Beruflich Dokumente

Kultur Dokumente

Os in Keltron Kannur

Hochgeladen von

Anoop VzdOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Os in Keltron Kannur

Hochgeladen von

Anoop VzdCopyright:

Verfügbare Formate

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

CHAPTH 1

I1LC1tC1IC

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

INTRODUCTION

As a part oI our MBA curriculum, organization study is the area where our theoretical knowledge

under study with an organization to Iind out its overall working, learn about origin, growth and

development oI the company, understand and analyses about the quality policy oI the organization and

the role oI each department in the organization dealing industrial products and also oI the working

culture oI the executive and the workers. The organization study at Keltron Component Complex

Limited (KCCL), Kannur has provided me with inIormation oI various aspects and has been a valuable

help and assistance to me.

Keltron is India`s Iirst and the largest electronics corporation in the State sector. Keltron has been a

catalyst in making electronics work in almost every aspect oI our daily liIe, since 1973. It is India's

leading capacitor manuIacturing company. It oIIers the widest range oI capacitors covering various

types oI aluminum electrolytic capacitors, AC motor start capacitors, motor run capacitors and power

Iactor correction (PFC) capacitors.

The main objective oI the study was to get the overall idea about the Iunctions oI an organization.

This report provides details about the diIIerent departments and Iunctions oI the organization.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

OB1ECTIVES OF THE STUDY

To study the organizational structure oI the company

To understand the Iunctions oI various departments

To gain practical knowledge about the Iunctioning oI various departments oI the organization

To understand the strength and weakness oI the organization

To understand the external environment oI the organization

METHODOLOGY

The 'Organization study`` at KELTRON is based on a descriptive study. The data collections were both

Irom primary and secondary sources.

PRIMARY DATA SOURCES;

Interview with managers, oIIice staII and workers

InIormal talk with employees and observations

SECONDARY DATA SOURCES;

ata collected Irom annual reports, departmental report and catalogues etc.

ata collected Irom company website and Wikipedia

ata collected Irom books

SCOPE OF THE STUDY

The study is intended provide managerial insight to a management student. II will enable him to take up

responsibilities oI a manager at ease and provide him more conIidence. The scope oI the study is

conIined to a Iew selected departments and their Iunctions. The trainee may also get a Ieel about how

business executives operate in their work settings.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

LIMITATIONS OF THE STUDY

The limited time Irame oI two weeks in conducting study is the major constraint.

More talks with the Top oIIicials oI the company were not possible due to their busy schedule.

The conclusions and the inIerence are drawn only on the basis oI the report, received Irom the

interviews and it may be colored by personal bias.

CHAPTERISATION

Chapter 1. deals with the introduction oI the study. This chapter highlights the objectives, scope and the

limitations oI the study

Chapter 2: deals with industry proIile

Chapter 3: deals with company proIile. The company details includes company history, product

portIolio, prospective customers, competitors, organization structure etc

Chapter 4: lays down the various departments and its Iunctions.

Chapter 5: deals wlLh Lhe SWC1 and C81L8'S analysls

Chapter : concludes the report with Iindings, suggestions and conclusion.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

CHAPTH

I1tS1L ILCtI1t

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

INDUSTRY PROFILE

INTRODUCTION

ALUMINIUM ELECTROLYTE CAPACITORS

Electrolytic capacitors are passive electronic components whose basic Iunction is to store energy.

Fundamentally, it is a charge storage device which consists oI two conducting plates separated by an

insulator called dielectric. A variety oI capacitors are in use in electronic and electrical circuits.

A Capacitor is identiIied by the type oI dielectric or plate material used on it. Some oI the most common

capacitors which Iind widespread application in electronics as well as electrical industries are paper,

plastic Iilm (such as Polystyrene, Polypropylene, Polycarbonate, etc.), Ceramic, Mica, Aluminium

Electrolytic, Tantalum, and others.

A capacitor is expressed in terms oI its capacitance, in MF (micro-Iarads) and its working voltage in

Volts (V). Other parameters which speciIy its quality are Leakage Current, issipation Factor (also

reIerred to as Loss Factor).

