Beruflich Dokumente

Kultur Dokumente

Dam Types

Hochgeladen von

Hitesh ParghiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dam Types

Hochgeladen von

Hitesh ParghiCopyright:

Verfügbare Formate

International Journal of Science & Technology Volume 3, No 2, 173-189, 2008

Influences on Selection of the Type of Dam

M. Emin EMIROGLU

Firat University, Faculty of Engineering, Civil Eng. Dept. Elazig, TURKIYE

(Received: 07.05.2007 ; Accepted: 28.07.2008)

Abstract: Heuristics and empirical knowledge from experts are vital parts of any water resources planning

process. The selection of the type of dam requires a significant amount of empirical input from experts and specialists in the form of heuristic rules, expert opinions and inferences, and rules of thumb. Only very small percentage of such knowledge is well documented in the literature. It is also difficult to obtain all of the relevant knowledge related to the selection of the type of dam at the same time. The objective of this study is to discuss the factors influencing the selection of the type of dam by giving examples from rules of thumb and also to present typical cross sections for types of dams to be constructed on different foundations.

Baraj Tip Seimine Tesir Eden Faktrler zet: Uzmanlardan edinilen meslek kurallar ve tecrbeye dayal bilgiler, su kaynaklar planlama srecinde

hayati nem tamaktadr. Baraj tip seiminde uzmanlardan alnan tecrbelerle edinilmi bilgiler, uzman fikirleri ve meslek kurallar olduka nemlidir. Bu tr tecrbeye dayal bilgilerin ok az bir ksm literature gemitir. Baraj tipi seimine karar verirken her zaman tecrbeli mhendislerle almak veya onlara her zaman ulamak mmkn olmamaktadr. Bu almann amac baraj tip seimiyle ilgili tecrbelere dayal ok deerli meslek kurallarn literatre aktarmak ve farkl baraj temelleri zerine hangi baraj tip enkesitlerinin seilebileceini mhendislerin kullanmna sunmaktr.

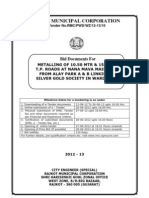

1. Introduction During the early stages of planning and design, the selection of the site and the type of dam should be carefully considered. It is only in exceptional cases that an experienced engineer can say that only one type of dam is suitable for a given dam site. Except in cases where the selection of type is obvious, it will be found that preliminary designs will be required for several types of dams before it can be shown which is the best solution from the standpoint of direct costs and all other factors. It is, therefore, important to emphasize that the project is likely to be expensive unless decisions regarding selection of the type are based upon adequate study after consultation with competent engineers. The selection of the best type of dam for a particular site calls for thorough consideration of the characteristics of each type, as related to physical features of the site and the adaptation to the purposes the dam is supposed to serve, as well as safety, economy, and other pertinent limitations. The final choice of type of dam is made after consideration of these factors. In this study, factors affecting the selection of the type of dam and the dam types to be constructed on the different foundations were discussed according to experiences. 2. Dam Types The dam types known at present are as follows [1]: Embankment Dams

Homogeneous earthfill dam Earthfill with toe drain dam Zoned earthfill dam Earthfill with horizontal drain dam Earthfill with vertical and horizontal drains dam Earth and rockfill, central core dam (CCRD) Earth and sand-gravel, central core dam Earth and rockfill, inclined core dam (ICRD) Concrete face rockfill dam (CFRD) Bituminous concrete face earth and rockfill dam Steel face rockfill dam Thin membrane face earth and rockfill dam

M. Emin Emiroglu

Concrete Gravity Dams

Lean roller compacted concrete (RCC) dam Medium-paste RCC dam High-paste content RCC dam The faced symmetrical hardfill dam (FSHD) Roller compacted dam (RCD) Conventional concrete gravity dam (CCD) Prestressed dam

Arch Dams

Thin arch dam Conventional concrete arch gravity dam RCC arch gravity dam Cupola (double-curvature arch) dam

Buttressed Dams

Flat slab buttress dam Round-head buttress dam Diamond head buttress dam Decked buttress dam Multiple arch dam

mean settlement problems for core type dams and it might be better to construct some type of concrete dam (e.g. RCC). One of the primary factors in determining the suitability of a site for an arch dam is the width-toheight ratio. Ideally, the ratio should be relatively small (4 or less) for the use of thin arch dam. The V-shaped dam site are, generally, more favorable to the design of an acceptable arc dam than are U-shaped dam sites. Although not often a controlling factor in the selection of the type of dam, a symmetrical or nearby symmetrical dam site is desirable for an arc dam. Another dam type (e.g. CFRD) may prove to be a more economical structure if the dam site is extremely asymmetrical.

Valley Shape. Gorge. Narrow V-shaped. Wide V-shaped. Narrow U-shaped. Wide U-shaped. Wide valley. Quite wide valley. Valley with irregular cross-sections. Simplicity of constructing a road to the dam site. The existence of deep gorges with extremely steep abutment walls and the difficulty of transport of earth material to dam site. The possibility of valley to transport earthfill material in every level. Changes in valley cross section. The condition of the river in plan (curve or flat). Local changes in slope of the abutments. Gradient of abutments of the valley. Bottom width of the valley.

3. Factors Affecting the Selection of the Type of Dam Topography Topographic considerations include the surface configuration of the dam site and of the reservoir area and accessibility to the and to construction materials. Topography, in large measure, dictates the first choice of the type of the dam. A few examples are given below related to this issue: The curve of the river in plan, and changes in valley cross section, may favor adoption of an upstream sloping core rather than central core to reduce the quantities of earthfill. Local changes in slope of the abutments may lead to differential settlement and cracking, necessitating more extensive filter drains, or favoring CFRD construction. A narrow stream flowing between high, rocky walls would naturally suggest a concrete overflow dam. The low, rolling plains field would, with equal fitness, suggest an earthfill dam with a separate spillway. Earthfill dams have been constructed in almost every conceivable type of topography but are generally not used where deep gorges with extremely steep abutment walls are present. Broad valleys lead to central core dams. Steep canyon walls at the dam site can

174

Geotechnical and geological structure of the dam site Foundation conditions depend upon the geological character and thickness of the strata which are to carry the weight of the dam, their inclination, permeability, and relation to underlying strata, existing faults, and fissures. The foundation will limit the choice of type to a certain extent, although such limitations can frequently be modified, considering the height of

Influences on Selection of the Type of Dam

the proposed dam. For example, a foundation of competent rock is essential for any arch dam. The rock should be sound and durable to provide a satisfactory foundation for the life of the structure. Another of example of this issue, if a high dam is being considered, compressive strength of the foundation is an important

consideration in the selection of the type of dam. In cases where the river section of a wide valley provides a competent rock foundation close to the surface and the overburden increases towards either or both abutments, composite dams (concrete dam + embankment dam) can be selected.

Foundation type. Rock. Alluvium. Gravel. Silt and fine sand. Clay. Non uniform (lithologies). Condition of the bearing capacity of the foundation of rock. Very good (>7 MPa) Good (4 to 7 MPa) Medium (2 to 4 MPa) Low (1 to 2 MPa) Very low (<1 MPa) Condition of the bearing capacity of the foundation of alluvium. Good (>600 kPa) Medium ( 200 kPa to 600 kPa) Low (<200 kPa) Condition of the bearing capacity of the foundation of gravel. Good (>600 kPa) Medium ( 200 kPa to 600 kPa) Low (<200 kPa) Condition of the bearing capacity of the foundation of silt or fine sand. Good (>300 kPa) Medium ( 100 kPa to 300 kPa) Low (<100 kPa) Condition of the bearing capacity of the foundation of clay. Very good (300-600 kPa) Good (150-300 kPa) Medium (75-150 kPa) Low (<75 kPa) Shearing resistance of the foundation materials. The existence of the wedge or block failures. Condition of necessity of the foundation grouting. Very low (0.0 to 12.5 kg/m) Low (12.5 to 25.0 kg/m) Moderately low (25 to 50.0 kg/m) Moderately high (50 to 100 kg/m) High (100 to 200 kg/m) Very high (>400 kg/m) Modulus of elasticity of the rock foundation. Good (>3.40 GPa) Medium (2 to 3.40 GPa) Low (1 to 2 GPa) Very low (<1 GPa) Modulus of elasticity of the non-rock foundation. 175

