Beruflich Dokumente

Kultur Dokumente

Solar Still Research Paper

Hochgeladen von

Gopakumar NairOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Solar Still Research Paper

Hochgeladen von

Gopakumar NairCopyright:

Verfügbare Formate

International Journal of Physical Sciences Vol. 4 (11), pp.

705-712, November, 2009

Available online at http://www.academicjournals.org/ijps

ISSN 1992 - 1950 2009 Academic Journals

Full Length Research Paper

Theoretical analysis of water distillation using solar

still

D. W. Medugu* and L. G. Ndatuwong

Department of Physics, Adamawa State University, Mubi Nigeria.

Accepted 16 September, 2009

In developing countries, lack of safe and unreliable drinking water constitutes a major problem. To

alleviate this problem, a solar still was designed and tested in Mubi, Adamawa State of Nigeria. The

radiation from the sun evaporates water inside the solar still at a temperature higher than the ambient.

The principle of operation is the greenhouse effect provided with the glass cover. Energy balances are

made for each element of the still; solar time, direction of beam of radiation, clear sky radiation, optical

properties of the cover, convection outside the still, convection and evaporation inside are accounted.

Theoretical analysis of the heat and mass transfer mechanisms inside this solar still has been

developed. The measured performance was then compared with results obtained by theoretical

analysis. The results clearly show that the instantaneous efficiency increases with the increase of solar

radiation and with the increase of feed water temperature. The distillation efficiency of the still is 99.64%

as compared to the theoretical analysis.

Key words: Solar still, greenhouse effect, ambient, convection, evaporation, feed water.

INTRODUCTION

Portable water may be described as water fit for human

consumption (Medugu and Malgwi, 2006). Supply of

portable water is a major problem in underdeveloped as

well as in some developing countries. Along with food

and air, water is a basic necessity for human beings.

However, a large fraction of the Worlds population, about

1.1 billion people, do not have access to improved or

microbiologically save source of water for drinking and

other essential purposes (WHO, 2002). In addition, there

are many coastal locations where sea water is abundant

but portable water is not available. It is really very fortu-

nate that in terms of high water demand, solar radiation is

also intense. It is therefore beneficial to exploit solar

energy directly by installing solar stills. Two major

advantages favor the use of solar stills clean and free

energy and friendly to environment.

The consumption of save or quality water based on its

source, extent of treatment or consumer handling do not

take into consideration several well documented pro-

blems. One of the problems is protected or improved

sources, such as boreholes and treated urban supplies,

*Corresponding author. E mail: dalemedugu@yahoo.com.

can still be contaminated such that microbiologically

unsafe water is delivered. In some cities in Nigeria, the

water systems draw unsafe water from unprotected or

contaminated sources and deliver it to consumers with no

or inadequate treatment. Yet, these water systems are

classified or categorized as improve or safe. Another

problem is contamination of water during distribution;

whether water is piped or carried into the home. Many

communities have protected improved water supplies and

treated water that is microbiologically safe when

collected, or when it leaves a treatment plant. However,

substandard water distribution systems, intermittent water

pressure due to power outages and other disruption and

illegal connections to the distribution system often lead to

the introduction of fecal contamination and therefore,

microbiologically contaminated water at the consumers

tap or collection point (Sobsey, 2002).

A further problem is that water collected for domestic

use often becomes re contaminated or further

contaminated by unsafe consumer storage and handling

practices at the household level. Many people continue to

obtain their water on daily or frequent basis from any

available source and either carried it or otherwise have it

delivered to the home for personal use. Typically, this

water is not treated or otherwise protected from subse-

706 Int. J. Phys. Sci.

Supply Fill Port

Overflow Port

Tap

Trough

Distilled Output

Collector

Stand

Sun

) (t I

) (t I R

g

Glass Cover

) ( ) 1 ( t I R

g

) (

) ( ) 1 )( 1 (

t I R

t I R R

w

w g g

=

ew

q

.

rw

q

.

cw

q

.

) (

,

t I

w

w

q

.

) (

,

t I

b

b

q

.

Basin Liner

rg

q

.

cg

q

.

Feed Water

Figure 1. Schematic of the system.

quent contamination during use. Such household water is

at the risk of being contaminated by various pathogenic

viruses, bacteria and parasites associated with feacal

wastes and other sources (Sanyaolu et al., 2002).

Distillation is a good method to obtain portable water.

However, the conventional distillation processes such as

multi effect fresh evaporation, thin film distillation,

reverse osmosis and electrodialysis are energy intensive

techniques and are not feasible for large fresh water

demands. Therefore, solar distillation seems to be a pro-

mising method and an alternative way for supplying small

communities in remote areas and islands with water. In

fact, it has been reported that for such places, solar distil-

lation could be the most favorable way for water supply.

