Beruflich Dokumente

Kultur Dokumente

Drawing Sheets

Hochgeladen von

Mona Diaa0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

187 Ansichten11 SeitenDrawings are produced on standard sized sheets, ranging from AO to A4. Drawings may be made in three ways: freehand sketching by hand with drafting equipment computer assisted using computer software to produce the drawing. Drawings are made to standard so that they: use the same symbols, lines, dimensioning techniques etc. Can be understood in different places, that is interstate or internationally. There are several drawing standards available both nationally and internationally.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDrawings are produced on standard sized sheets, ranging from AO to A4. Drawings may be made in three ways: freehand sketching by hand with drafting equipment computer assisted using computer software to produce the drawing. Drawings are made to standard so that they: use the same symbols, lines, dimensioning techniques etc. Can be understood in different places, that is interstate or internationally. There are several drawing standards available both nationally and internationally.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

187 Ansichten11 SeitenDrawing Sheets

Hochgeladen von

Mona DiaaDrawings are produced on standard sized sheets, ranging from AO to A4. Drawings may be made in three ways: freehand sketching by hand with drafting equipment computer assisted using computer software to produce the drawing. Drawings are made to standard so that they: use the same symbols, lines, dimensioning techniques etc. Can be understood in different places, that is interstate or internationally. There are several drawing standards available both nationally and internationally.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

Producing drawings

Drawings are produced on standard sized sheets, ranging from AO to A4.

Drawings may be made in three ways:

freehand sketching

by hand with drafting equipment

computer assisted using computer software to produce the drawing (computer

aided drafting - CAD)

Copying or !reproducing drawings

Depending olmsize, drawings may be reproduced by:

phowcopYing

dye:lii:Ie reproduction

cOlmrputer plotting

inkjpt printing

Ask the to show you some samples

Drawing s-tandards

Engineering dl1'awings and other technical drawings have to be done in ways that all

engineers can; recognise. These ways are called standards or conventions.

Drawings are made to standard so that they:

use the same symbols, lines, dimensioning techniques etc.

can be understood in different places, that is interstate or internationally.

Australian Standards are usually shortened to AS. The drawings in this module are on

standard sized sheets as stated in AS1100.

There are several drawing standards available both nationally and internationally. For

this module all: our drawings should follow the rules of:

Australian Standard 1100 - Technical Drawing - Part 101 - General Principles

Aus,tralian Standard 1102 - Graphic Symbols for Electrotechnology. (Parts 1 -

15 as appropriate.)

:MEC076 Engineering Drawing Interpretation 1

Resource Package ", ii J

December, 1995-

6

Standard Drawing Sheets

Size

There are five sizes ranging from AO, the largest, to A4, the smallest. As you go from

size AO to size A4, each sheet is half the previous sheet. See the figure shown below.

420mm

A3

210mm

E

A4

E

t'-

Cl)

N

AD is 841 x 1198

A1

AO

841mm

841mm

E

E

t'-

Cl)

N

A4

E

E

Cl)

tn

420mm

E

A2

E

Cl)

tn

MEC076 - 1 - 1 I

Border

The suggested border is proportional in size to the size of the sheet. In the drawing

below the borders on an AO sheet are larger than the borders on an A 1 sheet, and so on

down to A4

5

7

A4

I

~ (200)

A3t

10

(283)

7 (283)

A2

14

~ ( 4 ~ 0 )

A1

(400)

10

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1995-

14

!

7

20

28

-10

(566)

(566)

14

10

(801)

14

(1133)

Preferred Series sheets

k " iI 'II

7

20

AD

(801

20

28

20

MEC076 - 1 - 2 I

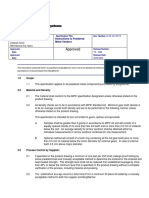

Title block Information

The title block identifies a

range of data relating to

the drawing;. It includes the

name of the;company, the

name of what is drawn, the

drawing sheet: number for

storage and; r.eference

purposes, who drew the

drawing, who)checked the

drawing, andi0ther

important inwrmation

regarding thfi;drawing,

along with a1 fJistory of any

changes that:. have been

made since tlire drawing

was originally,rdrawn.

Each companD' has its own

title block.

