Beruflich Dokumente

Kultur Dokumente

Inverted Pendulum Using State Space Method

Hochgeladen von

Wm HanifOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inverted Pendulum Using State Space Method

Hochgeladen von

Wm HanifCopyright:

Verfügbare Formate

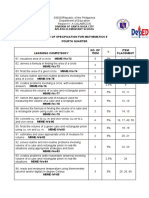

LAB 5 : INVERTED PENDULUM USING STATE-SPACE METHOD 1.0 OBJECTIVE i. ii. iii. iv.

To determine the discrete state-space for inverted pendulum. To check the controllability and observability in inverted pendulum system. To determine control design via pole placement with adding reference input of full-state feedback system. To learn a technique for estimating the states of a plant using observer design. 2.0 MATLAB PROGRAM. Procedures M-file code M=0.5; m=0.2; b=0.1; 1 i=0.006; g=9.8; l=0.3; p=i*(M+m)+M*m*1^2; %denominator for the A and B matrices A=[0 0 B=[ 0; 0; 1 0 0 0 m*g*l*(M+m)/p 0; 0; 1; 0];

0 -(i+m*l^2)*b/p (m^2*g*l^2)/p 0 -(m*l*b)/p -(i+m*l^2)/p;

m*l/p]; C=[1 0 D=[0; 0]; Ts=1/100; pend=ss(A,B,C,D); pend_d=c2d(pend,Ts,'zoh') F=[1.0000 0.0100 0.0001 0.0000; 0 0.9982 0.0267 0.0001; 0 0.0000 1.0016 0.0100; 0 -0.0045 0.3119 1.0016]; 4 G=[0.0001 0.0182; 0.0002; 0.0454]; 0 0 0; 0 1 0];

H=[1 0 J=[0; 0];

0 0 0; 0 1 0];

Ts=1/100; pend_d=ss(F,G,H,J,Ts);

co=ctrb(pend_d); ob=obsv(pend_d); Controllability=rank(co) Observability=rank(ob)

T=0:0.01:5; U=0.2*ones(size(T)); F=[1.0000 0.0100 0.0001 0.0000; 0 0.9982 0.0267 0.0001; 0 0.0000 1.0016 0.0100; 6 0 -0.0045 0.3119 1.0016]; G=[0.0001 0.0182; 0.0002; 0.0454]; H=[1 0 J=[0; 0]; x=1; y=1; 0 0 0; 0 1 0];

Q=[x 0 0 0 R=1;

0 0 0; 0 0 0; 0 y 0; 0 0 0];

K=dlqr(F,G,Q,R) Ts=1/100; sys_cl=ss(F-G*K,G,H,J,Ts); [Y,T,X]=lsim(sys_cl,U); stairs(T,Y) legend('Cart (x)','Pendulum (phi)')

Procedures M-file code T=0:0.01:5; U=0.2*ones(size(T)); 10 F=[1.0000 0.0100 0.0001 0.0000; 0 0.9982 0.0267 0.0001; 0 0.0000 1.0016 0.0100; 0 -0.0045 0.3119 1.0016]; G=[0.0001 0.0182; 0.0002; 0.0454];

H=[1 0 J=[0; 0];

0 0 0; 0 1 0];

x=5000; %weighting factor for the cart position y=100; Q=[x 0 0 0 R = 1; K = dlqr(F,G,Q,R) Nbar = -61.55; Ts = 1/100; sys_cl = ss(F-G*K,G*Nbar,H,J,Ts); [Y,T,X]=lsim(sys_cl,U); stairs(T,Y) legend('Cart (x)','Pendulum (phi)') %weighting factor for the pendulum angle 0 0 0; 0 0 0; 0 y 0; 0 0 0];

Procedures M-file code F=[1.0000 0.0100 0.0001 0.0000; 0 0.9982 0.0267 0.0001; 0 0.0000 1.0016 0.0100; 0 -0.0045 0.3119 1.0016];

12

G=[0.0001 0.0182; 0.0002; 0.0454];

H=[1 0 J=[0; 0];

0 0 0; 0 1 0];

x=5000; %weighting factor for the cart position y=100; %weighting factor for the pendulum angle

