Beruflich Dokumente

Kultur Dokumente

© SRAM Corporation - September 2003 PN 95.4308.627.000, Rev. B

Hochgeladen von

farkasdanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

© SRAM Corporation - September 2003 PN 95.4308.627.000, Rev. B

Hochgeladen von

farkasdanCopyright:

Verfügbare Formate

For exploded diagram and part number information, refer to the Spare Parts Catalog available on our website

at www.rockshox.com. Contact your local distributor or visit the RockShox website at www.rockshox.com for ordering information. Information contained in this publication is subject to change at anytime without prior notice. For the latest technical information, visit our website at www.rockshox.com. Names used in this manual may be trademarks or registered trademarks of others. SRAM Corporation September 2003 PN 95.4308.627.000, Rev. B

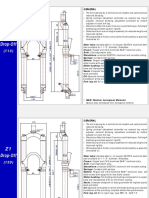

2 0 0 2 J U DY S L & X C S E R V I C E G U I D E

2002-2004 Judy SL & XC Service Guide

TOOLS NEEDED

Sft Gass aey lse 24mm 6-point Socket PatcFcdMle lsi ae alt Biodegradable Solvent RockShox 5 wt. Oil Shock Pump Football-style pump needle 5mm Hex W rench 1"ln,1 daee sf bitebtl buh 2 og " imtr ot rsl ote rs Ln,clnrclrd og yidia o To q e W rench ru

After every 100 hours of riding, or less depending on riding conditions and riding style, the following service should be performed. This service should be performed by a qualified mechanic, using proper tools.

R E M O V E S P R I N G S TA C K

HINT: RIGHT AND LEFT IS DETERMINED FROM THE RIDERS PERSPECTIVE.

1A

1. Remove the air cap from the left side of the fork (fig. 1A). Insert a lightly lubricated football-style pump needle into the air valve and remove the air from the Air Assist chamber

INSERTION INTO THE RUBBER AIR VALVE. DAMAGED IF THE NEEDLE IS INSERTED DRY. THE

IMPORTANT:

THE

FOOTBALL NEEDLE MUST BE LUBRICATED BEFORE

THE

AIR VALVE MAY BE

UPGRADE KIT AVAILABLE:

KITS ARE :

03-04

SCHRADER VALVE/ALUMINUM TOP

CAP ASSEMBLY IS COMPATIBLE WITH THE

11.4306.446.000 11.4306.446.001 (BLACK TOP CAP)

2002 JUDY XC/SL. AVAILABLE (SILVER TOP CAP ) AND

1B

2. Using a 24mm socket wrench, remove the top caps (part numbers: 11.4306.206.000 for non-adjust and 11.4306.446.000 or 11.4306.446.001 for air assist side).

16

SRAM Corporation 2002 JUDY SL & XC SERVICE GUIDE

2002-2004 Judy SL & XC Service Guide

3. Remove the spring guide and coil spring from the left side of the fork (coil spring/spacer kit 11.4306.208.000).

LOWER LEG REMOVAL

4. Judy SL Only: Gently pull downward to remove the rebound adjuster knob from the right shaft bolt (external rebound adjuster knob kit 11.4304.960.000).

5. Loosen shaft bolts five turns (fig. 5A) and tap firmly with a plastic faced mallet to separate the shafts from the lower tubes (fig. 5B). Keep a bucket nearby to catch the oil. Inspect the condition of removed oil. If the oil is opaque and/or milky (water contamination), the lower tube assembly should be cleaned. Remove the shaft bolts completely.

5A

5B

PN 95.4308.627.000, REV. B

17

2002-2004 Judy SL & XC Service Guide

6. Carefully slide the lower tube assembly off of the upper tubes. 7. Use a biodegradable solvent (Simple Green, Pedros, or equivalent) and a 12" long, 1 " diameter soft bristle bottle brush to clean the lower tube internals. Dry thoroughly.

