Beruflich Dokumente

Kultur Dokumente

Creep-Rupture Assessment of Super Heater Tubes

Hochgeladen von

kangsungjinOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Creep-Rupture Assessment of Super Heater Tubes

Hochgeladen von

kangsungjinCopyright:

Verfügbare Formate

Creep-Rupture Assessment of Superheater Tubes Using Nondestructive Oxide Thickness Measurements

T.J. Wardle Babcock & Wilcox Barberton, Ohio, U.S.A.

Presented to: ICOLM (International Conference on Life Management and Life Extension of Power Plant) Xian, P.R. China May 2000

BR-1697

Abstract

Steam-carrying superheater and reheater tubes in fossil-fired boilers operating at temperatures above 900F (482C) are subject to failure by creep-rupture. These tubes form an internal oxide layer that inhibits heat transfer through the wall and causes the tube metal temperature to increase over time. The thickness of this oxide can be used with unit operating data and wall thickness measurements to estimate the remaining creep-rupture life of a tube. In 1986 The Babcock & Wilcox Company designed and built the portable, ultrasonic Nondestructive Oxide Thickness Inspection System (NOTIS) for measuring this oxide. Prior to the development of this system, the only method to measure this internal oxide was through the destructive removal of tube samples. The application of NOTIS makes it possible to nondestructively assess a large number of tubes in a relatively short time. By assessing a large number of tubes within a superheater, rather than assessing only a few tube samples, better decisions can be made regarding component replacements and the identification of unusual unit operating conditions.

Introduction

Superheater tubes producing steam at temperatures of 900F (482C) and higher are subject to failure by creeprupture. Creep is the process where metals exposed to high temperature and sustained stress over long periods of time will gradually deform and eventually fail. Superheaters in

modern utility and industrial boilers are manufactured from various materials ranging from carbon steels in the cooler sections to stainless steel grades in the hottest outlet sections. The allowable stresses used in superheater design are set by the ASME Code. For alloys in the hottest sections of the superheater, the allowable stress is based on a finite creep-rupture life. If some other factor does not cause the premature failure of a superheater tube, some tubes will eventually fail by creep. Over the years there have been numerous tests conducted by many sources, including Babcock & Wilcox (B&W), to quantify the creep behavior of steels commonly used in boiler superheater construction. ASTM has compiled and published much of this data. Assuming that we know the stress and temperature that a tube has experienced over its service life, it is a relatively direct process to determine its creep life. At a given point in time, we should be able to determine what portion of a tubes creep life has been expended, and what portion remains. For alloy superheater tubes such as SA-213 grades T11 and T22, stress and temperature are not usually constant during a tubes service life. When a tube enters service the metal in contact with the internal steam begins to form a layer of magnetite (Fe3O4) scale. This oxide grows thicker in service and its growth over time is dependent on metal temperature. This oxide layer is also a barrier to heat transfer and as its thickness increases, metal temperatures must also increase to maintain a constant outlet steam temperature. Typically, tube metal temperatures increase from 1 to 2F (0.6 to 1.1C) for each 0.001 inch (0.03 mm) of internal oxide formed. In addition to the metal temperature increase, tube wall thinning due to erosion, corrosion or

Babcock & Wilcox

other wastage mechanisms can occur over time. This tube wall loss causes increased stress in a tube operating at a constant internal pressure. Allowing for these changing conditions of tube metal temperature and tube stress over time is key to reliable creep life prediction of alloy superheater tubes.

fractions states that if the applied stress and temperature conditions are varied, the sum of the life fractions associated with each set of conditions equals 1 at failure. Robinsons Rule may be expressed as follows: (t/tf)1 + (t/tf)2 + + (t/tf)n = 1 at failure

