Beruflich Dokumente

Kultur Dokumente

CI221 Finite Element Notes

Hochgeladen von

Sholpan SholpsOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CI221 Finite Element Notes

Hochgeladen von

Sholpan SholpsCopyright:

Verfügbare Formate

CI 221 Computational Methods

Introduction to Finite Element Analysis

Dr Andrew TM Phillips

While intended to give an overview of this part of the course these notes are not a complete

record and should not be treated as a substitute for attending lectures and tutorials.

Copyright 2010. All rights reserved.

Aim of this part of the course:

The aim of this part of the course is to introduce the nite element method, and inves-

tigate its application in particular in structural engineering. Emphasis is placed on the

use of Matlab and GSA in achieving this.

No one believes the results of a computational model, except the person who put to-

gether the model. Everyone believes the results of an experimental test, except the person

who put together the experiment.

Recommended reading

The following suggested textbooks may be useful for students looking to do further read-

ing on the subjects introduced in this part of the course.

Kwon and Bang, The Finite Element Method Using MATLAB

Ferreira, MATLAB Codes for Finite Element Analysis

Zienkiewicz, Taylor and Zhu, The Finite Element Method: Its Basics and Funda-

mentals

Zienkiewicz and Morgan, Finite Elements and Approximation

1

1 Introduction

The nite element method is a very powerful mathematical technique that has found

signicant application in structural engineering, as well as other elds of science and

engineering.

The rst recognised use of the Finite Element Method as we know it is that of

Turner et al.

1

who used it to numerically model aircraft wings using a mesh of triangular

elements. In introducing the nite element method we will rst look at the Galerkin

method of weighted residuals for approximating functions, before moving on to look at

strong and weak function formulations.

1.1 Galerkin method of weighted residuals

Although the Galerkin method is not the only method of weighted residuals available for

approximating functions we will investigate it, as we will see later on that it has particular

relevance to the nite element method.

Let us rst consider the following dierential governing equation:

d

2

u

dx

2

u + x = 0 (1.1)

In order to dene the problem let us introduce a domain, 0 < x < 1, and let us also

dene boundary conditions, u(0) = 0, and u(1) = 0. This information can be rewritten

in the form:

_

d

2

u

dx

2

u + x = 0, 0 < x < 1

u(0) = 0, and u(1) = 0

(1.2)

The rst step for any method of weighted residuals is then to determine a trial function

which contains unknown coecients to be determined. Here we will select the trial

function:

1

Turner et al., Stiness and Deection Analysis of Complex Structures, Journal of Aeronautical

Sciences 23(9):805-823,854, 1956

2

u = ax(1 x) (1.3)

where u denotes an approximate solution for u, and a is the unknown coecient. The trial

function, u suggested has been chosen as it satises the boundary conditions specied

for the governing dierential equation ( u(0) = 0, and u(1) = 0). It is observed that the

goodness of t of the approximate solution to the exact solution is dependent on the trial

function. Having selected a a trial function we dene a residual, R by substituting u into

the governing dierential equation:

R =

d

2

u

dx

2

u + x = 2a ax(1 x) + x (1.4)

where because u will be dierent to the exact solution, the residual R will not be equal

to zero for all values of x within the domain. Having dened the residual, R we can now

combine this with a weighting function w in order to determine the value of the coecient,

a such that our chosen trial function provides the best t that can be achieved compared

to the exact solution. To do this we set the integration of the weighted residual over the

domain to zero:

_

1

0

wR dx =

_

1

0

w

_

d

2

u

dx

2

u + x

_

dx

=

_

1

0

w(2a ax(1 x) + x) dx = 0

(1.5)

For Galerkins method we set the weighting function based on the chosen trial function,

such that:

w =

d u

da

= x(1 x) (1.6)

Hence for the chosen trial function, setting the integrated weighted residual over the

domain to zero we have:

_

1

0

x(1 x)(2a ax(1 x) + x) dx = 0 (1.7)

which can be solved to give a = 0.2272.

3

Although not discussed here the governing dierential function can be solved exactly

to give:

u = x

1

(e

1

e

1

)

(e

x

e

x

) (1.8)

Hence we can plot the solution provided by our chosen trial function against our exact

solution, as shown in Figure 1.1.

0 0.2 0.4 0.6 0.8 1

0

0.01

0.02

0.03

0.04

0.05

0.06

x

u

(

s

o

l

i

d

r

e

d

)

,

u

Figure 1.1: u, the exact solution (solid red) and u, the approximate solution (dash-dot

blue) found using the Galerkin weighted residual method

In order to improve the approximation we can change the trial function, and increase

the number of independent coecients. Hence another trial function could be:

u = a

1

x(1 x) + a

2

x

2

(1 x) (1.9)

where a

1

and a

2

are independent coecients. This trial functions gives the residual:

R =

d

2

u

dx

2

u + x = a

1

(2 x + x

2

) + a

2

(2 6x + x

2

+ x

3

) + x (1.10)

In order to nd appropriate values for a

1

and a

2

we dene the same number of weight-

ing functions as we have unknowns. For the Galerkin method these are dened:

4

w

i

=

u

a

i

(1.11)

So for the given trial function we have:

w

1

= x(1 x), w

2

= x

2

(1 x) (1.12)

Hence for the chosen trial function, we can dene two weighted residuals, and set their

integrals to zero over the domain:

_

1

0

w

1

Rdx = 0,

_

1

0

w

2

Rdx = 0 (1.13)

giving simultaneous expressions, that in matrix form can be solved to give a

1

= 0.1457

and a

2

= 0.1628:

_

11/30 11/60

11/60 1/7

__

a

1

a

2

_

=

_

1/12

1/20

_

(1.14)

Hence we can plot the solution provided by our 1st-order and 2nd-order chosen trial

functions against our exact solution, as shown in Figure 1.2. It is observed that the

2nd-order chosen trial function has a very high goodness of t for the exact solution.

1.2 Weak formulation of the Galerkin method

When we were operating on the trial function previously we were using the strong form,

where the evaluation of the integrated weighted residual relied on the highest order of

derivative term in the residual having a non-zero value. This restricted our choice of trial

functions to those where:

2

u

x

2

= 0 (1.15)

We can however apply integration by parts to the strong form, in order dene the

weak form:

5

0 0.2 0.4 0.6 0.8 1

0

0.01

0.02

0.03

0.04

0.05

0.06

x

u

(

s

o

l

i

d

r

e

d

)

,

u

Figure 1.2: u, the exact solution (solid red), 1st-order approximate solution (dash-

dot blue), and 2nd-order approximate solution (dotted black) found using the Galerkin

weighted residual method

_

1

0

w

_

d

2

u

dx

2

u + x

_

dx =

_

1

0

_

dw

dx

d u

dx

w u + wx

_

dx +

_

w

d u

dx

_

1

0

= 0 (1.16)

If we refer back the our original trial function for the governing dierential equation

it can be seen that we will arrive at the same value of a using the weak form as we did

for the strong form:

_

1

0

(w

w u + wx)dx + [w u

]

1

0

= 0

u = ax(1 x), u

= a 2ax, w = x(1 x), w

= 1 2x

a = 0.2272

(1.17)

While for the originally chosen trial function this is not seen to have any immediate

advantage, we can go on to introduce the concept of using piecewise continuous trial

functions.

6

1.3 Piecewise continuous trial functions

It is observed that regardless of whether a strong or weak formulation is adopted the

accuracy of any approximate solutions depends on the chosen trial function. However

selecting a trial function is not always an easy task. The is particularly true if the exact

function varies widely over the problem domain, if the domain has a complex shape in

two or three dimensions, or if the domain, or problem has a complex set of boundary

conditions. The task can be made easier by selecting piecewise continuous trial functions.