Aluminium Electrolytic Capacitors are being used extensively Ior consumer electronic goods all over

the world. Like any other type oI capacitor the Aluminium Electrolytic Capacitors (AECs) too have two

plates separated with a dielectric. While most other types oI capacitors are bi-polar in nature (any

polarity voltage can be connected to either oI the plates) a good majority oI AECs are polar. The

outstanding advantage oI electrolytic capacitors is the large capacitance/volume ratio. The large

capacitance in ECs arises Irom very thin Iilm oI dielectric used oI the order oI 10

-6

cm.

The method oI making Iilm is by making anodic oxidation. Metals like Aluminium, Tantalum,

Vanadium, Magnesium, Bismuth and Antimony are readily coated with a Iilm oI dielectric by

electrolytic "Iorming process". The Iorming process consists oI the deposition oI a thin Iilm oI

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

Aluminium Oxide on the surIace oI the plate. Aluminium Ioil enters in the tank oI electrolyte with a

constant voltage applied and passes through the tank until the required thickness oI Iilm is produced

The essential parts oI electrolytic capacitors and their Iunctions are:-

PARTS FUNCTIONS

Aluminium Ioil Positive or anode

Oxide Iilm ielectric

Electrolyte Negative or true cathode

(Usually a paste oI glycol and ammonium tetra borate)

Spacers Necessary to separate the cathode and anode Iilm Irom direct contact

A second Aluminium Ioil Contact electrode to the electrolyte - the cathode

Table: 2.1

The etched Ioil type is similar in construction to the plain Ioil type but the anode Ioil is mildly acid

etched beIore Iorming with a consequent increase in the anode surIace area. As the electrolyte is a paste

it is able to make contact with the whole oI the thin oxide Iilm that is Iormed on this undulating surIace.

It is essential to control the etching process closely so that 'thin` spots are not leIt on the Ioil and also to

ensure that no acid is leIt which might contaminate the Ioil. The increase in surIace area results in a

considerable increase in the capacitance obtainable.

Although the capacitors have common Iunction oI storing the electrons/energy, it is used in almost all

the sectors oI the economy. For instance, capacitors are used in various appliances like air-conditioners,

reIrigerators, motors, coolers, pumps and Ians. Railways, power, cement, steel, automotive, electronics--

almost all the sectors make use oI them. New projects across diIIerent sectors will have direct impact on

the demand oI the capacitors. Electrolytic capacitors are mainly used in radio receiver, tape-recorders,

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

TV (Black & White, Colour), PA equipment. Hi-Ii system, deIence computer, communication

equipments and industrial applications.

New projects across diIIerent sectors will have direct impact on the demand oI the capacitors. More the

new projects more will be the demand Ior capacitors. emand is also directly related on demand Ior

consumer durables like reIrigerators and air conditioners. Thus capacitors have universal application and

in some Iorm or the other it is used by both households as well as industries.

GLOBAL SCENARIO:

Faster, Better and Cheaper` is the slogan that drives today`s electronic industry. Consumers are buying

goods at a Iaster rate than the past. Electronic industry now Iollows the slogan Innovate or Perish`.

Thus we can see number oI novel and modiIied products in the market today.

AIter the record year in 2000 the global capacitor market declined in both 2001 and 2002 and it was not

until the second halI oI 2003 that the market started to show signs oI a sustained recovery. The recovery

gained momentum in the Iirst halI oI 2004 Iuelled by strong demand and Iirmer pricing. However, with

additional capacity coming on stream combined with the potential build up oI inventories, pricing is

once again expected to come under pressure. This resulted in a slowing market in 2005 and into the Iirst

halI oI 2006. The market is expected to experience a period oI stronger growth in 2009.

The basic technology Ior the manuIacture oI Aluminium Electrolytic Capacitors has changed a little

since the Iirst high perIormance AECs using Iormed and Etched Aluminium Foil was developed in late

1930's. However, over the years, especially with the advent oI modern equipment utilizing integrated

circuit and with the demand imposed by improved and consistent perIormance over extended period oI

time, substantial adaption and process improvement have been made.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

The major global players in electrolytic capacitors are:

Barker MicroIarads, Inc. (USA)

Cornell ubilier Electronics, Inc. (USA)

uraCap International Inc. (Canada)

Elna Co. Ltd. (Japan)

Epcos AG (Germany)