M. Emin Emiroglu

The existence of deeply weathered rock at higher levels of the dam site. Condition of the permeability of the foundation. Stability of the abutments. Safety of the abutments of valley. The presence of instability on the left or right abutment due to large triangular wedge blocks dipping steeply towards the river. The existence of joint patterns in an abutment (their orientation, inclination and filled with clay or silt etc.). The existence of badly fractured rock in abutments. Presence of differential deformation of the foundation along the axis of the dam. Bedrock depth below stream channel. The possible landslide or rock slide areas at the dam site. Compressibility of the foundation. The nominal value of hydraulic gradient, for seepage under a dam varies by at least one order of magnitude according to type. The association between the dam height and the alluvium depth. Depth of the alluvium more than the dam height. Depth of the alluvium approximately near the dam height. Depth of alluvium approximately half of the dam height. Depth of the alluvium much less than half of the dam height. Condition of the relative density of the sand-gravel foundations. Very loose (0-15) Loose (15-35) Medium dense (35-65) Dense (65-85) Very dense (85-100)

Availability of construction material Elimination or reduction of transportation expense for construction materials, particularly those which are used in great quantity, will affect a considerable reduction in the total cost of the project. Therefore, sometimes the most economical type of dam is the one for which acceptable construction materials exist within a relatively short distance from the site. The whole question of suitable construction materials and reasonable haul distance is one of economics, and the selection of type of dam is usually based upon economy. A few examples are given below related to this issue: An abutment supply of a single material points to the use of a homogeneous dam. Sufficient quantities of both previous and impervious materials lead to the use of zoned dams. If the local supply of aggregate is not adequate or the distance cement must be transported from the source is long, concrete gravity dam should not be selected. Instead of the dam type, CFRD can be selected.

The haul distances and costs of transportation of suitable materials to the dam site. The availability of suitable earthfill within economic haul distance. Quantity and quality of available materials. The uniformity of the available earthfill. The existence of material in thin bed formal and despoliation very large area of beautiful land or in adequate thickness. Groundwater level of the borrow area. Usability of the excavated material in dam. 176

Influences on Selection of the Type of Dam

The quantities and properties of the materials from the required excavation for the spillway, foundation cutoff trench, outlet works and other appurtenant structures. Supply of materials. Cost of the expropriation of the material in the borrow area. Soils for embankments. Rock for embankments and riprap. Sandy clay, clayey sand and gravel-sand-clay soils. Concrete agregate (sand, gravel, crushed stone). Cementitious materials Portland cement Flyash Ground fines Calcined clay Limestone fines Ground granulated blast furnace slag

Spillway size and location The spillway is a vital appurtenance of a dam. Frequently its size and type and the natural restrictions in its location will be the controlling factors in the choice of the type of dam. For example, the cost of constructing a large spillway is frequently a considerable portion of the total cost the project. In such cases, combining the spillway and dam into one structure should be desirable, indicating the adoption of a concrete overflow dam. Another of example of this issue, if topographic conditions or spillway capacity requirements are such that the spillway cannot be located away from the dam, an overflow spillway can be provided over the buttresses.

Magnitudes of the floods to be bypassed. The presence or absence of suitable sites for spillway. The presence of large spillway for required capacity and devotion of a major part of the dam for the spillway. The existence in unstable abutments for spillway excavation.

Uruguay River in Southern Brazil. Two types of dam (ICRD and CFRD) were compared with respect to cost. Cost of the CFRD was 43.416 x 106 $ and cost of the ICRD was 49.383 x 106 $. Therefore, the CFRD was selected [12]. Another of example of this issue, four dam types were considered in detail by the design engineers for Monksville dam in the USA. Cost of RCC was 18.1 x 106 $, cost of earthfill was 20.3 x 106 $, cost of CFRD was 25.6 x 106 $, and cost of CCD was 33.6 x 106 $. Therefore, RCC was selected [2].

Estimates of cost for dam alternatives.

Environment and public opinion Environmental considerations have very important in the design of dams. These factors can have a major influence on the type of dam constructed. The principal influence of the environmental laws and regulations on selection of a specific dam type is the need to consider maximum protection for the environment which can affect the type of dam, its dimensions, locations, location of spillway and appurtenant facilities. For example, if the dam is large and central core rockfill dam is the cheapest dam type and core material is available only in thin beds and to obtain sufficient will be despoiled a very large area of beautiful land, in this case, public opinion can have a major role in the adoption of a thin arch dam instead of rockfill dam despite difficulties with the foundations.

177

Cost After safety and fulfillment of the purpose for which the project is designed, cost is usually the most important factor in the selection of the type of dam. For example, Ita dam is located on

M. Emin Emiroglu

The possibility of flood inundation during construction The possibility of inundation by floods during construction may favor a concrete dam. For example; it is important to mention the behavior of RCC dams in the case of overtopping. During the construction of the Santa Eugenia dam, two floods occurred which exceeded the capacity of the river diversion outlet; these overtopped the dam during its construction with significant flow volumes. The concrete placed did not sustain any damage, but the machinery at the site was washed away [3]. The economical condition of the country The amount of production of cement, pozzolan and steel, parallel to the industrial development of a country, can be effective on the selection of the type of dam. For example, if there is a lack of the steel, then buttress dam should not be selected

The supply of manufactured material such as cementitious materials, steel, asphalt in the country. The possibility of the application of new technology by contractors in the country.

lesser time by continuing to place rockfill in the wet season. Another example of this issue, If constructing a dam on a permeable soil foundation, cutoff may be achieved by a cutoff wall at the upstream toe rather than a rolled earth cutoff under the central core, so that the cutoff wall can be constructed at the same time as the rest embankment. The mean annual precipitation;

Excessively rainy (>1000 mm) Rainy (500 to 1000 mm) Semiarid (200 to 500 mm) Arid (< 200 mm)

Non availability of side personnel with particular skills At many sites neither skilled contractors nor artisans are available. This can preclude the adoption of dams that require intricate formwork or very high-quality concrete. The embankment type of dam or a masonry gravity dam may then prove most suitable. Seismicity Although many dams have failed throughout history, very few of these failures resulted from earthquakes, and none involved major concrete dams. However, the earthquake-induced damage to the Koyna Dam, near Poona, India, in 1967 and the Hsinfengkiang Dam, near Canton, People's Republic of China, in 1962 indicated that concrete dams not immune to earthquake damage as had commonly been presumed [5]. Because millions of people live in the floodplains downstream of these dams, it is essentials that increasing attention be given to the selection of the type of dam of these structures. Height of the dam Height of the dam is an important factor for the selection of the type of the dam. For example, earthfill with toe drain has been used for larger dams in the past, but should be limited to low (say less than 10 m) dams in low hazard locations. Heights of the dam suggested according to experience are given below.