Consider piecewise linear functions in a one dimensional domain:

i

(x) =

_

_

(x x

i1

)/h

i

for x

i1

x x

i

(x

i+1

x)/h

i+1

for x

i

x x

i+1

0 for x < x

i1

, or x > x

i+1

(1.18)

The piecewise linear functions can be represented graphically as shown in Figure 1.3.

Figure 1.3: Piecewise linear functions

Let us go on to dene a piecewise linear trial function such that:

u = a

1

1

(x) + a

2

2

(x) (1.19)

where a

1

and a

2

are unknown coecients and

1

and

2

are dened:

1

(x) =

_

_

3x for 0 x 1/3

2 3x for 1/3 x 2/3

0 for 2/3 x 1

(1.20)

7

2

(x) =

_

_

0 for 0 x 1/3

3x 1 for 1/3 x 2/3

3 3x for 2/3 x 1

(1.21)

The trial function, u can then be rewritten as:

u =

_

_

a

1

(3x) for 0 x 1/3

a

1

(2 3x) + a

2

(3x 1) for 1/3 x 2/3

a

2

(3 3x) for 2/3 x 1

(1.22)

and graphically represented as shown in Figure 1.4.

Figure 1.4: Piecewise linear trial functions

The Galerkin method gives the following weighting functions:

w

1

=

_

_

3x for 0 x 1/3

2 3x for 1/3 x 2/3

0 for 2/3 x 1

(1.23)

w

2

=

_

_

0 for 0 x 1/3

3x 1 for 1/3 x 2/3

3 3x for 2/3 x 1

(1.24)

The integrated weighted residuals over the domain are given:

I

wR1

=

_

1

0

(w

1

u

w

1

u + w

1

x)dx = 0 (1.25)

I

wR2

=

_

1

0

(w

1

u

w

1

u + w

1

x)dx = 0 (1.26)

8

where [w

i

u

] is omitted recognising that w

1

(0) = w

1

(1) = w

2

(0) = w

2

(1) = 0.

We can go on to evaluate the weighted integrals:

I

wR1

=

_

1/3

0

[3(3a) 3x(a

1

(3x)) + (3x)x] dx

+

_

2/3

1/3

[3(3a

1

+ 3a

2

) (2 3x)(2a

1

3a

1

x + 3a

2

x a

2

) + (2 3x)x] dx

+

_

1

2/3

0 dx = 0

(1.27)

I

wR2

=

_

1/3

0

0 dx

+

_

2/3

1/3

[3(3a

1

+ 3a

2

) (3x 1)(2a

1

3a

1

x + 3a

2

x a

2

) + (3x 1)x] dx

+

_

1

2/3

[3(3a

2

) (3 3x)(3a

2

3a

2

x) + (3 3x)x] dx = 0

(1.28)

giving simultaneous equations, that in matrix form can be solved to give a

1

= 0.0488 and

a

2

= 0.0569:

_

6.2222 2.9444

2.9444 6.2222

__

a

1

a

2

_

=

_

0.1111

0.2222

_

(1.29)

Hence we can plot the solution provided by our piecewise linear trial functions against

our exact solution, as shown in Figure 1.5. It is observed that although a good t is not

achieved with just two piecewise linear trial functions, a good t could be achieved with

the introduction of additional piecewise linear trial functions. While this will not be done

here, it is clear that computationally the process could quickly be automated.

Exercise: Download the Oasys GSA refresher tutorial from BlackBoard

and remind yourself of how to put together simple truss and frame structures.

GSA is based on the stiness method and you should look in the help documents for

the stiness matrices used for bar and beam elements respectively. When we move on to

the implementation of the nite element method for analysing structures we will rst of

all remind ourselves of the matrix stiness method, which is covered in the second year

structural mechanics course.

9

0 0.2 0.4 0.6 0.8 1

0

0.01

0.02

0.03

0.04

0.05

0.06

x

u

(

s

o

l

i

d

r

e

d

)

,

u

Figure 1.5: u, the exact solution (solid red), u approximate solution (dash-dot blue) using

piecewise linear trial functions

10

1.4 Galerkin Finite Element Formulation

Having introduced the concepts of the Galerkin method, and piecewise continuous trial

functions we can go on to introduce a more formal system of nite elements. Let us

consider an individual nite element as shown in Figure 1.6.

Figure 1.6: Individual nite element with nodes at x

i

and x

i+1

The element shown has two nodes at x

i

and x

i+1

with nodal variables u

i

and u

i+1

at those nodes. We will assume that our unknown trial function is of the form:

u = c

1

x + c

2

(1.30)

This trial function can be expressed in terms of the nodal variables ( u

i

and u

i+1

),

replacing c

1

and c

2

with the nodal variables:

u(x

i

) = c

1

x

i

+ c

2

= u

i

u(x

i+1

) = c

1

x

i+1

+ c

2

= u

i+1

(1.31)

Thus solving simultaneously we obtain:

c

1

=

u

i+1

u

i

x

i+1

x

i

c

2

=

u

i

x

i+1

u

i+1

x

i

x

i+1

x

i

(1.32)

Substituting expressions for c

1

and c

2

back into our unknown trial function we have:

u = N

1

(x) u

i

+ N

2

(x) u

i+1

(1.33)

11

where:

N

1

(x) =

x

i+1

x

h

i

, N

2

(x) =

x x

i

h

i

, h

i

= x

i+1

x

i

(1.34)

and N

1

and N

2

are referred to as linear shape functions.

The shape functions are such that at node n

i

, the shape function N

i

will have a value

of 1, while at all other nodes it will have a value of zero. Thus the linear shape functions,

N

1

and N

2

for a single element can be graphically represented as shown in Figure 1.7.

Figure 1.7: Linear shape functions for a single nite element (e

1

), with two nodes (n

1

and n

2

)

It is noted that in general:

n

i=1

N

i

(x) = 1 (1.35)

We can go on to look at a system of four nite elements as shown in Figure 1.8 which

we will use to nd an approximation to the actual solution using the weak form of the

governing dierential we looked at previously:

I

wR

=

n

i=1

_

x

i+1

x

i

(w

w u + wx)dx + [ u

w]

1

0

= 0 (1.36)

For an individual element e

i

we maintain the relationship:

u = N

1

(x)u

i

+ N

2

(x)u

i+1

(1.37)

12

Figure 1.8: Four nite elements (e

1

to e

4

), with ve nodes (n

1

to n

5

) with linear shape

functions

where from the Galerkin method the weighting functions w

1

and w

2

are based on the

shape functions N

1

and N

2

:

w

1

= N

1

(x)

w

2

= N

2

(x)

(1.38)

and the integrated weighted residual for an individual element e

i

is:

I

wR(e

i

)

=

_

x

i+1

x

i

_

_

N

1

N

2

_

[N

1

N

2

]

_

N

1

N

2

_

[N

1

N

2

]

_

dx

_

u

i

u

i+1

_

+

_

x

i+1

x

i

_

N

1

N

2

_

x dx

(1.39)

Hence if we have a domain between 0 and 1, with nodes at x = 0, x = 0.25, x =

0.5, x = 0.75 and x = 1, then we can derive the integrated weighted residual for each

element in the form:

I

wR(e

i

)

=

_

1

h

i

+

h

i

3

1

h

i

+

h

i

6

1

h

i

+

h

i

6

1

h

i

+

h

i

3

__

u

i

u

i+1

_

+

_

h

i

6

(x

i+1

+ 2x

i

)

h

i

6

(2x

i+1

+ x

i

)

_

(1.40)

where h

i

= x

i+1

x

i

13

We can then write the integrated weighted residual for each element in matrix form:

I

wR(e

1

)