Guangdong Fenghua Advanced Technology (Holding) Co. Ltd. (China)

Hitachi AIC, Inc. (Japan)

itano Enterprise Corp. (Taiwan)

Haimen Sancon Jetwell Electronics Co., Ltd. (China)

Illinois Capacitor, Inc. (USA)

Jacktronics Electronics Company (China)

Arcotronics Group (Italy)

Evox RiIa Group Oyj (Finland)

Lelon Electronics Corp. (Taiwan)

Nichicon Corp. (Japan)

NIC Components Corp. (USA)

Nippon Chemi-Con (Japan)

Panasonic Corporation (Japan)

Sanyo Electronic evice Company (Japan)

The end-use markets oI aluminium electrolytic capacitors are:

Consumer Electronics

Computers and Peripherals

Telecommunications

Industrial Applications

Inverters

General-Use Inverters

Inverter Air Conditioners

Other Inverters

1o

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ASIAN MARKET TREND: Chinese Capacitor Saga and a comparison with India

China, considered to be one oI the Asian dark horses, has made an astounding progress in the capacitor

industry. The technological, economical, and social policies adopted by the Chinese government have

provided a tremendous boost and encouragement to the Chinese manuIacturers and entrepreneurs.

Supportive import, economic, and development policies have encouraged leading multinationals in the

Iield to set up development and manuIacturing Iacilities in conjunction with the local Chinese players.

This drive has positioned China, unknown and unheralded a decade ago, on the world capacitor map

China has the capacity and technical know-how to produce capacitors oI all types. Varieties oI capacitor

manuIactured range Irom the most advanced surIace-mount ceramic chip capacitors, high-voltage

capacitor banks to the basic components. Capacitor unit sizes range Irom universal-scale, highly

automated, high-volume (mass production) plants down to small garage operations oI the small-scale

entrepreneurs. The technology and size oI the manuIacturing machinery deployed in these plants ranged

Irom state-oI-the-art high-volume version operating in clean-room environments down to the simple

manual machines Iunctioning in unprotected environments. All the large-sized capacitor Iactories are

government-owned or joint ventures with government companies. Most oI the capacitor production and

usage aspects are directly or indirectly government-controlled companies. The number oI Iactories is

more than 500. The production oI ceramic capacitors is 40 billion, electrolytic capacitors 25 billion, and

plastic Iilm capacitors 15 billion. The large-scale units are 25. A large and growing demand Ior

capacitors exists Irom all sectors in China. This oIIers a unique advantage in the setting up oI modern

large-scale plants. These plants can obtain their basic loads Irom the domestic market. Rest oI the

production is exported on marginal-cost basis. This aspect enables Chinese capacitors to be price-

competitive in the export market and the valuable Ioreign exchange earner.

The leading Asian producers oI Aluminium Electrolytic Capacitors are as Iollows:

China

O Andex

O Matsushita Precision

O Bennic Components

O Bonnex Enterprises

1apan

O Nippon Chemicon

O Nichicon

O Shin EL Tsushin Kogyo

O Hitachi Condenser

11

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

South Korea

O Samhwa Elec/Nichicon Korea

O aewoo

O Korea Elna

O Samsung

O ongsung

INDIAN SCENARIO:

The size oI Indian market Ior capacitors is estimated to be around Rs 1000crore. uring the last Iew

years capacitors market has posted a healthy growth oI 10 percent annually. According to a Market

survey the annual requirement oI all kinds oI capacitors in India has been estimated at 1500 million

pieces. . Like any other electrical equipment market, capacitor market is also characterized by the co-

existence oI both organized and unorganized players. However, it is more Iragmented with around

25,000 capacitor players operating in the country.

ue to economic recession and subsequent global meltdown, demand Ior capacitors too has adversely

aIIected. All the major user industries like automobile, cement and steel were adversely aIIected

(especially in the third quarter oI 2008-2009 Iiscal) and also the demand Ior the consumer durables like

air-conditioners and reIrigerators moved southwards. As a result capacitors market encountered sluggish

demand. To cope up with the slackness in demand, many well-known manuIacturers have reduced the

prices oI their products. Indian capacitor industry is dependent on imports Ior some oI its raw materials.

omestic manuIacturers complain about the aberration in duty structure which is hampering the growth.