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1995-

C

A

f-

B

l-

C

l-

D

ISSUE

1 I 2

DATE ZONE CHANGE BY CKD

AMENDMENTS

1 I ? I

3 4 5 I 6

DO NOT SCALE

ALL DIMENSIONS IN MILLIMETRES

A

f-

SAMPLE OF A STANDARD

SHEET LAYOUT

B

WITH A BLANK TITLE BLOCK

THE LAYOUT VARIES FROM

ORGANISATION TO ORGANISATION

t>

f-

C

f-

UNLESS NOTED OTHER'MSE

~ - - E I -

DRAWN

D

TOLERANCES ARE: TRACED

MATERiAl CHECKED

LINEAR

AffROVED TITLE

ISSUED

ANGULAR

RECORD OF ISSUE

DRAWlNG PRACTICE

FINISH

'" I

I I I

I SIZE I DRG N' I SHT

AS 1100 I I I I

SCALE

::\ 4 ~ 6

V

1 MEC076 - 1 - 31

8

Parts of a title block

The next few pages will explain what information is conveyed by each part of a title block.

The name of the company

Each company designs its own title block and has quantities of each size of drawing sheets

printed.

TAFE ENGINEERING PTY LTD

The above designation has been used as an example to identify drawings used in TAFE, and will

be seen on all the examples shown.

UNLESS N01E.D

E3-

D!<AWN

TOLERANCES ME: 1MCED

MAm",L CHECKED

UNEAR

A"""DYED TITLE

DRAWING PRACTICE

FINISH

SCALE

AS 1100 I I

3 4

Title

This is a description of what is drawn on the sheet

Below are two examples

UNLESS NOTED OTHERWISE

TOLERANCES ME:

UNEAR

ANGU!.AR

DRAWING PRACTICE

A51100

3

UNLESS NOTED OTHERWISE

TOLERANCES ARE:

ANGUlAR

-cG

MATERIAL

FINISH

D<AWN

1MCED

CHEmD

_DYED

TITLE

I

" I

SCALE

I I

4

TITLE

SCALE

MEC076 Engineering Drawing Interpretation I

Resource Package

December, 199/f

TAFE ENGINEERING PTY LTD

10

EXHAUST DUeTING ASSEMBLY

I S1;E

DRGN'

I

324

5 6

TAFE ENGINEERING PTY LTD 10

EXHAUST DUCT

DUeTING DETAILS

I S1;E

DRGW

I

324

5 6

TAFE ENGINEERING PTY LTD

h ., .. iI 'II

9

Size, Scale and Drawing Number

The drawing number or sheet number may be abbreviated to DRWG N. or DWG Nand SHT N.

TAFE ENGINEERING PTY LTD

TITLE

EXHAUST DUCT

DUeTING DETAILS

SCALE iSIZE IDRWG N".

A31 324

/

Sheet Number. (SHT). Optional. Every sheet

in a set of drawings for a particular device or

assembly is numbered.

Drawing Number. (DRWG No. or DRG No.). This number

is a number given by the company to a particular drawing

or set of drawings for something to be constructed.

Where sheet numbers are not used drawing numbers are

usually in sequence, for example 1010, 1011, 1012, etc.

'------ Size. This is the size of the original sheet that

the drawing was drawn on. It is not necessarily

the size of the sheet you are looking at because

you may be looking at a coPy that has been

reduced or expanded.

Scale. Not all components or constructions are drawn full size. ego The plans

for a house are not drawn full size for obvious reasons. Hence, large objects are

drawn to reduced scale such as \1, full size (1:2), 1110 full size, (1:10) full size (1:1)

etc.

The scale box for full sized drawings are usually marked 1:1 or full size. A half size

drawing would be marked 1:2, a 1/10 full size 1:10 and so on.

On the other hand, very small components are drawn larger than full size. ego

Twice full size would be marked as 2:1, five times full size would be marked 5:1 and

so on.

Students should now attempt

questions 1 to 4 Exercise 1-1 page 14

I MEC076 - 1 - 4 I

The next section provides reference material which you may need to refer back to while

completing the module.

Drawn, Traced, Checked, Approved, Issued and Record of Issue

(Refer to sample sheet on page 16)

Drawn (Zone D4)

The draftsperson places either their name or initials in this box.

Traced (Zone D4)

The tracer who made the ink tracing places either their name or initials in this box. Tracing

has now virtually been replaced by CAD.

Checked (Zone D4)

The person who checks the drawing for accuracy, errors, correct quantities, spelling, safety

considerations etc. places their name or initials in this box.

