Beruflich Dokumente

Kultur Dokumente

Small Scale-Paper Making

Hochgeladen von

Gnana SSOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Small Scale-Paper Making

Hochgeladen von

Gnana SSCopyright:

Verfügbare Formate

90.

PROFILE ON SMALL SCALE PAPER MAKING

90 - 2 TABLE OF CONTENTS PAGE I. II. III. SUMMARY PRODUCT DESCRIPTION AND APPLICATION MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY AND PRODUCTION PROGRAMME IV. MATERIALS AND INPUTS A. MATERIALS B. UTILITIES V. TECHNOLOGY AND ENGINEERING A. TECHNOLOGY B. ENGINEERING VI. MANPOWER AND TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT VII. FINANCIAL ANALYSIS A. TOTAL INITITAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEITS 90 - 3 90 - 3 90 - 4 90 - 4 90 - 6 90 - 7 90 - 7 90 - 8 90 - 9 90 - 9 90 - 10 90 - 12 90 - 12 90 - 14 90 - 14 90 - 15 90 - 16 90 - 16 90 - 17

90 - 3

I.

SUMMARY

This profile envisages the establishment of a plant for the production of 7,500 tonnes of paper per annum.

The current demand for the proposed product is estimated at 46,359 tonnes per annum and it is projected to reach 67,055 tonnes by the year 2014.

The project will create employment opportunity for 75 persons.

The total investment cost of the project is estimated at Birr 34.86 million, out of which Birr 20 million is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 24% and a net present value (NPV) of Birr 29.97 million, discounted at 10.5%.

II.

PRODUCT DESCRIPTION AND APPLICATION

Paper is used for writing and printing, for wrapping and packaging, and a variety of other applications ranging from kitchen towels to the manufacture of building materials. In modern times, its production in large quantities has been a significant factor in the increase in literacy and the raising of educational levels of people throughout the world.

The most commonly used paper types are stationary paper (i.e. printing and writing), news print, wrapping & packaging, and paper card.

Small scale paper making is defined as one having a capacity of less than 30 tonnes of paper per day; this also includes hand-made paper.

90 - 4 III. MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past supply and Present Demand

Paper has become an important necessity of our day to day life. Modern life depends on paper and millions of tonnes of it are made and used each year. The range of possible uses of paper is limitless and new ways of using it are being devised daily.

We use paper for news prints, magazines, writing, printing, packaging, sanitary purpose and household uses. Books, exercise books, report cards, receipts, envelops greeting cards, calanders, diaries, wall papers, toilet tissue, towels are a few among the usages of paper.

The supply of paper in Ethiopia is dominated by imported products. The only paper producing factory in Ethiopia is Ethiopian Pulp and Paper Share Company which is located at Wonjj. This factory has a production capacity of 8,000-10,000 tonnes, annually. Due to the limited production capacity of the country's sole producer of paper, the country imports a large quantity of paper from oversees (see Table 3.1).

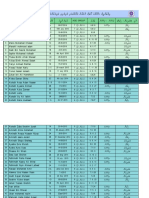

Table 3.1 PAPER SUPPLY IN TONNES Year 1988 1999 2000 2001 2002 2003 Average Domestic 7,489 10,420 5,143 6,144 7,719 6,683 7,266 Import 20,313 160,612 413,432 100,302 32,216 35,926 127,132 Total 27,802 171,032 418,565 106,446 39,935 42,609 134,398

90 - 5 As can be seen from Table 3.1, the 1998/2003 average annual domestic production of paper was 7,266 tonnes while in the same period 127,132 tonnes of paper have been imported which means the average total supply of paper during the period under consideration was 134,398 tonnes per annum, of which only about 5% was locally produced.

Supply of paper has shown a leap in the three years (1999-2001) and returns back to the under 50, 000 tonnes level in 2002. Excluding the leap years, the average annual total supply remains 36,782 tonnes with an annual growth rate of 8.8%.

Applying this annual growth rate, the current effective demand for paper is estimated at 46, 359 tonnes.

2.