Q=[x 0 0 0 R=1;

0 0 0; 0 0 0; 0 y 0; 0 0 0];

K=dlqr(F,G,Q,R); poles=eig(F-G*K)

Procedures M-file code

F=[1.0000 0.0100 0.0001 0.0000; 0 0.9982 0.0267 0.0001; 0 0.0000 1.0016 0.0100; 14 H=[1 0 0 -0.0045 0.3119 1.0016]; 0 0 0; 0 1 0];

P=[-0.3 -0.31 -0.32 -0.33]; L=place(F',H',P)'

T=0:0.01:5; U=0.2*ones(size(T));

F=[1.0000 0.0100 0.0001 0.0000; 0 0.9982 0.0267 0.0001; 0 0.0000 1.0016 0.0100; 0 -0.0045 0.3119 1.0016]; G=[0.0001 0.0182; 0.0002; 0.0454]; H=[1 16 0 J=[0; 0]; x=5000; y=100; Q=[x 0 0 0 R=1; K=dlqr(F,G,Q,R) Nbar=-61.55; L=[2.6310 -0.0105; 0 0 0; 0 0 0; 0 y 0; 0 0 0]; 0 0 0; 0 1 0];

172.8146 -0.0129 -2.2954

-1.3468; 2.6304; 173.2787];

Fce=[F-G*K

G*K;

zeros(size(F)) (F-L*H)]; Gce=[G*Nbar; zeros(size(G))]; Hce=[H zeros(size(H))]; Jce=[0;0]; Ts=1/100; sys_cl=ss(Fce,Gce,Hce,Jce,Ts); [Y,T,X]=lsim(sys_cl,U); stairs(T,Y) legend('Cart (x)','Pendulum (phi)')

3.0

RESULTS

Procedures

Results a= x1 x1 x2 x3 1 0 0 0 x2 0.009991 0.9982 -2.272e-005 -0.004544 u1 x1 -9.085e-005 x2 x3 x4 c= y1 y2 d= y1 y2 -0.01816 0.0002275 0.04552 x1 x2 x3 x4 1 0 0 0 u1 0 0 0 1 0 0 x3 0.02672 1.002 0.3119 x4 0.0001336 0.01001 1.002 0.0001336 4.453e-007

x4 b=

Sampling time: 0.01 Discrete-time model.

10

Controllability = 4 Observability = 4

Procedures Results

11

x=1, y=1 K = -0.9384 -1.5565 18.1110

K= -0.9384 -1.5565 18.1110

3.3499

3.3499

0 .1 Cr ( ) at x Pn u mp i) e d lu ( h Tr=0.48s at 0.014873kg Ts= 4.8s at -0.00025719kg

05 .0

0 Tr=0.27s at 0.00341673kg - .0 05

- .1 0

- .1 05 Ts= 4.94s at -0.21923kg - .2 0

- .2 05

0 .5

1 .5

2 .5

3 .5

4 .5

Figure 1: Step response for weighing factor x=1 and y=1.

Procedures

Results

12

K= -61.9836 -33.3719 95.4404 18.8911

x 10

-3

10

Tr=0.17s at 0.002613kg 2

Cart (x) Pendulum (phi)

1 Ts= 2.01s at -5.4651e-006kg 0 Tr=0.14s at 0.00093131kg -1

-2 Ts= 1.52s at -0.0032227kg -3

-4

0.5

1.5

2.5

3.5

4.5

Figure 2: Step response for weighing factor x=5000 and y=100.

poles = 12 0.9156 + 0.0729i 0.9156 - 0.0729i 0.9535 + 0.0079i 0.9535 - 0.0079i

Procedures

Results

13

14

L= 2.6310 -0.0129 -2.2954 -0.0105 2.6304 173.2787 172.8146 -1.3468

K = -61.9836 -33.3719 95.4404 18.8911

16

0.2 0.15 0.1 0.05 0 -0.05 -0.1 -0.15 -0.2

Tr= 0.58s at 0.067686kg Tr=1.28s at 0.19758kg

Cart (x) Pendulum (phi)

Ts= 4.16s at -6.149e-10kg

0.5

1.5

2.5

3.5

4.5

Figure 3: Overall system response including observer.