178

Climate and construction

time

available

for

The design of a dam is often considerably affected by climate, mainly because of the importance of the weather during the construction period. It is difficult to construct earthfill embankments during wet weather, or in freezing temperatures [4]. In these cases, it is often advantageous to adopt CFRD or ICRD. In very arid areas there may be a shortage of water for construction, therefore, favoring CFRD than earthfill dam. For the design and construction of the most satisfactory and economical dam, an adequate amount of time is required. For example, the time available for construction may influence dam type selection, particularly, if considered in relation to other factors such as climate, in a climate of well defined wet and dry seasons it may be practicable to construct an earth and rockfill or earthfill dam, but only two dry seasons. A CFRD may be constructed in

Influences on Selection of the Type of Dam

Homogeneous earthfill dam, less than 5 m Earthfill with toe drain dam, less than 10 m Zoned earth fill dam, less than 20 m Earthfill with horizontal drain dam, less than 10m Earthfill with vertical and horizontal drains dam, less than 50 m Earth and rockfill, central core dam, very high, but bigger than 15 to 20 m. Earth and sand-gravel, central core dam, less than 140 m. Earth and rockfill, sloping core dam, very high but higher than 15 to 20 m. Concrete face rockfill dam (CFRD), very high but higher than 20 m. Bituminous concrete face earth and rockfill dam, less than 50 m. Steel face rockfill dam, less than 40 m. Thin membrane face earth and rockfill dam, less than 30 m. Lean roller compacted concrete (RCC) dam, very high or very low Medium-paste RCC dam, very high or very low High-paste content RCC dam, very high or very low The faced symmetrical hardfill dam (FSHD), very high or very low Roller compacted dam (RCD), very high or very low Conventional concrete gravity dam, very high or very low Cupola (double-curvature arch) dam, high or very high Thin arch dam, very high or very low Arch gravity dam, very high or very low Multiple arch dam, very high or very low Flat slab buttress dam, very high or very low Round-head buttress dam, very high or very low

of a few hours to obtain "peaking" power. For dams constructed to retain reservoirs of such specialized types, especially conservative slopes and zonings for the upstream embankment portions are often justified. The reservoir fluctuation condition;

>1-2 0.5 to 1 0.125 to 0.5 m/ hour 0.060 to 0.125 0.015 to 0.060 0.0125 to 0.015 <0.0125 m/hour m/ hour m/ hour m/ hour m/ hour m/ hour

Rapidity of construction Foundation treatment and zoning details may also be influenced by the time available for construction. A CFRD dam may be constructed in lesser time by continuing to place rockfill in the wet season. The very rapid rate of placement of RCC has many advantages; e.g. it can allow a relatively high dam to be constructed in one dry season, and thus reduce requirements of the diversion works [6]. The time of placement of RCC dams is very short. For example, Stagecoach dam, 46 m high with RCC volume of 34 000 m3, was built in little more than 37 days. Another example of this issue, Galeswille dam, 51 m high and 161 000 m3, was built in ten weeks. Intended use of water in reservoir and benefit-cost relation Consideration of the purpose a dam is to serve often suggests the type most suitable. The tolerable seepage loss for some domestic water supply projects may be very low. For flood control dams, on the other hand, there is no economic limitation on the maximum quantity of leakage. Few sites exist where a safe and serviceable dam could not be build. But in many instances, conditions inherent in the site result in a project cost in excess of the justifiable expenditure. The results of a search for desirable dam sites often determine whether a project can be built at a cost consistent with the benefits to be derived from it.

179

Function of the reservoir Depending on the use planned for the reservoir, different designs may be justified at a given site. The reservoir function determines in part the tolerable loss of water due to leakage through and under the dam. It also determines the reservoir hydrograph which influences the dam stability. At some reservoirs the water level is never lowered and the upstream slope never subjected to "rapid drawdown" conditions. At the other extreme, the reservoirs for some hydroelectric power installations are kept full for long periods of time and then lowered in a span

M. Emin Emiroglu

Staged construction condition It is often economic to construct a dam in two or more stages. In water supply, irrigation or hydropower projects, demand in the early years can be met with a lower dam and smaller storage. If staging is planned, this favors adoption of CFRD or ICRD. Knowledge and courage of the engineers Safety, construction feasibility, adaptability of type features, cost, and existing conditions, such as climate, geology, availability of materials, and topography, are thoroughly evaluated to assist in making a type choice. However, except in the rare cases where site conditions preclude consideration of more than one type, the choice depends to a certain extent on individual preferences which reflect the judgment and experience of the designer. Contracts, standards, and decisions for every country conservative

Safety Safety, of course, is the first consideration. It is impossible to build with safety some types of dams if certain foundations and other characteristics of the site exist. Consideration of these factors will often decrease considerably the number of possible types from which to choose. Probable wave action An earth dam must be protected from damage caused by the erosive action of waves beating on the upstream slope. The severity of the wave action and amount of protection needed for the embankment are related to the length of the reservoir surface over which the wind velocities in the locality. Probable ice action Ice load is usually important only for small dams. Ice load can be important in circumstances where ice sheets form to appreciable thicknesses and persist for lengthy periods. In such situations ice pressures may generate a considerable horizontal thrust near crest level. The pressure exerted on the dam is complex function of ice thickness, scale and rate of temperature rise resulting in expansion, and the degree of restraint existing at the perimeter of the ice sheet. Foundation excavation Economic considerations dictate that the excavation volume should be minimized. Whether the water intakes structures to be passed through the dam In some cases, passing through the dam of water intake structures may be necessary. This case may influence the selection of the type of dam. Discharge of the river Narrow valleys, good foundations, and large stream flows tend to favor the selection of concrete dams, whereas wide valleys, poor foundations, and small stream flows tend to favor embankment dams.

180

Conservative designs may be advisable for dams in parts of the world where experienced contractors and supervisory personnel are not available. Even in the United States, earth dams constructed by U.S. Bureau of Reclamation just after World II, when no dams had been built for a long period, were provided with somewhat flatter slopes than usual, mainly because it was feared that the personnel would not have the skill necessary to produce embankment of high quality. Simplicity of river diversion All construction considerations contribute to the selection of type. Certain features, such as relative simplicity of diversion, may favor the selection of a concrete gravity dam. Diversion can be made over low blocks or through permanent or temporary sluices. Forming is simple. To these advantages may be added the fact that the dam can be designed for overtopping during construction without serious damage. These factors affect the construction schedule and thereby the cost.

Influences on Selection of the Type of Dam

The design flood peak flow;

Very large (>10 000 m3/s) Large (7 500 to 10 000 m3/s) Medium (2 000 to 7 500 m3/s) Little (500 to 2 000 m3/s) Fairly little (<500 m3/s)

In dry climates where lack of water may prevent the use of earth core material a diaphragm type rockfill dam can be used. For large rivers, this item is relatively unimportant except for quality of the water. For small streams and offstream reservoirs, water for construction purposes may be difficult to obtain. Appearance Appearance does not usually influence the selection of the type of dam. After the choice is made, every effort is made to achieve a pleasing appearance. 4. Typical Cross Sections for Types of Dams to be Constructed on Different Foundations Rock Foundation A strong low permeability rock foundation is suited to any type of dam construction, but may favor construction of a CFRD, RCC or in particular circumstances arch dam. The economy of materials or the overall cost should be the ruling factor. The removal of disintegrated rock together with the sealing of seams and fractures by grouting is frequently necessary. Karst limestone foundations are a special case, where extensive grouting and other work may be needed to limit leakage to acceptable level. Such situations favor adoption of a design, which allows for grouting to continue during embankment construction or after it is completed. This may tend to favor CFRD or ICRD. Weaker rocks such as clay shales, some sandstones, weathered basalt, etc., may present significant problems to the design and construction of a dam and may heavily influence the type of dam selected. In some sedimentary rocks, particularly interbedded weak claystone and mudstone, and strong sandstone, which have been subject to folding and/or faulting, bedding plane shears may exist, resulting in low affective friction angles. In these circumstances, flat slopes may be required on the embankment, favoring earthfill with vertical and horizontal drains. Cross sections belong to dam types to be constructed on the rock foundations are given in Fig. 1. These cross sections were developed according to experiences.

181

The effects of aggressive water on dams The reservoir water may include the dissolved chemicals (e.g. acids) that might be harmful for concrete. This case may influence the selection of the type of dam. The water difference between headwater and tailwater The water difference between headwater and tailwater is important for the concrete gravity dam. Most foundation materials are acceptable for consideration of a gravity dam under 15 m in height and with a difference between headwater and tailwater less than 6 m. The effects of uplift force under the dam The uplift pressure is a major factor in gravity dam. Buttress dams have an advantage over solid gravity dams where uplift pressures are concerned. The hydrostatic pressure or uplift at the base of the dam is relieved between the buttresses and the small remaining uplift pressure on the buttresses does not materially affect the stability of the structure. Danger of war and sabotage The dam sites where is danger of war and sabotage are chosen more resistant dam types. For example, buttressed dams are more subject to damage or destruction by sabotage or military attack than massive dams. Because of the thinness of their members they are sensitive to even moderate deterioration of the concrete; hence they must be carefully built and careful consideration must be given to any unusual exposure conditions. Lack of water for construction

M. Emin Emiroglu

Alluvium Foundation

For the wide valley and deep overburden, an earthfill dam is usually the best solution. The embankment dam base is so wide that the load-bearing capacity is seldom a problem except in the case of soft clays. Alluvial foundation mean seepage problems will be present and their permeability and depth can mean changes in the earthfill type used. If special cutoffs are used, a definite type can be suggested depending on the cutoff location.