Indeed, several solar still designs have been proposed

and many of them have found significant application

worldwide. Nevertheless, solar distillation systems have

low operation and maintenance costs and require large

installation areas and high initial investments. However, it

is the best solution for remote areas and small commu-

nities in arid zones with lack of drinking water.

This paper concerns a study and theoretical analysis of

solar still. It has been designed and installed in Mubi,

Adamawa State of Nigeria, which has a great solar

energy potential.

SYSTEM DESCRIPTION AND OPERATING PRINCIPLE

Figure 1 shows a schematic diagram of the designed solar still,

which consists of a shallow triangular plastic basin. The inner part

of the basin consists of an absorber plate made of galvanized steel

and painted to form a matt black surface (absorptivity of about 0.98

and emissivity of about 0.08 from absorbed energy). The absorber

plate is insulated from the bottom to prevent heat losses. Several

thermometers were installed to measure the glass cover tempe-

rature, the water temperature and the ambient temperature. The top

of the basin is covered with 3 mm thick transparent glass

(transmissivity of about 0.88). The glass is tilted to the angle of

latitude of Mubi, Adamawa State Nigeria, 1015, to ensure maxi-

mum transmission of solar radiation into the still as well as enabling

condensed vapor to trickle down the trough built in the still basin.

The edges of the glass are sealed with headlamp gum so that the

entire basin becomes air tight. The entire material is made of quality

material designed to withstand the harsh conditions produced by

water and sunlight and it is placed on a wooden stand. The design

incorporates a supply fill port through which water is added into the

still. Purified drinking water is collected from the distilled output

collector. There is an overflow port, which will flow out excess water

in the still.

The contaminated water is poured into the still to partially fill the

basin through supply fill port. Care was taken in adding the water at

a slow enough rate to prevent splashing onto the interior of the still

glazing or overflowing into the collection trough. The solar radiation,

I(t) after reflection and absorption by the glass cover is transmitted

inside the still enclosure. This transmitted radiation, g I(t) is further

partially reflected, Rw I(t) and absorbed, w I(t) by the water mass.

The attenuation of solar flux in water mass depends on its

absorptivity and depth. The solar radiation finally reaches the

blackened surface, generally known as the basin liner, where it is

mostly absorbed. After absorption of solar radiation at the basin

liner, most of the thermal energy is converted to water mass and a

small quantity is lost to the atmosphere, by conduction. Conse-

quently, the water gets heated, leading to an increased difference

of water and glass cover temperatures. There are basically three

modes of heat transfer, radiation,

rw

q

.

; convection,

cw

q

.

; and

evaporation,

ew

q

.

from the water surface to the glass cover after

releasing the latent heat. The condensed water vapor trickles down

the inclined glass cover to an interior collection trough from there it

is collected into the storage container through distilled output

collection port. The thermal energy received by the glass cover,

through radiation, convection and latent heat, is lost to the ambient

by radiation and convection.

Theoretical analysis

In this section a complete mathematical model that describes the

processes in the basin of the solar still is presented. These models

will assist in determining the hourly saturated vapor pressures of

water and glass, the convective and evaporative losses coefficients

from the water surface to the glass, the distillate output and the

instantaneous efficiency of the still.

Tiwari et al. (1989) explained the fraction of solar flux at different

components of the still unit as shown in Figure 1 and

mathematically expressed as:

Solar flux absorbed by the glass cover is

g g g

R ) 1 (

'

=

(1)

Solar flux reflected by the water mass

w g g w

R R R ) 1 )( 1 (

'

=

(2)

Solar flux absorbed by the water mass

w w g g w w

R R A ) 1 )( 1 )( 1 (

' '

=

(3)

Solar flux absorbed by the basin liner

) 1 )( 1 )( 1 )( 1 (

'

w w g g b b

R R =

(4)

Solar flux lost by the ambient, through water and glass cover, will

be

Medugu and Ndatuwong 707

) 1 )( 1 )( 1 )( 1 )( 1 (

'

w w g g b a

R R L =

(5)

If the evaporation processes inside the still unit is considered as

isobaric atmospheric process at thermal equilibrium, then all the

absorbed solar radiation is utilized for evaporation and thermal

losses. An energy balance for steady state around the water basin

can be written as (Tamini, 1987):

Rate of Energy In = Rate of Energy Out

That is,

losses ew s b w

Q Q A t I

. .

' '

) ( ) ( + = +

(6)

But

L m Q w

ew

. .

=

,

s a w L losses

A T T U Q ) (

'

.

=

and

w b w

) ( ) (

, '

= +

Where:

ew

Q

.

is the heat which is utilized by solar still for obtaining

m

kg of

distilled water per

2

m

per day;

'

L

U

is the overall heat transfer coefficient from water to ambient

through top, bottom and sides of the still unit;

As is the area of the still;

Tw and Ta are the temperature of the water inside the still and

ambient temperature respectively;

L is the latent heat of vaporization;

w m

.

is the daily output of the distillate.