Basic Life Prediction Theory

Laboratory studies of the creep-rupture properties of steels have made the prediction of tube creep life possible. Laboratory specimens, heated to a controlled temperature, are loaded with a known stress. The time to failure is then measured. By testing samples of a particular grade of material at various combinations of stress and temperature, the creep-rupture properties for that material can be quantified. There are several ways in which creep data can be presented. One method is to plot laboratory test data using the LarsonMiller Parameter (LMP). The LMP is a function relating temperature and time.[1] This parameter is defined as: LMP = T (20 + log t) where T is the temperature of the test specimen in degrees absolute (deg. F + 460) and t is the time (in hours) the material is at this test temperature. This LMP data can be related to stress as illustrated in Figure 1. The relationship between stress and LMP is used to predict a probable time to the onset of creeprupture failure. In its simplest form, if we know the temperature and hoop stress at which a tube is operating, the predicted time to creep-rupture failure for that set of conditions can be determined from the plot of LMP versus stress. The remaining life of the tube is the difference between the total expected creeprupture life at a given set of conditions, minus the actual time that tube has spent at those conditions. To evaluate the ever changing stress and temperature conditions normally experienced by a superheater or reheater tube during its service life, creep life fractions are used. A creep life fraction is the ratio (t/t f) of the time a tube spends at a specific stress and temperature (t) to the time it would take these conditions to cause creep-rupture failure (tf). Robinsons rule of life

The subscripts 1 through n indicate each stress-temperature condition.

Temperature Estimation

To begin any estimation of tube creep life, the metal temperature in operation must be known or estimated. Metal temperatures are rarely measured directly in boiler tubes. Thermocouple temperatures are sometime available from a limited number of outlet header tube stubs. However, even where thermocouple data is available, it provides a measurement of temperature of the unheated tubes in the penthouse or vestibule. This indication of outlet steam temperature would still need to be correlated to the metal temperature of the heated tube in the gas pass. Fortunately, each tube contains a record of its individual thermal history in its internal (steam-side) oxide scale. Since the growth of this internal scale is a function of time and temperature, it provides a means for estimating the tubes average metal temperature. This is true of the intermediate chromiummolybdenum (Cr-Mo) alloys containing up to about 9% chromium, carbon-molybdenum steels and carbon steels. Stainless steels, however, do not normally develop an internal oxide that can be measured by nondestructive means. There are a number of published algorithms available for estimating metal temperature from oxide thickness data. These expressions typically cover the intermediate Cr-Mo alloys containing from 1% to 3% chromium, such as SA-213 grade T11 (1-1/4Cr-1/2Mo) and grade T22 (2-1/4Cr-1Mo). One of the most widely known of these formulas is that developed by Dr. D. N. French. [2] Dr. Frenchs time-temperature-oxide relationship is expressed as: Log X = 0.0002 [T * (20 + log t )] - 7.25 In this formula X equals the scale thickness in mils, T equals absolute temperature (deg. F + 460) and t is the time in hours. In addition, there are numerous other expressions that have been published that relate oxide growth, time and temperature.[3]

Stress Minimum Code Allowable

Mean

Tube Creep Life Prediction Methodology at B&W

Probability of Failure

>0% Chance of Failure

LMP

50% Chance of Failure

Figure 1 Stress v. LMP plot illustrating the statistical distribution of failure for a specific classification or grade of tubing.

To estimate the effects of varying conditions of stress and temperature, the past and future life of the tube is broken down into specific intervals of time. For example, B&W divides past service into ten (10) equal time intervals and future service is projected in 10,000 hour intervals. A temperature and stress are calculated for each interval and then used to calculate a creep life fraction for that interval. Based on the measured oxide thickness, and knowing the time the tube has been in service, an oxide growth rate can be calculated. The tube is assumed to have contained no internal oxide scale at the time it entered service. A mathematical model of the oxide growth rate can thus be defined, and an oxide thickness calculated for each interval of time. A tube metal tempera-

