Beruflich Dokumente

Kultur Dokumente

PCPCH033 Belanak FPSO

Hochgeladen von

FAR_A_DAYOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PCPCH033 Belanak FPSO

Hochgeladen von

FAR_A_DAYCopyright:

Verfügbare Formate

Belanak FPSO

____________________________________________________________________________________________________________

Project

Balanak FPSO, West Natuna Field, Indonesia

______________________________________________________________________________

Location

Dalian New Shipbuilding Heavy Industries Ltd, P.R China

________________________________________________________________________ Client

Conoco Indonesia

________________________________________________________________________ Consultants

Halliburton Far East PTE Ltd.

________________________________________________________________________ Pipe system

Ameron Bondstrand series 7000M conductive pipe with Taper/ Taper adhesive bonded joints. Bondstrand series 2416C conductive fittings with Taper/ Taper adhesive bonded joints and Key Lock mechanical joints. Diameters 2 through to 16 (50 400mm). Total metres of Ameron Bondstrand GRE: 3500M

________________________________________________________________________ Operating Conditions

Operating pressure: 5.2 bar. Design pressure: 7.6 bar. Test pressure: 16 bar and 24bar. Operating temperature: 120F. Design temperature: 120F. Ambient temperature: 30C.

________________________________________________________________________ Design Life

30 Years

________________________________________________________________________ Scope of Work

Training of local workforce in Ameron Bondstrand handling and installation techniques. Pipex conducted all jointing of pressure critical systems and installation of all mechanical joints. Pipex specialist advisory role in GRE installation to Dalian New Shipyard and client. Inspection of all completed pipework systems with a ZERO testing failure rate. Pipex provided design assistance from UK based Halliburton offices, including GA & isometric production by Pipex Ltd, whereby Ameron BV (Holland) performed stress analysis of all pressure critical GRE pipe systems. Ameron PTE (Singapore) produced all spool drawings in batches for prefabrication of GRE pipework at their Singapore plant, and carried out 100% pre-testing of all materials prior to delivery to site according to client requirements and scheduling. Pipex handled all Project Management activities from the UK including all procurement activities.

____________________________________________________________________________________________________________

Bondstand GRE

- Ballast system 4, 6, 10, 12, 14. 5.2bar working

pressure, 16bar test pressure. - Seawater Cooling system 2 to 16. 5.2bar working pressure, 24bar test. - Inert gas tank purging system 8. Non-pressure system. - Tank sounding system 2. Non-pressure system. - Level protection system 4. Non-pressure system. - Inert gas cooling system 8, 10. 5.2bar working pressure, 24bar test pressure. - Inert gas deck seal system 3, 14. 5.2bar working pressure, 24bar test. - Slop tank dip pipe system 3, 6, 8, 10. Non-pressure system. - Mooring chain cooling system 2. Non-pressure system. - Incinerator quench system 6. Non-pressure system.

________________________________________________________________________

Any other information Pipex Advantages

The FPSO was built under the American Board of Shipping (ABS) classification. - Lightweight material = reduction in installation costs and duration. - Smooth internal bore - reduction in pumping costs - Corrosion resistant material = reduced through life cost - Bacteria resistant = reduced marine growth - Service life of 30 years = maintenance free Pipex was awarded the Gold Award for Supplier Excellence by Conoco Phillips for the project.

Award Winning

PCPCH033

Das könnte Ihnen auch gefallen

- Coastal Ocean Observing SystemsVon EverandCoastal Ocean Observing SystemsYonggang LiuNoch keine Bewertungen

- Send Perhitungan Ritase Driver 2018-08Dokument19 SeitenSend Perhitungan Ritase Driver 2018-08Asep KingNoch keine Bewertungen

- Bumi ArmadaDokument60 SeitenBumi Armadamanimaran75Noch keine Bewertungen

- Ship Shore Safety Check ListDokument3 SeitenShip Shore Safety Check ListRoberto StepicNoch keine Bewertungen

- Time Schedule Docking Project PDFDokument1 SeiteTime Schedule Docking Project PDFagus bahar27Noch keine Bewertungen

- Js Insight Gas Form CDokument64 SeitenJs Insight Gas Form CSomayajula SuryaramNoch keine Bewertungen