Equation (6) can now be written as

s a w L s w

w

ew

A T T U A t I L m Q ) ( ) ( ) (

'

. .

= =

(7)

The heat transfer occurs outside the still, from the glass cover and

the bottom and side insulation. Heat transfer within the still is refer-

red to as internal heat transfer mode which consists of radiation,

convection and evaporation as shown in Figure 1.

The external heat transfer, radiation and convection losses from

the glass cover to the outside atmosphere

g

q

can be expressed as

cg rg g

q q q + =

(8)

Where;

) (

4 4

.

s g g rg

T T q =

(9)

And

) (

.

a g cg cg

T T h q =

(10)

Where;

708 Int. J. Phys. Sci.

Tg is the temperature of the glass and may be assumed to be

uniform due to the small thickness of the glass cover;

Ts is the sky temperature;

g is the emissitivity of glass cover;

is the Stefan Boltzmann constant;

hcg is forced convective heat transfer coefficient from the glass to

ambient air.

Equation (9) can also be written as

) (

.

a g rg rg

T T h q =

(11)

with

) (

) (

4

A g

s g

g rg

T T

T T

h

=

(12)

By substituting equations (11) and (10) into equation (8) gives

) ( ) (

1

.

a g g a g cg rg g

T T h T T h h q = + =

(13)

For the effect of free convection and radiation from the glass cover,

g

h

1

is given as (Watmuff et al., 1977):

v h

g

8 . 3 7 . 5

1

+ =

(14)

Where; v is the wind speed in m/s.

In case the radiation and convective losses are to be evaluated

separately, the radiative heat transfer coefficient,

rg

h

can be obtain

from equation (12) and the convective heat transfer coefficient,

cg

h

can be obtain from the relation (Watmuff et al., 1977)

v h

cg

0 . 3 8 . 2 + =

(15)

Heat is also lost from the water in the basin to the ambient through

the insulation and subsequently by convection and radiation from

the bottom or side surface of the still.

The bottom loss coefficient, Ub can be written as

1 1

1

/

1 1 1 1

|

|

.

|

\

|

+

+ + =

|

|

.

|

\

|

+ =

rb cb i i w b w

b

h h L k h h h

U

(16)

Where; ki and Li are the thermal conductivity of air and the

insulation thickness respectively.

The side heat loss coefficient, Us can be approximated as

s

ss

b s

A

A

U U =

(17)

Where; Ass is the surface area in contact with water and As is the

area of the basin of the still. Us can be neglected if Ass<<As.

The rate of heat loss per m

2

from the basin liner to ambient can be

written as;

) (

.

a b b b

T T h q =

(18)

Where;

1

1

|

|

.

|

\

|

+

+ =

rb cb i

i

b

h h k

L

h

(19)

The internal heat transfer mode, that is, the heat exchange from the

water surface to the glass cover inside the still unit is governed by

radiation, convection and evaporation. In this case, the water

surface and the glass cover are considered as infinite parallel

planes. The rate of radiative heat transfer,

rw

q

.

from the water

surface to the glass cover for these infinite parallel planes is given

by

) (

4 4

.

g w g rw

T T q =

(20)

) (

.

g w rw rw

T T h q =

(21)

Where; hrw is the radiative heat transfer coefficient from the water

surface to the glass cover and is given by (Watmuff et al., 1977).

[ ] ) 546 )( (

2 2

+ + + =

g w g w g rw

T T T T h

(22)

Here Tw and Tg are measured in Kelvin.

Heat transfer occurs across humid area in the distillation unit by

free convection, which is caused by the effect of buoyancy, due to

density variation in the humid fluid, which occurs due to the

temperature gradient in the fluid. Hence, the rate of heat transfer

from the water surface to the glass cover,

cw

q

.

by convection is the

upward direction through the humid fluid and can be estimated by

) (

.

g w cw cw

T T h q =

(23)

The convective loss coefficient from the water surface to the glass

hcw is given as (Dunkle, 1961)

3 / 1

3

10 9 . 268

) (

884 . 0

(

+ =

w

w g w

g w cw

P x

T P P

T T h

(24)

Where; Pw and Pg are the saturation partial pressures of water at

water temperature and glass temperature, respectively.

The mass transfer coefficient, he, in terms of convective heat

transfer coefficient hcw (equation (24)) is given by (Baum et al.,

1970):

T a

w

pa cw

e

P M

M

C

L

h

h 1

=

(25)

Medugu and Ndatuwong 709

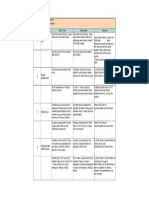

Table 1. Overall results of solar still taken over a period of 9 h in Mubi, Nigeria.