Babcock & Wilcox

ture, which considers the insulating property of the oxide, is then calculated for each time interval. Likewise, a linear rate of wall thinning is determined for the tube. This rate is based on the present measured tube wall thickness, an assumed original tube wall thickness, and the hours that the tube has spent in service. The original tube wall thickness, since it is likely unknown, is assumed to be the minimum specified tube wall thickness plus the manufacturers tube wall tolerance. A function describing wall thickness and time can then be defined and a wall thickness in each time interval calculated. This predicted wall thickness is used with the tube diameter and operating pressure to calculate a stress for each interval of time. With a stress and a temperature determined for each interval, the creep life fraction is determined. Given the stress, the LMP of failure may be found from the creep-rupture database. Knowing the temperature and the LMP of failure, the time (tf) a new tube would last at each set of conditions can be determined. The creep-life fraction (t/tf) is then the time the tube spent at a set of conditions (t) divided by the time a new tube would last at those conditions (tf). The life fractions are then summed until they total 1. Summing the values of the life fractions provides a prediction of total tube creep life. The remaining life is then obtained by subtracting the tube service time from the total theoretical life. Life fraction analysis is relatively accurate and is the most widely accepted method for estimating tube lives. It is not an exact science, however, and relies on certain assumptions being made to estimate tube remaining life. Usually, it is assumed that the unit will operate in the future much as it has in the past, e.g. steam temperature within the tube remains constant with time and wall thinning rates are constant with time. It is also assumed that creep-rupture will be the primary failure mode and that the tube will not suffer a short-term overheat as a result of pluggage or loss of cooling steam flow. The major problem affecting accuracy is the wide variation in creep-rupture properties (Figure 1). For a given stress and temperature, failure times can vary significantly from one tube to another. Remaining lives can also be reduced by short excursions to higher temperatures during service, that is, a change in operating conditions. The Babcock & Wilcox Company recommends that calculated remaining creep life data be used along with other information, such as tube failure rate, and not taken as an absolute value by itself. For example, if creep life predictions indicate many tubes are near end-of-life, and the unit is experiencing long term creep-rupture failures, then this is an indication that the affected bank is due for replacement. Conversely, if creep life predictions indicate remaining life in excess of 100,000 hours for most tubes, then any failures that occur are more likely isolated problems and replacement of an entire tube bank is not warranted.

The most desirable tubes for sampling may be buried deep within the bank and difficult, or impossible, to remove and replace. As a result, decisions on superheater replacement had to be based on a limited, and potentially unrepresentative, number of samples. A nondestructive method was needed that could measure both the oxide and wall thickness of a superheater tube without the removal of samples from the unit. A series of laboratory trials conducted by B&W during the mid 1980s determined that the accuracy of traditional ultrasonic thickness (UT) testing decreased as internal oxide scale increased. The inability of traditional UT thickness methods to detect the oxide-metal interface meant that a thickness measurement included not only the wall thickness, but also most of the oxide thickness. For example, given a tube with a thickness of 0.200 inch (5.08 mm) and an oxide of 0.040 inch (1.02 mm), traditional UT would measure approximately 0.230 inch (5.84 mm). Due to a mismatch between the velocity of sound in steel and the internal oxide, measurements taken using traditional UT thickness techniques include a major percentage of the internal oxide thickness.

NOTIS System

In 1986, B&W developed NOTIS (Nondestructive Oxide Thickness Inspection Service). NOTIS is a patented1 nondestructive ultrasonic test capable of measuring the thickness of both the tube wall and internal oxide scale in superheater tubes. The system is similar in many ways to standard ultrasonic wall thickness tests. A special transducer, connected to a microprocessor controlled pulser-receiver, is coupled to a tubes prepared outside diameter (OD) surface and a pulse of ultrasound is directed into the tube. The reflections from the metal-oxide interface and the oxide-air interface are displayed on the NOTIS equipment and the times of travel from the OD surface to the metal-oxide and oxide-air interfaces are measured. These timeof-flight measurements are then converted to wall and oxide thickness. The NOTIS system provides a resolution of one (1) mil, and an accuracy of 2 mils. Oxides as small as four (4) mils can be measured using this system with proper surface preparation. This accuracy has been confirmed through the evaluation of hundreds of samples. In addition, the Electric Power Research Institute (EPRI) in the U.S. verified the accuracy of measuring oxide scale with NOTIS in calibration tests at two power plants. The OD of the tube should be cleaned to bright metal, similar to the normal requirements for standard UT thickness testing. Sand blasting (or equivalent) is the preferred method of surface preparation but grinding may be required for particularly rough or pitted tube surfaces such as might be encountered with coal ash corrosion. Impact methods of removing the external scale (needle guns, chipping hammers, etc.), as well as thermal methods like hot popping (the use of an oxy-fuel torch to heat an area), must be avoided as these methods can also dislodge the internal oxide. Depending on tube surface condition and access to the test areas, a two (2) person team using the NOTIS system can test between 200 and 400 tube locations in eight (8) hours.