- China Floating Roof TanksDokument4 SeitenChina Floating Roof TanksjavadNoch keine Bewertungen

- Fpso Kakap Natuna - Modec Fpso - Fso ProjectDokument2 SeitenFpso Kakap Natuna - Modec Fpso - Fso ProjectjeffreymacaseroNoch keine Bewertungen

- Life Extension Methodology For Floating Production InstallationsDokument37 SeitenLife Extension Methodology For Floating Production InstallationsDinhQuangDatNoch keine Bewertungen

- Belanak FPSODokument6 SeitenBelanak FPSOabet133Noch keine Bewertungen

- Marine Offshore Safety Sign PDFDokument9 SeitenMarine Offshore Safety Sign PDFyoungfpNoch keine Bewertungen

- Waste Delivery Receipt Form For The Vessels Calling Romania's PortsDokument13 SeitenWaste Delivery Receipt Form For The Vessels Calling Romania's Portssuiramamid79Noch keine Bewertungen

- Pt. Megacipta Satria Mitsubishi Diesel Generator Load Test RecordDokument13 SeitenPt. Megacipta Satria Mitsubishi Diesel Generator Load Test Recordali sNoch keine Bewertungen

- Berth GuideDokument123 SeitenBerth Guidetaitommy100% (1)

- Form 8 PDFDokument96 SeitenForm 8 PDFDavid Nugroho100% (1)

- OIL CBM Brochure 2015Dokument3 SeitenOIL CBM Brochure 2015prasetyoNoch keine Bewertungen

- 2015 TTT Loading Master Program Oil Gas ChemicalsDokument6 Seiten2015 TTT Loading Master Program Oil Gas ChemicalstenggarayNoch keine Bewertungen

- Presentasi Kuliah Tamu SKK MigasDokument29 SeitenPresentasi Kuliah Tamu SKK MigasJohanna KusumaNoch keine Bewertungen

- Annual Report 2005Dokument132 SeitenAnnual Report 2005zackypragmaNoch keine Bewertungen

- Presentaion On HP Marine Loading Arm Control and Operating FunctionDokument36 SeitenPresentaion On HP Marine Loading Arm Control and Operating FunctionSushilNoch keine Bewertungen

- Java StarDokument1 SeiteJava StarSyaifudin Comunity Jupi'zNoch keine Bewertungen

- Dong-Kyu Choi PDFDokument33 SeitenDong-Kyu Choi PDFParthiban NagarajanNoch keine Bewertungen

- Mooring Master VacancyDokument2 SeitenMooring Master VacancyAnonymous UCveMQNoch keine Bewertungen

- Dacon Rescue Scoop Design GuidelinesDokument4 SeitenDacon Rescue Scoop Design GuidelinesJon LopezNoch keine Bewertungen

- Mooring OperationsDokument12 SeitenMooring OperationsVu NguyenNoch keine Bewertungen

- SRJ Apr May 2009Dokument92 SeitenSRJ Apr May 2009majdirossrossNoch keine Bewertungen

- Tanker LCC Operating ProceduresDokument37 SeitenTanker LCC Operating ProceduresCiocio CiohodaruNoch keine Bewertungen

- Appendix A - Sizing and Capacities of Gas PipingDokument4 SeitenAppendix A - Sizing and Capacities of Gas PipingTohid KarimiNoch keine Bewertungen

- PLN-E-02 Oil Spill Response Plan-20180901Dokument54 SeitenPLN-E-02 Oil Spill Response Plan-20180901muh_akbar2451100% (3)

- Angle of Deck Edge ImmersionDokument1 SeiteAngle of Deck Edge ImmersionyuniardimzNoch keine Bewertungen

- Project Plan Template in Excel FreeDokument2 SeitenProject Plan Template in Excel FreeSyahril SaharNoch keine Bewertungen

- Buku Saku SurveyorDokument1 SeiteBuku Saku SurveyorsalmatiahNoch keine Bewertungen

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDokument2 Seiten4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorenaNoch keine Bewertungen

- Work Schedule Cleaning TANKER - PT AKR NILAMDokument1 SeiteWork Schedule Cleaning TANKER - PT AKR NILAMnhariwijayaNoch keine Bewertungen