=

_

4.08333 3.95833

3.95833 4.08333

__

u

1

u

2

_

+

_

0.0104167

0.0208333

_

(1.41)

I

wR(e

2

)

=

_

4.08333 3.95833

3.95833 4.08333

__

u

2

u

3

_

+

_

0.0416667

0.0520833

_

(1.42)

I

wR(e

3

)

=

_

4.08333 3.95833

3.95833 4.08333

__

u

3

u

4

_

+

_

0.0729167

0.0833333

_

(1.43)

I

wR(e

4

)

=

_

4.08333 3.95833

3.95833 4.08333

__

u

4

u

5

_

+

_

0.1041667

0.1145833

_

(1.44)

which can be combined to give:

I

wR

=

_

_

4.08333 3.95833 0 0 0

3.95833 8.16667 3.95833 0 0

0 3.95833 8.16667 3.95833 0

0 0 3.95833 8.16667 3.95833

0 0 0 3.95833 4.08333

_

_

_

_

u

1

u

2

u

3

u

4

u

5

_

_

+

_

_

0.0104167 u

(0)

0.0625

0.125

0.1875

0.1145833 + u

(1)

_

_

= 0

(1.45)

where u

(0) and u

(1) are referred to as the Neumann boundary conditions. In practice we have

what are referred to as the Dirichlet boundary conditions:

u(0) = u

1

= 0, u(1) = u

5

= 0

14

Thus we can alter the integrated weighted residual relationship with the known boundary

conditions:

_

_

1 0 0 0 0

3.95833 8.16667 3.95833 0 0

0 3.95833 8.16667 3.95833 0

0 0 3.95833 8.16667 3.95833

0 0 0 0 1

_

_

_

_

u

1

u

2

u

3

u

4

u

5

_

_

=

_

_

0

0.0625

0.125

0.1875

0

_

_

(1.46)

giving:

u

1

= 0, u

2

= 0.0352, u

3

= 0.0569, u

4

= 0.0505, u

5

= 0

We can substitute back into our unknown trial function for each element to give:

u

_

_

N

1

(x) u

1

+N

2

(x) u

2

= 0.1408x for 0 x 0.25

N

1

(x) u

2

+N

2

(x) u

3

= 0.0352 + 0.0868(x 0.25) for 0.25 x 0.5

N

1

(x) u

3

+N

2

(x) u

4

= 0.0569 0.0256(x 0.50) for 0.5 x 0.75

N

1

(x) u

4

+N

2

(x) u

5

= 0.0505 0.2020(x 0.75) for 0.75 x 1

(1.47)

Hence we can plot the solution provided by the Galerkin nite element formulation against

our exact solution, as shown in Figure 1.9. It is observed that although a reasonable t is

achieved with four elements, a better t could be achieved with the introduction of additional

elements. While this will not be done here, it is clear that computationally the process could

quickly be automated. It should be noted in particular that although the residual (u u) is

zero at the nodes, this is not the case in the length of the element.

So we have demonstrated the application of the Galerkin nite element formulation to a

particular governing dierential relationship. It can be seen that the method is easily applied

to a variety of physical phenomena. We shall look at the nite element method as applied in

structural mechanics.

15

0 0.2 0.4 0.6 0.8 1

0

0.01

0.02

0.03

0.04

0.05

0.06

x

u

(

s

o

l

i

d

r

e

d

)

,

u

Figure 1.9: u, the exact solution (solid red), u approximate solution (dash-dot blue) using

the Galerkin nite element formulation

16

2 Structural Finite Elements

2.1 Axial bar element

Let us rst consider a bar element, that is an element which only resists axial forces. At this

stage we will also introduce a local coordinate system onto the bar such that at the rst node,

n

1

we have = 1, and at the second node, n

2

we have = +1, as shown in Figure 2.1.

Figure 2.1: 1D bar element and associated linear shape functions

If a force per unit length is applied to the bar as shown in Figure 2.2 we can go on to look

at the strain energy and external work associated with axial deformation of the element.

Figure 2.2: 1D bar element with an axial load per unit length, p applied

The total strain energy can be expressed as:

U =

1

2

_

+a

a

x

A dx (2.1)

17

where A is the cross-sectional area of the bar (assumed to be constant). Taking the elastic

modulus of the material to be E we have

x

= E

x

and:

U =

1

2

_

+a

a

EA

2

x

dx (2.2)

with

x

=

du

dx

we have:

U =

1

2

_

+a

a

EA

_

du

dx

_

2

dx (2.3)

The external work associated with the axial deformation of the element is:

W =

_

+a

a

p u dx (2.4)

In the relative coordinate system the axial displacement function can be expressed as:

u = N

1

()u

1

+N

2

()u

2

(2.5)

which can be expressed in matrix form:

u = Nu

e

= [N

1

N

2

]

_

u

1

u

2

_

(2.6)

The strain energy in terms of the relative coordinate system can be expressed:

U =

1

2

_

+1

1

EA

_

1

a

2

__

du

d

_

2

a d (2.7)

du

d

is found from

= J

x

where J is referred to as the Jacobian operator, or derivative

transformation matrix between the global and the local coordinate systems.

x

= J

1

(2.8)

In the case of a bar element J =

x

= a, and J

1

=

1

a

In addition it is noted that x = a.

18

Given

du

d

=

_

dN

1

d

dN

2

d

_

_

u

1

u

2

_

= N

u

e

the strain energy can be expressed:

U =

1

2

u

T

e

_

+1

1

EA

a

N

T

N

d u

e

(2.9)

giving:

U =

1

2

u

T

e

K

e

u

e

(2.10)

where K

e

is the element stiness matrix:

K

e

=

EA

a

_

+1

1

N

T

N

d (2.11)

For the bar element

dN

1

d

=

1

2

and

dN

2

d

= +

1

2

and the element stiness matrix is:

K

e

=

EA

a

_

+1

1

_

1

2

+

1

2

_

[

1

2

+

1

2

]d =

EA

2a

_

+1 1

1 +1

_

=

EA

L

_

+1 1

1 +1

_

(2.12)

The external work in terms of the relative coordinate system can be expressed:

W

e

=

_

+1

1

pua d = u

T

e

a

_

+1

1

pN

T

d (2.13)

giving:

W

e

= u

T

e

f

e

(2.14)

where f

e

is the matrix of nodal forces equivalent to the applied distributed load:

f

e

= a

_

+1

1

pN

T

d =

pL

2

_

1

1

_

(2.15)

19

For a system of elements, as illustrated in Figure 2.3 we can express the strain energy and

work done by the external forces as:

U =

1

2

u

T

n

i=1

K

e

u =

1

2

u

T

Ku (2.16)

W = u

T

n

i=1

f

e

= u

T

f (2.17)

where K and f are the system stiness and force matrices.

Hence we have a global system expressed in matrix form:

Ku = f (2.18)

Figure 2.3: System of 1D bar elements

2.1.1 Numerical integration

Integrals arising from the computational implementation of the nite element method may

be solved using numerical integration, for example Gauss quadrature. Considering a function

f(x), x [1, +1] the integral I =

_

+1

1

f(x) dx may be represented by the weighted sum of the

values of f(x) at the Gauss points. The position and weightings of the Gauss points relate to

the chosen number, as described in Table 1.

Table 1: Gauss point positions and weightings

n x

i

W

i

1 0 2.0

2 1/

3 1.0

3 0 8/9

_

3/5 5/9

The technique is exact for 2n1 polynomials where n is the chosen number of Gauss points.

20

Exercise:

The MATLAB code over the page, uses the nite element method to analyse

the bar structure shown in Figure 2.4.

Make notes next to the Matlab code and draw a owchart on the blank page following,

using pseudo-code to indicate your understanding of the Matlab code. Experiment with making

changes to the code. In particular develop your understanding of how the stiness and force

matrices are constructed, and how the displacement matrix is derived.