Historical Practice

Prior to the late 1980s, the only means of measuring the internal oxide scale in a superheater tube was through the destructive removal of a sample. The oxide thickness could then be measured in the laboratory using polished metallographic specimens. This provided accurate measurement of the internal oxide and wall thickness but has numerous drawbacks. The removal and replacement of samples is time consuming and costly.

U.S. Patent No. 4,669,310

Babcock & Wilcox

Benefits of Nondestructive Testing of Superheater Tubes

The most obvious benefit of using nondestructive methods to assess the remaining creep life of tubes is the large number of tests that can be conducted in a relatively short period of time. Thus, decisions regarding the overall condition of a superheater can be based on a much broader and more representative sampling than could be accomplished economically through the destructive removal of tube samples. Also, a careful review of the oxide thickness, wall thickness and remaining life data can provide much information about the operation of the unit. Oxide thickness is an indication of relative temperature exposure. The hotter the tube, the heavier the oxide. Typically, in wall fired units, gas temperatures will be lower at the sidewalls and will peak near the quarter points and/or center of the unit. In tangentially fired units, gas temperatures tend to peak closer to the sidewalls. Since oxide thickness tends to follow gas temperatures, oxide thickness data can provide an indication of unit gas temperature distribution. By evaluating the oxides within the tubes in a single tube row (e.g. leading edge tube row of the reheat superheater in all elements across the unit), areas of gas temperature unbalance can be identified. In addition, unexpectedly heavy oxides in one tube or element could be an indication of reduced steam flow through a particular flow circuit within an element or pendant. Wall thickness data can also be an indicator to the occurrence of certain problems. Reduced wall thickness in the tubes on either side of a soot blower cavity can indicate soot blower erosion. If all tubes with reduced wall thickness are in the same area of the superheater, this could indicate that erosion or ash corrosion is occurring. If heavy oxides are combined with the thinning, the tubes in that area may be running hotter due to higher gas velocity or gas temperature. Higher gas temperatures and the insulating effect of thicker oxides can enhance the potential for ash corrosion that would cause a rapid thinning of the tube walls. During the nondestructive inspection the tube is evaluated for exfoliation, or disbonding, of the oxide scale from the inside surface. Exfoliation is the flaking of scale particles and is readily identified by abrupt changes in the oxide thickness within a test area. These particles can be carried in the steam flow to the turbine where they can cause solid particle erosion. Oxide flakes can also accumulate in the lower tube bends of vertical superheaters and cause reduced steam flow. Reduced flow results in higher metal temperatures and heavier internal oxides. Therefore, it is important to quantify the extent of exfoliation within a superheater. If exfoliation is severe, chemical cleaning or tube replacement may be necessary to stop solid particle erosion from doing costly damage to the turbine.

reports, there are a variety of graphical formats in which the results are also displayed. Our standard graphical display is referred to as a full component plot. An example is presented in Figure 3. This plot is a map of tube remaining life through a superheater at a single plane of inspection (see Figure 2). It effectively helps target areas of the superheater in need of replacement. Each tube is assigned a coordinate within a grid. The grid is based on the element number (counted from sidewall to sidewall) and tube row number (counted front to rear or bottom to top). This plot is similar to a plan view in a vertical superheater, or a front view in a horizontal superheater. The remaining life of each tube is put into one of five ranges and assigned a color coded number. The most critical remaining lives, those tubes with lives of

Presentation of NOTIS Test Results Data Analysis

The advent of personal computers has allowed engineers, regardless of location, to perform complex mathematical computations in fractions of a second that used to take hours or days. Creep-rupture life fraction analysis is one of those areas where a significant improvement in productivity is possible. A side benefit is the use of these same computers to provide graphical presentations of data that were historically presented only in tables or hand drawn plots and sketches. Although B&W continues to provide tabular data as part of our NOTIS inspection

Figure 2 Side view of a reheat superheater showing a NOTIS inspection plane.

Babcock & Wilcox

Figure 3

Example of a full component plot.

50,000 hours or less, are assigned a red 5. The least critical tubes, those with lives of 200,000 hours or greater, are assigned a blue 1. The ranges can be modified to suit a particular customers needs. There are additional graphical displays that can assist in the analysis of the data. These plots supplement the full-component plot and are particularly useful in illustrating significant trends or unit problems. These plots graph wall thickness, oxide thickness or remaining life for a single tube row at a single elevation. The abscissa is the element number across the unit and the ordinate is the measure of wall thickness, oxide thickness or remaining life. An example of a single elevation oxide thickness plot is displayed in Figure 4.

