Beruflich Dokumente

Kultur Dokumente

Monorail

Hochgeladen von

rosemaryhere8649Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Monorail

Hochgeladen von

rosemaryhere8649Copyright:

Verfügbare Formate

1.

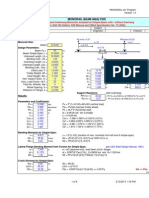

EVALAUTION OF MONORAIL BEAM

WEIGHT OF EQUIPMENT (6P-5031, 6P-5032 & 6P-5033)

Weight of pump, Wpump := ( 216kg + 970kg + 56kg)g Wpump g Therefore use a 1.5-tonne monorail Monorail capacity, MR c := 1.5tonne g TCwt := 89lbf MR c = 14.71 kN TCwt = 0.396 kN P max1 = 15.106 kN IMF := 1.25 LFtrans := 0.2 H max := LFtrans P max LFlong := 0.1 Lmax := LFlong P max F u := 420MPa Lmax = 1.52 kN H max = 3.04 kN say P max := 15.2kN = 1.242 tonne Wpump = 12.18 kN

kPa := 1000Pa

Weight of trolley +chain Maximum load,

P max1 := MRc + TCwt

P max = 3.417 kip

Impact factor for monorails, Transverse load factor Transverse load,

H max = 0.683 kip

Longitudinal load factor, Longitudinal load,

Lmax = 0.342 kip

:= 0.9 Length,

F y := 350MPa Ls := 4.5m

E := 200000MPa

G s := 77000MPa

1.1 PRELIMINARY SECTION SELECTION CRITERIA

Ls 500

allow :=

allow = 9 mm

3

Ix_reqd :=

IMF Pmax Ls 48E allow

Ix_reqd = 2.004 10 mm

Maximum moment,

M max :=

IMF1.5 Pmax Ls 4

M max = 32.063 kN m

Material & Section Property S250x38

Depth of section, Thickness of web, Thickness of flange, J s := 250 10 mm

9 3 4

d := 254mm tw := 7.9mm tf := 12.5mm Ix := 51.4 10 mm

6 6 4

>Ix_reqd

Iy := 2.8 10 mm

3

Cw := 40.9 10 mm

S x := 405 10 mm Zx := 465 10 mm

3

S y := 47.5 10 mm Zy := 81.3 10 mm ry := 24.1mm Ls ry = 186.722

3

A s := 4810mm

rx := 103mm

M r := 72.95kN m

> Mmax

Using a C200x17 on the top flange to limit weak axis deflection. A s_C := 2170mm

2

Ix_C := 13.5 10 mm

7

Iy_SC := Iy + Ix_C ry_SC := Ls ry_SC Iy_SC A s + As_C

Iy_SC = 1.63 10 mm ry_SC = 48.324 mm

= 93.121

< 200

1.2 CHECKING TENSION IN THE WEB

ft =

P P P = = 2 A (2t w )(3.5k ) (7 k )t w

(Ref Q&A MSC Steel Interchange) From Steel tables

Intersection of web and fillet,

k := 37mm 1.5( IMF) P max 2 tw 3.5k

Tensile stress in the web,

ft :=

ft = 13.929 MPa

Allowable stress,

allow := min 0.9Fy , 0.85 0.9F u

allow = 315 MPa

Check_web_ten := if ft < allow , "Web OKAY" , "Web failure" Check_web_ten = "Web OKAY"

1.3 CHECKING BENDING OF THE BOTTOM FLANGE

fb =

M (eP / 4) 0.75 P = = 2 S (t f )2 e(t f ) / 3

(Ref Q&A MSC Steel Interchange) Bending stress in the flange, fb := 1.5( IMF) 0.75P max tf

2

fb = 136.8 MPa Check_flg_bend := if fb < allow , "Flange OKAY" , "Flange failure" Check_flg_bend = "Flange OKAY"

1.4 CHECKING SECTION FOR COMBINED BENDING AND TORSION

f bt =

M x M y M fl + + Sy Sx Sy 2

M y := 6.4kN m i := 3.35in d 2 i 2

M x := 33.2kN m Dimension,

(Ref Harrington Trolley Specs) d1 = 71.955 mm

Distance, d1 :=

tf

1.5( IMF) Hmax d1 M fl := Mx Sx d tf 4 My Sy Mfl S y0.5

Ls M fl = 1.911 kN m

fbt :=

fbt = 297.159 MPa

Check_bend_tor := if fbt < allow , "Section OKAY in bending and torsion" , "Section NOT OKAY in bending and torsion" Check_bend_tor = "Section OKAY in bending and torsion"

1.5 DESIGN OF CRANE STOP

F y_angle := 300MPa Allowable stress, Crane stop force, Moment, allow_angle := 0.9Fy_angle allow_angle = 270 MPa CStop = 3.8 kN