Approved (Zone D4)

The chief design engineer is often the one who goes over the drawings for another opinion and

safeguard. They then sign or initial this box.

Issued (Zone D4)

This is the date when, after thorough checking, the drawings are issued to the workshop or

subcontractors and construction started or tenders called for.

Record of issue (optional) (Zone D4)

On the sample sheet there are ten small squares for this function. The first issue is A. If any

changes or modifications are carried out, this is noted in the amendments box as a later

issue B, C, D etc.

The drawings then have to be reissued with the amendment shown as issue B. All issue 'A'

drawings, must be destroyed. Any previous 'A' issue drawings that are now incorrect and do

not get destroyed could cause catastrophic problems in production.

From this it becomes very obvious that it is critical that before making anything, it must be

ensured that,the drawings being used are the latest issues. Old drawings that have been on

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1995-

10

the bench, under the bench or in drawers for months or years pose a real threat to industry.

All this can be overcome by a simple phone call to the drawing office in most cases. Otherwise

if any doubt exists a check should be made with your immediate supervisor.

Projection symbols

First angle projection

Third angle projection

{@--f----}

{----}-@

The two symbols shown above represent two methods of placing views on a drawing. Even

though Third angle is the preferred or standard for engineering drawings in Australia, some

industries still use first angle. It is imperative that both systems are understood so that

costly and embarrassing errors are not made. On some drawings, even an experienced

draftsperson has to look carefully to determine which system has been used. A comparison

between first angle and third angle is demonstrated in the next sheet using pictures of a car.

Material (Zone D4)

This box is for listing the types of material that the object is made from. This can not always

be used because there are often a number of objects made from different materials drawn on

the one sheet. In this case the type of material will have to be noted under each object.

Finish (Zone D4)

The designer of any object must determine how smooth each surface has to be. Most things

need to have a range of different surface finishes on them. If the object is basically the same

all over the surface finish is placed in the box followed by the letters UNO. (unless noted

otherwise)

Students should attem t uestions 5, 6, 7 and 8 in Exercise 1-1 age 14

I MEC076 - 1 - 5 I

Drawn below is a practical example of first angle projection. Note that the respective view is

projected to the opposite side that you are looking at.

First angle rojection

Projection symbol

Right end view C

(Back of car)

MEC076 Engineering Drawing Interpretation 1

Resource Packa$e

December, 1996

I I

I

L::::.=.

~ c D

\II

DSZ

I

Bottom view E

(Underneath of car)

-f

D

I

,

E

Front view A

(Side of car)

Top view D

(Top of car)

--c

-==;--A

Left end view B

(Front of car)

h " iI ill

11

Drawn below is a practical example of third angle projection. Note that the respective view is

projected to the same side that you are looking at (mirror image).

Third angle rojection

Projection symbol

Left end view B

(Front of car)

---A

B--

r---:/

'------\

/ I

I

L::::.=.

~ ' D ~

\1

1

[5 I

Top view D

(Top of car)

D

~

t

E

Front view A

(Side of car)

q

Bottom view E

(Underneath of car)

A ~

---C

Note: All drawings in this book will be using third angle projection.

Right end view C

(Back of car)

I MEC076 - 1 - 6 I

(Refer again to Drawing No. 5210 - 1A Sheet 2 of 4 on page 16)

All dimensions in millimetres (Zone A3, A4)

This notation saves the draftsperson from having to write 'mm' after each dimension that is

placed on a drawing.

Tolerance (Zone D3)

Tolerance is the amount of variation permitted in the size of a component.

Drawing practice (Zone D1, D2)

This box denotes the standard to which the drawing is drawn.

Amendments (Zone D1, D2)

ALL DIMENSIONS IN MILLIMETRES

TOLERANCE

LINEAR

ANGULAR

DRAWING PRACTICE

AS 1100

This is a critical area on the draWing. Quite often pieces of equipment or components are

modified for a wide range of reasons. When a modification is made and the modified drawing is

distributed, it means that there is the possibility that the previous drawing/s are still sitting

around somewhere. Unless all earlier copies are recovered and destroyed, there is the

possibility that future work could be carried out using the wrong drawing/so

Note: It is critical when working to any drawing, that it is verified that the drawing is the

latest issue before commencing work. Always be careful about working from

draWings that look as though they have been around for a considerable time. they

may be out of date.