Projected Demand

Since modern life needs usage of paper every day, the demand for paper is increasing with population and modernization. Changes in life style, growth in standard of living, the service and industrial sector and educational coverage will contribute to the growth in demand for paper. In forecasting the demand for paper, therefore, GDP growth rate attained in 1999-2004 i.e, 3.76% is applied. The projected demand is presented in Table 3.2. Table 3.2 PROJECTED DEMAND FOR PAPER Year 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 Demand (Tonnes) 48,102 49,911 51,787 53,735 55,755 57,859 60,027 62,284 65,625 67,055

90 - 6

3.

Pricing and Distribution

As a new entrant to the market, the project under study will have an advantage of using latest technology as against the existing domestic producer which will enable to produce at a lesser cost and better quality. The recommended price for the envisaged project is Birr 4 per kg. The product can be distributed by establishing own distribution outlets in strategic towns or by using hired or commissioned agents.

B.

PLANT CAPACITY AND PRODUCTION PROGRAMME

1.

Plant Capacity

From the technical point of view, a small-scale paper mill is one, which has a capacity of less than 30 tonnes per day. Accordingly, considering the demand projections worked out in the market study section, it is proposed that a plant with a daily capacity of 25 tonnes per day is recommended. This is equivalent to 7,500 tonnes per year.

Production capacity is based on a schedule of 300 working days per annum and 3 shifts of eight hours per day.

2.

Production Programme

The envisaged production programme is given in Table 3.4. The schedule is worked out in consideration of the time required for gradual build-up in labour productivity and finetuning of machinery. Production will start at 75% of plant capacity in the first year of operation and reache full-gear in the 3rd year of operation and thenafter.

90 - 7

Table 3.4 PRODUCTION PROGRAMME

Year Capacity Utilization [%] Production (tonnes)

1 75 5,625

2 85 6,375

3-10 100 7,500

IV.

MATERIALS AND INPUTS

A.

MATERIALS

In tropical developing countries, where wood is often in short supply there are a number of sources of fiber. These include straw (e.g. from wheat, barley or rice), bagasse, maize stalks, bamboo, cotton cuttings, lint and fluff, rags (from cotton material), hemp and sisal from old ropes and jute. In the Benishangul-Gumuz region, maize stalks and bamboo are believed to be easily obtainable, especially through commercial farming. In addition if proper maintenance is applied, the existing bamboo forests could be utilized as a source of raw material.

Chemicals are also required in the paper making process. These include caustic soda, lime, ammonia- & calcium sulphate, chlorine, hypochlorite, alum, starch, china clay and talc.

The raw materials required for the envisaged small scale paper plant and corresponding estimated cost are indicated in Table 4.1.

90 - 8

Table 4.1 ANNUAL MATERIALS REQUIREMENTS AND COST (IN TONNES)

Sr. No. 1 2 3 4 Description Wood* NaOH Cl2 CaO Qty. 18,750 2,010 375 101.25 Grand Total

*

Unit Price (Birr) 200 4,360 2,270 1,200 L.C

Cost ('000 Birr) F.C Total 3,750.00 5696.34 553.31 78.98 6,328.63 8,763.6 851.25 121.5 13,486.35

3,750.00 3,067.26 297.94 42.53 7,157.73

Bamboo and, agro-residues are believed to be the major fibers for paper making in the Benishangul Gumuz region.

B.

UTILITIES

Electricity, water and steam are the three major utilities required by the plant. Steam is supposed to be generated by electric boilers; hence, its cost to the project are included in electricity and water costs. Table 4.2 shows annual requirements and associated costs at full production capacity. Annual cost of utilities, at the proposed full production capacity, is estimated at Birr 4,642,500. Table 4.2 ANNUAL UTILITIES REQUIREMENT AND COST

Sr. No. 1 2 3

Description Electricity Water Steam

Unit of Measure kWh m3 Tonne Grand Total

Qty. 10,500,000 750,000 75,000

Unit Price (Birr) 0.335 1.5 -

Total Cost (Birr) 3,517.50 1,125 4,642.50

90 - 9

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Production Process

The process of making paper is based on the fact that wet cellulose fibers bind together when dried under restraint. The processing of paper usually involves the initial separation of the cellulose fibers to form a wet pulp, some form of treatment, such as beating and refining, while in the pulped state, to enhance the quality of the final product, then forming of the sheet paper by hand molding or by paper making machine, and drying. Some further processing is often carried out before or during drying to acquire the desired finish.