T (h)

I(t)

(W/m

2

)

V

(m/s)

Ta

(

o

C)

Tw

(

o

C)

Tg

(

o

C)

Pw

(N/m

2

)

Pg

(N/m

2

)

hcw

(W/m

2 o

C)

hew

( W/m

o

C)

mew

(kg/m

2

h)

(Tw Ta)/I(t)

(

o

C/W)

i

07:00 452 0.10 27.0 29.2 27.6 4004.44 3657.58 1.1130 3.9264 0.0095 0.0049 1.39

08:00 475 1.05 28.1 30.6 28.5 4331.43 3849.28 1.1224 4.1935 0.0133 0.0053 1.85

09:00 541 1.80 28.8 34.9 30.4 5487.77 4270.49 1.1599 7.4117 0.0502 0.0094 6.16

10:00 820 2.30 30.0 47.1 35.2 10373.63 5561.03 2.3107 15.2070 0.2726 0.0209 22.07

11:00 1041 2.80 31.4 62.2 41.6 21395.54 7832.82 3.2475 34.7934 1.0796 0.0296 68.85

12:00 1238 3.40 31.6 69.0 45.0 29029.40 9329.15 3.3014 44.0987 1.5942 0.0302 85.49

13:00 1108 3.30 32.0 66.0 43.2 25411.54 8508.45 3.1751 38.3050 1.3155 0.0307 78.82

14:00 830 2.60 31.8 60.4 39.8 19694.32 7129.43 2.9565 29.3452 0.9106 0.0345 72.83

15:00 601 2.10 31.2 53.2 35.3 14010.09 5608.02 2.7050 20.6618 0.5571 0.0366 61.54

16:00 256 1.48 30.8 40.3 34.2 7119.02 5282.78 1.7897 5.6293 0.0517 0.0371 20.89

Where:

PT is the total gas pressure;

Mw is the mass of water vapor;

Ma is mass of air and;

Cpa the specific heat per unit volume at constant pressure of the

mixture.

The rate of heat transfer per unit area from the water surface to the

glass cover can be obtained by substituting the appropriate values

for the parameters in equation (25) (Malik et al., 1982). Thus;

) ( 013 . 0

.

g w cw ew

P P h q =

(26)

Cooper (1973) derived similar equation and is given as

) ( 0162 . 0

.

g w cw ew

P P h q =

(27)

Rearranging equation (27) gives

) (

.

g w ew ew

T T h q =

(28)

Where;

g w

g w

cw ew

T T

P P

h x h

=

3

.

10 273 . 16

(Cooper, 1973) (29)

The values of Pw and Pg (for the range of temperature 10

0

C - 90

0

C)

can be obtained from the expression (Fernandez and Chargoy,

1990):

|

.

|

\

|

+

=

273

5144

317 . 25 exp ) (

T

T P

(30)

Where; P(T) is the saturated vapor pressure. The hourly yield of the

solar still is given as:

3600

) (

.

x

L

T T

h m

g w

ew

ew

=

(Tiwari et al., 1989) (31)

The thermal efficiency of solar still can be defined as the ratio of the

amount of thermal energy utilized to get a certain amount of distilled

water to the incident solar energy within a given time interval.

Further, the instantaneous efficiency of the still unit

i

can be

determined as follows:

100

) (

) (

) (

.

x

t I

T T h

t I

q

g w ew

i

= =

(32)

Where; I(t) is the amount of solar radiation within a given time

interval.

RESULTS AND DISCUSSION

The resolution of equations presented in the theoretical

analysis section were employed to determine the result

shown in Table 1 after some measurements as the hours

of the day change from after sunrise to sunset. The

corresponding plots for the ambient, water and glass

temperatures verses the time of the day are displayed in

Figure 2. The curves are essentially quadratic with

maxima occurring at 31.6, 69.0 and 45.0

o

C for ambient,

water and glass respectively. It was noticed that the

temperatures of the water and glass increase to maxima

due to different heat flows (by convection, radiation and

evaporation), going up to the glass.

Figure 3 shows a plot of the hourly variation of

saturated partial pressures of water at water and glass

temperatures, while plots of convective, evaporative

coefficients and distillate against time; and best

characterization curves are shown in Figure 4. Variation

of instantaneous efficiency with

) ( / ) ( t I T T

a w

is shown

710 Int. J. Phys. Sci.

0

10

20

30

40

50

60

70

80

7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00

t(h)

T

a

,

T

w

,

T

g

Ta

o

C

Tw

o

C

Tg

o

C

Figure 2. Ambient, water and glass temperature profiles over a 9 h period.

0

5000

10000

15000

20000

25000

30000

35000

7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00

t(h)

P

w

,

P

g

PwN/m

2

Pg N/m

2

Figure 3. Hourly variation of saturated partial pressures of water at water and glass temperatures.