Issues may be recorded using the alphabet; A, B, C, D .... or numerically; 1, 2, 3,4 .....

The date the change has been made is noted.

The next column is deSignated 'zone'. Zone is where to find the change on the drawing. It is

similar to a street directory in that there are letters A, B, C, D down the page and the

numbers 1, 2, 3,4 ..... across the page. This allows the draftsperson to indicate where to look

MEC076 Engineering Drawing Interpretation 1

Resource Package-

December, 1995-

k " iI J

12

on the sheet to find the change that has been made. If directly under a number and beside a

letter it would be noted for example B4. If between numbers it may appear as B4 or B5 and

you would need to look for it. Some companies identify changes by showing the issue in a

triangle near to the change. See Zone B3.

Change is where the description of the change in the drawing is placed. It gives a record of

what it was originally.

There are a number of columns that will vary from company to company, depending on what

they want to record, however, the initials of the draftsperson who drew the change/s and the

initials of who checked the change/s is standard procedure.

ECN = Engineering change notice. This is a form issued by some companies to drafters

instructing them to carry out the change.

ISSUE DATE ZONE CHANGE ECN BY CKD

AMENDMENTS

Parts list or materials list (See page 20 for an example Zone D5 and D6)

This box of information is a summary of every component that goes to make up whatever is

drawn. Where there are many drawings that make up the full set for a particular

construction, there is usually a column that contains the drawing number for each component

or components on that sheet.

Look at the drawing on the next page for a summary of what has been covered so far.

Students should now com lete exercise 1-1 on age 14 and 15

MEC076 - 1 - 7 I

1 I 2 I 3 4 I 5 I

ALL DIMENSIONS ARE IN MILLIMETRES

DO NOT SCALE

MAIN FEATURES OF A DRAWING SHEET

1

A

1. Border

2. Zones

I--

3. Amendments Chart

4. Title Block

B

5. Projection Symbol

6. Material

~

7. Finish

8. Drawing Standards Number

9. Tolerances

c 10. Parts List

I-

2

...

D

ISSUE DATE ZONE

1

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1995-

\

\

\

\

\

\

3

/

/

/

/

..

\ CHANGE

\ AMENDMENTS

I ?

to highlight the drawing area.

for finding a location on the drawing - similar to a street

directory - for example Dl

this shows any changes made to a drawing. It is important for

a tradesperson to have the latest drawing to work from.

for identifying the drawing and filing it. It also contains other

useful information.

to show the method of orthographic projection used.

to specify the type of material used, ego aluminium.

the quality or type offinish required.

the particular standard the drawing conforms to.

the allowable size range acceptable for the parts.

list and description of the parts shown on the drawing.

5

ITEM No DESCRIPTION MATERIAL

PARTS LIST

UNLESS NOTED OTHERWISE

~ - 8

DRAWN

TOLERANCES ARE: TRACED

CHECKED

G)

MATERIAL

LINEAR

@

APPROVED TITLE

ISSUED

ANGULAR

RECORD OF ISSUE

BY CKD

DRAWING PRACTICE (8 '

FINISH

(7)

A, I I I I I SIZE I DRG N

SCALE

AS 1100 U I I I I

I ~ 4 I

"

I

V

", iI if!

13

6

A

f-

B

10

I- ~

c

f-

No. REQUIRED

D

G)

I SHT

R

I MEC076 - 1 - 8 I

Student Exercises 1 - 1

Referring to the drawing No. 5210 - 1A sheet 2 of 4, (page 16) answer the following

questions.

1. How many drawing sheets make up the full set for the hydraulic punch?

2. What company owns this set of drawings?

3. To what" scale is each component drawn to?

4. What siire sheet was the original drawing drawn on?

-----------------------------------------------------------

5. When wet1e the drawings first issued?

6. Where do)you find out what material each component is made from?

7. In the fii:1ish box are the letters UNO. What do the letters stand for and what do

they mean?

MEC076 Engineering Drawing Interpretation 1

Resource PackaEe

December, 1998"

14

8. The punching diameter'C' of the punch can be made to different diameters.

Referring to the chart, how many different diameters can be ordered?

9. What is the tolerance on all linear dimensions?

10. What material is the cup seal made from?

11. What is the date of the last issue of the drawing?

12. The material for the cup seal has been changed since the original issue of the

drawings. What material was it originally made from?