The Babcock & Wilcox Company can also provide additional engineering services to assist in the evaluation of superheaters. Sometimes just knowing the remaining creep-rupture life of a tube is not sufficient. Babcock & Wilcox can also provide engineering answers to what if scenarios. What is the effect of reducing, or increasing, future outlet steam temperature? What is the effect of increasing or decreasing the unit operating pressure? What benefit can be gained from chemical cleaning of the superheater to remove the insulating internal oxide layer? The principles of life fraction analysis can be applied to answer these and other questions.

References Conclusion

B&W has performed the NOTIS test service in the evaluation of over four hundred (400) superheaters and reheaters. The advantages of using B&Ws nondestructive service are obvious compared to the old method of removing from five (5) to ten (10) tube samples to evaluate a superheater. The increased amount of data made available by this nondestructive test allows decisions to be made more rapidly and with greater confidence.

1. F.R. Larson and J. Miller, A Time-Temperature Relationship for Rupture and Creep Stresses, Trans ASME, July 1952, p765-775. 2. D.N. French, Metallurgical Failures in Fossil Fired Boilers, John Wiley & Sons, New York, 1983, p249. 3. R. Viswanathan, Damage Mechanisms and Life Assessment of High-Temperature Components, ASM International, Metals Park, OH, 1989, p229-230.

Babcock & Wilcox

Figure 4

Example of a single elevation plot of element versus oxide thickness.

Copyright 2000 by The Babcock & Wilcox Company, a McDermott company. All rights reserved. No part of this work may be published, translated or reproduced in any form or by any means, or incorporated into any information retrieval system, without the written permission of the copyright holder. Permission requests should be addressed to: Market Communications, The Babcock & Wilcox Company, P.O. Box 351, Barberton, Ohio, U.S.A. 44203-0351. Disclaimer Although the information presented in this work is believed to be reliable, this work is published with the understanding that The Babcock & Wilcox Company and the authors are supplying general information and are not attempting to render or provide engineering or professional services. Neither The Babcock & Wilcox Company nor any of its employees make any warranty, guarantee, or representation, whether expressed or implied, with respect to the accuracy, completeness or usefulness of any information, product, process or apparatus discussed in this work; and neither The Babcock & Wilcox Company nor any of its employees shall be liable for any losses or damages with respect to or resulting from the use of, or the inability to use, any information, product, process or apparatus discussed in this work.

Babcock & Wilcox

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Environmental, Health, and Safety Guidelines For Thermal Power Plant - FilesDokument33 SeitenEnvironmental, Health, and Safety Guidelines For Thermal Power Plant - FileskangsungjinNoch keine Bewertungen

- Urea Hydrolysis PDFDokument14 SeitenUrea Hydrolysis PDFkangsungjinNoch keine Bewertungen

- Flow of Fluids Through Valves, Fittings and Pipe (Crane)Dokument133 SeitenFlow of Fluids Through Valves, Fittings and Pipe (Crane)kangsungjin100% (1)

- A Review of Explicit Approximations of Colebrook's EquationDokument5 SeitenA Review of Explicit Approximations of Colebrook's EquationkangsungjinNoch keine Bewertungen

- Tecnicas para Cartas de Amor U OdioDokument4 SeitenTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- Alfa Laval Pump Handbook PDFDokument257 SeitenAlfa Laval Pump Handbook PDFkashifwarsiNoch keine Bewertungen

- Corrosion TableDokument2 SeitenCorrosion TableVijayakumar AtthuluriNoch keine Bewertungen

- FINAL - Thermal+Power IFC REPORTDokument33 SeitenFINAL - Thermal+Power IFC REPORTwidyo saptotoNoch keine Bewertungen

- Environmental, Health, and Safety General GuidelinesDokument99 SeitenEnvironmental, Health, and Safety General GuidelineskangsungjinNoch keine Bewertungen

- (Welding) s7Dokument113 Seiten(Welding) s7Popo YuppyNoch keine Bewertungen

- A Case Study of The Selective Catalystic ReductionDokument6 SeitenA Case Study of The Selective Catalystic ReductionkangsungjinNoch keine Bewertungen