Nonrock foundation such as silt, sand, gravel and clay may be acceptable for RCC dam, CCD, and FSHD at low heights of dam. It is suggested by experts that gravity dams less than 20 m height can be constructed on alluvium foundations. The Lower Chase Creek, Cedar Falls and Dryden dams, RCC dams, constructed in USA was located in a valley where the foundation was alluvium [7]. The foundation geology at a dam site often dictates the type of dam suitable for that site. Unlike arch, high-gravity, and buttress dams, which require a sound rock foundation, embankment dams are readily adapted to earth foundations. Therefore, it can be said that earthfill dam can be constructed on the alluvium foundations. It is possible to construct on alluvium foundation an earth and sand-gravel, central core dam that is 140 m height. It is possible to show as examples for earthfill dams constructed on alluvium foundations BorAkkaya Dam in Turkey; Rose Valley Dam in Canada; Duncan Lake Dam in Canada; Kennewick Levee, McNary Dam in USA; Wanapum Dam in USA and Mangla Closure Dam in Pakistan [8, 9 and 10]. There are necessity rock foundations for rockfill dams. If the foundation is alluvium, expert human due to excessive settlement does not suggest it using of large rocks in shell. In this case, sand-gravel material is used as shell material. Santa Juana dam can be shown as an example for above conclusion. Santa Juana dam was a rockfill concrete face on the Huasco River in the northern Chile. Santa Juana dam was founded on 30 m deep clean gravel-cobble alluvium. The

182

Santa Juana dam is 103 m high, with a crest length of 400 m [11]. Cross sections belong to dam types to be constructed on the alluvium foundations are given in Fig. 2. Clay Foundation Sites with thick deposits of soft and compressible soil generally have been avoided in the past, but as time passes and the better sites are gradually built upon, sites with soft foundations must be used with increasing frequency. However, there are not easy or economical methods to deal with soft clay foundations. Foundations of fine-grained soils are usually impermeable enough to preclude the necessity of providing design features for under seepage and piping. However, inclined and horizontal filterdrainage blankets provide good protection against unknown geologic conditions, cracking, dispersive soils, and design and construction defects. The main problem with these foundations is stability. In addition to the obvious danger of bearing failure of foundations of saturated silts and clays, the designs must take into account the effect of foundation saturation of the dam and of appurtenant works by the reservoir. Soil foundations should have strength properties equal to or greater than that of the embankment. The entire area to be occupied by the dam should stripped to a sufficient depth to remove all unsuitable materials, including surface boulders, loose rock, debris, topsoil, and vegetation, that might interfere with the paper bonding of the embankment with the foundation. So, a stiffer foundation should be achieved. A good drainage should be achieved for protecting the embankment soil from saturation, and facilitates the dissipation of pore water pressures from beneath the embankment, thus allowing the consolidation of the soft foundation soils. As consolidation occurs, the shear strength of the foundation is increased, resulting in an increase in the factor of safety against bearing capacity failure. Clay foundations can be used for the support of earthfill dams but require special treatment. If the foundation material is weaker than the earthfill, the critical slip surface would generally pass

Influences on Selection of the Type of Dam

through the foundation. Therefore, to maintain equilibrium, designers extend the slip surface using flatter slopes or toe berms. Since there may be considerable settlement of the dam if the clay is unconsolidated and the moisture content is high, clay foundations ordinarily are not suitable for the construction of concrete gravity dams, should not be used for CCRD, ICRD, CFRD, bituminous concrete face earth and rockfill dam, steel face rockfill dam. Clay foundations are acceptable for consideration of a gravity dam under 15 m in height and with a difference between headwater and tailwater less than 6 m. Foundations for rockfill dams must be capable of resisting settlement and deformation. Sand drains are useful for clay foundations. In addition to this, staged construction of the embankment with pore pressure monitoring could be adopted. Cross sections belong to dam types to be constructed on the clay foundations are given in Fig. 3. These cross sections were developed according to experiences. Silt or Fine Foundation Arc dams are suited to narrow gorges, subject to uniform sound rock of high strength and limited deformability in foundation and abutments. Concrete gravity dams are suited to wide valleys, provided that excavation depth is less than 5 10 m. Buttress dams are suited as gravity dams, but higher contact stresses require sound rock. Rockfill dams are constructed on the rock foundations. Therefore, dam types above mentioned are not suitable for silt or fine sand foundations. However, this foundation type is acceptable for consideration of a gravity dam under 15 m in height and with a difference between headwater and tailwater less than 6 m and introducing necessary foundation treatment. Silt or fine sand foundations are suitable for the construction of earthfill dams. But, foundation treatment is necessity. Cross sections belong to dam types to be constructed on the silt or fine sand foundations are given in Fig. 4.

Non Uniform Foundation Occasionally, situations may occur where reasonably uniform foundations of any of the foregoing descriptions cannot be found and where a non uniform foundation of rock and soft material must be used if the dam is to be built. Such unsatisfactory conditions can often be overcome by special design features. Each site, however, presents a problem for appropriate treatment by experienced engineers. Only one dam or composite dam can be constructed on the non uniform foundations. Composite dam use the advantages of both the embankment dam and the concrete dam. They generally consist of concrete gravity (conventional or rcc) or buttress sections in combination with earthfill or rockfill sections. The concrete dam portion incorporates the ability to pass flood flows over or through the section during construction and act as the spillway after construction, and the earth or rockfill sections take advantage of flow cost construction and local materials. Except for the hydraulic considerations mentioned above topography is the main reason for the selection of a composite dam. The topography for combination dams is usually associated with plains locations or zone of land where plains and mountains meet, but seldom with mountains terrain itself. Wide valleys often provide favorable sites for the use of combination dams. Foundation conditions are the second most important factor in selecting a combination type dam. In cases where the river section of a wide valley provides a competent rock foundation close to the surface and overburden increases toward either or both abutments, composite dam can be economical. If a combination concrete-embankment structure is being considered, the concrete portion must have a foundation of acceptable quality. Cross sections belong to dam types to be constructed on the non uniform foundations are given in Fig. 5.

183

M. Emin Emiroglu

R

Water level Riprap Earthfill Chimney drain

S

Water level

Water level Riprap Coffer dam

ra in D

Earthfill Clay

Earthfill

Riprap Earthfill General excavation level Grout curtain Water level Random Eartfill Cut off level Chimney drain Earthfill General excavation level Rock slope protection Internal sand drain

Grout curtain Water level Riprap

Cut off level General excavation level Internal sand drain Water level

Grout curtain

Cut off level

Chimney drain Earthfill

Riprap Drain Earthfill General excavation level

Water level Riprap

Riprap

Cut off level

General excavation level Grout curtain

Cut off level Water level

General excavation level

Cut off level

Water level Riprap Coffer dam

Rockfill

Rolled clay core

Rockfill Rockfill General excavation level Grout curtain

Thin clay core

Rockfill

Steel plate m 1

m Compacted gravel and stone Gravel and rock General Cut off level excavation level Grout curtain

Earthfill

General excavation level Grout curtain

Cut off level

Cut off level

Parapet wall Concrete face

Asphaltic concrete impervious membrane

fin es

Spillway crest

ve ra ng ea Cl

Rockfill

Grout curtain Water level

Grout curtain

m 1 CCD (Convensional concrete dam) m=0.75 + -

Water level Thin membran (thickness 0.2 mm to 2 m)