REMOVAL

OF

DAMPER

AND

PLUNGER SHAFT

8. Using a long cylindrical rod, push the air assist plunger until the lower spring guide protrudes from the crown (Air Assist Plunger Assembly Kit 11.4306.207.000). Unthread the spring guide/plunger assembly until the rubber u-cup has passed the top cap threads.

NOTE: YOU

WILL NEED TO REPLACE THE U-CUP WITH THE IMPROVE ORING AIR SEAL UPON REINSTALLATION

8A

(11.4307.208.010).

9. Using the long cylindrical rod, push the damper assembly through and out the top of the upper tubes.

NOTE: USE

CARE NOT TO DAMAGE THE PISTON GLIDE RING!

8B

A L L T R AV E L S PA C E R C O N F I G U R AT I O N

10. Note the all travel spacer on the plunger and damper assembly. For 100 mm of travel, remove the all travel spacer from the damper shaft. Move the all travel spacer on the plunger assembly so that it sits between the spring and the plunger (see fig. 10).

All Travel Spacer

10

All Travel Spacer

80 mm Damper and Plunger Assembly

100 mm Damper and Plunger Assembly

18

SRAM Corporation 2002 JUDY SL & XC SERVICE GUIDE

2002-2004 Judy SL & XC Service Guide

DAMPER

AND

P L U N G E R S H A F T I N S TA L L AT I O N

Washers

11. Do not confuse the damper assembly with the air assist plunger assembly The damper assembly can be easily identified by the series of washers below the piston. 12. Install the damper assembly (right leg) and plunger assembly (left leg) through the top of the upper tubes.

REPLACE THE U-CUP. OF THE

11

IMPORTANT:

BEFORE INSTALLING THE PLUNGER DO NOT DAMAGE THE U-CUP UPPER TUBE.

ASSEMBLY, YOU MUST SEAL ON THE THREADS

Judy XC and SL Damper Assembly

13. Reinstall the spring (with spring guide) into the left side. Install the air assist and non-adjust top caps lightly by hand.

13

LO W E R T U B E I N S TA L L AT I O N

14. Slide the lower tube assembly onto the upper tube assembly until just before the lower bushing engages with the upper tube.

THE LOWER LEGS.

14

IMPORTANT: ENSURE

THE GREY DUST SEALS ARE PROPERLY SEATED IN

REFILL FLUIDS

15. Invert the fork and fill the left leg with 30 cc RockShox 10 wt. oil. Use 5 wt. oil for faster rebound or 15 wt. for slower rebound).

TUNING TIP: 30 cc 10 wt. oil YOU CAN USE A LIGHTER OR HEAVIER WEIGHT OIL TO ADJUST THE AMOUNT OF DAMPING.

15

16. Slide the lower tubes completely onto the upper tubes until the shaft fully engages the lower tubes. 17. Inspect the nylon crush washers for wear or damage and replace if necessary. 18. Judy SL: BEFORE installing the rebound adjuster knob into the hollow shaft bolt, insert the knob into the damper and turn the rebound valve to the full clockwise position. Then remove the knob. THIS PREVENTS DAMAGE TO THE PLASTIC REBOUND ASSEMBLY IN THE SHAFT.

PN 95.4308.627.000, REV. B 19

2002-2004 Judy SL & XC Service Guide

19. Using the spring to hold the plunger and damper shafts in place, install lower shaft bolts and torque to 60 in-lb. Judy SL: Firmly press the rebound adjuster knob into the right hollow shaft bolt.

19

60 in-lb

20. Turn the fork right-side up. Extend the fork and fill the right upper tube (fig. 20A) with 160 cc RockShox 10 wt. oil (5 or 15 wt. optional). Then pour 10 cc 10 wt. oil into the left upper tube (fig. 20B). Cycle the fork to circulate the oil through the damper.

ADJUST THE AMOUNT OF DAMPING.