CStop := max2( IMF) Lmax , 0.1( IMF) P max

CStopM := 1.5

CStop 2

65mm

CStopM = 0.185 kN m S leg := 8mm ( 65mm) 6

2

Section modulus of projecting leg,

S leg = 5633.333 mm

Bending stress,

fbCStop :=

CStopM S leg

fbCStop = 32.885 MPa

Check_CStop_bend := if fbCStop < allow_angle , "Angle OKAY" , "Angle failure" Check_CStop_bend = "Angle OKAY"

1.6 CHECKING BOLTS IN TENSION

Tensile capacity of M-20 bolts, Tbolt_cap := 141kN 1.5IMF Pmax 4 Wbolt_ten = 7.125 kN

Tensile load on bolts,

Wbolt_ten :=

Check_ten_bolt := if Wbolt_ten < Tbolt_cap , "Bolts OKAY" , "Bolts fail in Tension" Check_ten_bolt = "Bolts OKAY"

1.7 CHECKING BOLTS IN SHEAR

Shear capacity of M-20 bolts, V bolt_cap := 113kN

Shear load on bolts,

V bolt_shear :=

1.5( IMF)

Lmax + H max 4

V bolt_shear = 1.593 kN

Check_shear_bolt := if Vbolt_shear < Vbolt_cap , "Bolts OKAY" , "Bolts fail in Tension" Check_shear_bolt = "Bolts OKAY"

Das könnte Ihnen auch gefallen

- Design of Monorail BeamDokument6 SeitenDesign of Monorail BeamMahata Priyabrata100% (2)

- Monorail Beam Design 3TDokument22 SeitenMonorail Beam Design 3Tdeepak_dce_me100% (3)

- Monorail DesignDokument8 SeitenMonorail Designtali011971Noch keine Bewertungen

- Monorail Crane Girder CalculationDokument4 SeitenMonorail Crane Girder Calculationrony100% (1)

- Monorail CalculationDokument10 SeitenMonorail CalculationMiftakhu ZaimNoch keine Bewertungen

- Design of Monorail SystemsDokument21 SeitenDesign of Monorail Systemsapi-3840630100% (4)

- Design of MonorailDokument9 SeitenDesign of MonorailAnonymous Q8XIGqHyCNoch keine Bewertungen

- "Monorail" - Monorail Beam Analysis: Program DescriptionDokument7 Seiten"Monorail" - Monorail Beam Analysis: Program DescriptionvenkieeNoch keine Bewertungen

- FILLET WELD STRENGTH CALCULATIONSDokument8 SeitenFILLET WELD STRENGTH CALCULATIONSshadab521Noch keine Bewertungen

- Lifting Eye DesignDokument1 SeiteLifting Eye DesignFabio Okamoto0% (1)

- Shear Connection I-SecDokument36 SeitenShear Connection I-SecRaveendra Babu CherukuriNoch keine Bewertungen

- Monorail Beam Design 07Dokument5 SeitenMonorail Beam Design 07bakellyNoch keine Bewertungen

- Monorail Beam DesignDokument6 SeitenMonorail Beam DesignAnand.5Noch keine Bewertungen

- EC3 - Offshore Padeye DesignDokument4 SeitenEC3 - Offshore Padeye Designscaricatutto100% (1)

- General Purpose Worksheet CalculationsDokument24 SeitenGeneral Purpose Worksheet CalculationsBolarinwadeNoch keine Bewertungen

- Base PlateDokument12 SeitenBase PlateD SRINIVAS100% (1)

- MonorailDokument13 SeitenMonorailleodegarioporralNoch keine Bewertungen

- MonorailsDokument11 SeitenMonorailsSharyn PolleyNoch keine Bewertungen

- 8 Padeye - Spreadsheet Check1Dokument4 Seiten8 Padeye - Spreadsheet Check1oluomo1Noch keine Bewertungen

- Crane Beam DesignDokument7 SeitenCrane Beam DesignTharanga Pradeep100% (2)

- Design of C and I Shape Weld GroupDokument4 SeitenDesign of C and I Shape Weld GroupkarthicksipNoch keine Bewertungen

- Monorail calculation beam sizingDokument5 SeitenMonorail calculation beam sizingSulakxan Kuru100% (2)

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Dokument10 SeitenAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarNoch keine Bewertungen

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDokument1 SeiteCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- OFD5 JACKET IN-PLACE ANALYSIS BOAT IMPACT CALCULATIONDokument5 SeitenOFD5 JACKET IN-PLACE ANALYSIS BOAT IMPACT CALCULATIONBolarinwaNoch keine Bewertungen

- 6a Padeye Aisc 360 2005Dokument6 Seiten6a Padeye Aisc 360 2005mjlazoNoch keine Bewertungen

- Drop Object-Plastic HingeDokument8 SeitenDrop Object-Plastic HingeBolarinwaNoch keine Bewertungen