4.0

OBSERVATION

14

Procedures

Observation The c2d command is used in procedure 1 to convert continuous to

discrete state-space equation with sampling time, Ts=0.01. The output displayed in a, b, c, and d matrices in form discrete time model.

The output shown that the controllability and observability is 4.

In figure 1 and 2, the curve in green represents the pendulum's angle, in radians, and the curve in blue represents the cart's position in meters. With including commands Nbar equals -61.55, the step response will be as shown in figure 3 with same gain, K in procedure 3.

The poles location for the system without the observer as shown in result (procedure 5).

To find L matrix, used place commands in matlab and the output shown as result in procedure 6.

Figure 4 shown as same as figure 3. The curve in green represents 7 the pendulum's angle, in radians, and the curve in blue represents the cart's position in meters with the gain, K also the same value.

15

5.0

ANALYSIS In order to convert the continuous state-space equations to discrete state-space is

by using c2dm commands in the Matlab. To use this c2dm commands, we need to specify six arguments: four state-space matrices (A, B, C, and D), sampling time (Ts in sec/sample), and the 'method'. The sampling time should be smaller than 1/(30*BW) sec, where BW is the closed-loop bandwidth frequency. The method we will use is the zeroorder hold ('zoh') same as lab before. The next step is to check the controllability and the observability of the system. For the system to be completely state controllable, the controllability matrix must have the rank of n. The rank of the matrix is the number of independent rows (or columns). In the same token, for the system to be completely state observable, the observability matrix must also have the rank of n. Since our controllability matrix and observability matrix are '4x4', the rank of both matrices must be 4. The function rank can give you the rank of each matrix. From result in procedure 2, this proves that our discrete system is both completely state controllable and completely state observable. In figure 1, the pendulum's and cart's overshoot appear fine, but their settling times need improvement and the cart's rise time needs to be decreased. Also the cart has, in fact, moved in the opposite direction. For x=1, y=1 the settling time, Ts is greater than 5 seconds and rise time for cart is over than 1 second. When increase the weighting factors (x=5000, y=100), with settling time, Ts is about 2 seconds for pendulum(phi) and less than 2 seconds for cart (x). For carts rise time, TR is less than 1 second. The plot in figure 2, all design requirements are satisfied except the steady-state error of the cart position (x). To obtain the desired output, the reference input is scaled so that the output equals to the reference. This can be easily done by introducing a feedforwarding scaling factor called Nbar. This function will find the scale factor for a full-state feedback system to eliminate the steady-state error. Unfortunately, in this lab, the user-defined function rscale cannot use to find Nbar. But certainly it can find from trial and errors. After several trials, the Nbar equals to -61.55 provided the satisfactory response. From the plot

16

in figure 3, notice that the steady-state error of the cart's position have been eliminated and the designed of system satisfied all design requirements. The above response satisfies all design requirements; however, it was found assuming all states are measurable. This assumption may not be valid for all systems. The technique is developed for estimating the states of a plant from the information that is available concerning the plant. The system that estimates the states of another system is called an observer. Thus, in this section a full-order state observer is designed to estimate those states that are not measurable. To design the observer, first, find the L matrix. To find the L matrix, the poles needed to find the system without the observer (the poles of F-G*K). The observer poles are placed to make the observer works a lot faster than the system without the observer. The Matlab function place is used to find the L matrix. From figure 4, as noticed, this response is about the same as before, and all of the design requirements have been satisfied. Table 1: Summarized of the settling time and rise time for all tasks. Without observer poles time Rise Time, Tr Settling time, Ts 6.0 COMMENT In this lab, first step is same as before that to convert the continuous to discrete state-space equation. For inverted pendulum, we used matlab function called c2d to convert that equation. Then we need to check either the system is completely state controllable or completely state observable. From result in procedure 2, this proves that our discrete system is both completely state controllable and completely state observable. From figure 1, we can see the pendulum's and cart's overshoot appear fine, but their settling times need improvement and the cart's rise time needs to be decreased when we X=1 y=1 Cart Pend 0.27s 0.48s 4.94s 4.8s Weighing factor X=5000 y=100 Cart Pend 0.14s 0.17s 1.52s 2.01s With observer poles X=5000 y=100 Cart pend 0.58s 1.28s 4.16s