- Flow of Fluids Through Valves, Fittings and Pipe (Crane)Dokument133 SeitenFlow of Fluids Through Valves, Fittings and Pipe (Crane)kangsungjin100% (1)

- M-506 Co2 Corrosion ModelDokument18 SeitenM-506 Co2 Corrosion ModelEdgar Enrique Diaz MarquinaNoch keine Bewertungen

- Low Temperature CatalystDokument29 SeitenLow Temperature CatalystkangsungjinNoch keine Bewertungen

- (Welding) s7Dokument113 Seiten(Welding) s7Popo YuppyNoch keine Bewertungen

- FAC and Cavitation: Identification, Assessment, Monitoring, PreventionDokument7 SeitenFAC and Cavitation: Identification, Assessment, Monitoring, PreventionkangsungjinNoch keine Bewertungen

- 8.10 Chemical Reactors: Control and Optimization: F. G. ShinskeyDokument14 Seiten8.10 Chemical Reactors: Control and Optimization: F. G. ShinskeyDAANoch keine Bewertungen

- ADG001Dokument19 SeitenADG001prufino2Noch keine Bewertungen

- 000000000001004930Dokument162 Seiten000000000001004930Diego Soto Sandoval100% (1)

- 8.8 Chemical Reactors: Batch SequencingDokument24 Seiten8.8 Chemical Reactors: Batch SequencingkangsungjinNoch keine Bewertungen

- (Welding) s7Dokument113 Seiten(Welding) s7Popo YuppyNoch keine Bewertungen

- A Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićDokument5 SeitenA Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićLutfi LailaNoch keine Bewertungen

- 1081ch8 11 PDFDokument9 Seiten1081ch8 11 PDFjut klayNoch keine Bewertungen

- Thermal Power EHS Guideline 2017Dokument61 SeitenThermal Power EHS Guideline 2017nunukantaNoch keine Bewertungen

- FINAL - Thermal+Power IFC REPORTDokument33 SeitenFINAL - Thermal+Power IFC REPORTwidyo saptotoNoch keine Bewertungen

- Thermal Power EHS Guideline 2017Dokument61 SeitenThermal Power EHS Guideline 2017nunukantaNoch keine Bewertungen

- JIS G3101 2004 Chem MechDokument1 SeiteJIS G3101 2004 Chem Mechtonaoh2009Noch keine Bewertungen

- Thermal Power EHS Guideline 2017Dokument61 SeitenThermal Power EHS Guideline 2017nunukantaNoch keine Bewertungen

- Environmental, Health, and Safety General Guidelines - 2008Dokument33 SeitenEnvironmental, Health, and Safety General Guidelines - 2008kangsungjinNoch keine Bewertungen

- Ml12335a508 PDFDokument279 SeitenMl12335a508 PDFkangsungjinNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Release Not Ese Tabs 2015 V 1510Dokument7 SeitenRelease Not Ese Tabs 2015 V 1510jwanroNoch keine Bewertungen

- Forces and Stresses On Ships (Compatibility Mode)Dokument44 SeitenForces and Stresses On Ships (Compatibility Mode)Htin Lin Aung100% (1)

- Impact Analysis Using ADINA: Daniel Jose Payen, PH.DDokument34 SeitenImpact Analysis Using ADINA: Daniel Jose Payen, PH.DAdolfo Gálvez VillacortaNoch keine Bewertungen

- Control Sys Nov-2015Dokument40 SeitenControl Sys Nov-2015krkpanduNoch keine Bewertungen

- Code of Practice For Construction With Large Panel PrefabricatesDokument43 SeitenCode of Practice For Construction With Large Panel PrefabricatesNarasimha DvlNoch keine Bewertungen

- Numerical Analysis of Aircraft Nose Landing Gear Using FEA: Jithin Malayil Jacob, Dr. Evangelia Ganniari PapageorgiouDokument9 SeitenNumerical Analysis of Aircraft Nose Landing Gear Using FEA: Jithin Malayil Jacob, Dr. Evangelia Ganniari PapageorgiouДмитрий ДмитренкоNoch keine Bewertungen