The stages involved in transforming raw materials into paper in a small scale mill are the following operations: Delivery and preparation, Bleaching and refining, Sheet forming, Coating, drying & calendaring, and Cutting & packing.

Effluent treatment and disposal is another topic, which needs careful attention. The effluent from a paper mill can contain different chemical species, which, if discharged directly into the environment, would cause untold damage. In medium and large-scale plants specialized recovery equipment is used to reclaim chemicals for reuse or for incineration to provide energy. This is not cost effective in smaller plants and so some form of treatment and/or disposal is required. Biological treatment plants, such as the anaerobic digester, are sometimes used to treat the effluent. This method has the added

90 - 10 benefit of producing methane through digestion of the organic matter in the effluent, which can be used to provide as much as 30 % of the mill's energy requirement. The remaining sludge can, then, be disposed off on the land.

2.

Source Of Technology

The manufacturing technology and machinery for small scale paper production can be obtained from renowned suppliers in Europe and Asia. The following company can be contacted for the supply of machinery and knowhow:

Small Industries Research Institute (SIRI), PO Box 2106, 4/43 Roop Nagar, Delhi 110 007, India. Tel: +91 11291 81 17.

B.

ENGINEERING

1.

Machinery And Equipment

The list of machinery and equipment required for a small scale paper making plant is given in Table 5.1. It should be understood that a pulp & paper mill is generally capital intensive. On this basis, total cost of machinery and equipment is estimated at 20 million, out of which Birr 13 million is required in foreign currency.

90 - 11 Table 5.1 LIST OF MACHINERY AND EQUIPMENT Sr. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 2. Pulper Breaker Beater / refiner Washer Refining equipment De-flaking equipment Screen Cleaners Fourdrinier machine Headbox or flow-box Press Dryer Reeling, winding and sheeting equipment, Handling equipment Size press Machine Cutting machine Laboratory equipment Auxiliary equipment Boiler Description No. (Set) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Set Set 1

Land, Building And Civil Works

Total land requirement of the project is estimated at 10,000m2 out of which 3000m2 is built-up area. Cost of building construction is estimated at about Birr 4.5 million. Total land lease cost, for a period of 70 years is estimated at about Birr 1,400,000. Thus, the total investment cost of land, building and civil works assuming that the total land lease cost will be paid in advance will be Birr 5.9 million.

90 - 12

3.

Proposed Location

It is highly recommendable (and also sustainable) to base a pulp -& paper mill on commercial forests, i.e. trees that are planted on purpose with modern re-forestation schemes.

In view of this, any of the major irrigable areas of the region in the Assosa zone; namely, Afa, Dabus, Checorsa, Afafir, Yabus, Shilla or Fafa could be considered for setting the small-scale paper plant. In addition if proper maintenance plan is arranged the location could be in Kamashi and Metekel zones to utilize the existing bamboo forests/plantation.

VI.

MANPOWER AND TRAINING REQUIREMENTS

A.

MANPOWER REQUIREMENT

Table 6.1 shows the list of manpower required and the estimated annual labour costs. Total manpower requirement, including skilled and unskilled labour, is 75 persons. Correspondingly, the total annual labour cost including fringe benefits, is estimated at Birr 726,750.

90 - 13

Table 6.1 MANPOWER REQUIREMENT AND ANNUAL LABOR COSTS

Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. 9.

Description

Req. Monthly Salary Annual Salary No. (Birr) 3000 2500 2000 2000 2200 2200 800 800 600 900 1200 2000 4000 1000 14400 1200 1200 4000 450 2000 48450 12112.5 60562.5 (Birr) 36000 30000 24000 24000 26400 26400 9600 9600 7200 10800 14400 24000 48000 12000 172800 14400 14400 48000 5400 24000 581400 145350 726750

General Manager Production & Technical Manager Pulp Mill Division Head Paper Mill Division Head Finance & Administration Manager Commercial Manager Accountant Sales Person Purchaser

1 1 1 1 1 1 1 1 1 3 2 1 4 1 24 2 2 20 3 4 75

10. Clerk 11. Secretary 12. Quality Control Manager 13. Production Foreman 14. Chemist 15. Operator 16. Mechanic 17. Electrician 18. Unskilled Labour 19. Guard 20. Diver Total

Workers Benefit = 25% of Basic Salary Grand Total

90 - 14

B.