13. What component is named at zone B5?

14. What Australian Standard has the drawing been drawn to?

15. Is the drawing drawn to first angle projection or third angle projection?

I MEC076 - 1 - 9 I

16. Can you tell if the drawing is first or third angle projection from the information in

the Title Block (yes/no)

17. How many of each of these components is required when assembling the finished

hydraulic punch?

18. What angular tolerance applies to angles on the components?

19. What are the initials of the person who approves the original drawings?

20. What are the initials of the person who checked the latest amendments?

21. How are the ends of the sleeve spring and punch spring to be finished off in

manufacture?

22. What drawing number is shown in zone D6?

23. What angle of projection does this symbol represent?

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 199&

@)------}

24. What units are all the dimensions in?

25. What is the drawing title?

h I, iii '"

I MEC076 - 1 - 10 I

15

MEC076 - 1 - 11

Page 16

1

1

2 3 4 5

1

6

ALL DIMENSIONS IN MILLIMETRES

DO NOT SCALE

50

I" 140 1

,,,.

0.

4 HOLES EQUISPACED

25 110 FREE LENGTH

ON.0 30 P.C.D.

--A- -

--n-

-45

DRill RI5 x 20 DEEP

;p

I 5 U'CUT TO.077

TAP M6 xl x 15

A r-'

r

1.1

2x45'-

"-

A

R3--.,. 651D - - -- -

./ ""-

L

.075.0e

r .0 35

C B

/ \

.065

( I \

- --'--r,t-:- -- .0!iO -

. - -- .065

-

\ I / I

-

LMQ

/

'"

V

R6

-

KG-

!10/

16

Allover

DRIll.031 THRU

UNO

TAP RP1I25

"""'1:2'

0

nO

SLEEVE SPRING

I .080.00

27

0

CD PISTON

.079.95

MATl - SPRING STEEL CUP SEAL

SCREWCUT

TWO FUll TURNS CLOCKWISE

MATl - MOULDED

M80x2-

B BOTH ENDS SQUARED & GROUND MATl - M.S.

o CYLINDER HEAD

B

REQD -1 OFF REQD -1 OFF REQD-lOFF

MATl -C.I.

REQD -1 OFF

- -

4 HOLES EQUISPACED

ON.030 P.C.D. 45

PART 0C

TOL

DRlll.06.5 THRU I FREE lENGTH' I NUMBER NOM

C'SINK.012 x 90 INC

rfA- \7r -r -

-0.01

50 30 5

P521012 12

-0.02

-I- r I ,;\

-0.01

2911)- I \Y, -

P521014 14

-0.02 .028.5,

-.022

- -

L -(d.- P521016 16

:8:8k

F

/r'-

.03J.99 C

' '\ -

C

-

.04

P521018 18

r---i--- ---

"'<--

- -

P521020 20

:8Bb

@

30

45

Rl

\..1 x45

PUNCH SPRING

P521022 22 lYP

JL

.054.5 MATl - SPRING 5TEEL

@

I-- PUNCH

I--

3.5 FULL TURNS ANTICLOCKWISE

@

BOTH ENDS SQUARED & GROUND MATl - DIE STEEL HEAT TREATED TO BS 1407

PACKING PLATE REQD -1 OFF REQD -1 OFF

MATl- M.S.

REQD -1 OFF

D

UNLESS NOTED OTHERWISE

-@--E3-

DRAWN Wl

..m.J

MANUFACTURING AND ENGINEERING

D

TOLERANCES ARE:

TRACED SK EDUCATIONAL SERVICES DIVISION

MATERIAL

CHECKED

,ID

TITLE

LINEAR 0,25

APPROVED AP, COMPONENTS

B 18 -12 - 97 B3 CUP SEAL WAS lEATHER 36975 TAG DS AS LISTED

ISSUED 1;:> -1;:> - 87

HYDRAULIC PUNCH

A 12 -12 - 97 ISSUED FOR PRODUCTION DS TAG

ANGULAR 015'

RECORD OF ISSUE

ISSUE DATE ZONE CHANGE ECN BY CKD DRAWING PRACTICE

FINISH

X B I I SCALE SIZE I DRG N" SHT

AMENDMENTS AS 1100

I I

1: Z A3

5210 -1A

ZOF4

1

1

2 3 4 5

1

6

Das könnte Ihnen auch gefallen

- Mod 7 Book 7 Engineering DrawingDokument48 SeitenMod 7 Book 7 Engineering Drawingranjit prasadNoch keine Bewertungen