17

use x=1 and y=1. Since we increase x=5000 and y=100, the step response shown as figure 2 but the steady-state error of the cart position (x) are not satisfied. We use Nbar equals to -61.55 provided the satisfactory response. From the plot in figure 3, notice that the steady-state error of the cart's position have been eliminated and the designed of system satisfied all design requirements. And lastly to confirm that the system is satisfied all design requirement, the technique is developed for estimating the states of a plant from the information that is available concerning the plant is called an observer. With using place function to find L matrix, from figure 4, this response is about the same as before, and all of the design requirements have been satisfied.

7.0

CONCLUSION After this lab, conclusion that can make is the discrete state-space equation for

inverted pendulum is a= x1 x1 x2 x3 1 0 0 x2 0.009991 0.9982 -2.272e-005 x3 0.02672 1.002 x4 0.0001336 0.01001 0.0001336 4.453e-007

18

x4 b=

-0.004544 u1

0.3119

1.002

x1 -9.085e-005 x2 x3 x4 c= y1 y2 d= y1 y2 -0.01816 0.0002275 0.04552 x1 x2 x3 x4 1 0 0 0 u1 0 0 0 1 0 0

with sampling time is 0.01. The discrete system for inverted pendulum is both completely state controllable and completely state observable. From figure 1(x=1 and y=1), the step response shows that the design is not satisfied all design requirements. When increase x=5000 and y=100 the plot in figure 2 are shown but only steady-state error for carts position (x) are not satisfied. By using Nbar commands, the steady-state error of the cart's position have been eliminated and the designed of system satisfied all design requirements as shown in figure 3. The place command is used to find L matrix in order to design observer. From figure 4, this response is about the same as before, and all of the design requirements have been satisfied.

19

8.0

REFERANCES 1. 2. 3. Lab sheet 2, BER 4113 Digital Control, Digital Dc Motor Speed Control With Pid Control Amran Mohd Zaid , July 2007 Electronic and circuit analysis using MATLAB (Second Edition) , John Okyeke Attia. MATLAB Programming David C. Kuncicky, Prentice Hall, 2005.

20

21

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Packed Bed Catalytic Reactor Chapter 19Dokument33 SeitenPacked Bed Catalytic Reactor Chapter 19Faris Rahmansya NurcahyoNoch keine Bewertungen

- 4th Periodical Test in Math 5-NewDokument9 Seiten4th Periodical Test in Math 5-NewMitchz Trinos100% (2)

- A Complete Analytical Solution To The Inverse Kinematics of The Pioneer 2 Robotic ArmDokument7 SeitenA Complete Analytical Solution To The Inverse Kinematics of The Pioneer 2 Robotic ArmWm HanifNoch keine Bewertungen

- Assignment v2Dokument3 SeitenAssignment v2Rayed Awad AlsahlaneeNoch keine Bewertungen

- Lab1 VHDLDokument10 SeitenLab1 VHDLWm HanifNoch keine Bewertungen

- Polezero PDFDokument13 SeitenPolezero PDFvoru89Noch keine Bewertungen

- Métodos de Fı́sica Teórica II - CF367 Lista de Exercı́cios I Dirac delta function propertiesDokument1 SeiteMétodos de Fı́sica Teórica II - CF367 Lista de Exercı́cios I Dirac delta function propertiesFernando Bazílio de LimaNoch keine Bewertungen

- FE DP1 Math AASL P1 SolDokument10 SeitenFE DP1 Math AASL P1 SolJustin Clement TjiaNoch keine Bewertungen

- Jyothi Swarup's SAS Programming ResumeDokument4 SeitenJyothi Swarup's SAS Programming Resumethiru_lageshetti368Noch keine Bewertungen

- Handbook of Operational Amplifier ApplicationsDokument94 SeitenHandbook of Operational Amplifier Applicationshermiit89% (9)