TRAINING REQUIREMENT

An on-site training programme can be arranged for key production, maintenance and quality control personnel in consultation with the machinery and technology supplier. Additionally, a training programme can be arranged at the Ethiopian Pulp & Paper Share Company. Cost of training of this nature is estimated at Birr 300,000.

VII.

FINANCIAL ANALYSIS

The financial analysis of the small scale paper making project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

2 years 30 % equity 70 % loan

Tax holidays Bank interest Discounted cash flow Repair and maintenance Accounts receivable Raw material, local Raw material, imported Work in progress Finished products Cash in hand Accounts payable

3 years 10.5% 10.5% 5 % of the total plant and machinery 30 days 60 days 90 days 1 day 30 days 5 days 30 days

90 - 15 A. TOTAL INITIAL INVESTMENT COST

The total initial investment cost of the project including working capital is estimated at Birr 34.86 million, of which about 44% will be required in foreign currency. The breakdown of the total initial investment cost is shown in Table 7.1.

Table 7.1 INITIAL INVESTMENT COST ('000 BIRR)

Sr. No. 1 2. 3. 4. 5. 6. Land

Cost Items

Foreign Currency 13,0000 -

Local Currency 1,400.00 4,500.00 7,000.00 150.00 250.00 4,877.40

Total

1,400.00 4,500.00 20,000.00 150.00 250.00 4,877.40 31,177.40 3,717.6 34,895.00

Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure* Total Investment cost

13,0000 2,413.00 15,413.00

18,177.40 1,304.60 19,482.00

Working Capital Grand Total

----------* Pre-production expenditure include interest during construction (Birr 4.17 million), training (Birr 300,000), and costs of registration, licensing and formation of the company including legal fees, commissioning expenses, etc.

90 - 16 B. PRODUCTION COST

The annual production cost at full operation capacity of the plant is estimated at Birr 23.01 million (see Table 7.2). The material and utility cost accounts for 79 per cent while repair and maintenance take 1.12 per cent of the production cost.

Table 7.2 ANNUAL PRODUCTION COST ('000 BIRR)

Year Items Raw Material and Inputs Labour direct Utilities Maintenance and repair Labour overheads Administration cost Total Operating Costs Depreciation Cost of Finance Total Production Cost 3 10,114.8 261.6 3,481.9 195.0 109.0 174.4 14,336.7 2,450.0 2,423.1 19,209.8 4 11,463.4 296.5 3,946.1 221.0 123.5 197.7 16,248.3 2,450.0 2,180.8 20,879.1 7 13,486.5 348.8 4,642.6 260.0 145.4 232.6 19,115.6 2,450.0 1,453.9 23,019.7 10 13,486.5 348.8 4,642.6 260.0 145.4 232.6 19,115.6 2,260.0 726.9 22,102.5

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to equity (Return on equity) and net profit plus interest on total investment (return on total investment) show an increasing trend during the life-time of the project. The income statement and the other indicators of profitability show that the project is viable.

90 - 17

2.

Break-even Analysis

The break-even point of the project is estimated by using income statement projection. Be = Fixed Cost Sales Variable cost 3. Pay -back Period = 23 %

The investment cost and income statement projection are used to project the pay-back period. The project's initial investment will be fully recovered within 5 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 24 % and the net present value at 10.5% discount rate is Birr 29.97 million.

D.

ECONOMIC BENEFITS

The project can create employment for 75 persons. In addition to supply of the domestic needs, the project will generate Birr 31.9 million in terms of tax revenue. Moreover, the Regional Government can collect employment, income tax and sales tax revenue. The establishment of such factory will have a foreign exchange saving effect to the country by substituting the current imports.