0

5

10

15

20

25

30

35

40

45

50

7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00

t (h)

h

c

w

,

h

e

w

,

m

e

w

hcw W/m

2 o

C

hew W/m

o

C

mew kg/m

2

h

Figure 4. Convective, Evaporative coefficients and hourly distillate.

in Figure 5. A better efficiency of 85.48% has taken place

at 12:00 h, which can be explained by the existing, at this

time, of a better intensity of solar radiation (1238 W/m

2

)

as well as a better temperature of the feed water

(69.0

o

C) yielding an important quantity of distillate water

of about 1.5942 kg/m

2

h (Figure 4). Figure 6 shows the

Medugu and Ndatuwong 711

0

10

20

30

40

50

60

70

80

90

0.0049 0.0053 0.0094 0.0209 0.0296 0.0302 0.0307 0.0345 0.0366 0.0371

(Tw-Ta)/I(t)

i

Figure 5. Variation of the instantaneous efficiency with ) ( / ) ( t I T T

a w

.

0

10

20

30

40

50

60

70

80

0.1 1.05 1.8 2.3 2.8 3.4

v(m/s)

T

w

C

Figure 6. The impact of the wind velocity on the temperature of water inside the still.

variation of temperature of water inside the still with the

wind velocity taken from 7:00 12:00 h. The increasing in

wind velocity, leads to an increasing production in

distilled water, as well as to a better cooling of the inner

and the outer glass sides, followed by an important

temperature difference between the water and the inner

side of the glass, where this difference is of great interest,

as it represents the cooling agent of the glass and where

the external heat losses by convection can reach their

maximum, as the coefficient of external heat exchange is

dependent on the wind velocity according to the relation

in equation (14).

The experimental result of distillate of water from the

constructed still is presented in Figure 7. The productivity

of distillate water corresponds favorably with the theore-

tical analysis obtained in Figure 4. Their maxima taken

place at 12:00 h, where solar radiation intensity and the

temperature of water inside the still are high, are 1.6 and

1.5942 kg/m

2

h for practical and computed values

respectively giving an efficiency of 99.64%.

Conclusion

A solar still was constructed and studied under actual

environmental conditions of Mubi, Adamawa State of

Nigeria. It is an economical means to provide portable

water for remote areas and small communities in arid

712 Int. J. Phys. Sci.

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

7:00 8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00

t(h)

D

i

s

t

i

l

l

a

t

e

Figure 7. Distillate flow rate verses time.

zones. Theoretical analysis of heat and mass transfer

mechanisms inside the still has been developed. Experi-

mental investigations on the distillation performance of

the solar still have been carried out. The experimental

results obtained show that it corresponds favorably with

the theoretical analysis and the productivity of the still

increases with the intensity of solar radiation and the

temperature of feed water. The results show that the

system has distillation efficiency of 99.64% as compared

to the theoretical analysis.

REFERENCES

Baum VA, Bayaramov RB, Maievsky YM (1970). The Solar Still in the

Deserts. Proceedings of International Solar Energy Congress,

Melbourue p. 426.

Cooper PI (1973). Maximum Efficiency of a Single Effect of Solar Still.

Solar Energy 15: 205.

Dunkle RV (1961). Solar Water Distillation, The Roof Type Still and a

Multiple Effect Diffusion Still, International Heat Transfer, A.S.M.E.

Proceedings of International Heat Transfer, part v, University of

Colorado p. 895.

Fernandez J, Chargoy N (1990). Multistage, Indirectly Heated Solar

Still. Solar Energy 44: 2-215.

Malik MAS, Tiwari GN, Kumar A, Sodha MS (1982). Solar Distillation.

Pergamon press, New York.

Medugu DW, Malgwi DI (2006). Design and Development of Solar Still

for Effectiveness in Eliminating Microbial Contamination and Salt in

Mubi, Adamawa State, Nigeria. Niger. J. Phys. 18(2): 203-209.

Sanyaolu BO, Malgwi DI, Mashauri DA (2002). Performance Evaluation

of some Natural Fibers for Snow and Sand Filter Protection. Afr. J.

Environ. Pollut. Health.2: 61- 66.

Sobsey MD (2002): Managing Water in the Home: Accelerated Health

Gains from Improved Water Supply. Chapel Hill, North Carolina,

U.S.A.

Tamini A (1987). Performance of Solar Still with Reflectors and Black

Dye. International J. Solar Wind Technol. 4: 443.

Tiwari GN, Gupta SP, Lawrence SA (1989). Transient Analysis of Solar

Still in the presence of Dye. Energy Convers. Manage. 29: 59.

Watmuff JH, Characters WWS, Proctor D (1977): Solar and Wind

Induced External Coefficients for Solar Collectors, Complex, Vol.2.

World Health Organization (WHO) (2002): Water, Sanitation and Health

Department of Protection of the Human Environment, Geneva.