- Relation between resolution III and confounded responsesDokument50 SeitenRelation between resolution III and confounded responsesrohitrealisticNoch keine Bewertungen

- Stratified Random Sampling PrecisionDokument10 SeitenStratified Random Sampling PrecisionEPAH SIRENGONoch keine Bewertungen

- Angle of Repose & Angle of FrictionDokument4 SeitenAngle of Repose & Angle of Frictionganmoses50% (2)

- BMS Sem 1 DSC Ge Sec Vac (Edit)Dokument27 SeitenBMS Sem 1 DSC Ge Sec Vac (Edit)VISHESH 0009Noch keine Bewertungen

- Demand: - Demand (D) Is A Schedule That Shows The Various Amounts of ProductDokument2 SeitenDemand: - Demand (D) Is A Schedule That Shows The Various Amounts of ProductRaymond Phillip Maria DatuonNoch keine Bewertungen

- A Tutorial On Cross-Layer Optimization in Wireless NetworksDokument12 SeitenA Tutorial On Cross-Layer Optimization in Wireless Networkshendra lamNoch keine Bewertungen

- Fisika Zat Padat I: Dosen: Dr. Iwantono, M.Phil Jurusan Fisika Fmipa-UrDokument78 SeitenFisika Zat Padat I: Dosen: Dr. Iwantono, M.Phil Jurusan Fisika Fmipa-UrMailestari Wina YanceNoch keine Bewertungen

- A Comparison of Subspace Methods For Sylvester Equations: Mathematics InstituteDokument9 SeitenA Comparison of Subspace Methods For Sylvester Equations: Mathematics InstituteDurga SivakumarNoch keine Bewertungen

- Javascript - Domain Fundamentals AssignmentsDokument43 SeitenJavascript - Domain Fundamentals AssignmentsSana Fathima SanaNoch keine Bewertungen

- Lecture 5Dokument7 SeitenLecture 5sivamadhaviyamNoch keine Bewertungen

- Governor System (Electrical Part)Dokument142 SeitenGovernor System (Electrical Part)የፐፐፐ ነገርNoch keine Bewertungen

- MCS 1st SemesterDokument15 SeitenMCS 1st SemesterRehman Ahmad Ch67% (3)

- Hindu Temple Fractals - Vastu N Carl JungDokument31 SeitenHindu Temple Fractals - Vastu N Carl JungDisha TNoch keine Bewertungen

- G (X) F (X, Y) : Marginal Distributions Definition 5Dokument13 SeitenG (X) F (X, Y) : Marginal Distributions Definition 5Kimondo KingNoch keine Bewertungen

- Report On Fingerprint Recognition SystemDokument9 SeitenReport On Fingerprint Recognition Systemaryan singhalNoch keine Bewertungen

- Material Models in PlaxisDokument136 SeitenMaterial Models in PlaxismpvfolloscoNoch keine Bewertungen

- RF Energy Harvesting in Relay NetworksDokument44 SeitenRF Energy Harvesting in Relay NetworksYeshwanthSuraNoch keine Bewertungen

- Average Internal Rate of Return and Investment Decisions: A New PerspectiveDokument40 SeitenAverage Internal Rate of Return and Investment Decisions: A New PerspectiveBharat MaraiyaNoch keine Bewertungen

- Mathematics Curriculum in MalaysiaDokument38 SeitenMathematics Curriculum in MalaysiaSK Lai100% (1)

- Trigonometry Worksheet with 15 ProblemsDokument2 SeitenTrigonometry Worksheet with 15 ProblemsChandrasegran NargesNoch keine Bewertungen

- Aerodynamics MCQs on Low Speed AerodynamicsDokument4 SeitenAerodynamics MCQs on Low Speed AerodynamicsHarish MathiazhahanNoch keine Bewertungen

- Solid State PhysicsDokument281 SeitenSolid State PhysicsChang Jae LeeNoch keine Bewertungen

- Etabs NotesDokument11 SeitenEtabs Noteskarimunnisa sheikNoch keine Bewertungen

- SRB Session1 RofsDokument4 SeitenSRB Session1 RofsFullo Flores MarviloneNoch keine Bewertungen