- Confined Space Entry Log Sheet 2019Dokument1 SeiteConfined Space Entry Log Sheet 2019Oneneo NeooneNoch keine Bewertungen

- Tank T-59 Crane Schedule Dated 18 Sep 2016Dokument1 SeiteTank T-59 Crane Schedule Dated 18 Sep 2016SUKhanNoch keine Bewertungen

- Presentasi Maritime DARMADIDokument11 SeitenPresentasi Maritime DARMADIashkisaragiNoch keine Bewertungen

- Shipyard PresentationDokument21 SeitenShipyard PresentationSyed Mubashir Ali H ShahNoch keine Bewertungen

- Jurnal Offshore Semi SubmersibleDokument16 SeitenJurnal Offshore Semi SubmersibleRidzkyNoch keine Bewertungen

- APS Company Profile Presentation To KSO PTM EP Telaga Said March 11 2014Dokument26 SeitenAPS Company Profile Presentation To KSO PTM EP Telaga Said March 11 2014Nik AbduhNoch keine Bewertungen

- Specification Sheet MLA PDFDokument2 SeitenSpecification Sheet MLA PDFRobin Abu FaqihNoch keine Bewertungen

- BARQI BROTHERS Company Profile - 2022Dokument25 SeitenBARQI BROTHERS Company Profile - 2022Muljono MolNoch keine Bewertungen

- SOP Tug Boat Positioning PDFDokument7 SeitenSOP Tug Boat Positioning PDFyuniarsoNoch keine Bewertungen

- Pt. Pancaran Samudera Transport: Ship ParticularDokument2 SeitenPt. Pancaran Samudera Transport: Ship Particularangga andi ardiansyahNoch keine Bewertungen

- Marine Breakaway Coupling - FinalDokument15 SeitenMarine Breakaway Coupling - FinalSafi Safi100% (1)

- ENG CL 04 - ER Arrival ChecklistDokument4 SeitenENG CL 04 - ER Arrival Checklist김순혁Noch keine Bewertungen

- Fuel Oil Transit Terminal Situbondo: Preliminary StudyDokument17 SeitenFuel Oil Transit Terminal Situbondo: Preliminary StudyDoni AndreanaNoch keine Bewertungen

- 11788312Dokument390 Seiten11788312solikah sriningsihNoch keine Bewertungen

- Checklist SkkpiDokument27 SeitenChecklist SkkpiarisNoch keine Bewertungen

- b7, b7m, l7, l7m, b16 Stud BoltsDokument1 Seiteb7, b7m, l7, l7m, b16 Stud BoltsyongdingNoch keine Bewertungen

- 7) Catalogue - Sea Chest Cover & Sea Connection Pipe PlugDokument16 Seiten7) Catalogue - Sea Chest Cover & Sea Connection Pipe PlugmarcusNoch keine Bewertungen

- Term of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4Dokument7 SeitenTerm of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4tiantaufik100% (1)

- KMDSI Maintenance LogDokument1 SeiteKMDSI Maintenance LogKosNoch keine Bewertungen

- QMS System References PDFDokument2 SeitenQMS System References PDFAbdhel X-Meta100% (1)

- Ship Safety Check Lists LoadingDokument1 SeiteShip Safety Check Lists LoadingcatalinNoch keine Bewertungen

- Density Correction Factor For Diesel Vs TemeperatureDokument3 SeitenDensity Correction Factor For Diesel Vs Temeperaturedon121don121Noch keine Bewertungen

- Maintenance Instructions For The Type Ces 3000 Hyperbaric Fire ExtinguisherDokument16 SeitenMaintenance Instructions For The Type Ces 3000 Hyperbaric Fire ExtinguisherBonar StepanusNoch keine Bewertungen

- Peralatan A - F (Update)Dokument33 SeitenPeralatan A - F (Update)AnnisaNoch keine Bewertungen

- High Range Water-Reducing and Slump Retaining Concrete AdmixtureDokument2 SeitenHigh Range Water-Reducing and Slump Retaining Concrete AdmixtureghazanfarNoch keine Bewertungen

- C32 Energy Container Spec SheetDokument5 SeitenC32 Energy Container Spec SheetFAR_A_DAY100% (1)