Taiwan

O Kaimei Electronic

O Yeong Long

O Matsushita Taiwan

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

CHAPTH

CCMIA ILCtI1t

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

COMPANY PROFILE

ABOUT KELTRON:

Keltron, Kerala State Electronics evelopment Corporation Limited, is a public sector Electronics

Company located in Kerala. It is headquartered at the capital city oI Kerala, Thiruvananthapuram. The

company is under the direct control oI the State government oI Kerala. The registered name oI the

company is Kerala State Electronics evelopment Corporation Limited (KSEC). The name

KELTRON was coined Irom two words, Kerala Electronics and when it was necessary to use a small

word in Telegrams reIerring to the company.

Keltron is India`s Iirst and the largest electronics corporation in the State sector. Keltron has been a

catalyst in making electronics work in almost every aspect oI our daily liIe, since 1973. The tag line

launching a State-owned electronics enterprise, more than a quarter century ago, read 'spearheading an

electronics revolution in Kerala. It was an experiment by Government oI Kerala to transIorm the laid-

back, picturesque Kerala State known Ior its spices, natural beauty, Kathakali and the Onam boat races,

to an arena Ior industrial and technological development. That was how Keltron was born.

Within Iive years oI its inception, Keltron had set up a production centre in every district oI the State.

More than 5,000 people were engaged directly or indirectly by Keltron Ior the manuIacture oI electronic

goods. The model oI a State-owned electronics corporation was so successIul that several other States in

India Iollowed suit - launching their own electronics corporations. Over the years, Keltron has built up a

strong inIrastructure spread over 7,00,000 sq It oI built-up area. Equipped with computer-based Iacility

Ior system design & engineering, and soItware development tools Ior embedded systems, Keltron today

is Iully geared to oIIer high quality integrated manuIacturing solutions.

A strong inIrastructure, enterprising team oI people, innovative operational methods, accent on quality

and customer-orientation are the core competencies oI the organization which has made things happen

all these years. Keltron`s expertise in high quality manuIacturing is the direct result oI the highly skilled,

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

multi-disciplinary team oI graduate engineers, project managers and a skilled workIorce with a proven

track record in complex precision manuIacturing. Currently, Keltron employs a work Iorce oI 2000 oI

which 400 are Engineers who possess extensive hands-on experience in technology integration and

adoption, high-tech manuIacturing operations and in managing turn-key projects. Man power at Space

Electronics section has been specially trained at Indian Space Research Organization (ISRO) in high-

reliability soldering, harnessing and QC. Keltron also provides technical manpower to major

organizations like ONGC and VSSC, and collaborators like Hitachi, Japan.

Ensuring quality is a continuous on-going process at all production units. Each Iacility has a Quality

epartment whose business is to see that all quality norms are strictly adhered to in the manuIacturing

process. The manuIacturing centers at Trivandrum , Aroor (Near Cochin), Kannur and Kuttipuram (In

Malappuram) are ISO9001:2000 certiIied. Inspectorate oI Naval Armament (SINA-T), has implemented

their customized quality systems at Keltron Equipment Complex, Trivandrum. The manuIacturing plants

Ior Capacitors, Crystals & Resistors have been granted LCSO approval. In order to meet the stringent

quality requirements oI ISRO, ES-control measures have been strictly adopted at the speciIied areas.

Keltron has an All India Sales Network in place with Iull-Iledged Marketing OIIices in Mumbai, elhi,

Kolkata, Chennai, Bangalore, Hyderabad, Ahmedabad and Trivandrum to provide the quickest possible

service to customers.

Keltron`s capabilities lie in the Iollowing distinct areas:

O Availability oI large pool oI experienced technical manpower.

O Strong inIrastructure and manuIacturing experience.

O Commitment to quality.

O Access to top level technology support.

.