- Drawing StandardsDokument12 SeitenDrawing StandardsAgung Bayu100% (1)

- Understanding Y14 5 Dimension Ing and TolerancingDokument114 SeitenUnderstanding Y14 5 Dimension Ing and Tolerancingfunnyface9Noch keine Bewertungen

- Engineering Drawings Lecture Detail Drawings-Book44Dokument28 SeitenEngineering Drawings Lecture Detail Drawings-Book44mlkz_01100% (1)

- Topic 2 - Formats & Title BlockDokument21 SeitenTopic 2 - Formats & Title BlockAmir DanialNoch keine Bewertungen

- TOPIC 4.1 - Blueprint InterpretationDokument43 SeitenTOPIC 4.1 - Blueprint InterpretationgepigavinceNoch keine Bewertungen

- Engineering Drawings - GD&TDokument45 SeitenEngineering Drawings - GD&TMichael Wood100% (1)

- MACHIENDRAWINGUnit 1Dokument18 SeitenMACHIENDRAWINGUnit 1Pusker BeralNoch keine Bewertungen

- Unit 1 Industrial DrawingsDokument30 SeitenUnit 1 Industrial DrawingskhalimnNoch keine Bewertungen

- Detail DrawingDokument28 SeitenDetail DrawingRoan SantibañezNoch keine Bewertungen

- Blueprint Reading and SketchingDokument185 SeitenBlueprint Reading and SketchingFélix DésourdyNoch keine Bewertungen

- MHTN Architects Cad and Drafting GuidelinesDokument40 SeitenMHTN Architects Cad and Drafting GuidelinesMiguel PerdomoNoch keine Bewertungen

- US Navy Course - Blueprint Reading and Sketching NAVEDTRA 14040Dokument185 SeitenUS Navy Course - Blueprint Reading and Sketching NAVEDTRA 14040peterpaulwNoch keine Bewertungen

- Professional English in Use Engineering-10-13 PDFDokument4 SeitenProfessional English in Use Engineering-10-13 PDFNino IvanidzeNoch keine Bewertungen

- Assignment: 1 General InformationDokument9 SeitenAssignment: 1 General InformationCiro CordeiroNoch keine Bewertungen

- IC Workshop Materials 09 - Construction Drawing PracticesDokument43 SeitenIC Workshop Materials 09 - Construction Drawing PracticesooiNoch keine Bewertungen

- DrawstandDokument7 SeitenDrawstandMacedo S OliveiraNoch keine Bewertungen

- Drawing Sheet Sizes: Lecture Note On Perform Advanced Engineering Detail Drafting by Using CADDokument28 SeitenDrawing Sheet Sizes: Lecture Note On Perform Advanced Engineering Detail Drafting by Using CADMelku AbebeNoch keine Bewertungen

- MEC1000 Technical Drawing GuideDokument39 SeitenMEC1000 Technical Drawing GuideRicardo Rincon VegaNoch keine Bewertungen

- Engineering Drawings Practice PDFDokument27 SeitenEngineering Drawings Practice PDFSuriyakumar SundaramNoch keine Bewertungen

- ENGINEERING Drawing Fundamentals: An Introduction to Technical Drawing SkillsDokument29 SeitenENGINEERING Drawing Fundamentals: An Introduction to Technical Drawing Skillsnotonectal100% (2)

- CAD StandardsDokument26 SeitenCAD StandardsruayoNoch keine Bewertungen

- An Introduction to Pro/SHEETMETAL: A Project Based ApproachDokument47 SeitenAn Introduction to Pro/SHEETMETAL: A Project Based ApproachMirek BlaszkoNoch keine Bewertungen

- Fundamentals of Engineering Drawing BasicsDokument31 SeitenFundamentals of Engineering Drawing Basicsengidadereje100% (1)

- Introduction To Technical DrawingDokument3 SeitenIntroduction To Technical Drawingcadhub4uNoch keine Bewertungen

- STUCTURALDokument22 SeitenSTUCTURALAubrey Lynn BarreraNoch keine Bewertungen

- Engineering Graphics Tutorial Provides Insights Into Technical DrawingsDokument8 SeitenEngineering Graphics Tutorial Provides Insights Into Technical Drawingsmahdzia0% (1)