- Menck Mhu HammersDokument4 SeitenMenck Mhu Hammersg1376741Noch keine Bewertungen

- Standard Round SlingDokument2 SeitenStandard Round SlingFAR_A_DAYNoch keine Bewertungen

- Brochure Container Specification en PDFDokument0 SeitenBrochure Container Specification en PDFProf C.S.Purushothaman0% (1)

- MB-Q10212C: Budgetary QuotationDokument5 SeitenMB-Q10212C: Budgetary QuotationFAR_A_DAYNoch keine Bewertungen

- Van-Beest Catalogue Complete enDokument175 SeitenVan-Beest Catalogue Complete enmaomontesNoch keine Bewertungen

- Van-Beest Catalogue Complete enDokument175 SeitenVan-Beest Catalogue Complete enmaomontesNoch keine Bewertungen

- Salvage Engineer's Handbook: ChaptersDokument89 SeitenSalvage Engineer's Handbook: ChaptersWing HauNoch keine Bewertungen

- Installation Procedure Kamos RTJ GasketDokument16 SeitenInstallation Procedure Kamos RTJ Gasketekhwanhakim100% (3)

- User Manual: (Capacity 6 Passengers)Dokument50 SeitenUser Manual: (Capacity 6 Passengers)FAR_A_DAY100% (1)

- LashCon IMO - Rev 9.0 - tcm144-287975Dokument4 SeitenLashCon IMO - Rev 9.0 - tcm144-287975vigines89Noch keine Bewertungen

- Diving O&g411Dokument52 SeitenDiving O&g411phsemNoch keine Bewertungen

- Crest 252 - Profile & Deck PlanDokument1 SeiteCrest 252 - Profile & Deck PlanFAR_A_DAYNoch keine Bewertungen

- Wstda Standard Web SlingsDokument36 SeitenWstda Standard Web SlingslsgmzNoch keine Bewertungen

- F-12-1 Bottom Plug Arrangement PDFDokument2 SeitenF-12-1 Bottom Plug Arrangement PDFFAR_A_DAYNoch keine Bewertungen

- Conectores GraylocDokument0 SeitenConectores Graylocpablotorresbozzo2686Noch keine Bewertungen

- Ansi - 2012 - Ball ValveDokument12 SeitenAnsi - 2012 - Ball ValveFAR_A_DAYNoch keine Bewertungen

- C 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BDokument65 SeitenC 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BFAR_A_DAY100% (3)

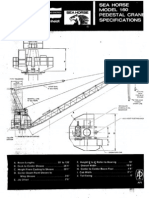

- ASV EM - Seahorse Pedestal Crane (API-2C) Crane ChartDokument4 SeitenASV EM - Seahorse Pedestal Crane (API-2C) Crane ChartFAR_A_DAYNoch keine Bewertungen

- Offshore PadeyeDokument2 SeitenOffshore PadeyeFAR_A_DAYNoch keine Bewertungen

- H 2 1 Scantling PlanDokument1 SeiteH 2 1 Scantling PlanFAR_A_DAYNoch keine Bewertungen

- F-1-1-2 Outfitting Arrangement PDFDokument1 SeiteF-1-1-2 Outfitting Arrangement PDFFAR_A_DAYNoch keine Bewertungen

- Stopper Plate CalculationDokument1 SeiteStopper Plate CalculationFAR_A_DAYNoch keine Bewertungen

- API 650 Tank Design CalculationDokument8 SeitenAPI 650 Tank Design CalculationHoracio RodriguezNoch keine Bewertungen

- Mathcad - Winch Base CalDokument7 SeitenMathcad - Winch Base CalFAR_A_DAYNoch keine Bewertungen

- Capacity of The Link BridgeDokument5 SeitenCapacity of The Link BridgeFAR_A_DAYNoch keine Bewertungen

- Mathcad - HPU Skid Design and Winch Bolting ChecksDokument5 SeitenMathcad - HPU Skid Design and Winch Bolting ChecksFAR_A_DAYNoch keine Bewertungen

- Design of Plate GirderDokument109 SeitenDesign of Plate GirderFAR_A_DAYNoch keine Bewertungen

- Company - ListDokument666 SeitenCompany - ListbobidmrNoch keine Bewertungen

- Borewell Installations PDFDokument218 SeitenBorewell Installations PDFIndrajeet DodlaNoch keine Bewertungen