The Matlab code can also be downloaded from BlackBoard.

Figure 2.4: Example Bar Structure

21

1 % Axial bar problem using the Finite Element Method by Andrew Phillips

2 % adapted from Ferreira, MATLAB codes for Finite Element Analysis

3

4 clear all

5 close all

6

7 % E, elastic modulus (N/mm2)

8 % A, area of crosssection (mm2)

9 % L, length of bar (mm)

10

11 E=2.05

*

105;

12 A=pi

*

102;

13 EA=E

*

A;

14 L=900;

15

16 % information on the structure will be kept in a structure array

17 s1 = struct();

18

19 % generating node coordinates and element connectivities

20

21 % setting the number of Elements

22 s1.numElements = 3;

23 % generating equally spaced nodes

24 s1.nodeCoords = 0:L/s1.numElements:L;

25 % setting coords in the x direction

26 s1.nodeXCoord = s1.nodeCoords;

27 % setting the number of Nodes

28 s1.numNodes = size(s1.nodeCoords,2);

29

30 % assigning Nodes to Elements

31 ii = 1:s1.numElements;

32 s1.elementNodes(:,1) = ii;

33 s1.elementNodes(:,2) = ii+1;

34

35 % degrees of freedom (1 at each node for a bar element)

36 s1.globalDOF = s1.numNodes;

37

38 % setting up matrices (K, u, f)

39 s1.stiffness = zeros(s1.globalDOF); % square matrix (n x n)

40 s1.displacements = zeros(s1.globalDOF,1); % column matrix (n x 1);

41 s1.force = zeros(s1.globalDOF,1); % column matrix (n x 1);

42

43 % applied loading (N)

44 s1.force(2) = 1200;

22

45

46 % deriving the system stiffness matrix

47

48 % element degrees of freedom

49 for ee=1:s1.numElements

50 elementDOF = s1.elementNodes(ee,:);

51 nn = size(elementDOF,2);

52 lengthElement = s1.nodeXCoord(elementDOF(2))s1.nodeXCoord(elementDOF(1));

53 detJacobian = lengthElement/2;

54 invJacobian = 1/detJacobian;

55

56 % using a single central Gauss point in each element (xi=0, W=2)

57 xi=0; W=2;

58 shape=struct();

59 shape.shape=[1xi; 1+xi]/2;

60 shape.naturalDerivatives=[1; 1]/2;

61 Xderivatives=shape.naturalDerivatives

*

invJacobian;

62

63 % B matrix (derivates of the shape functions)

64 B=zeros(1,nn); % single row

65 B(1:nn) = Xderivatives;

66

67 % assembling the system stiffness matrix

68 s1.stiffness(elementDOF,elementDOF)=s1.stiffness(elementDOF,elementDOF)...

69 +B'

*

B

*

W

*

detJacobian

*

EA;

70 end

71

72 % prescribed global degrees of freedom

73 s1.prescribedDOF = [1 4];

74

75 % solution

76 activeDOF=setdiff([1:s1.globalDOF]', [s1.prescribedDOF]);

77 U=s1.stiffness(activeDOF,activeDOF)\s1.force(activeDOF);

78 s1.displacements(activeDOF)=U;

79

80 % output displacements and reactions

81 disp('Displacements')

82 [(1:s1.globalDOF)' s1.displacements]

83

84 F=s1.stiffness

*

s1.displacements;

85 reactions=F(s1.prescribedDOF);

86 disp('Reactions')

87 [s1.prescribedDOF' reactions]

23

Blank page for pseudo-code owchart for the bar structure example.

24

2.1.2 Rotational transformation

In introducing the nite element formulation for an axial bar element we implicitly dealt with

transformation between a global (x) and a relative () coordinate system in one-dimension. If

we are to use bar elements in two-dimensional or three-dimensional problems we must also be

able to deal with transforming between the relative coordinate system, and a x, y or x, y, z

coordinate system. We will limit ourselves here to transforming between the one-dimensional

relative () system and a two-dimensional global (x, y) system.

Referring to the global system of equations:

Ku = f (2.19)

We can recall the system of equations for an individual bar element:

K

e

u

e

= f

e

EA

L

_

+1 1

1 +1

__

u

1

u

2

_

=

_

f

1

f

2

_

(2.20)

It is noted that in the above equation u

1

and u

2

are one-dimensional deformation values at

nodes n

1

and n

2

, and f

1

and f

2

are the associated applied forces. Going to a two-dimensional

coordinate system u

e

and f

e

will expand to 4 1 matrices and the element stiness matrix K

e

will expand to a 4 4 matrix:

K

e

u

e

= f

e

EA

L

_

_

+1 0 1 0

0 0 0 0

1 0 +1 0

0 0 0 0

_

_

_

_

u

x1

u

y1

u

x2

u

y2

_

_

=

_

_

f

x1

f

y1

f

x2

f

y2

_

_

(2.21)

It is observed that K

e

is similar to second order strain and stress tensors that we have

encountered before. As such it transforms in the same way as every second order tensor. That

is if we have an element at an angle in the x, y system as shown in Figure 2.5 we can transform

the element stiness matrix in the relative system into the element stiness matrix in the global

system, required in order to allow us for a structural system to combine all of the element

stiness matrices to give us a system stiness matrix.

25

Figure 2.5: Bar element at an angle with respect to the x, y coordinate system

K

G

e

= L

T

e

K

e

L

e

(2.22)

K

G

e

=

_

_

cos sin 0 0

sin cos 0 0

0 0 cos sin

0 0 sin cos

_

_

EA

L

e

_

_

+1 0 1 0

0 0 0 0

1 0 +1 0

0 0 0 0

_

_

_

_

cos sin 0 0

sin cos 0 0

0 0 cos sin

0 0 sin cos

_

_

(2.23)

K

G

e

=

EA

L

e

_

_

cos

2

cos sin cos

2

cos sin

cos sin sin

2

cos sin sin

2

cos

2

cos sin cos

2

cos sin

cos sin sin

2

cos sin sin

2

_

(2.24)

where K

G

e

is the element stiness matrix in the global system, K

e

is the element stiness matrix

in the relative system, L

e

is the directional cosine matrix, and L

e

is the length.

26

Truss Example

We can now adapt the Matlab code developed for our rst bar element example

in order to analyse the truss system shown in Figure 2.6.

Figure 2.6: Example Truss Structure

You should check the results that you nd using Oasys GSA. You should nd a close match

between the stiness method and the nite element method when using bar elements, as imple-

mented here.

27

1 % Axial bar truss problem using the Finite Element Method by Andrew Phillips

2 % adapted from Ferreira, MATLAB codes for Finite Element Analysis

3

4 clear all

5 close all

6

7 % E, elastic modulus (N/mm2)

8 % A, area of crosssection (mm2)

9 % L, length of bar (mm)

10

11 E=2.05

*

105;

12 A=pi

*

102;

13 EA=E

*

A;

14

15 % information on the structure will be kept in a structure array

16 s1 = struct();

17

18 % generating node coordinates and element connectivities

19

20 % generating the node coordinates (6 nodes)

21 s1.nodeCoords = [0 0; 0 3000; 3000 0; 3000 3000; 6000 0; 6000 3000];

22 % setting coords in the x and y directions

23 s1.nodeXCoord = s1.nodeCoords(:,1);

24 s1.nodeYCoord = s1.nodeCoords(:,2);

25 % setting the number of Nodes

26 s1.numNodes = size(s1.nodeCoords,1);

27

28 % assigning Nodes to Elements (11 elements)

29 s1.elementNodes = [1 2; 1 3; 2 3; 2 4; 1 4; 3 4; 3 6; 4 5; 4 6; 3 5; 5 6];

30 % setting the number of Elements

31 s1.numElements = size(s1.elementNodes,1);

32

33 % degrees of freedom (2 at each node for a bar element in 2D space)

34 s1.globalDOF = s1.numNodes.