Gr

Non-cohesive fines

Non-cohesive fines Rockfill

av el w

Concrete facing RCC (Roller compacted concrete)

ith

Concrete facing

Rockfill Rockfill

Water level Sand and gravel Drain Cut off level Grout curtain Grout curtain

General excavation level

(FSHD) The faced symmetrical hardfill dam

Water level Riprap Earthfill Horizontal drain

Cut off level General excavation level

Water level Riprap Earthfill

Water level

Riprap Earthfill

Toe drain

Grout curtain

Grout curtain Water level Riprap

General Cut off level excavation level

Grout curtain

Cut off level General excavation level

Water level Riprap

d Ran

Water level

Ra nd om

Rockfill

Clay

Rockfill General excavation level

Rockfill

Grout curtain

Rockfill

General excavation level

Thin Arc Dam

Grout curtain

Cut off level

Water level Water level Convensional concrete (Arc Gravity Dam) Decked buttress

Cl ay

om

Cut off level

Water level

Flat slab buttress

Water level Riprap

ill

Water level Riprap Asphalt or concrete Rockfill General excavation level Rockfill Riprap

ellan Misc fill eous

Pit run gravelly sand

Core Material Washed gravelly sand

ckf Ro

Quarry fines

Rockfill Grout curtain

Miscella neous Rockfill fill

Weak rock foundation Water level Massive buttress: Diamond head

Water level

Water level Cupola or doublecurvatura arc

Water level Massive buttress: Roundhead m 1 m=0.8 - 1.0

Water level RCC Arc Gravity Dam m 1 m=0.8 - 1.0

Multiple arch or multiple cupola

Top gallery Max tailwater level Lower gallery

Pulvino

Fig. 1. Some cross-sections of dams to be constructed on rock foundations 184

Influences on Selection of the Type of Dam

A

Water level Riprap Earthfill Chimney drain

Water level Riprap Drain Earthfill

Water level Riprap Earthfill

Random eartfill

. . . .. . . . . .. . . . . ..... . . . . .. Alluvium.... . .... . . . ... . . .

.. . ...... ... . .... .. . . . . . off . . . ... .Cut.. wall... . . .

. .. .. . . . . . . . .. . . ... . . . . . .Alluvium. ... . . . . .Cut. .wall ... . off . ... .. . . . . . . . . .. . . .. . .

Bedrock

. .. . .. . . . .. . ....Alluvium . .. . . .. . . . ... . .. . .... . .

Bedrock

Filter

. .. ... . . ..Alluvium. . . . . ...... . .. . . .

Grout curtain

Bedrock

Water level Riprap Chimney drain Earthfill

Internal sand drain

Water level Riprap Blanket Drain Earthfill

Water level Riprap Blanket Chimney drain Earthfill Rock slope protection Internal sand drain

. . . .. . .. . .. . . . . .Alluvium. .... . . ... .. . .

Bedrock

. . . . . .. . . .. ....... . ..... .

. . . . . . . . . .. . . . .. ... . . ..... . . . . . . . .. . . ... . . Alluvium . . ... . . .. ...... . .... . . . . . . . .. . . .. . . .. .

Bedrock

Grout curtain

.. . . . . . . . . .. . . . .. . .. .. . . .. .. .. . .. . . ... .... .. . .... . . . . Alluvium . .. . . . . . . . . . . .. . . . .. . ... . .. . .

Bedrock

Water level Riprap Coffer dam Clay

Sand and gravel

Water level Riprap

Water level Steel plate

m

. . . . . .. ... . . .... . . .. . .. . . . .. . . . . ... . . . off wall . .. . . . .. .Alluvium .. . .... . .. .Cut.. . .. ... . . . .. . . .

Bedrock

Rolled clay core

Sand and gravel

Sand and gravel

Clay

. .. . . . .... . Alluvium. .. . . . . .. . .

Sand and gravel

Compacted gravel and stone Gravel and rock

. .. . . . . .. . . ..

Grout curtain

.. . . .. . . . .. . . . ... . .Cut.off wall. ..... . .. . . Alluvium. . . . . . . . . . . .. .

Bedrock

Parapet wall Concrete face

Asphaltic concrete impervious membrane

ng ea Cl es

Spillway crest Concrete facing RCC

(Roller compacted concrete)

el wi th

Concrete facing Reinforced concrete apron

fin

rav el

Non-cohesive fines

Gravel

Gravel and rock

Non-cohesive fines

Random gravel fill

Gravel and rock

Reinforced concrete apron

Gr av

Riprap

Plinth

. . . . . ... . . . . . . . . . . . .. . Alluvium . . . .. .. Conctere .. cut . ...... . . . .off . .. . . . . .. .. .... . . .. . . .

Gravel

. . . . .. . . . . . . . . . . . . . Conctere. . . . Alluvium . . . . . . .. . . .. . .cut off. . .... . .. . . . . . ... .. . .. . . . .

Gravel

. .. . . . . . . . .. . . . . . .. .. . . . . .. . . Gravel . . . . . . . .. . .Alluvium . . .. .. . . . . . . Drain pipe Getextile . ..

Sheet pile cutoff

Spillway crest

Water level Thin membran

(thickness 0.2 mm to 2 m)

Water level Sand and gravel Reinforced concrete apron (FSHD)

The faced symmetrical hardfill dam

Reinforced concrete apron

CCD

(Conventional concrete dam)

Reinforced concrete apron Riprap

. .. . .. . . . . . . .. . Alluvium . . . . . . . . .Gravel . Getextile . . .. . . . . . . .. .. . . .Drain pipe

Sheet pile cutoff

. .. . . . . . . . .. . . . . . . . . Alluvium . . . . .... Cut off wall ... . . . . .. . . . ... . . . .. . . . .

Bedrock

.. . . . . . . . . . . . . . .. . . .. . .. . . . . . .. ... . .. . . . Alluvium ... . . .. . . . . . . . . . . .

Sheet pile cutoff

Water level Riprap Earthfill

Horizontal drain

Water level Riprap Earthfill

Water level Riprap Earthfill Toe drain

. . . .. . . . .. . . . . ..... . . . . .. Alluvium.... . ... .. . . .. . . .

.. . ...... .. . .... .. ... . . . off . . .Cut.. wall. . . ... . . . . ..

. . . .. . . .. . . . . .... . . . . .. Alluvium.... . ... .. . . .. . . .

.. . . ...... .. . .... . .... . . off . . .Cut.. wall. . . ... . . . . ..

Bedrock

. . . .. . . .. . . . . .. . . . . . . ... . . . . . . . . . . off .. .. . . .. Alluvium.. . . ... . ...Cut.. wall. . . . . . . . ... . . . . .. .

Bedrock

Bedrock

Water level Riprap

nd om

Water level Riprap

Ran dom

Water level Riprap

Cl ay

and gravel . . . ... . . . . Alluvium . . . .. . .

Sand

Clay

. . .. . . . . . . . . .. . .. . .. .

Grout curtain

Sand and gravel

Ra

Sand and gravel

Blanket

Sand and gravel

.. . . . Alluvium . .

. . . . . . .. . . . . . . . .. .. . . . .. . .... .. .

Grout curtain Bedrock

Bedrock

. . . . . . . . . . . . . . . ... . . . . . . . . . ... . Slurry trench. . . .Alluvium. ... ... . . . . . . . ..