- CE 101 2016 1 Lab Exercise 5Dokument4 SeitenCE 101 2016 1 Lab Exercise 5Halil Ibrahim HiçyılmazNoch keine Bewertungen

- Technical Drawing GuideDokument37 SeitenTechnical Drawing GuidehamidhardNoch keine Bewertungen

- BS8888 DraftingDokument35 SeitenBS8888 DraftingJonathan Lynch100% (3)

- Layout and Standards for Engineering DrawingsDokument6 SeitenLayout and Standards for Engineering DrawingsgembulflowNoch keine Bewertungen

- BASE EN GaDokument95 SeitenBASE EN Ganitin400100% (2)

- Blueprint Reading & SketchingDokument177 SeitenBlueprint Reading & SketchingGary J. Davis, P. E.Noch keine Bewertungen

- Mini ProjectDokument58 SeitenMini ProjectHemantNoch keine Bewertungen

- CycloneDokument22 SeitenCyclonenaser hasan fauziNoch keine Bewertungen

- Cad Standard ManualDokument23 SeitenCad Standard ManualNoly TicsayNoch keine Bewertungen

- SMEA1304Dokument164 SeitenSMEA1304y2k405 kaosNoch keine Bewertungen

- Structural Drawings Housing: BuildingDokument21 SeitenStructural Drawings Housing: Buildingatac101Noch keine Bewertungen

- CAD Drawing FundamentalsDokument21 SeitenCAD Drawing FundamentalsSyed HassanYousafNoch keine Bewertungen

- Cambridge Engineering - U4 - DesignDokument8 SeitenCambridge Engineering - U4 - DesignLucas MonteNoch keine Bewertungen

- Chapter One Fundamentals of Machine Drawing Drawing Sheet SizesDokument28 SeitenChapter One Fundamentals of Machine Drawing Drawing Sheet SizesGùrmë GùrmëNoch keine Bewertungen

- File ManagementDokument5 SeitenFile ManagementBren Chavez EnadNoch keine Bewertungen

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkVon EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkBewertung: 3 von 5 Sternen3/5 (1)

- Notes on Mechanical Drawing - Prepared for the Use of Students in Mechanical, Electrical and Chemical EngineeringVon EverandNotes on Mechanical Drawing - Prepared for the Use of Students in Mechanical, Electrical and Chemical EngineeringNoch keine Bewertungen

- A Classification System to Describe Workpieces: DefinitionsVon EverandA Classification System to Describe Workpieces: DefinitionsW. R. MacconnellNoch keine Bewertungen

- How to Make Patent Drawings - A Brief Treatise on Patent Drafting for the Use of Students, Draftsmen and InventorsVon EverandHow to Make Patent Drawings - A Brief Treatise on Patent Drafting for the Use of Students, Draftsmen and InventorsNoch keine Bewertungen

- Complete PCB Design Using OrCAD Capture and PCB EditorVon EverandComplete PCB Design Using OrCAD Capture and PCB EditorBewertung: 5 von 5 Sternen5/5 (1)

- Manual of Engineering Drawing: British and International StandardsVon EverandManual of Engineering Drawing: British and International StandardsBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Von EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Noch keine Bewertungen

- Certified Solidworks Professional Advanced Weldments Exam PreparationVon EverandCertified Solidworks Professional Advanced Weldments Exam PreparationBewertung: 5 von 5 Sternen5/5 (1)

- Advanced AutoCAD® 2022 Exercise Workbook: For Windows®Von EverandAdvanced AutoCAD® 2022 Exercise Workbook: For Windows®Noch keine Bewertungen

- Purchasing Audit ProgrammeDokument12 SeitenPurchasing Audit ProgrammemercymabNoch keine Bewertungen

- Hospital Design and Infrastructure 2012Dokument8 SeitenHospital Design and Infrastructure 2012milham09Noch keine Bewertungen

- Curriculum Vitae New 2017 MD Sajid AlamDokument6 SeitenCurriculum Vitae New 2017 MD Sajid AlamAlam MD SazidNoch keine Bewertungen

- LINCOLN Lubrication Centro - MaticDokument53 SeitenLINCOLN Lubrication Centro - Maticrmartinf2527Noch keine Bewertungen