Das könnte Ihnen auch gefallen

- Article1380631778 - Medugu and MdatuwongDokument8 SeitenArticle1380631778 - Medugu and MdatuwongKuna KunavathiNoch keine Bewertungen

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Dokument16 SeitenIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNoch keine Bewertungen

- Purification of Water by Solar Energy: Department of Renewable Energy, University College of Engineering, KotaDokument7 SeitenPurification of Water by Solar Energy: Department of Renewable Energy, University College of Engineering, Kotayatharth sharmaNoch keine Bewertungen

- Research Paper Solar Still PDFDokument10 SeitenResearch Paper Solar Still PDFMd IrfanNoch keine Bewertungen

- A Plastic Solar Water Purifier With High Output: John WardDokument5 SeitenA Plastic Solar Water Purifier With High Output: John WardDrEmadEl-SaidNoch keine Bewertungen

- 2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaDokument5 Seiten2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaRahul TripathiNoch keine Bewertungen

- Chapter 2 EnglishDokument9 SeitenChapter 2 Englishdgdhdh_66Noch keine Bewertungen

- Solar Water Purification Research PaperDokument4 SeitenSolar Water Purification Research Paperpkzoyxrif100% (1)

- Solar DesalinationDokument22 SeitenSolar DesalinationAsmaa RamadanNoch keine Bewertungen

- Design and Performance Analysis of A Modified Vacuum Single Basin Solar StillDokument8 SeitenDesign and Performance Analysis of A Modified Vacuum Single Basin Solar StillRaamesh GaikwaadNoch keine Bewertungen

- Solar Water Purification System: Presented by Rohit Sen (Me)Dokument17 SeitenSolar Water Purification System: Presented by Rohit Sen (Me)Santoshi AgrawalNoch keine Bewertungen

- Water DesalinationDokument8 SeitenWater DesalinationMehwishNoch keine Bewertungen

- 1 s2.0 S277294002300005X MainDokument6 Seiten1 s2.0 S277294002300005X MainAswin SanthoshNoch keine Bewertungen

- Design of Solar Distillation SystemDokument8 SeitenDesign of Solar Distillation SystemRahul TripathiNoch keine Bewertungen

- Solar Thermal Desalination Technologies: Hazim Mohameed Qiblawey, Fawzi BanatDokument12 SeitenSolar Thermal Desalination Technologies: Hazim Mohameed Qiblawey, Fawzi BanatAsmaa RamadanNoch keine Bewertungen

- Water DesalinatorDokument34 SeitenWater DesalinatorFour WheelsNoch keine Bewertungen

- Solar Water PurifierDokument42 SeitenSolar Water PurifierAakash DindigulNoch keine Bewertungen

- Mini CapstoneDokument10 SeitenMini CapstoneNathalia SantiagoNoch keine Bewertungen

- A Review On Various Solar Still DesignsDokument10 SeitenA Review On Various Solar Still DesignsajaymNoch keine Bewertungen

- Proposed Title of Research InterestDokument4 SeitenProposed Title of Research InterestMac KYNoch keine Bewertungen

- Design and Fabrication of Water Purification System Using Solar EnergyDokument2 SeitenDesign and Fabrication of Water Purification System Using Solar EnergyMuzaffarNoch keine Bewertungen

- Fabricaton of Solar Water Desalination by Using Photovoltaic MethodDokument43 SeitenFabricaton of Solar Water Desalination by Using Photovoltaic MethodvinothNoch keine Bewertungen

- Thermal and Economic Analyses of Solar Desalination System With Evacuated Tube CollectorsDokument7 SeitenThermal and Economic Analyses of Solar Desalination System With Evacuated Tube CollectorsMohamed AliNoch keine Bewertungen

- Solar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaDokument10 SeitenSolar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaTrimo Wahyu Bimantoro100% (1)

- 03 Nato Arw Paper 2006Dokument9 Seiten03 Nato Arw Paper 2006yatharth sharmaNoch keine Bewertungen

- Solar Distillation 7534 EIywQXODokument16 SeitenSolar Distillation 7534 EIywQXOMUHAMMED FAISALNoch keine Bewertungen

- Thermoeconomic Analysis of Solar Distillation System With Stepped-Corrugated Absorber PlateDokument20 SeitenThermoeconomic Analysis of Solar Distillation System With Stepped-Corrugated Absorber PlateJyotin KateshiaNoch keine Bewertungen

- Performance Analysis of Wick Type Solar Stills A ReviewDokument14 SeitenPerformance Analysis of Wick Type Solar Stills A Reviewamr mesalemNoch keine Bewertungen

- 0 AbsDokument2 Seiten0 AbsSilvers RayleighNoch keine Bewertungen

- Fabrication of Sea Water DesalinatorDokument44 SeitenFabrication of Sea Water DesalinatorvinothNoch keine Bewertungen

- Design and Fabrication of Solar Desalination System: P. VijayakumarDokument5 SeitenDesign and Fabrication of Solar Desalination System: P. Vijayakumarmichelangelo lemonNoch keine Bewertungen

- Experimental Verification and Analysis of Solar Parabolic Collector For Water DistillationDokument6 SeitenExperimental Verification and Analysis of Solar Parabolic Collector For Water DistillationInnovative Research PublicationsNoch keine Bewertungen

