungen

- SprutCAM 1Dokument150 SeitenSprutCAM 1Galletti DenisNoch keine Bewertungen

- Chapter 12Dokument34 SeitenChapter 12Thanh Van DaoNoch keine Bewertungen

- Assignment Cyber Law E.N 54Dokument6 SeitenAssignment Cyber Law E.N 54Tajamul IslamNoch keine Bewertungen

- TukacadDokument17 SeitenTukacadajay kalangiNoch keine Bewertungen

- Operating System VirtualizationDokument13 SeitenOperating System VirtualizationSachin JainNoch keine Bewertungen

- Romana T-3805-EDokument19 SeitenRomana T-3805-EjorgeNoch keine Bewertungen

- Akun SiswaDokument10 SeitenAkun Siswagame advenNoch keine Bewertungen

- Ran Week 17 2021Dokument5 SeitenRan Week 17 2021Joseph F ChikuseNoch keine Bewertungen

- D63983GC20 - 30 - US Oracle Hyperion Financial Reporting 11.1.2 For EssbaseDokument3 SeitenD63983GC20 - 30 - US Oracle Hyperion Financial Reporting 11.1.2 For EssbaseChinmaya MishraNoch keine Bewertungen