- November 2016Dokument20 SeitenNovember 2016Deepak JainNoch keine Bewertungen

- Thesis - PHD - 2014 - Grid Connected Doubly Fed Induction Generator Based Wind Turbine Under LVRTDokument198 SeitenThesis - PHD - 2014 - Grid Connected Doubly Fed Induction Generator Based Wind Turbine Under LVRTjose-consuelo100% (1)

- Carrying Channel (1 1/2" X 0.6mm X 5m)Dokument1 SeiteCarrying Channel (1 1/2" X 0.6mm X 5m)Carl LeonardoNoch keine Bewertungen

- Constructibility Issues For Highway ProjectsDokument9 SeitenConstructibility Issues For Highway ProjectsNouran M. RadwanNoch keine Bewertungen

- NO Nama Produk AKL Produk Code Size Principal Keterangan QTY Harga Harga + PPN 10% Lumbal SystemDokument2 SeitenNO Nama Produk AKL Produk Code Size Principal Keterangan QTY Harga Harga + PPN 10% Lumbal SystemIndraSuryadibrataNoch keine Bewertungen

- Business Challenges: Case StudyDokument4 SeitenBusiness Challenges: Case StudySanjay ThakkarNoch keine Bewertungen

- Googleplex, Mountain View: Designing Interior Spaces at An Urban Scale - Untapped CitiesDokument11 SeitenGoogleplex, Mountain View: Designing Interior Spaces at An Urban Scale - Untapped CitiesDiogo Machado100% (1)

- StructuralSupportCat CA 105701Dokument156 SeitenStructuralSupportCat CA 105701mansour14100% (1)

- Company Profile Prima VistaDokument10 SeitenCompany Profile Prima VistaInche Helmi Dori DoriNoch keine Bewertungen

- Materials Engineering SpecificationDokument2 SeitenMaterials Engineering SpecificationRonald AraujoNoch keine Bewertungen

- How Toyota Achieved Success Through Its Unique Management PhilosophyDokument66 SeitenHow Toyota Achieved Success Through Its Unique Management PhilosophyKakon AnmonaNoch keine Bewertungen

- Metro RailDokument59 SeitenMetro Railகீர்த்திவாசன் தமிழன்50% (2)

- JIT FullDokument6 SeitenJIT FullSuguna SubramaniamNoch keine Bewertungen

- Into The Abyss by Carol Shaben (Excerpt)Dokument35 SeitenInto The Abyss by Carol Shaben (Excerpt)Random House of Canada100% (1)

- 04 Training Proposal TemplateDokument41 Seiten04 Training Proposal TemplateMohd Syahidie60% (5)

- 12 - ToyotaDokument87 Seiten12 - Toyotawaddah100% (2)

- Grinding Aid Performance Analysis for Three Cement MillsDokument1 SeiteGrinding Aid Performance Analysis for Three Cement Millsanurag soniNoch keine Bewertungen

- Master Planning Process Diagram - Google SearchDokument3 SeitenMaster Planning Process Diagram - Google SearchKevin RotichNoch keine Bewertungen

- Application Erc Case No. 2012-013 RC Iselco IIDokument78 SeitenApplication Erc Case No. 2012-013 RC Iselco IIKathlene Lacosta LastimosaNoch keine Bewertungen

- Man Co4 Lo1 AssessmentDokument3 SeitenMan Co4 Lo1 AssessmentHarshwardhan KhardeNoch keine Bewertungen

- 11188-04 InstructivoDokument20 Seiten11188-04 InstructivoLuis AlonsoNoch keine Bewertungen

- Potential Causes of Gearbox Noise and Solutions to Reduce Noise LevelsDokument3 SeitenPotential Causes of Gearbox Noise and Solutions to Reduce Noise LevelsKumar SanthanamNoch keine Bewertungen

- Abdul Rauf - Mechanical Engineer-Production ManagerDokument3 SeitenAbdul Rauf - Mechanical Engineer-Production ManagercdeekyNoch keine Bewertungen

- Vision, Mission and SWOT of Tata NanoDokument5 SeitenVision, Mission and SWOT of Tata NanoSaprem KulkarniNoch keine Bewertungen

- Previews NSF 51 12 PreDokument11 SeitenPreviews NSF 51 12 PreEl_Proesor0% (1)

- Project Completion, Handover and Operations GuideDokument11 SeitenProject Completion, Handover and Operations GuideJustine Sheinna SebleroNoch keine Bewertungen