Bedrock

Fig. 2. Some cross-sections of dams to be constructed on alluvium foundations (Emiroglu, et al., 2002) 185

Cl ay

M. Emin Emiroglu

C L A Y

Miscellaneous fill

Water level Riprap Earthfill Chimney drain Clay

Miscellaneous fill

Water level Riprap Drain D<< H Shear key Bedrock Earthfill Clay

Miscellaneous fill

Water level Riprap Earthfill Random earthfill

Miscellaneous fill

D>>H

Vertical sand drain Bedrock Water level

D<< H

Clay Bedrock

Shear key

Water level Riprap Miscellaneous fill

Water level Riprap Earthfill (Staged construction) Clay Blanket drain Chimney drain Earthfill Internal sand drain

Chimney drain Earthfill

Internal sand drain Miscellaneous fill

Riprap

Clay

Blanket drain

Bedrock

Bedrock

Water level Riprap Coffer dam Clay Earthfill

Water level Riprap Clay Earthfill Earthfill Clay Clay Earthfill Water level Thin membran

(thickness 0.2 mm to 2 m)

Earthfill

Clay Bedrock Bedrock Spillway crest Water level Concrete facing Earthfill RCC Clay

Clay

Horizontal drain

Bedrock

Water level

Water level Riprap

Concrete facing

CCD

Earthfill

Clay Bedrock Bedrock Water level Riprap Earthfill Toe drain Earthfill Clay Water level Riprap

nd om

Cl

ay

Clay Bedrock Water level

d Ran

Ra

Clay

Earthfill

FSHD

om

Clay Clay Bedrock Bedrock Bedrock Water level Water level CC Riprap Earthfill

Water level Riprap Earthfill D<< H Asphalt core wall Earthfill Drain Clay Bedrock Clay Shear Key RCD or RCC

Stabilizing fill

Stabilizing fill

Clay

D>>H

Bedrock

D: Clay Foundation Depth H: Dam Height CCD: Convensional concrete dam RCC: Roller compacted concrete RCD: Roller compacted dam CC: Convensional concrete Note: CCD, RCC and FSHD can be constructed on the clay foundation if height of dam is low. Note: Shear key can be constructed if the clay foundation depth is low. Note: Vertical sand drains can be constructed if the clay foundation depth is very high.

Water level Riprap Concrete core wall

Earthfill

Clay fill

Clay fill

Earthfill Horizontal drain Shear Key Clay Bedrock

D<< H

Fig. 3. Some cross-sections of dams to be constructed on clay foundations 186

Influences on Selection of the Type of Dam

S I L T

O R

F I N E

S A N D

F O U N D A T I O N

Water level Riprap Earthfill Chimney drain Silt or fine sand

Water level

Water level

Drain

Riprap

Earthfill

Riprap Eartfill Random Earthfill Silt or fine sand

Silt or fine sand

Water level Water level Riprap Water level

Chimney drain Internal sand drain

Riprap

Drain

Riprap Earthfill Silt or fine sand

Chimney drain Earthfill Silt or fine sand

Rock slope protection Internal sand drain

Earthfill Silt or fine sand

Water level Riprap

Coffer dam Clay Earthfill

Water level Riprap Clay

Earthfill

Water level Thin membran Clay Earthfill

(thickness 0.2 mm to 2 m)

Earthfill

Earthfill Silt or fine sand

Silt or fine sand

Silt or fine sand

Water level Water level Riprap CCD Silt or fine sand Silt or fine sand Earthfill

Spillway crest Concrete facing RCC Concrete facing

Silt or fine sand

Water level Water level Riprap Earthfill

Horizontal drain

Riprap Earthfill

Cl ay

Water level Earthfill FSHD

Silt or fine sand

Silt or fine sand Silt or fine sand

Water level Riprap

Ra nd om

CCD: Convensional concrete dam RCC: Roller compacted concrete dam

dom R an

Water level Riprap Earthfill Toe drain

Earthfill

Clay

FSHD: The faced symmetrical hardfill dam

Earthfill

Silt or fine sand

Note: CCD, RCC and FSHD can be consructed on the silt or fine foundation if height of dam is very low Note: Slopes for embankment dams must be very flat (e.g. 1 vertical and 7 horizontal)

Silt or fine sand

Fig. 4. Some cross-sections of dams to be constructed on silt or fine sand foundations 187

M. Emin Emiroglu

N O N

Water level Riprap Earthfill Chimney drain

U N I F O R M

Water level Riprap Drain

Earthfill Clay

Water level Riprap Earthfill General Cut off level excavation level Grout curtain Random Earthfill General excavation Cut off level level

Coffer dam

Earthfill

Grout curtain

General excavation Cut off level level

Grout curtain

Water level Riprap Chimney drain Earthfill Cut off level

Internal sand drain

Water level Riprap

Drain Earthfill

General excavation level

Water level Riprap Chimney drain Earthfill General excavation level Rock slope protection Internal sand drain

General excavation level Grout curtain

Cut off level

Cut off level

Water level Riprap Upsttream cofferdam Riprap

Clay Alluvium Upsttream cofferdam Riprap Clay Alluvium

Water level Riprap Pervious material Spillway excavation zone Alluvium Upsttream cofferdam Riprap Clay Rock foundation Sound rock foundation Grout curtain Grout curtain Rockfill

Water level Riprap

Semi - pervious material Clay core

Semi - pervious material

Rockfill Clay core Rockfill Crushed rock Alluvium Waste fill

Rockfill

Clay core

Rockfill Rockfill

Rock foundation Grout curtain

Sound rock foundation

Rock foundation

Parapet wall Concrete face

Asphaltic concrete impervious membrane

ea Cl

fin es

Spillway crest

Concrete facing

l ve ra ng

Non-cohesive fines

Rockfill

Non-cohesive fines

Rockfill

Gr av el

Concrete facing RCC

(Roller compacted concrete)

wi

th

Rockfill Rockfill

Grout curtain Grout curtain

Water level

Water level Thin membran

m 1 CCD (Convensional concrete dam) m=0.75

+ -

Water level Sand and gravel Drain FSHD (The faced symmetrical hardfill dam) Grout curtain

(thickness 0.2 mm to 2 m)

General excavation level

Cut off level

Grout curtain

Water level Riprap Earthfill

Horizontal drain

Water level Riprap Drainage boreholes Surcharging fill Alluvium Clay Random fill Water level Riprap Earthfill Toe drain

Grout curtain

Cut off level

Weak rock

Alluvium Grout curtain

Cut off level

General excavation level

Riprap Protective shell Riprap Upsttream cofferdam

Clay

Protective shell

Water level

Clay Waste fill Alluvium Sound rock foundation

Clay Pervious fill

uv ium

Random fill

Impervious fill Rockfill

Berm fill Clay Clay Clay

Rockfill

All

Clay

Sand gravel fill zone

ro ck

Alluvium

Clay

Rockfill zone

Alluvium

Sound rock foundation

Silty - sandy gravel Grout curtain

Rock foundation

Silty - sandy gravel

So un d

Weak rock

Weak rock

So

d ro un

ck

Weak rock

Water level Riprap

Water level Riprap

Water level Riprap

Random fill

Alluvium Grout curtain

Chimney drain Clay Fractured rock

Drain Random fill

Weak rock

Earthfill

Clay

Earthfill

Clean fine sand General excavation level

Cut off level

Sound rock

Alluvium

Water level Riprap

Riprap

Clay Alluvium Marn

Semi - pervious material

Rockfill Riprap Miscellaneous fill Pit run gravelly sand Rockfill Core Material Washed gravelly sand Quarry fines

Decomposed volcanic series

Rockfill

Miscellaneous fill

Grout curtain

Weak rock foundation

Fig. 5. Some cross-sections of dams to be constructed on non-uniform foundations 188

Influences on Selection of the Type of Dam

Conclusions There is one type of dam that, in combination with its spillway and other ancillary works, will produce the most economical development of a particular dam site. Many factors influence the selection of the type of dam. Before reaching a decision to select a dam type, of all the factors influencing the selection of a type of dam must be taken into account all together. The selection of the type of dam requires a significant amount of empirical input from experts and specialists. In this paper, a lot of rules of thumb and cross sections of dams for different foundations are presented. By considering of the rules of thumb, the designing engineer can reduce his/her change of error in selection of type of dam.