*

2;

35

36 % setting up matrices (K, u, f)

37 s1.stiffness = zeros(s1.globalDOF); % square matrix (n x n)

38 s1.displacements = zeros(s1.globalDOF,1); % column matrix (n x 1);

39 s1.force = zeros(s1.globalDOF,1); % column matrix (n x 1);

40

41 % applied loading (N)

42 s1.force(4) = 50000; % node 2, DOF 2

43 s1.force(8) = 100000; % node 4, DOF 2

44 s1.force(12) = 50000; % node 6, DOF 2

28

45

46 % deriving the system stiffness matrix

47

48 % element degrees of freedom

49 for ee=1:s1.numElements

50 indice = s1.elementNodes(ee,:);

51 % assigns Global DOF to the element

52 elementDOF = [indice(1)

*

21 indice(1)

*

2 indice(2)

*

21 indice(2)

*

2];

53 % length of each element in the x and y directions

54 xa = s1.nodeXCoord(indice(2))s1.nodeXCoord(indice(1));

55 ya = s1.nodeYCoord(indice(2))s1.nodeYCoord(indice(1));

56 lengthElement = sqrt(xa.2+ya.2);

57 thetaElement = atan(ya/xa);

58 % Ke in the relative system

59 Ke Relative = [1 0 1 0; 0 0 0 0; 1 0 1 0; 0 0 0 0];

60 % Setting up the transformation to the global system

61 C = cos(thetaElement);

62 S = sin(thetaElement);

63 L element = [C S 0 0; S C 0 0; 0 0 C S; 0 0 S C];

64 % Ke in the global system

65 Ke Global = EA./lengthElement.

*

(L element'

*

Ke Relative

*

L element);

66 % assembling the system stiffness matrix

67 s1.stiffness(elementDOF,elementDOF) =...

68 s1.stiffness(elementDOF,elementDOF)+Ke Global;

69 end

70

71 % prescribed global degrees of freedom

72 s1.prescribedDOF = [1 2 10];

73

74 % solution

75 activeDOF=setdiff([1:s1.globalDOF]', [s1.prescribedDOF]);

76 U=s1.stiffness(activeDOF,activeDOF)\s1.force(activeDOF);

77 s1.displacements(activeDOF)=U;

78

79 % output

80 fprintf('Solution\n\n')

81

82 % output displacements and reactions

83 disp('Displacements:')

84 for n=1:s1.globalDOF

85 fprintf('Global DOF %02d, %+1.4e \n',n,s1.displacements(n));

86 end

87 fprintf('\n');

88

29

89 F=s1.stiffness

*

s1.displacements;

90 reactions=F(s1.prescribedDOF);

91 disp('Reactions:')

92 for n=1:size(s1.prescribedDOF,2);

93 fprintf('Global DOF %02d, %+1.4e \n',s1.prescribedDOF(n),reactions(n));

94 end

95 fprintf('\n');

96

97 % output axial strains

98 for n=1:s1.numElements

99 indice = s1.elementNodes(n,:);

100 xa = s1.nodeXCoord(indice(2))s1.nodeXCoord(indice(1));

101 ya = s1.nodeYCoord(indice(2))s1.nodeYCoord(indice(1));

102 s1.originallengthElement(n) = sqrt(xa.2+ya.2);

103 xanew = (s1.nodeXCoord(indice(2)) + s1.displacements(indice(2)

*

21))...

104 (s1.nodeXCoord(indice(1))+ s1.displacements(indice(1)

*

21));

105 yanew = (s1.nodeYCoord(indice(2)) + s1.displacements(indice(2)

*

2))...

106 (s1.nodeYCoord(indice(1))+ s1.displacements(indice(1)

*

2));

107 s1.finallengthElement(n) = sqrt(xanew.2+yanew.2);

108 s1.strainsElement(n) = (s1.finallengthElement(n)s1.originallengthElement(n))...

109 ./s1.originallengthElement(n);

110 end

111

112 disp('Strains:')

113 for n=1:s1.numElements

114 fprintf('Element %02d, %+1.4e \n',n,s1.strainsElement(n));

115 end

116 fprintf('\n');

117

118 % output axial stresses

119 s1.stressesElement = E.

*

s1.strainsElement;

120 disp('Stresses:')

121 for n=1:s1.numElements

122 fprintf('Element %02d, %+1.4e \n',n,s1.stressesElement(n));

123 end

124 fprintf('\n');

30

2.2 Euler-Bernoulli beam element

The Euler-Bernoulli beam element is based on standard or engineering beam bending theory.

The assumptions used in formulating standard beam bending theory are:

Plane sections remain plane after deformation.

Plane sections remain perpendicular to the neutral axis after deformation.

These assumptions are illustrated in Figure 2.7.

Figure 2.7: Euler-Bernoulli Beam Bending

Based on Figure 2.7 and the standard denition of strain we have the relationship:

11

(x

2

) =

du

1

dx

1

=

d

dx

1

_

x

2

du

2

dx

1

_

= x

2

d

2

u

2

dx

2

1

= x

2

Where is the curvature. The curvature of the beam is taken as:

=

1

R

=

d

ds

=

d

2

u

2

dx

2

1

31

Where R is the radius of curvature, and ds is the distance along the curve as illustrated in

Figure 2.8, which for small deections can be considered equal to dx

1

.

Figure 2.8: Beam curvature

With regards to a nite element formulation for a two noded element we can specify two

degrees of freedom at each node, as shown in Figure 2.9.

Figure 2.9: Degrees of freedom for a two noded Euler-Bernoulli beam element

We can dene four shape functions as illustrated in Figure 2.10 and given:

N

1

() = +

1

4

(1 )

2

(2 +) (2.25)

N

2

() = +

1

8

L(1 )

2

(1 +) (2.26)

N

3

() = +

1

4

(1 +)

2

(2 ) (2.27)

N

4

() =

1

8

L(1 +)

2

(1 ) (2.28)

32

1 0.5 0 0.5 1

0.4

0.2

0

0.2

0.4

0.6

0.8

1

N

N

1

N

2

N

3

N

4

Figure 2.10: Hermite cubic shape functions for an Euler-Bernoulli beam element

The adopted hermite shape functions are said to have C

1

continuity, whereas our original

linear shape functions had C

0

continuity. That is to say that C

1

shape functions are continuous

across nodes for the rst derivative, while C

0

shape functions are continuous for the value only.

It is noted that N

2

() and N

4

() do not reach values of 1 or zero at the relevant nodes. However

these shape functions relate to the angle of rotation, , or the slope at each of the nodes, =

du

2

dx

1

.

Thus the relationship is true for

dN

2

d

and

dN

4

d

as shown in Figure 2.11 and given:

dN

2

d

=

1

4

(1 2 + 3

2

) (2.29)

dN

4

d

=

1

4

(1 + 2 + 3

2

) (2.30)

The strain energy associated with bending of the element can be obtained as:

U =

1

2

_

V

E

2

11

dV (2.31)

Where dV = dAdx

1

, thus:

U =

1

2

_

+a

a

EI

_

2

u

2

x

2

1

_

2

dx

1

=

1

2

_

+1

1

EI

a

4

_

2

u

2

x

2

1

_

2

a d (2.32)

33

1 0.5 0 0.5 1

0.4

0.2

0

0.2

0.4

0.6

0.8

1

d

N

dN

2

dN

4

Figure 2.11: dN

2

and dN

4

for an Euler-Bernoulli beam element

From the chain rule it is found that

d

2

u

2

d

2

=

1

a

2

d

2

u

2

dx

2

1

=

4

L

2

d

2

u

2

dx

2

1

. In addition it is noted that

x = a =

L

2

.