- Shutdown Panel Functional SpecDokument17 SeitenShutdown Panel Functional SpecCandice Williams100% (1)

- Bill of Quantities-Civil (0514) - 2930 Cast Hse RevDokument24 SeitenBill of Quantities-Civil (0514) - 2930 Cast Hse RevVenkata RaoNoch keine Bewertungen

- Led BulbDokument2.476 SeitenLed BulbCrystle Florence VillafloresNoch keine Bewertungen

- PVC Soprano RecorderDokument9 SeitenPVC Soprano RecorderCecilia004Noch keine Bewertungen

- Steel Trade CatalogDokument172 SeitenSteel Trade CatalogjlcarcaustohNoch keine Bewertungen

- API2611 ArticleDokument4 SeitenAPI2611 ArticlepemyconsultingNoch keine Bewertungen

- Standar Soportes Sierra GordaDokument117 SeitenStandar Soportes Sierra GordaClaudio PuentesNoch keine Bewertungen

- Corrosion Control in Oil and Gas PipelinesDokument4 SeitenCorrosion Control in Oil and Gas PipelinesJaime Tiburcio Cortés100% (1)

- Nominal Pipe Size - Wikipedia, The Free EncyclopediaDokument7 SeitenNominal Pipe Size - Wikipedia, The Free EncyclopediaAngel DiosdadoNoch keine Bewertungen

- Cost Estimates Piping R.A DicksonDokument18 SeitenCost Estimates Piping R.A Dicksoncateerpillar100% (3)

- ASTM D140 Bitumen Sampling PDFDokument5 SeitenASTM D140 Bitumen Sampling PDFlab copriNoch keine Bewertungen

- Es 16Dokument7 SeitenEs 16Nuttaphon100% (1)

- Liquefied Gas Pump Installation GuideDokument6 SeitenLiquefied Gas Pump Installation GuideLuis Meza ArevaloNoch keine Bewertungen

- Hindalco SpecificationDokument15 SeitenHindalco SpecificationRavi JainNoch keine Bewertungen

- SD-DD - BHA and Drillstring - Standard Components PDFDokument4 SeitenSD-DD - BHA and Drillstring - Standard Components PDFНик ЕлисееваNoch keine Bewertungen

- Assembly Instructions SF OrionDokument3 SeitenAssembly Instructions SF OrionSamim MaqsoodNoch keine Bewertungen

- NarrativeReport OjtDokument7 SeitenNarrativeReport OjtMina SaflorNoch keine Bewertungen

- Es2184d - Cleaning and Flushing of Hydraulic Systems & ComponentsDokument9 SeitenEs2184d - Cleaning and Flushing of Hydraulic Systems & Componentsferfilho100% (2)

- High Pressure Piping Safety Incidents in Urea Plants: Mark BrouwerDokument10 SeitenHigh Pressure Piping Safety Incidents in Urea Plants: Mark Brouwervaratharajan g rNoch keine Bewertungen

- Pre Commissioning and Commissioning SafetyDokument32 SeitenPre Commissioning and Commissioning SafetyAssya MohammedNoch keine Bewertungen

- 4 WastewaterDokument74 Seiten4 WastewaterKyle TsengNoch keine Bewertungen

- Piping Class - GS70Dokument1 SeitePiping Class - GS70Dmitriy RybakovNoch keine Bewertungen

- For WONO:::10547 (BHUSAWAL TPS EXP.U1:500MW)Dokument6 SeitenFor WONO:::10547 (BHUSAWAL TPS EXP.U1:500MW)zero2enfinityNoch keine Bewertungen

- Shaft SinkingDokument11 SeitenShaft SinkingLavudiya RajkumarNoch keine Bewertungen

- Manjung Power Station - MalaysiaDokument96 SeitenManjung Power Station - MalaysiaMakoya_malume100% (1)

- Catalogo Gates Acoples y Mangueras PDFDokument626 SeitenCatalogo Gates Acoples y Mangueras PDFJose Antonio Gutierrez Lopez100% (1)

- Type 300 Clamped Diaphragm SealDokument4 SeitenType 300 Clamped Diaphragm SealhdrNoch keine Bewertungen