References

1. Emiroglu, M.E., Tuna, A., and Arslan, A., (2002). Development of an Expert System for Selection of Dam Type on Alluvium Foundations, Engineering with Computers, 18(1), pp 24-37. 2. Hansen K. D., (1994). Built in the USA-RCC dams of the 1990s. International Water Power & Dam Construction, April 1994, pp. 24-32. 3. Franco, M. A., and Cordova, J. Y., (1995). The Spanish approach to RCC dam engineering. The Int. Journal On Hydropower & Dams, Volume 2, pp. 72-79. 4. Fell, R., MacGregor, P., and Stapledon, D., (1992). Geotechnical engineering of embankment dams, A. A. Balkema / Rotterdam/ Brookfield. 5. Thomas, H. H., (1976). The Engineering of large dams. Jhon Wiley & Sons, London. 6. Dunstan, M.R.H., (1994). The state - of - the - art of RCC dams, The International Journal On Hydropower & Dams, March 1994, pp. 44-54. 7. Hansen, K.D., and Reinhardt, W.G. (1991). RollerCompacted Concrete Dams. McGraw-Hill, Inc., New York. 8. Jones, J. C. (1967). Deep cut offs in pervious alluvium, combining slurry trenches and grouting. Ninth Congress on Large Dams, vol. I, 509. 9. Design of small dams. (1987). Bureau of Reclamation, U.S. Govt., Printing Office, Denver, Colorado. 10. State Water Works, (1997). Dams and Hydroelectric Power Plants in TURKEY, General Directorate of State Hydraulic Works, Ankara. 11. Astete, J.; Martin, L. S., and Alvarez, L., (1992). The Santa Juana CFRD for irrigation in northern Chile. International Water Power & Dam Construction, April 1992. 12. Sobrinho, J. A. and da Cunha, J. C. (1985). It damselection of type. published in Concrete Face Rockfill Dams-Design, Construction and Performance, edited by J. B. Cooke, J. L. Sherard, ASCE, pp. 601-607.

189

Das könnte Ihnen auch gefallen

- Influences On Selection of The Type of DamDokument13 SeitenInfluences On Selection of The Type of DamDeybin RodriguezNoch keine Bewertungen

- Concrete Under Uniaxial CompressionDokument11 SeitenConcrete Under Uniaxial Compressionsreejithp1040% (1)

- (Joshaghani Et Al, 2015) Optimizing Pervious Concrete Pavement Mixture Design by Using The Taguchi MethodDokument9 Seiten(Joshaghani Et Al, 2015) Optimizing Pervious Concrete Pavement Mixture Design by Using The Taguchi MethodPSirotinNoch keine Bewertungen

- ECG353 Week 10 - 11 Chapter 4Dokument44 SeitenECG353 Week 10 - 11 Chapter 4Muhd MuqhreyNoch keine Bewertungen

- Permeability and SeepageDokument41 SeitenPermeability and SeepageJayakumar JanardhananNoch keine Bewertungen

- Application of Foamed ConcreteDokument5 SeitenApplication of Foamed ConcretesintayehuNoch keine Bewertungen

- Stone Columns PresentationDokument19 SeitenStone Columns PresentationDr Rajiv Kumar100% (1)

- Geotech 1 Lecture 2 StructureDokument38 SeitenGeotech 1 Lecture 2 StructureAli AsadNoch keine Bewertungen

- Micropiles Prospects & ChallengesDokument28 SeitenMicropiles Prospects & Challengesbarad1Noch keine Bewertungen

- CE-461 Doc MRKDokument143 SeitenCE-461 Doc MRKMahmoud I. Mahmoud100% (2)

- ICE Lecture #8 Geotechnical EngineeringDokument47 SeitenICE Lecture #8 Geotechnical Engineeringshahid aliNoch keine Bewertungen

- Rip Rap SummaryDokument79 SeitenRip Rap SummaryMarcoTacoNoch keine Bewertungen

- 13 Dewatering of FoundationsDokument65 Seiten13 Dewatering of FoundationsZahoor AhmadNoch keine Bewertungen

- FoundationDokument1 SeiteFoundationbagmassNoch keine Bewertungen

- Modelling the tensile behavior of plain concrete under flexural loadingDokument7 SeitenModelling the tensile behavior of plain concrete under flexural loadingAhmad MensaNoch keine Bewertungen

- Literature Review of Punching Shear in Reinforced Concrete Slabs FinalDokument93 SeitenLiterature Review of Punching Shear in Reinforced Concrete Slabs FinalTùng NguyễnNoch keine Bewertungen

- Waffle SlabDokument23 SeitenWaffle SlabAmgad TalalNoch keine Bewertungen

- Soil Mechanic and Foundation: Dr. KY SambathDokument26 SeitenSoil Mechanic and Foundation: Dr. KY SambathPhanith100% (1)

- CE-882 DEEP FOUNDATIONS: SOIL CLASSIFICATIONDokument86 SeitenCE-882 DEEP FOUNDATIONS: SOIL CLASSIFICATIONAmmar Ayub100% (2)

- Curved BeamsDokument14 SeitenCurved BeamsRajesh MaleyNoch keine Bewertungen

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Von EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Noch keine Bewertungen

- Lateral Response of Piled Raft Under Vertical LoadDokument9 SeitenLateral Response of Piled Raft Under Vertical LoadManojit SamantaNoch keine Bewertungen

- Construction Control of Earthfill DamsDokument101 SeitenConstruction Control of Earthfill DamsLatifa Haouech100% (1)

- Chapter 5Dokument28 SeitenChapter 5Jaswinder KaurNoch keine Bewertungen

- Expansive Soil-Causes and TreatmentsDokument11 SeitenExpansive Soil-Causes and TreatmentsBiswas UpretyNoch keine Bewertungen

- 01 - Civil Engineering Q A Self-Learning PDFDokument2 Seiten01 - Civil Engineering Q A Self-Learning PDFAbdur RahmanNoch keine Bewertungen

- Chapter (4 Retaining Wall)Dokument28 SeitenChapter (4 Retaining Wall)Henok YalewNoch keine Bewertungen

- Microsoft Word - CHAPTER 1 Sheet Pile Wall Final PDFDokument21 SeitenMicrosoft Word - CHAPTER 1 Sheet Pile Wall Final PDFhelen haileselassie100% (1)

- Pile Foundations - 2Dokument33 SeitenPile Foundations - 2Teo Peng KeatNoch keine Bewertungen

- ConcreteDokument31 SeitenConcreteShashank Patole100% (1)

- Retaining Wall Types NewDokument33 SeitenRetaining Wall Types NewIsbel100% (1)

- GroutingDokument15 SeitenGroutingDev Thakkar100% (1)

- Guide Geotechnical Investigation Elevated Water TankDokument9 SeitenGuide Geotechnical Investigation Elevated Water TankR Mani MuruganNoch keine Bewertungen

- PSC Lecture NotesDokument32 SeitenPSC Lecture NotesHaider Shah100% (1)

- ConsolidationDokument17 SeitenConsolidationthak49100% (1)

- Foundation of Structures 1Dokument25 SeitenFoundation of Structures 1A K100% (1)

- Lecture 01Dokument77 SeitenLecture 01shreekanth bapatNoch keine Bewertungen

- Natural Wood Fibres For Self Healing ConcreteDokument6 SeitenNatural Wood Fibres For Self Healing ConcretesubathraponniNoch keine Bewertungen

- Sub Grade PropertiesDokument76 SeitenSub Grade PropertiesSivakumar M100% (4)

- Foundation Design in High Rise PDFDokument20 SeitenFoundation Design in High Rise PDFAstha GoyalNoch keine Bewertungen

- Well Point Dewatering System ExplainedDokument15 SeitenWell Point Dewatering System ExplainedMostafa AbdellaNoch keine Bewertungen

- Pile Cap DesignDokument7 SeitenPile Cap DesignSaahasBhardwaj100% (1)

- Isolated Sloped Footing: Types, Uses, Advantages & DesignDokument79 SeitenIsolated Sloped Footing: Types, Uses, Advantages & DesignAnonymous PWdOlxYNoch keine Bewertungen

- Slope Protection PDFDokument88 SeitenSlope Protection PDFSandeep Kumar DangdaNoch keine Bewertungen

- WRD14 (545) P PDFDokument34 SeitenWRD14 (545) P PDFer.dksahoiNoch keine Bewertungen

- Lecture 4 Geotechnical Investigation PDFDokument55 SeitenLecture 4 Geotechnical Investigation PDFMalik ZainNoch keine Bewertungen

- Bridge investigation factorsDokument17 SeitenBridge investigation factorsJakka hitheshiniNoch keine Bewertungen

- 1.elements of Dam EngineeringDokument40 Seiten1.elements of Dam EngineeringIzet Mehmetaj100% (1)

- Design of Earth and Rockfill Dam - FinalDokument76 SeitenDesign of Earth and Rockfill Dam - FinalManasi Yadav100% (1)