Given

d

2

u

2

d

2

=

d

2

N

d

2

u

e

= N

u

e

the strain energy can be expressed:

U =

1

2

u

T

e

EI

a

3

_

+1

1

N

T

N

du

e

(2.33)

giving

U =

1

2

u

T

e

K

e

u

e

(2.34)

where K

e

is the element stiness matrix:

K

e

=

EA

a

3

_

+1

1

N

T

N

d (2.35)

and:

N

=

1

L

_

6

L

3 1 6

L

3 + 1

_

(2.36)

Using the Hermite shape functions the element stiness matrix is found as:

34

K

e

=

EI

L

3

_

_

12 6L 12 6L

6L 4L

2

6L 2L

2

12 6L 12 6L

6L 2L

2

6L 4L

2

_

_

(2.37)

It is observed that this is the same as the matrix derived using a virtual work approach,

therefore an exact match should be found between the stiness method and the nite element

method when using Euler-Bernoulli beam elements as formulated here.

If we apply a uniform load to the element as shown in Figure 2.12 we can state the work

done by the external forces in deforming the element as:

W =

_

+a

a

pu dx = u

T

e

a

_

+1

1

pN

T

d (2.38)

Figure 2.12: Uniformly distributed loading for an Euler-Bernoulli beam element

The vector of nodal forces and moments is then found as:

f

e

= a

_

+1

1

pN

T

d = pL

_

_

1/2

L/12

1/2

L/12

_

_

(2.39)

It is observed that these have the same magnitude as the xed end reactions and moments

for a uniformly loaded xed end beam, which you will have encountered when using the stiness

method.

35

Euler Bernoulli Beam Example

The Matlab code below can be used to model the simply supported and xed

end beams shown in Figure 2.13 using Euler-Bernoulli beam elements.

Adapt the code for the dierent boundary conditions, and perform a convergence study

(increasing the number of elements, and recording the predicted deection at midspan) to nd

the number of Euler-Bernoulli beam elements required to nd the analytical midspan deections.

You will recall that these are

max

=

5pL

4

384EI

for a simply supported beam, and

max

=

pL

4

384EI

for a xed end beam.

Note the eect that using the nodal force vector has on the reported reaction values. Plot

the nodal displacements for 2, 4, 8, 16, 32 and 64 elements for both the simply supported and

xed end beams and comment on what you think is a sensible mesh density with regards to

accurately reproducing the displaced shapes of the beams.

Figure 2.13: Example Truss Structure

36

1 % EulerBernoulli beam problem using the Finite Element Method

2 % by Andrew Phillips

3

4 clear all

5

6 % comment to show successive plots on the same graph

7 close all

8

9 % E, elastic modulus (N/mm2)

10 % I, second moment of area of crosssection (mm4)

11 % L, length of beam (mm)

12

13 E=2.05

*

105;

14 I=8.249

*

107;

15 EI=E

*

I;

16 L=10000;

17

18 % information on the structure will be kept in a structure array

19 s1 = struct();

20

21 % generating node coordinates and element connectivities

22

23 % setting the number of Elements

24 % asking the user for the number of elements

25 s1.numElements = input('How many elements do you wish to use? ');

26 % generating equally spaced nodes

27 s1.nodeCoords = 0:L/s1.numElements:L;

28 % setting coords in the x direction

29 s1.nodeXCoord = s1.nodeCoords;

30 % setting the number of Nodes

31 s1.numNodes = size(s1.nodeCoords,2);

32

33 % assigning Nodes to Elements

34 ii = 1:s1.numElements;

35 s1.elementNodes(:,1) = ii;

36 s1.elementNodes(:,2) = ii+1;

37

38 % degrees of freedom (2 at each node for an EB beam element)

39 s1.globalDOF = s1.numNodes.

*

2;

40

41 % setting up matrices (K, u, f)

42 s1.stiffness = zeros(s1.globalDOF); % square matrix (n x n)

43 s1.displacements = zeros(s1.globalDOF,1); % column matrix (n x 1);

44 s1.force = zeros(s1.globalDOF,1); % column matrix (n x 1);

37

45

46 % applied loading

47 % load per unit length

48 % (kN/m to N/mm)

49 p = 5;

50

51 % deriving the system stiffness matrix

52

53 % element degrees of freedom

54 for ee=1:s1.numElements

55 indice = s1.elementNodes(ee,:);

56 % assigns Global DOF to the element

57 elementDOF = [indice(1)

*

21 indice(1)

*

2 indice(2)

*

21 indice(2)

*

2];

58 % length of the element

59 lengthElement = s1.nodeXCoord(indice(2))s1.nodeXCoord(indice(1));

60 Le = lengthElement;

61 % Ke

62 Ke = EI./(Le.3)

*

[...

63 12 6.

*

Le 12 6.

*

Le;...

64 6.

*

Le 4.

*

Le.2 6.

*

Le 2.

*

Le2;...

65 12 6.

*

Le 12 6.

*

Le;...

66 6.

*

Le 2.

*

Le.2 6.

*

Le 4.

*

Le.2];

67 % fe

68 fe = p.

*

[Le./2; Le.2./12; Le./2; Le.2./12];

69 % assembling the system stiffness matrix

70 s1.stiffness(elementDOF,elementDOF) =...

71 s1.stiffness(elementDOF,elementDOF)+Ke;

72 % assembling the nodal force vector

73 s1.force(elementDOF)=s1.force(elementDOF)+fe;

74 end

75

76 % prescribed global degrees of freedom

77

78 % simply supported

79 s1.prescribedDOF = [1 s1.globalDOF1];

80

81 % fixed end

82 % s1.prescribedDOF = [1 2 s1.globalDOF1 s1.globalDOF];

83

84 % solution

85 activeDOF=setdiff([1:s1.globalDOF]', [s1.prescribedDOF]);

86 U=s1.stiffness(activeDOF,activeDOF)\s1.force(activeDOF);

87 s1.displacements(activeDOF)=U;

88

38

89 % output

90 fprintf('Solution\n\n')

91

92 % output displacements and reactions

93 disp('Displacements:')

94 for n=1:s1.globalDOF

95 fprintf('Global DOF %02d, %+1.4e \n',n,s1.displacements(n));

96 end

97 fprintf('\n');

98

99 F=s1.stiffness

*

s1.displacements;

100 reactions=F(s1.prescribedDOF);

101 disp('Reactions:')

102 for n=1:size(s1.prescribedDOF,2);

103 fprintf('Global DOF %02d, %+1.4e \n',s1.prescribedDOF(n),reactions(n));

104 end

105 fprintf('\n');

106

107 % plot the vertical displacements

108 fig1=figure(1);

109 plot(s1.nodeXCoord,s1.displacements(1:2:s1.globalDOF),'x r');

110 grid on

111 title('EulerBernoulli Beam Example');

112 xlabel('Horizontal Distance');

113 ylabel('Vertial Deflection');

114 hold on

39

2.3 Timoshenko beam element

Alternative beam bending theories to the standard beam bending theory exist, and the formu-

lation of the Timonshenko beam element is an example of the application of one of these.

Timoshenko beam bending theory can be considered as an extension of standard beam

bending theory, in which deections due to shear strains are also taken into account. The

assumptions used in formulating Timoshenko beam theory are:

Plane sections remain in plane after deformation.

Plane sections need not remain perpendicular to the neutral axis.

The rst of these assumptions in particular will be looked at with regards to compatibility.

The additional contribution to deformation due to considering shear strains is illustrated in

Figure 2.14. The contribution of shear strains to deformation of a beam is seen to increase as

the depth:span ratio increases.