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

The products oI KELTRON consist oI a diversiIied Iield like:

Aerospace Electronics

Security Surveillance Systems like CCTV systems, Attendance/Access control systems, security

electronic products

Intelligent Transportation Systems

Strategic Electronic products Ior eIence and Space departments

InIormation Technology Solutions like Intranet and Inter-oIIice Communication solutions, Web

application development, Website hosting, IT Training, Support services

Process Automation Systems

I Card Project Electoral photo identity card, Touch screen Kiosks, SMART Cards, Bar coded

cards, employees identity cards

Power Electronics Systems High-Irequency IGBT converters, RectiIiers, Industrial Battery

Chargers, High Capacity Voltage Stabilizers, AC & C distribution boards

Electronic Components Aluminium Electrolytic Capacitors, Motor Start Capacitors, Metallised

Plastic Iilm Capacitors, Ceramic isc Capacitors, Carbon/Metal Iilm Resistors, Piezoelectric

Quartz Crystals, Transducers, NTC Thermostats

KELTRON COMPONENT COMPLEX LTD. (KCCL)

Keltron Component Complex Limited (KCCL) is a Government oI Kerala undertaking

promoted by Kerala State Electronic evelopment Corporation (KSEC) and Iounded by Mr. K.P.P

Nambiar. Keltron Component Complex Ltd is located at Keltron Nagar, 15 km Irom Kannur in Kerala.

The company has a land area oI 44,100 square meter, and a Iactory area oI 9150 square meter. It is

India's leading capacitor manuIacturing company. It oIIers the widest range oI capacitors covering

various types oI aluminium electrolytic capacitors, AC motor start capacitors, motor run capacitors and

power Iactor correction (PFC) capacitors.

Keltron Component Complex Limited (KCCL) was incorporated on 8

th

October 1974 as an

associated company oI Kerala State Electronic evelopment Corporation Limited (KSEC). It started

its operation in the year 1976. KCCL`s headquarters is situated at Trivandrum. It is a public limited

company established Ior the manuIacture oI Aluminium Electrolytic Capacitors oI KSEC on 28

th

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

August 1986. A plant Ior the manuIacture oI 18 million pieces oI Aluminium Electrolytic Capacitor was

established in collaboration with M/S N.V Sprague Electromag Belgium, which was a subsidiary oI

Sprague Electric Co. USA. The company went into commercial production in August 1978. The

expansion oI capacitor plant was undertaken in a phased manner to 55 million pieces by 1984-1985 and

150 million pieces by 1990-1991. The production increased to 145 million pieces in 1999-2000.

Keltron Component Complex Limited markets its products under the brand name KELTRON

oI its parent Company. It has a state oI the art manuIacturing Iacility with sophisticated automatic

machines Irom Japan, Taiwan and Europe. It has the capability to produce all types oI Aluminium

Electrolytic Capacitors which conIorm to national and international standards. The manuIacturing

technology is constantly upgraded by R& Centre oI the Company which has the recognition oI the

epartment oI ScientiIic & Industrial Research, Ministry oI Science & Technology, Govt. oI India. The

Company's Quality system has been conIerred with the ISO 9001 accreditation by M/s KPMG

MISSION

'The company aims at maximum satisIaction oI the customers by providing goods which meets the

requirements. And they are committed to achieve goal with the involvement oI employer at all levels

VISION

Keltron`s corporate vision as the company enters the 21

st

century is

To emerge as a strong and selI reliant business enterprise with customer Iocus, proIit orientation

and proIessional outlook.

To build up Keltron as a model PSU in the sunrise Technology Sector oI Electronics and IT.

To Iunction as a backbone oI electronic industry in the state.

To continue to play the role oI nodal agency oI government Ior accelerating the growth oI

development oI this core industry in this state.

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

PROSPECTIVE CUSTOMERS;

The Electrolytic Capacitors are widely used in TV sets, Radio, Tape Recorders, Telephone

instruments, Electronic exchanges, Communication equipments, eIence equipments etc. The present

customers include major Indian manuIactures like BEL, ITI, C-OT, HCL, TATA TELECOM, BPL

TELECOM, BPL, ONIA, SHARP INIA, VIEOCON, CROMPTON CREAVES, TEXLA, ECIL,

INIAN AIRPORT AUTHORITY etc.

COMPETITORS;

The major competitors in India Ior Electrolytic Capacitors are Punssumi India Ltd, Uptron,

Webelson, Philips, Incap, Elnet etc. With the onset oI liberalization oI economy and bringing capacitors

under OGL the company has to compete with international brands like Rubycon, Nichicon, Panasonic,

Samsung, Elna etc.