Das könnte Ihnen auch gefallen

- Corrugated Paper BoxDokument13 SeitenCorrugated Paper BoxhibadaNoch keine Bewertungen

- Maize StarchDokument15 SeitenMaize StarchpadhaiNoch keine Bewertungen

- Tin Containers Making-PlantDokument26 SeitenTin Containers Making-PlantEsayas Mekonnen100% (1)

- Animal FeedDokument27 SeitenAnimal FeedYem Ane100% (1)

- Recycled PlasticDokument15 SeitenRecycled Plasticbig johnNoch keine Bewertungen

- Ground NutDokument19 SeitenGround Nutabel_kayel100% (1)

- Fdocuments - in Investment Office Anrs Embassy of Kraft Paper Company Name Maanshan HudongDokument26 SeitenFdocuments - in Investment Office Anrs Embassy of Kraft Paper Company Name Maanshan HudongSuleman100% (1)

- Macaroni and SpagheriDokument29 SeitenMacaroni and Spagheriyenealem AbebeNoch keine Bewertungen

- Whole Wheat FlourDokument4 SeitenWhole Wheat FlourSHRUTI AGRAWALNoch keine Bewertungen

- Shyam JVL Submitted ProjectDokument66 SeitenShyam JVL Submitted ProjectRaj Kishore Goswami100% (1)

- Profile On Mushroom FarmDokument20 SeitenProfile On Mushroom FarmMartha Getaneh100% (1)

- Profile On Production of Socks & StockingDokument17 SeitenProfile On Production of Socks & Stockinggetachew liger100% (1)

- Moringa Oil Business Plan and BudgetDokument15 SeitenMoringa Oil Business Plan and BudgetMoringaidNoch keine Bewertungen

- 2 Feasibility Study On DairyDokument40 Seiten2 Feasibility Study On DairyAdefrisNoch keine Bewertungen

- Welding Machine Production PlantDokument26 SeitenWelding Machine Production PlantJohn100% (1)

- Abdisa AdugnaDokument40 SeitenAbdisa AdugnaTesfaye DegefaNoch keine Bewertungen

- Inner FabricsDokument19 SeitenInner Fabricsabel_kayelNoch keine Bewertungen

- Profile On Production of GlucoseDokument15 SeitenProfile On Production of Glucosebig johnNoch keine Bewertungen

- Profile On The Production of VinegarDokument28 SeitenProfile On The Production of VinegarTed Habtu Mamo Asrat100% (1)

- Mechanization and Policy 2018-19Dokument18 SeitenMechanization and Policy 2018-19lucyNoch keine Bewertungen

- Dairy Prod.Dokument29 SeitenDairy Prod.yenealem Abebe100% (1)

- Ethiopian Agricultural Investment PotentialDokument22 SeitenEthiopian Agricultural Investment PotentialA.Nafi YürekliNoch keine Bewertungen

- Profile On Sheep and Goat FarmDokument14 SeitenProfile On Sheep and Goat FarmFikirie MogesNoch keine Bewertungen

- Sesame FarmDokument16 SeitenSesame Farmvusi_zwe28100% (1)

- Revised Marble ProductionDokument26 SeitenRevised Marble ProductionFirezegi TkelehaymanotNoch keine Bewertungen

- Ethiopia Tree Seeds and SeedlingsDokument16 SeitenEthiopia Tree Seeds and SeedlingsSteven Huang100% (1)

- Model Project ProfilesDokument13 SeitenModel Project Profilesabhisek guptaNoch keine Bewertungen

- Investment Office ANRS: Project Profile On The Establishment of Apple Production FarmDokument26 SeitenInvestment Office ANRS: Project Profile On The Establishment of Apple Production Farmbig johnNoch keine Bewertungen

- Profile On The Production of Tomato Sauce & KetchupDokument29 SeitenProfile On The Production of Tomato Sauce & Ketchupnidhi100% (1)

- Project Profile On The Establishment of Soybean Production Farm PDFDokument24 SeitenProject Profile On The Establishment of Soybean Production Farm PDFyohannes meazaneh100% (1)

- Honey ProcessingDokument29 SeitenHoney Processingyenealem Abebe100% (1)

- Guyiti Tengi FULL PROJECT FinalDokument51 SeitenGuyiti Tengi FULL PROJECT FinalJemalNoch keine Bewertungen

- Profile On The Production of Canned MeatDokument29 SeitenProfile On The Production of Canned MeatYem AneNoch keine Bewertungen