- Analysis of Mechanical Properties of Natural Fibre Composites by Experimental With FEADokument5 SeitenAnalysis of Mechanical Properties of Natural Fibre Composites by Experimental With FEArahul reddyNoch keine Bewertungen

- Rock Mechanics and Mining EngineeringDokument22 SeitenRock Mechanics and Mining EngineeringUmairKhalidNoch keine Bewertungen

- A Finite Element Approach For Locating The Center of Resistance of Maxillary TeethDokument12 SeitenA Finite Element Approach For Locating The Center of Resistance of Maxillary Teeth김재훈Noch keine Bewertungen

- Fluid Mechanics d203Dokument302 SeitenFluid Mechanics d203Vignesh SundaramNoch keine Bewertungen

- MDSP Diag 1Dokument3 SeitenMDSP Diag 1Tyron RebellonNoch keine Bewertungen

- Recommendations for Shear Lag Factors for Longitudinally Welded Tension MembersDokument22 SeitenRecommendations for Shear Lag Factors for Longitudinally Welded Tension MembersSergioAlcantaraNoch keine Bewertungen

- Flow Analysis and Structural Design of Penstock Bifurcation of Kulekhani III HEPDokument7 SeitenFlow Analysis and Structural Design of Penstock Bifurcation of Kulekhani III HEPSuhasNoch keine Bewertungen

- Ahmad Fitri Zainal AbidinDokument24 SeitenAhmad Fitri Zainal AbidinsureshgraphicsNoch keine Bewertungen

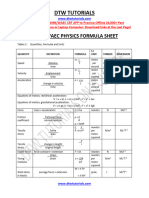

- DTW Tutorials 135 Physics Formula SheetDokument16 SeitenDTW Tutorials 135 Physics Formula Sheetggold0934Noch keine Bewertungen

- Prof. Dr.-Ing. Habil. Holm Altenbach, - Mechanics of Composite Structural Elements-Springer-Verlag BerliDokument487 SeitenProf. Dr.-Ing. Habil. Holm Altenbach, - Mechanics of Composite Structural Elements-Springer-Verlag BerliJohan100% (1)

- Machdes Project Group ScrewDokument6 SeitenMachdes Project Group ScrewSecret SecretNoch keine Bewertungen

- Stress Analysis of Machine ElementsDokument5 SeitenStress Analysis of Machine ElementsPeter SamuelNoch keine Bewertungen

- Dental Implant Biomechanics ForcesDokument57 SeitenDental Implant Biomechanics ForcesNikita Aggarwal100% (1)

- Theory of Structures (CE4G) Direct and Bending StressesDokument22 SeitenTheory of Structures (CE4G) Direct and Bending StressesDiptoNoch keine Bewertungen

- Lode Dependences Pressure-Sensitive Materials For Isotropic ElastoplasticDokument9 SeitenLode Dependences Pressure-Sensitive Materials For Isotropic Elastoplasticaasc1981Noch keine Bewertungen

- Thermal Stress Glass Cup ExampleDokument5 SeitenThermal Stress Glass Cup ExampleTarek_ElmelegyNoch keine Bewertungen

- Bending Test ExplainedDokument31 SeitenBending Test ExplainedAhmed KhasawnehNoch keine Bewertungen

- HW5 ch6 2011x PDFDokument8 SeitenHW5 ch6 2011x PDFMaryam Allayne AbastasNoch keine Bewertungen

- Thin Wall BeamsDokument32 SeitenThin Wall BeamsAllan Marbaniang100% (1)

- HSFG Bolts PDFDokument12 SeitenHSFG Bolts PDFmcwong_98Noch keine Bewertungen

- Prestress LossesDokument11 SeitenPrestress LossesCarlson CaliwanNoch keine Bewertungen

- The Magic of Sand (David Muir Wood)Dokument22 SeitenThe Magic of Sand (David Muir Wood)Ramiro ChairezNoch keine Bewertungen

- Essay On How I Can Add Value To Hydroserve Nigeria LimitedDokument2 SeitenEssay On How I Can Add Value To Hydroserve Nigeria LimitedAsuelimen titoNoch keine Bewertungen

- Structural Analysis and Design of Proces PDFDokument361 SeitenStructural Analysis and Design of Proces PDFmarceloNoch keine Bewertungen