20A

TUNING TIP:

YOU

CAN USE A LIGHTER OR HEAVIER WEIGHT OIL TO

160 cc 5 wt. oil

20B

10 cc 5 wt. oil

COIL SPRING

AND

TO P C A P I N S TA L L AT I O N

21. Reinstall the top caps using a 24 mm socket wrench. Torque the top caps to 40 in-lb.

21

40 in-lb

20

SRAM Corporation 2002 JUDY SL & XC SERVICE GUIDE

2002-2004 Judy SL & XC Service Guide

AIR PRESSURE

22. Rubber Air Valve: Lubricate football needle and insert pump into rubber air valve. Add the recommended air pressure (see Air Pressure Guidelines"). Carefully remove the football needle and re-install the air cap. Schrader Valve: Thread pump valve onto schrader valve and add the recommended air pressure. AIR PRESSURE GUIDELINES

Rider W e g t ( b A r Pre s re ih l) i su

<140 (63 kg) 140-160 (63-72 kg) 160-180 (72-81 kg) 180-200 (81-90 kg) >220 (99 kg) 05pi - s 51 pi -0 s 1-5pi 01 s 1-0pi 52 s

22

PN 95.4308.627.000, REV. B

21

Das könnte Ihnen auch gefallen

- GM Engines v-6, V-8Dokument23 SeitenGM Engines v-6, V-8jads301179Noch keine Bewertungen

- SU InstructionsDokument8 SeitenSU InstructionsSiddeNoch keine Bewertungen

- NA-R4B InstructionsDokument8 SeitenNA-R4B Instructionsone-eyed fat manNoch keine Bewertungen

- Manual Polaris XP TurboDokument429 SeitenManual Polaris XP Turbogaraldnemef100% (1)

- 99924-2093-03 FR730V FS730V FX730V English EbookDokument177 Seiten99924-2093-03 FR730V FS730V FX730V English EbookNHEL UMALINoch keine Bewertungen

- LinkedIn's Series B Pitch To Greylock - Pitch Advice For EntrepreneursDokument49 SeitenLinkedIn's Series B Pitch To Greylock - Pitch Advice For EntrepreneursfarkasdanNoch keine Bewertungen

- Remove & Install Boom CylindersDokument10 SeitenRemove & Install Boom CylinderschanlinNoch keine Bewertungen

- Suzuki GSX R 400 GK73A 1988 1989 Manual de Reparatie WWW - Manualedereparatie.infoDokument248 SeitenSuzuki GSX R 400 GK73A 1988 1989 Manual de Reparatie WWW - Manualedereparatie.infoLolok Tiviyanto100% (3)

- PLANO ELECTRICO Cat - Dcs.sis - Controller.Dokument4 SeitenPLANO ELECTRICO Cat - Dcs.sis - Controller.ctorres_505746Noch keine Bewertungen

- 1971 Johnson 60HP Outboards Service Manual PDFDokument5 Seiten1971 Johnson 60HP Outboards Service Manual PDFChrisStainton0% (1)

- CP150 SMDokument50 SeitenCP150 SMjacklyn ade putra100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- 50cc Scooter ManualDokument0 Seiten50cc Scooter ManualMarcelo FerreiraNoch keine Bewertungen

- Acura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6Dokument200 SeitenAcura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6CandieApple100% (1)

- Remove & Install Bucket CylinderDokument8 SeitenRemove & Install Bucket CylinderchanlinNoch keine Bewertungen

- Ac Compressor ServicingDokument25 SeitenAc Compressor ServicingffyddNoch keine Bewertungen

- EX1200-6 Operational PrincipleDokument301 SeitenEX1200-6 Operational Principleaarizal75% (4)

- Keyblanks GuideDokument36 SeitenKeyblanks GuidefarkasdanNoch keine Bewertungen

- The Art of KnowingDokument14 SeitenThe Art of KnowingfarkasdanNoch keine Bewertungen

- Manitou MT940-MT1740 HydraulicDokument234 SeitenManitou MT940-MT1740 HydraulicVeselina Gaidarska91% (22)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- TOYOTA 1CD-FTV D4D Engine FuelDokument27 SeitenTOYOTA 1CD-FTV D4D Engine FuelLuis Daniel Cortes100% (16)