Figure 2.14: Timoshenko Beam Bending

40

It is seen in Figure 2.14 that the assumption of plane sections remaining in plane after

deformation doesnt t with what we know about the shear distribution within a section. This

can to some extent be taken account of through the introduction of a shear correction coecient,

or shape factor, in our shear deformation relationship:

12

=

V

GA

(2.40)

Where V is the shear force acting across the section in the x

2

direction, G is the shear

modulus, normally taken as E/2(1 + ) where is Poissons ratio, and A is the area of the

cross-section. Various values of have been put forward for cross-sections of dierent shapes,

although 5/6 is often used.

The nite element formulation for a Timoshenko beam element is dierent to the formulation

for an Euler-Bernoulli beam element. Expressions for the curvature, , caused by bending

moments, and the angle, , caused by shear forces can be written in matrix form as:

_

_

=

_

0

d

dx

1

d

dx

1

1

__

u

2

_

(2.41)

Expressions for the bending moment, M, and the shear force, V can be written in matrix

form as:

_

M

V

_

=

_

EI 0

0 GA

__

_

(2.42)

We can dene a Timoshenko beam element using the same degrees of freedom at each node

as we had for the Euler-Bernoulli beam element, as shown in Figure 2.9. For the formulation

presented here we will use linear shape functions.

_

u

2

_

=

_

1

2

(1 ) 0

1

2

(1 +) 0

0

1

2

(1 ) 0

1

2

(1 +)

_

_

_

u

2(n

1

)

(n

1

)

u

2(n

2

)

(n

2

)

_

_

(2.43)

We can dene the B matrix as:

41

B = dN =

_

0

d

dx

1

d

dx

1

1

__

1

2

(1 ) 0

1

2

(1 +) 0

0

1

2

(1 ) 0

1

2

(1 +)

_

(2.44)

The element stiness matrix can then be dened as:

K

e

=

_

V

B

T

DB dV (2.45)

where D =

_

EI 0

0 GA

_

While the equivalent nodal force vector can be dened as:

f

e

=

_

V

N

T

p dV (2.46)

where p is a uniformly distributed load.

It is observed that the expressions for K

e

and f

e

are general relationships, such that we

could have used them in the development of the axial bar element, and the Euler-Bernoulli

beam element formulations. They are easy to implement using short blocks of code within a

numerical program such as Matlab, and also form the basis of other structural and continuum

nite element formulations that you will investigate in future years.

42

Timoshenko Beam Example

The Matlab code below can be used to model the simply supported and xed

end beams shown in Figure 2.13 (for the Euler-Bernoulli beam element example)

using Timoshenko beam elements.

Instead of using the previous section you should calculate I and A values for a cross-section

300mm in depth and 30mm in width. You may take as 5/6.

As you did for the Euler-Bernoulli beam example adapt the code for the dierent boundary

conditions, and perform a convergence study (increasing the number of elements, and recording

the predicted deection at midspan) to nd the minimum number of Timoshenko beam elements

required to nd consistent values for the midspan deection. You will see that the code makes

use of numerical integration, with two gauss points per element used for the integration related

to curvature, and a single gauss point used per element for the integration related to shear.

Repeat the convergence study for beam depths of 100mm and 900mm.

The analytical values for midspan deection using the Timoshenko formulation are:

max

=

5pL

4

384EI

pL

2

8GA

(2.47)

for a simply supported beam, and

max

=

pL

4

384EI

pL

2

8GA

(2.48)

for a xed end beam.

Repeat the exercise using Euler-Bernoulli beam elements for the new cross-sections and nd

the percentage increase in the midspan deections found using Timoshenko beam elements.

Discuss when you think the use of Timoshenko, as opposed to Euler-Bernoulli beam elements

could be important.

43

1 % Axial bar problem using the Finite Element Method by Andrew Phillips

2 % adapted from Ferreira, MATLAB codes for Finite Element Analysis

3

4 clear all

5 close all

6

7 % E, elastic modulus (N/mm2)

8 % A, area of crosssection (mm2)

9 % I, second moment of area (mm4)

10 % L, length of bar (mm)

11

12 E=2.05

*

105; %elastic (Young's) modulus

13 G=E/(2

*

(1+0.3)); %shear modulus

14 k=5/6; % shear correction factor%

15 b=30;

16 d=300;

17 A=b

*

d;

18 I=b

*

d3/12;

19 EI=E

*

I; %curvature%

20 kGA=k

*

G

*

A; %shear%

21 L=10000;

22

23 % D matrix

24 D=[EI 0; 0 kGA];

25

26 % information on the structure will be kept in a structure array

27 s1 = struct();

28

29 % generating node coordinates and element connectivities

30

31 % setting the number of Elements

32 % asking the user for the number of elements

33 s1.numElements = input('How many elements do you wish to use? ');

34 % generating equally spaced nodes

35 s1.nodeCoords = 0:L/s1.numElements:L;

36 % setting coords in the x direction

37 s1.nodeXCoord = s1.nodeCoords;

38 % setting the number of Nodes

39 s1.numNodes = size(s1.nodeCoords,2);

40

41 % assigning Nodes to Elements

42 ii = 1:s1.numElements;

43 s1.elementNodes(:,1) = ii;

44 s1.elementNodes(:,2) = ii+1;

44

45

46 % degrees of freedom (2 at each node for a T beam element)

47 s1.globalDOF = s1.numNodes.

*

2;

48

49 % setting up matrices (K, u, f)

50 s1.stiffness = zeros(s1.globalDOF); % square matrix (n x n)

51 s1.displacements = zeros(s1.globalDOF,1); % column matrix (n x 1);

52 s1.force = zeros(s1.globalDOF,1); % column matrix (n x 1);

53

54 % applied loading

55 % load per unit length

56 % (kN/m to N/mm)

57 p = 5;

58

59 % deriving the system stiffness matrix

60

61 % element degrees of freedom

62 for ee=1:s1.numElements

63 indice = s1.elementNodes(ee,:);

64 % assigns Global DOF to the element

65 elementDOF = [indice(1)

*

21 indice(1)

*

2 indice(2)

*

21 indice(2)

*

2];

66 % length of the element

67 lengthElement = s1.nodeXCoord(indice(2))s1.nodeXCoord(indice(1));

68 Le = lengthElement;

69 detJacobian = Le/2;

70 invJacobian = 1/detJacobian;

71

72 % two point gauss integration

73 xi=[+1/sqrt(3) 1/sqrt(3)]; W=[1 1];

74

75 for n=1:size(W,2)

76

77 shape=struct();

78 shape.shape=[1xi(n); 1+xi(n)]/2;

79 shape.naturalDerivatives=[1; 1]/2;

80 Xderivatives=shape.naturalDerivatives

*

invJacobian;

81

82 %%%% theta contribution

83 % B matrix (derivates of the shape functions)

84 B=zeros(2,4);

85 B(1,2) = Xderivatives(1);

86 B(1,4) = Xderivatives(2);

87 % assembling the system stiffness matrix

88 s1.stiffness(elementDOF,elementDOF)=s1.stiffness(elementDOF,elementDOF)...

45

89 +B'

*

B.

*

W(n).

*

detJacobian.

*

D(1,1);

90 %%%%

91

92 % assembling the nodal force vector

93 s1.force(elementDOF)=s1.force(elementDOF)+...

94 p

*

[shape.shape(1) 0 shape.shape(2) 0]'.

*

W(n).