- Desalinizacion Al VacioDokument10 SeitenDesalinizacion Al VacioValeria AlarcónNoch keine Bewertungen

- SOLAR WATER DISTILLATION SYSTEM MAIN Final1Dokument55 SeitenSOLAR WATER DISTILLATION SYSTEM MAIN Final1Jjp ParmarNoch keine Bewertungen

- Design of Solar Powered Desalination Plant: AbstractDokument5 SeitenDesign of Solar Powered Desalination Plant: AbstractMustafaNoch keine Bewertungen

- Solar Distillation - GSR WordDokument5 SeitenSolar Distillation - GSR WordGowri ShankarNoch keine Bewertungen

- International Journal of Applied Research & Studies ISSN 2278 - 9480Dokument7 SeitenInternational Journal of Applied Research & Studies ISSN 2278 - 9480Kuna KunavathiNoch keine Bewertungen

- Environmental Engineering Assignment ON Desalination of WaterDokument17 SeitenEnvironmental Engineering Assignment ON Desalination of WaterAditya JalanNoch keine Bewertungen

- Investigation of The EffectDokument13 SeitenInvestigation of The Effect20-003 Arifin SinambelaNoch keine Bewertungen

- Desalination: Keirrstian Roque C. AlvaradoDokument8 SeitenDesalination: Keirrstian Roque C. AlvaradoJuvelyn DaculaNoch keine Bewertungen

- Desalination: Keirrstian Roque C. AlvaradoDokument8 SeitenDesalination: Keirrstian Roque C. AlvaradoJuvelyn DaculaNoch keine Bewertungen

- Solar Still - Distillation: Pdhonline Course E425 (1 PDH)Dokument11 SeitenSolar Still - Distillation: Pdhonline Course E425 (1 PDH)Ravichandran GNoch keine Bewertungen

- Water-Stressed SolutionsDokument14 SeitenWater-Stressed SolutionsVipin VetriNoch keine Bewertungen

- Final PDFDokument22 SeitenFinal PDFRakibul Hassan RokibNoch keine Bewertungen

- Sellami 2017Dokument18 SeitenSellami 2017ritikNoch keine Bewertungen

- Effect of Angle Glass Cover and Type of Solar Collector Efficiency Glass Against The Sea Water Distillation ProcessDokument10 SeitenEffect of Angle Glass Cover and Type of Solar Collector Efficiency Glass Against The Sea Water Distillation ProcesstwoNoch keine Bewertungen

- Seawater Desalination For Production of FreshwaterDokument5 SeitenSeawater Desalination For Production of FreshwaterwizlanNoch keine Bewertungen

- My Final MathafodiDokument51 SeitenMy Final Mathafodiyatharth sharmaNoch keine Bewertungen

- Renewable EnergyDokument7 SeitenRenewable EnergyGauravGuptaNoch keine Bewertungen

- DesalinationDokument10 SeitenDesalinationAmirul AizatNoch keine Bewertungen

- Solar Water Treatment SystemDokument27 SeitenSolar Water Treatment SystemSantoshi AgrawalNoch keine Bewertungen

- RRLDokument19 SeitenRRLJBSNoch keine Bewertungen

- Performance Evaluation of A Conventional Solar Still With Different Types and Layouts of Wick MaterialsDokument10 SeitenPerformance Evaluation of A Conventional Solar Still With Different Types and Layouts of Wick MaterialsEr Dinesh ChauhanNoch keine Bewertungen

- Chemical Students PresentationDokument17 SeitenChemical Students PresentationManpreetSaranNoch keine Bewertungen

- Enhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater ManagementDokument26 SeitenEnhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater Managementgovinda reddyNoch keine Bewertungen

- Solar DesalinationDokument41 SeitenSolar DesalinationRahul TripathiNoch keine Bewertungen

- Portable Water Dispenser For DDokument12 SeitenPortable Water Dispenser For DPàrtërø Pàrtøh MdàdïcNoch keine Bewertungen

- Sustainable Water for the Future: Water Recycling versus DesalinationVon EverandSustainable Water for the Future: Water Recycling versus DesalinationNoch keine Bewertungen

- Solar-Hydrogen Energy Systems: An Authoritative Review of Water-Splitting Systems by Solar Beam and Solar Heat: Hydrogen Production, Storage and UtilisationVon EverandSolar-Hydrogen Energy Systems: An Authoritative Review of Water-Splitting Systems by Solar Beam and Solar Heat: Hydrogen Production, Storage and UtilisationNoch keine Bewertungen

- Pracheena MalayalamDokument150 SeitenPracheena MalayalamGopakumar NairNoch keine Bewertungen

- Nitya Parayana Slokas MalayalamDokument3 SeitenNitya Parayana Slokas MalayalamGopakumar NairNoch keine Bewertungen

- Political History of Modern KeralaDokument10 SeitenPolitical History of Modern KeralaGopakumar Nair0% (1)