- Design of Gantry Girders 1Dokument10 SeitenDesign of Gantry Girders 1Abhishek Agarwal100% (2)

- MONORAIL BEAM ANALYSISDokument7 SeitenMONORAIL BEAM ANALYSISDiego Andres RamosNoch keine Bewertungen

- Vertical Vessel Foundation Design Input Parameters: Geometrical DescriptionDokument8 SeitenVertical Vessel Foundation Design Input Parameters: Geometrical DescriptionAnonymous xcFcOgMiNoch keine Bewertungen

- Spreader Beam DesignDokument5 SeitenSpreader Beam DesigntndeshmukhNoch keine Bewertungen

- Skid Under The Lifting ConditionDokument150 SeitenSkid Under The Lifting ConditionAmarjit KulkarniNoch keine Bewertungen

- Lifting PadeyeDokument16 SeitenLifting PadeyeLưu XuânNoch keine Bewertungen

- End Plate DesignDokument4 SeitenEnd Plate DesignAgnon Fung100% (4)

- Connection Design SheetDokument47 SeitenConnection Design SheetStephen James100% (1)

- Jib Crane Example ProblemDokument7 SeitenJib Crane Example Problemearthboy2u100% (1)

- Column Base Plate DesignDokument4 SeitenColumn Base Plate Design_jessecaNoch keine Bewertungen

- Sendai Project Lifting Lug DesignDokument6 SeitenSendai Project Lifting Lug DesignkalpanaadhiNoch keine Bewertungen

- Pad Eye New ReleaseDokument10 SeitenPad Eye New ReleaseEnrique BarajasNoch keine Bewertungen

- Design of Padeye CalcDokument3 SeitenDesign of Padeye CalcBolarinwa89% (9)

- FD CC 275 KV Class 3 Rev DianADokument15 SeitenFD CC 275 KV Class 3 Rev DianADian Aulia Faujiah100% (1)

- Stair DesignDokument6 SeitenStair DesignBathrudeen IshakNoch keine Bewertungen

- RSE Part II ANswersDokument5 SeitenRSE Part II ANswersnyaungzinNoch keine Bewertungen

- Upgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectDokument14 SeitenUpgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectkuttakhaoNoch keine Bewertungen

- Post Tensioned Sample PDFDokument13 SeitenPost Tensioned Sample PDFอัชวิน เจริญสินNoch keine Bewertungen

- 2017-CE May PDFDokument32 Seiten2017-CE May PDFKristin Argosino100% (2)

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDokument26 SeitenWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNoch keine Bewertungen

- Slab Material and Reinforcement DesignDokument10 SeitenSlab Material and Reinforcement DesignSartua SitorusNoch keine Bewertungen

- Composite Bridge Design CalculatorDokument20 SeitenComposite Bridge Design CalculatoriGp2013Noch keine Bewertungen

- Design Gantry Girder Industrial Building CraneDokument28 SeitenDesign Gantry Girder Industrial Building Cranes_bharathkumar75% (12)

- RC Pier TabaDokument20 SeitenRC Pier TabaAbera MamoNoch keine Bewertungen

- Gear and CVT Combination CalculationsDokument5 SeitenGear and CVT Combination CalculationsSrijan VermaNoch keine Bewertungen

- 002Dokument22 Seiten002Emad ElhussienyNoch keine Bewertungen

- Design of PCC Abutment - Open FoundationDokument21 SeitenDesign of PCC Abutment - Open Foundationklynchelle89% (9)

- Single Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIDokument12 SeitenSingle Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIasad_naqvi100% (2)

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Dokument5 SeitenUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNoch keine Bewertungen

- Belt conveyor design and specificationsDokument24 SeitenBelt conveyor design and specificationsEnrique100% (1)

- Prestressed Double Tee Beams (Version 1)Dokument7 SeitenPrestressed Double Tee Beams (Version 1)benjaminNoch keine Bewertungen

- FOUNDATION ANALYSISDokument14 SeitenFOUNDATION ANALYSISJuli NirwantoNoch keine Bewertungen

- Asphalt Paving Principles GuidebookDokument90 SeitenAsphalt Paving Principles Guidebookforismei5644Noch keine Bewertungen

- Stadd 2005 American ExamplesDokument386 SeitenStadd 2005 American Examples7761430Noch keine Bewertungen

- CISC 9.2 Sections ViewerDokument1 SeiteCISC 9.2 Sections Viewerrosemaryhere8649Noch keine Bewertungen

- Grating Design DataDokument2 SeitenGrating Design DataericastorgalucoNoch keine Bewertungen

- Oil Sands 101 UpdateDokument36 SeitenOil Sands 101 Updaterosemaryhere8649Noch keine Bewertungen

- Beam Example1Dokument2 SeitenBeam Example1Indu ShresthaNoch keine Bewertungen

- Beam Column Base Plate DesignDokument10 SeitenBeam Column Base Plate DesignSPUD1100% (3)