- Husqvarna 611238238782 - 61Dokument6 SeitenHusqvarna 611238238782 - 61Mauro OliveiraNoch keine Bewertungen

- WH R924 G5.0-D IIIA 1444-1445 42836 2019-12-19 en PDFDokument292 SeitenWH R924 G5.0-D IIIA 1444-1445 42836 2019-12-19 en PDFJakub Daněk100% (1)

- Heavy-Duty Gas Turbine T16Dokument13 SeitenHeavy-Duty Gas Turbine T16Zafar AhmedNoch keine Bewertungen

- SEO Onpage Cheat SheetDokument3 SeitenSEO Onpage Cheat SheetfarkasdanNoch keine Bewertungen

- Harley Davidson 250 and 350 SprintDokument8 SeitenHarley Davidson 250 and 350 SprintElan Mutt Schwartz75% (4)

- Single Line Hose Reels: Nstallation InstructionsDokument12 SeitenSingle Line Hose Reels: Nstallation InstructionsLuisYaguiNoch keine Bewertungen

- Single Cylinder Air Compressor Repair ManualDokument13 SeitenSingle Cylinder Air Compressor Repair ManualGLNoch keine Bewertungen

- CAMERON France S.A.S: Front SheetDokument24 SeitenCAMERON France S.A.S: Front SheetkrishnsgkNoch keine Bewertungen

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDokument39 SeitenTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Part AprilDokument235 SeitenPart AprilElisa WibowoNoch keine Bewertungen

- EM35MR1 Electric Powered Actuator and 3103 Gas Valve: Installation and Operation ManualDokument42 SeitenEM35MR1 Electric Powered Actuator and 3103 Gas Valve: Installation and Operation Manualjorge lopezNoch keine Bewertungen

- Esquema Hidraulico ManitouDokument26 SeitenEsquema Hidraulico Manitouctorres_505746Noch keine Bewertungen

- 02 04DukeAirServiceGuide PDFDokument7 Seiten02 04DukeAirServiceGuide PDFgeert janNoch keine Bewertungen

- 03-04 Duke SL Air and Uturn Service GuideDokument11 Seiten03-04 Duke SL Air and Uturn Service Guidepaul7203Noch keine Bewertungen

- 2005 RockShox WartungshandbuchDokument99 Seiten2005 RockShox Wartungshandbuchpsagnes3142Noch keine Bewertungen

- Panther Dowty ForksDokument9 SeitenPanther Dowty ForksThunderbird3100% (1)

- 03-04 SID Rear Service Guide - Rev - BDokument5 Seiten03-04 SID Rear Service Guide - Rev - Bmaxpower2004Noch keine Bewertungen

- Duke XC SL Race ServiceDokument10 SeitenDuke XC SL Race ServicesilverapeNoch keine Bewertungen

- Brake System Volvo 1990 240/740/760Dokument13 SeitenBrake System Volvo 1990 240/740/760George_Karinsky100% (1)

- Recon Service GuideDokument12 SeitenRecon Service GuideJuho KauppinenNoch keine Bewertungen

- SM47013 PDFDokument8 SeitenSM47013 PDFHENKO7659Noch keine Bewertungen

- Power Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDDokument8 SeitenPower Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDCarlos VillaltaNoch keine Bewertungen

- CB IGH 5 SachsDokument6 SeitenCB IGH 5 SachsBoka LeventeNoch keine Bewertungen

- Rock Shox Judy Service Guide Rev - A PDFDokument9 SeitenRock Shox Judy Service Guide Rev - A PDFee1993Noch keine Bewertungen

- Assembly Compression AirDokument3 SeitenAssembly Compression Airaqshal candraNoch keine Bewertungen

- Tora Probe 1Dokument21 SeitenTora Probe 1Maik NormalNoch keine Bewertungen

- Fury 20 HST Technical ManualDokument8 SeitenFury 20 HST Technical ManualAlejandro ChavarriaNoch keine Bewertungen