- Main Body EddDokument18 SeitenMain Body Edddave tesfayeNoch keine Bewertungen

- Showarobit Flour Mill Project B PlanDokument30 SeitenShowarobit Flour Mill Project B PlanWubshet Birke100% (1)

- Composite FLourDokument27 SeitenComposite FLouryenealem AbebeNoch keine Bewertungen

- Project Profile On The Establishment of Commercial Starch Producing Plant Promoter: Dagnachew Kassahun Tel: 0918353443Dokument34 SeitenProject Profile On The Establishment of Commercial Starch Producing Plant Promoter: Dagnachew Kassahun Tel: 0918353443Rass Getachew100% (1)

- Market Study of Refined Edible OilDokument13 SeitenMarket Study of Refined Edible Oilmulugeta tetemkeNoch keine Bewertungen

- Chaff CutterDokument23 SeitenChaff CutterFekadie TesfaNoch keine Bewertungen

- Dairy FarmDokument14 SeitenDairy FarmTESFALEWATEHENoch keine Bewertungen

- Peanut Products Profile-FDokument27 SeitenPeanut Products Profile-Fyenealem AbebeNoch keine Bewertungen

- Business Plan For Machinery Rental and Material SupplyDokument8 SeitenBusiness Plan For Machinery Rental and Material SupplyAbenetNoch keine Bewertungen

- Avocado Farm and Processing PlantDokument14 SeitenAvocado Farm and Processing Plantsamuel teferi100% (1)

- Shaber GelanDokument49 SeitenShaber GelanRamon ColonNoch keine Bewertungen

- Dagim Lule Business Plan For MojoDokument36 SeitenDagim Lule Business Plan For MojoBereket KidaneNoch keine Bewertungen

- Profile On Production of LimeDokument15 SeitenProfile On Production of Limebig john100% (1)

- Investment Opportunity in Manufacturing Industry PDFDokument34 SeitenInvestment Opportunity in Manufacturing Industry PDFGashaw AlelignNoch keine Bewertungen

- Fruit PP-1Dokument13 SeitenFruit PP-1RedwanNoch keine Bewertungen

- Writing PadDokument25 SeitenWriting PadEsayas Mekonnen100% (1)

- ADisuu MulatDokument41 SeitenADisuu MulatTesfaye Degefa100% (1)

- Marketing Plan For TillersDokument15 SeitenMarketing Plan For TillersBharat Veer Singh RathoreNoch keine Bewertungen

- Profile On Small Scale Paper: MakingDokument17 SeitenProfile On Small Scale Paper: MakingSISAYNoch keine Bewertungen

- Sanitary NapkinDokument12 SeitenSanitary NapkinAnanth SettyNoch keine Bewertungen

- Corrugated Paper BoxDokument13 SeitenCorrugated Paper BoxGulfCartonNoch keine Bewertungen

- Exercise Books EthiopiaDokument23 SeitenExercise Books EthiopiaDilip Kumar Ladwa100% (3)

- Business Plan, Paper Recycling PlantDokument22 SeitenBusiness Plan, Paper Recycling PlantSucesor66650% (4)

- Fuel BriquetteDokument18 SeitenFuel BriquetteDikshit ParekhNoch keine Bewertungen

- Profile On Production of Fuel BriquetteDokument16 SeitenProfile On Production of Fuel BriquetteTung HuynhNoch keine Bewertungen

- MPRA - Paper - 17206 PDFDokument22 SeitenMPRA - Paper - 17206 PDFa.mNoch keine Bewertungen

- Final Ipe NaaaaDokument16 SeitenFinal Ipe Naaaaagility dreamsNoch keine Bewertungen

- Is Modern Capitalism Sustainable? RogoffDokument107 SeitenIs Modern Capitalism Sustainable? RogoffAriane Vaz Dinis100% (1)

- 11 January 2022 Dear Mohammed Rayyan,: TH TH RDDokument5 Seiten11 January 2022 Dear Mohammed Rayyan,: TH TH RDmrcopy xeroxNoch keine Bewertungen

- AJWS Response To July 17 NoticeDokument3 SeitenAJWS Response To July 17 NoticeInterActionNoch keine Bewertungen