- DamsDokument38 SeitenDamsmadangkNoch keine Bewertungen

- Geology's Role in Dam ConstructionDokument6 SeitenGeology's Role in Dam ConstructionLo LossNoch keine Bewertungen

- Prof. Sathish Kumar-Rockfill DamsDokument80 SeitenProf. Sathish Kumar-Rockfill DamsGAURAV KUMAR PATHAKNoch keine Bewertungen

- Tunnel and Road CuttingDokument20 SeitenTunnel and Road CuttingKaren DarilaNoch keine Bewertungen

- Study and Site Section of DAMDokument18 SeitenStudy and Site Section of DAMYuudai KaranNoch keine Bewertungen

- Chapter IDokument109 SeitenChapter IephremNoch keine Bewertungen

- Site Investigation and Laboratory TestingDokument14 SeitenSite Investigation and Laboratory Testinghiran peirisNoch keine Bewertungen

- EARTH DAMS - NewDokument30 SeitenEARTH DAMS - NewDr. Kiran YarrakulaNoch keine Bewertungen

- 202004120808040255gaurav Sriv Engg Geological InvestigationDokument17 Seiten202004120808040255gaurav Sriv Engg Geological InvestigationsekharNoch keine Bewertungen

- C.K.Pithawala College of Engineering & Technology: Site Assessment and Selection of Types of DamDokument35 SeitenC.K.Pithawala College of Engineering & Technology: Site Assessment and Selection of Types of DamAhmedNoch keine Bewertungen

- Onenote File GeologyDokument13 SeitenOnenote File GeologyAzeem KhanNoch keine Bewertungen

- Gen SC PSDokument2 SeitenGen SC PSHitesh ParghiNoch keine Bewertungen

- Abaqus Printed Document Jan 29 2015Dokument1 SeiteAbaqus Printed Document Jan 29 2015Hitesh ParghiNoch keine Bewertungen

- Printed Using Abaqus/CAE On: Sun Jan 04 18:17:53 India Standard Time 2015Dokument1 SeitePrinted Using Abaqus/CAE On: Sun Jan 04 18:17:53 India Standard Time 2015Hitesh ParghiNoch keine Bewertungen

- Behaviour of Bolted Joints of FRP Composite Laminated StructuresDokument4 SeitenBehaviour of Bolted Joints of FRP Composite Laminated StructuresHitesh ParghiNoch keine Bewertungen

- Project Report.....Dokument19 SeitenProject Report.....Hitesh Parghi100% (2)

- CheckDokument3 SeitenCheckHitesh ParghiNoch keine Bewertungen

- PlanDokument1 SeitePlanHitesh ParghiNoch keine Bewertungen

- Concrete Mix DesignDokument39 SeitenConcrete Mix DesignHitesh ParghiNoch keine Bewertungen

- Bolted Composite JointDokument28 SeitenBolted Composite JointHitesh Parghi50% (2)

- Finite Element BasicsDokument76 SeitenFinite Element Basicsletter_ashish4444Noch keine Bewertungen

- 875 - 3 Wind LoadDokument60 Seiten875 - 3 Wind LoadSandeep GuptaNoch keine Bewertungen

- RajkotDokument71 SeitenRajkotHitesh ParghiNoch keine Bewertungen

- Deposit Management: Prepared byDokument12 SeitenDeposit Management: Prepared byHitesh ParghiNoch keine Bewertungen

- DamDokument7 SeitenDamHitesh ParghiNoch keine Bewertungen

- 03a IGCSE Maths 4MB1 Paper 2R - January 2020 Examination PaperDokument32 Seiten03a IGCSE Maths 4MB1 Paper 2R - January 2020 Examination PaperMehwish ArifNoch keine Bewertungen

- Focal Points: Basic Optics, Chapter 4Dokument47 SeitenFocal Points: Basic Optics, Chapter 4PAM ALVARADONoch keine Bewertungen

- Clinical Microscopy ReviewerDokument31 SeitenClinical Microscopy ReviewerbokbokbokNoch keine Bewertungen

- Celda Carga - KIS-2BA - 5KNDokument4 SeitenCelda Carga - KIS-2BA - 5KNJosé TimanáNoch keine Bewertungen

- Is 15894-2018Dokument25 SeitenIs 15894-2018surender kumarNoch keine Bewertungen

- C - Brim - 1909 80 - QDokument40 SeitenC - Brim - 1909 80 - Qmanohar rathodNoch keine Bewertungen

- CN Lab ManualDokument49 SeitenCN Lab ManualKN DEEPSHI100% (1)

- Foundations On Friction Creep Piles in Soft ClaysDokument11 SeitenFoundations On Friction Creep Piles in Soft ClaysGhaith M. SalihNoch keine Bewertungen

- Module 6 The HypothesisDokument14 SeitenModule 6 The HypothesisJester Guballa de LeonNoch keine Bewertungen

- Kalman Filter Tutorial - PresentationDokument65 SeitenKalman Filter Tutorial - Presentationcarlazar100% (2)

- MOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doDokument2 SeitenMOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doĐặng Trung AnhNoch keine Bewertungen

- Standard Normal Distribution Table PDFDokument1 SeiteStandard Normal Distribution Table PDFWong Yan LiNoch keine Bewertungen

- Basic Concepts: ProbabilityDokument32 SeitenBasic Concepts: ProbabilityJhedzle Manuel BuenaluzNoch keine Bewertungen

- A Review On Promethee and Analytic Hierarchy Process With Its ApplicationDokument7 SeitenA Review On Promethee and Analytic Hierarchy Process With Its Applicationkherrouf YOUNESNoch keine Bewertungen

- CS250 LCD Keypad User Manual: GE InterlogixDokument32 SeitenCS250 LCD Keypad User Manual: GE InterlogixpttnpttnNoch keine Bewertungen

- Fire Strength Performance ofDokument3 SeitenFire Strength Performance ofMarimuthu KannimuthuNoch keine Bewertungen

- BUS STAT Chapter-3 Freq DistributionDokument5 SeitenBUS STAT Chapter-3 Freq DistributionolmezestNoch keine Bewertungen

- Lewis Structures and Shape of Molecules and HybridizationDokument12 SeitenLewis Structures and Shape of Molecules and HybridizationsanjuanaomiNoch keine Bewertungen

- Irfp4768Pbf: Application V 250V R 14.5M 17.5M I 93ADokument9 SeitenIrfp4768Pbf: Application V 250V R 14.5M 17.5M I 93AKrishna InamdarNoch keine Bewertungen

- Engineering Circuit Analysis 7th Edition: Chapter 17 SolutionDokument50 SeitenEngineering Circuit Analysis 7th Edition: Chapter 17 SolutionTaif ArifNoch keine Bewertungen

- 10th Geometrical ConstructionDokument2 Seiten10th Geometrical Constructionapi-242227794100% (1)

- Vitamins With Minerals Oral PowderDokument8 SeitenVitamins With Minerals Oral PowderWH PANDWNoch keine Bewertungen

- ROBERT_BECKER.BOM Wrapped Ref Des (Current Date, Sort by Item SeqDokument5 SeitenROBERT_BECKER.BOM Wrapped Ref Des (Current Date, Sort by Item SeqNAUBERTO F. DOS SANTOSNoch keine Bewertungen

- EE - Revision Through Question - GATE - 2020 PDFDokument138 SeitenEE - Revision Through Question - GATE - 2020 PDFRamesh KumarNoch keine Bewertungen

- Massive Transfusion ProtocolDokument2 SeitenMassive Transfusion ProtocolmukriNoch keine Bewertungen

- As Statistics Mechanics 1Dokument240 SeitenAs Statistics Mechanics 1claire zhouNoch keine Bewertungen

- Hadoop HiveDokument61 SeitenHadoop HivemustaqNoch keine Bewertungen

- Line Tension and Pole StrengthDokument34 SeitenLine Tension and Pole StrengthDon BunNoch keine Bewertungen

- Astrology, Believe It or Not - OCRDokument155 SeitenAstrology, Believe It or Not - OCRShashwat Singh Pokharel100% (2)