- Peec II - Peec III Brake Engine 10 P OkDokument10 SeitenPeec II - Peec III Brake Engine 10 P OkEduardo AlvarezNoch keine Bewertungen

- Article Engine Cylinder Block DisassemblyDokument17 SeitenArticle Engine Cylinder Block Disassembly94738183Noch keine Bewertungen

- R065E2Dokument7 SeitenR065E2Mk MakyNoch keine Bewertungen

- DV100 SMDokument51 SeitenDV100 SMjacklyn ade putraNoch keine Bewertungen

- Hydraulic Brake Booster Installation LC 200Dokument17 SeitenHydraulic Brake Booster Installation LC 200Yannick de WalqueNoch keine Bewertungen

- Ac Compressor ServicingDokument25 SeitenAc Compressor ServicingAnimemanuel MuñozNoch keine Bewertungen

- A/C Compressor Servicing: Please Read This FirstDokument22 SeitenA/C Compressor Servicing: Please Read This FirstbaylorguyNoch keine Bewertungen

- Lathe - Spindle - Replacement - RemovalDokument3 SeitenLathe - Spindle - Replacement - RemovalAriel MercochaNoch keine Bewertungen

- Eng 5.4-97Dokument25 SeitenEng 5.4-97Alexey KolmakovNoch keine Bewertungen

- DAKE Press Model 75 H - 907003Dokument6 SeitenDAKE Press Model 75 H - 907003mark_dayNoch keine Bewertungen

- Procedure For Removing Main Bearing of MAN B&W MC-C EngineDokument16 SeitenProcedure For Removing Main Bearing of MAN B&W MC-C EngineSuhas KassaNoch keine Bewertungen

- 18SP607 - Series 60 Egr Ddec V Fuel Pump, Combination Pressure Regulator / Check Valve, and N3 Injector O-Ring and Washer KitDokument7 Seiten18SP607 - Series 60 Egr Ddec V Fuel Pump, Combination Pressure Regulator / Check Valve, and N3 Injector O-Ring and Washer KitaraceliluciojimenezNoch keine Bewertungen

- Gruppe 150 enDokument28 SeitenGruppe 150 enMarco MaximilianoNoch keine Bewertungen

- Seac Sub AssoDokument6 SeitenSeac Sub Assobeard007Noch keine Bewertungen

- Dodge Ram A/C Compressor ClutchDokument7 SeitenDodge Ram A/C Compressor ClutchKkbhuvan KkNoch keine Bewertungen

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDokument10 SeitenOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiNoch keine Bewertungen

- Instructions and Parts List For Model 50H Hand-Operated Hydraulic PressDokument6 SeitenInstructions and Parts List For Model 50H Hand-Operated Hydraulic PressWaqar DarNoch keine Bewertungen

- Installation Manual Serial 4000 HW - Tuf-Lite IIDokument8 SeitenInstallation Manual Serial 4000 HW - Tuf-Lite IIAnonymous LBwADkNZHNoch keine Bewertungen

- SB388CDokument13 SeitenSB388CBenjamin LeedsNoch keine Bewertungen

- Marzocchi 01 Z1 - Dropoff ManualDokument18 SeitenMarzocchi 01 Z1 - Dropoff ManualHarry James BoundenNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Validation Board TemplateDokument1 SeiteValidation Board TemplatefarkasdanNoch keine Bewertungen

- Red Bull Success StoryDokument13 SeitenRed Bull Success StoryfarkasdanNoch keine Bewertungen

- Accounting For Developers 101Dokument7 SeitenAccounting For Developers 101farkasdanNoch keine Bewertungen

- Forrester Study On MobileDokument27 SeitenForrester Study On MobilefarkasdanNoch keine Bewertungen

- Brochure XGMA PDFDokument8 SeitenBrochure XGMA PDFJohn JohnNoch keine Bewertungen

- F46 615 FirePak F4600 HSC 2000usgpm SubmittalDokument2 SeitenF46 615 FirePak F4600 HSC 2000usgpm Submittalsergix zNoch keine Bewertungen