- (MX) Public Figures, Private LivesDokument3 Seiten(MX) Public Figures, Private LivesbestatemanNoch keine Bewertungen

- Turtle Walk WaiverDokument1 SeiteTurtle Walk Waiverrebecca mott0% (1)

- Letter To Singaravelu by M N Roy 1925Dokument1 SeiteLetter To Singaravelu by M N Roy 1925Avinash BhaleNoch keine Bewertungen

- Philippine ConstitutionDokument17 SeitenPhilippine ConstitutionLovelyn B. OliverosNoch keine Bewertungen

- Chase Dimond - The Ultimate BFCM Email Marketing PlaybookDokument92 SeitenChase Dimond - The Ultimate BFCM Email Marketing Playbookgreg redNoch keine Bewertungen

- Report WritingDokument3 SeitenReport WritingSeema SinghNoch keine Bewertungen

- 1-Introduction - Defender (ISFJ) Personality - 16personalitiesDokument6 Seiten1-Introduction - Defender (ISFJ) Personality - 16personalitiesTiamat Nurvin100% (1)

- HumanitiesprojDokument7 SeitenHumanitiesprojapi-216896471Noch keine Bewertungen

- Open Quruan 2023 ListDokument6 SeitenOpen Quruan 2023 ListMohamed LaamirNoch keine Bewertungen

- Internship Report Mca Audit Report InternshipDokument33 SeitenInternship Report Mca Audit Report InternshipJohnNoch keine Bewertungen

- Students Wants and NeedsDokument1 SeiteStudents Wants and Needsapi-262256506Noch keine Bewertungen

- Italian Budgeting Policy Between Punctuations and Incrementalism Alice Cavalieri Full ChapterDokument51 SeitenItalian Budgeting Policy Between Punctuations and Incrementalism Alice Cavalieri Full Chapterjames.philson408Noch keine Bewertungen

- Christian Biography ResourcesDokument7 SeitenChristian Biography ResourcesAzhar QureshiNoch keine Bewertungen

- You Are The Light of The WorldDokument2 SeitenYou Are The Light of The WorldKathleen Lantry100% (1)

- Before The Judge - Roger EDokument26 SeitenBefore The Judge - Roger ELexLuther1776100% (4)

- Daftar Kata Kerja Beraturan (Regular Verbs) : Kata Dasar Past Participle ArtinyaDokument6 SeitenDaftar Kata Kerja Beraturan (Regular Verbs) : Kata Dasar Past Participle ArtinyaEva Hirul MalaNoch keine Bewertungen

- Holiday/Vacation Policy: Annual HolidaysDokument18 SeitenHoliday/Vacation Policy: Annual HolidaysmalaysianheartNoch keine Bewertungen

- Vivekananda Institute of ManagementDokument8 SeitenVivekananda Institute of ManagementShubham YadavNoch keine Bewertungen

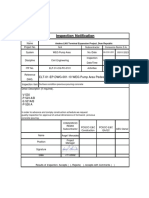

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDokument5 SeitenIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoNoch keine Bewertungen

- 2016 GMC Individuals Round 1 ResultsDokument2 Seiten2016 GMC Individuals Round 1 Resultsjmjr30Noch keine Bewertungen

- An Introduction To The Catholic Charismatic RenewalDokument5 SeitenAn Introduction To The Catholic Charismatic RenewalNoah0% (1)

- Nuclear Power Plants PDFDokument64 SeitenNuclear Power Plants PDFmvlxlxNoch keine Bewertungen

- Teens Intermediate 5 (4 - 6)Dokument5 SeitenTeens Intermediate 5 (4 - 6)UserMotMooNoch keine Bewertungen

- FRA - Project - NHPC - Group2 - R05Dokument29 SeitenFRA - Project - NHPC - Group2 - R05DHANEESH KNoch keine Bewertungen

- UAS English For Acc - Ira MisrawatiDokument3 SeitenUAS English For Acc - Ira MisrawatiIra MisraNoch keine Bewertungen

- Starmada House RulesDokument2 SeitenStarmada House Ruleshvwilson62Noch keine Bewertungen

- A Brief Journey Through Arabic GrammarDokument28 SeitenA Brief Journey Through Arabic GrammarMourad Diouri100% (5)