*

detJacobian;

95

96 end

97

98 % avoiding a problem described as 'shear locking'

99 % one point gauss integration when looking at shear

100 xi=[0]; W=[2];

101 for n=1:size(W,2)

102

103 shape=struct();

104 shape.shape=[1xi(n); 1+xi(n)]/2;

105 shape.naturalDerivatives=[1; 1]/2;

106 Xderivatives=shape.naturalDerivatives

*

invJacobian;

107

108 %%%% gamma contribution

109 % B matrix (derivatives of shape functions and shape functions)

110 B=zeros(2,4);

111 B(2,1) = Xderivatives(1);

112 B(2,3) = Xderivatives(2);

113 B(2,2) = shape.shape(1);

114 B(2,4) = shape.shape(2);

115 % assembling the system stiffness matrix

116 s1.stiffness(elementDOF,elementDOF)=s1.stiffness(elementDOF,elementDOF)...

117 +B'

*

B.

*

W(n).

*

detJacobian.

*

D(2,2);

118 %%%%

119

120 end

121 end

122

123 % prescribed global degrees of freedom

124

125 % simply supported

126 s1.prescribedDOF = [1 s1.globalDOF1];

127

128 % fixed end

129 % s1.prescribedDOF = [1 2 s1.globalDOF1 s1.globalDOF];

130

131 % solution

132 activeDOF=setdiff([1:s1.globalDOF]', [s1.prescribedDOF]);

46

133 U=s1.stiffness(activeDOF,activeDOF)\s1.force(activeDOF);

134 s1.displacements(activeDOF)=U;

135

136 % output

137 fprintf('Solution\n\n')

138

139 % output displacements and reactions

140 disp('Displacements:')

141 for n=1:s1.globalDOF

142 fprintf('Global DOF %02d, %+1.4e \n',n,s1.displacements(n));

143 end

144 fprintf('\n');

145

146 % midspan displacements

147 disp('Midspan Displacement:')

148 fprintf('%+1.4e \n\n',s1.displacements(s1.globalDOF/2));

149

150 F=s1.stiffness

*

s1.displacements;

151 reactions=F(s1.prescribedDOF);

152 disp('Reactions:')

153 for n=1:size(s1.prescribedDOF,2);

154 fprintf('Global DOF %02d, %+1.4e \n',s1.prescribedDOF(n),reactions(n));

155 end

156 fprintf('\n');

157

158 % plot the vertical displacements

159 fig1=figure(1);

160 plot(s1.nodeXCoord,s1.displacements(1:2:s1.globalDOF),'x r');

161 grid on

162 title('Timoshenko Beam Example');

163 xlabel('Horizontal Distance');

164 ylabel('Vertial Deflection');

165 hold on

47

- Blank page for notes -

48

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grass Mann 2004Dokument11 SeitenGrass Mann 2004Sholpan SholpsNoch keine Bewertungen

- R IntroDokument109 SeitenR IntroHartman József JociNoch keine Bewertungen

- Nastran TutorialDokument5 SeitenNastran TutorialSholpan SholpsNoch keine Bewertungen

- Blade DesignDokument13 SeitenBlade DesignDennyHalim.comNoch keine Bewertungen

- Lecture 14: Numerical Application: Solving Differential EquationsDokument9 SeitenLecture 14: Numerical Application: Solving Differential EquationsSholpan SholpsNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ELEMENTARY SCHOOL: No. of Days Level of UnderstandingDokument4 SeitenELEMENTARY SCHOOL: No. of Days Level of Understandingnorvel_19Noch keine Bewertungen

- Sol 42Dokument4 SeitenSol 42Gautham ShankarNoch keine Bewertungen

- Algebra Page Page 1-51-4Dokument49 SeitenAlgebra Page Page 1-51-4Ayush AhlawatNoch keine Bewertungen

- Statistics and Probability: Quarter 3 - Module 6: Central Limit TheoremDokument17 SeitenStatistics and Probability: Quarter 3 - Module 6: Central Limit TheoremYdzel Jay Dela TorreNoch keine Bewertungen

- Math Reviewer - AlgebraDokument9 SeitenMath Reviewer - AlgebraCristina Aquino-SajoniaNoch keine Bewertungen

- An Efficient Implementation of The RectaDokument10 SeitenAn Efficient Implementation of The RectaEthrigan DaemonicusNoch keine Bewertungen

- Math Unit One AssesmentDokument24 SeitenMath Unit One AssesmentArsalan Sajjad100% (2)

- 311 MergedDokument133 Seiten311 Mergedytty37290Noch keine Bewertungen

- Continuum MechanicsDokument1 SeiteContinuum MechanicsmurarivNoch keine Bewertungen

- Modeling Utah Population Data Math 1010 Project 1Dokument3 SeitenModeling Utah Population Data Math 1010 Project 1api-238079916Noch keine Bewertungen

- MAT1016 Applied-Discrete-Mathematical-Structures TH 1 AC40Dokument2 SeitenMAT1016 Applied-Discrete-Mathematical-Structures TH 1 AC40Karan DesaiNoch keine Bewertungen

- Class-12 Matrix WorksheetDokument3 SeitenClass-12 Matrix WorksheetHemant ChaudharyNoch keine Bewertungen

- 11 Maths Notes 04 Principle of Mathematical InductionDokument4 Seiten11 Maths Notes 04 Principle of Mathematical InductionAnudeex ShettyNoch keine Bewertungen

- Linear ProgrammingDokument20 SeitenLinear ProgrammingRamirez Mark IreneaNoch keine Bewertungen

- CFD t2 AssignmentDokument11 SeitenCFD t2 AssignmentShashank GuptaNoch keine Bewertungen

- Special Maths Contest 2022 First Round ProblemsDokument6 SeitenSpecial Maths Contest 2022 First Round Problemsdaramolaabraham16Noch keine Bewertungen

- Vedic Mathematics TutorialsDokument13 SeitenVedic Mathematics Tutorialsapi-3707902Noch keine Bewertungen

- Maa BookDokument3 SeitenMaa BookSrijan VermaNoch keine Bewertungen

- Time Domain Representation of Linear Time Invariant (LTI) SystemsDokument54 SeitenTime Domain Representation of Linear Time Invariant (LTI) SystemsJazmi MukhtarNoch keine Bewertungen

- Math Practise Paper X For XBDokument7 SeitenMath Practise Paper X For XBRAJ SHEKHARNoch keine Bewertungen

- Finite Element Analysis of Thin-Walled Structures-Dr John W. Bull - CRC Press (1988)Dokument264 SeitenFinite Element Analysis of Thin-Walled Structures-Dr John W. Bull - CRC Press (1988)Anonymous 1rLNlqUNoch keine Bewertungen

- Lambert 2018Dokument115 SeitenLambert 2018Jamsranjav EnkhbayarNoch keine Bewertungen

- 10 Final Humanit 4Dokument4 Seiten10 Final Humanit 4iisteNoch keine Bewertungen

- Binomial DistributionDokument5 SeitenBinomial DistributionGopalsamy SelvaduraiNoch keine Bewertungen

- Questions On Liapunov's Stability AnalysisDokument9 SeitenQuestions On Liapunov's Stability Analysiskibrom atsbha50% (2)

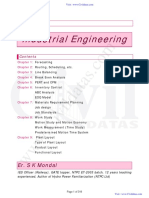

- Industrial Engineering by S K Mondal T&Q 12 PDFDokument318 SeitenIndustrial Engineering by S K Mondal T&Q 12 PDFmanas batraNoch keine Bewertungen

- Circular Functions PDFDokument2 SeitenCircular Functions PDFShane RajapakshaNoch keine Bewertungen

- Maths Today 4 RedDokument258 SeitenMaths Today 4 Redadmire matariranoNoch keine Bewertungen

- Lecture10 BclemmaDokument4 SeitenLecture10 BclemmaNancy NayakNoch keine Bewertungen

- Mathematical SymbolsDokument27 SeitenMathematical SymbolsErica JoyceNoch keine Bewertungen