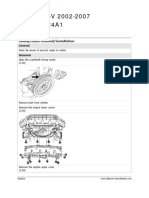

- Honda CR-V 2002-2007 2.4 16v K24A1: Timing Chain: Removal/installationDokument25 SeitenHonda CR-V 2002-2007 2.4 16v K24A1: Timing Chain: Removal/installationGuillermo BenitezNoch keine Bewertungen

- Ece370 Power & Energy Systems Homework Set 7 - SolutionsDokument7 SeitenEce370 Power & Energy Systems Homework Set 7 - Solutionsusman yimerNoch keine Bewertungen

- Continental Aerospace Technologies, IncDokument9 SeitenContinental Aerospace Technologies, IncVictor FernandezNoch keine Bewertungen

- Service Manual Series F12: Effective: June, 2006 Supersedes: August, 2003Dokument20 SeitenService Manual Series F12: Effective: June, 2006 Supersedes: August, 2003Ricardo SoaresNoch keine Bewertungen

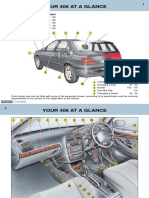

- 2003 Peugeot 406 Break 65020Dokument177 Seiten2003 Peugeot 406 Break 65020Jimmy AlemanNoch keine Bewertungen

- Bill of Quantity (Boq) For Electrical Works Bogapuram BranchDokument7 SeitenBill of Quantity (Boq) For Electrical Works Bogapuram BranchAye Myat KhaingNoch keine Bewertungen

- EWDLEWML Servo Motor DriverDokument14 SeitenEWDLEWML Servo Motor DriverWaleed LemsilkhiNoch keine Bewertungen

- Jet Kit InstallDokument2 SeitenJet Kit InstallmihaisimoNoch keine Bewertungen

- Allegra X-12, X-15R Section 3Dokument22 SeitenAllegra X-12, X-15R Section 3fibmetNoch keine Bewertungen

- Carmix en 5.5XL PDFDokument1 SeiteCarmix en 5.5XL PDFkarijosephNoch keine Bewertungen

- Service Manual: T4.85 / T4.95 / T4.105 / T4.115 With Hi-Lo Transmission With Mechanical or Power Shuttle TransmissionDokument81 SeitenService Manual: T4.85 / T4.95 / T4.105 / T4.115 With Hi-Lo Transmission With Mechanical or Power Shuttle TransmissionBruno MorelliNoch keine Bewertungen

- Angle Encoder & Mounting Kit Mounting Guide: MAN DieselDokument14 SeitenAngle Encoder & Mounting Kit Mounting Guide: MAN DieselŞansal DikmenerNoch keine Bewertungen

- Tad572ve enDokument2 SeitenTad572ve enPakito-sanNoch keine Bewertungen

- 2004 Model T Ignition and TimingDokument5 Seiten2004 Model T Ignition and Timingjorge Angel LopeNoch keine Bewertungen

- Updated Register of Licensed Electrical ContractorsDokument63 SeitenUpdated Register of Licensed Electrical ContractorsmachariakaruriNoch keine Bewertungen

- Pneumatic Roller: Ready For Heavy-Duty RoadworkDokument2 SeitenPneumatic Roller: Ready For Heavy-Duty RoadworkTaufiq AkbarNoch keine Bewertungen

- DC Motors and GeneratorsDokument14 SeitenDC Motors and GeneratorsPantheia DadpouNoch keine Bewertungen

- 37, 41, 42MT SSL Solenoids PDFDokument4 Seiten37, 41, 42MT SSL Solenoids PDFjuanNoch keine Bewertungen

- 1995 1996 Blazer Fuse BoxDokument4 Seiten1995 1996 Blazer Fuse BoxFrancisco MataNoch keine Bewertungen

- Industrial Robot CNC Equipment Arm Tooling Toolholder Grippers Milling BitsDokument8 SeitenIndustrial Robot CNC Equipment Arm Tooling Toolholder Grippers Milling BitsSalce SmithNoch keine Bewertungen