- Naga Vans HiDokument9 SeitenNaga Vans HiGopakumar NairNoch keine Bewertungen

- Kingdom of Travancore and The Travancore Royal FamilyDokument10 SeitenKingdom of Travancore and The Travancore Royal FamilyGopakumar Nair100% (2)

- History of TravancoreDokument499 SeitenHistory of TravancoreGopakumar NairNoch keine Bewertungen

- Company AddressDokument1 SeiteCompany AddressGopakumar NairNoch keine Bewertungen

- Small Water Pumping WindmillsDokument62 SeitenSmall Water Pumping WindmillsEngr.CutieApr2024Noch keine Bewertungen

- Zone 1678330388Dokument4 SeitenZone 1678330388Myo Myint MaungNoch keine Bewertungen

- River Diversion WorksDokument3 SeitenRiver Diversion WorksGezahegn Simachew40% (5)

- Citywide Action Plan For Upgrading Unplanned and Unserviced Settlements in Dar Es SalaamDokument78 SeitenCitywide Action Plan For Upgrading Unplanned and Unserviced Settlements in Dar Es SalaamUnited Nations Human Settlements Programme (UN-HABITAT)Noch keine Bewertungen

- SJM Vertical Mixed Flow PumpDokument6 SeitenSJM Vertical Mixed Flow PumpSérgio GnipperNoch keine Bewertungen

- Prefabricated Pumping Stations of Lowara A Xylem BrandDokument48 SeitenPrefabricated Pumping Stations of Lowara A Xylem Brandgeorge_efstratiadisNoch keine Bewertungen

- IWA City Stories SingaporeDokument2 SeitenIWA City Stories SingaporeThang LongNoch keine Bewertungen

- Technical SpecificationDokument51 SeitenTechnical SpecificationKarthick KumarNoch keine Bewertungen

- Delaware-Rondout Bypass TunnelDokument36 SeitenDelaware-Rondout Bypass Tunnelmkeit123100% (1)

- Summarize Notes Rule 9 - 20Dokument12 SeitenSummarize Notes Rule 9 - 20John Carlo LosolosoNoch keine Bewertungen

- Databese Peralatan PKS MayangDokument24 SeitenDatabese Peralatan PKS MayangRyan AndroNoch keine Bewertungen

- 117E CirisBorehole PDFDokument72 Seiten117E CirisBorehole PDFsukirajNoch keine Bewertungen

- Flow Meters & Waste MetersDokument7 SeitenFlow Meters & Waste MetersSankalpa KarunarathneNoch keine Bewertungen

- Records Management in Ministry of WaterDokument52 SeitenRecords Management in Ministry of WaterEdmond MulindwaNoch keine Bewertungen

- Environmental Studies Chapter-4 by VKDokument24 SeitenEnvironmental Studies Chapter-4 by VKTanveer ShaikNoch keine Bewertungen

- Rice Mills of Jharkhand and Their Pollutions Problems by Er. S.K.singhDokument3 SeitenRice Mills of Jharkhand and Their Pollutions Problems by Er. S.K.singhamanNoch keine Bewertungen

- 1.1 An Investigation On The Urban Water Supply Systems in Small Towns of Karoi and MaronnderaDokument3 Seiten1.1 An Investigation On The Urban Water Supply Systems in Small Towns of Karoi and MaronnderaBest JohnNoch keine Bewertungen

- Community DiagnosisDokument52 SeitenCommunity DiagnosisKen Ancheta Lagayada67% (3)

- A1Dokument1 SeiteA1Mark Allan RojoNoch keine Bewertungen

- FT & FV Comparison - R2Dokument1 SeiteFT & FV Comparison - R2Waqar Ahmed ShaikhNoch keine Bewertungen

- Nwpipe Water Pipe Design ManualDokument152 SeitenNwpipe Water Pipe Design Manualudayagirimuralimohan100% (2)

- Flood Emergency Response PlanDokument14 SeitenFlood Emergency Response PlanMamta TulsieramNoch keine Bewertungen

- Price ListDokument22 SeitenPrice ListjnaguNoch keine Bewertungen

- PDFDokument429 SeitenPDFFilipa ChinêsNoch keine Bewertungen

- Mebs6006 1112 10-Airside SystemDokument40 SeitenMebs6006 1112 10-Airside Systemsimoncarter313Noch keine Bewertungen

- Sample 10367 PDFDokument16 SeitenSample 10367 PDFShreya ChaubeyNoch keine Bewertungen

- Underfloor Heating MaualDokument24 SeitenUnderfloor Heating MaualCesar BlNoch keine Bewertungen

- Lire L'intégralité Du Statement de Roshi BadhainDokument3 SeitenLire L'intégralité Du Statement de Roshi BadhainL'express MauriceNoch keine Bewertungen

- Kaleshwaram ReportDokument17 SeitenKaleshwaram ReportHansika Madipadige100% (1)