RAW MATERIALS;

The main raw materials used Ior manuIacturing AEC's are:

O Etched aluminium Ioils 30 to 60 microns thick

O Formed aluminium Ioils and anodised etched aluminium Ioils 50 to 90 microns thick.

O Condenser paper, craIt and Manila Hemp and uplex

O Aluminium cans

O Lead tabs.

O Electrolytes

O Rubber bungs, EPM, EPT rubber.

O isc covers.

O Adhesive tape, high purity and high temperature.

O PVC heat shrinkable sleeve.

O Aluminium wire

O CP Wire (Copper plated) and Plain aluminium Ioil.

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

TECHNOLOGY AND IN-HOUSE R&D;

The epartment oI ScientiIic and Industrial Research, Ministry oI Science and Technology, Government

oI India, have approved the in-house Research and evelopment activities oI the Company. The

company acquired the technology Ior the design, development, manuIacturing and testing Irom its

collaborators M/S NV Sprague Electromag, Belgium. The manuIacturing process was mainly semi-

automatic and manual in nature which was subsequently upgraded by the company by sourcing state oI

the art automatic machinery Irom Japan and Taiwan during the expansions was undertaken. The

company also updated the technology by obtaining inIormation Irom suppliers on the latest

developments taking place in Japan, Korea and Taiwan on compactness and high temperature categories

oI capacitors with its in-house R & eIIects.

PLANT & MACHINERY;

The original machinery Ior manuIacturing 18 million pieces per annum oI capacitors was sourced Irom

M/S NV Sprague Electromag Belgium. Subsequently, Ior the expansion project the company sourced

automatic state oI the art machinery Irom M/S JCC Engineering co., Japan, M/S CK Corporation,

Japan and M/S ons Enterprises, Taiwan.

The engineers and technicians trained in Japan and Taiwan on the machines oversee the repair activities.

Technicians are provided on the job training, suIIicient stock oI spare parts are sourced and stored Irom

the suppliers Ior Iabrication oI spare parts, and tools room Iacility is also available.

INFRASTRUCTURE;

Land Area : 44,100 Sq.m

Factory Area : 9150 Sq.m

Connected Load / Captive power : 2300 KVA / 1000KVA

No. Automatic machines : 100 Nos

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

QUALITY POLICY;

The company aims at maximum satisIaction to their customers by providing goods that meet their

requirements. They are committed to achieving their policy with the involvement oI employees at all

level through a well reIined quality management system, which is continuously reviewed to enhance its

eIIectiveness and updated to meet changing requirements.

AWARDS & RECOGNITIONS;

National Productivity Award Ior 1988-89 under large scale electronic components units

Irom National Productivity council, New elhi.

ELCINA Award 1993 Ior excellence in Research & evelopment Ior work done in the Iield

oI Iorming technology

epartment oI scientiIic and Industrial Research, Ministry oI Science and Technology,

Government oI India approval Ior the in-house Research & evelopment

ISO 9001-2000 certiIication Irom KPMG-QR, USA, only Electrolytic Capacitor

manuIacture to have ISO 9001-2000 certiIication in India

SUBSIDIARIES OF KSEDC;

Keltron Resistors Ltd:

Keltron Resistors Ltd (KRL) located at Keltron Nagar, Kannur istrict was incorporated on 29

April 75 as a subsidiary oI Kerala State Electronics evelopment Corporation Ltd (KELTRON).

The Company was promoted to manuIacture Carbon Film Resistors and Metal Film Resistors.

The company has as installed capacity oI 217 million to manuIacture Resistors oI both type

Carbon Film Resistors and Metal Film Resistors in wattages 0.125, 0.250, 0.500, 1.000 and

2.000 per annum. This unit manuIactures Metal Film Resistors in both proIessional Grade and

General Purpose application. KRL markets its products through its Holding Company which is

the Sole Selling Agent viz. Kerala State Electronics evelopment Corporation Ltd (KELTRON).

o

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

Keltron Magnetics Ltd:

Keltron Magnetics Ltd (KML) is a subsidiary oI Kerala State Electronics evelopment

Corporation Ltd (KELTRON), established in the year 1975 Ior manuIacture oI

Electronics/Electrical Components and equipments. The company is situated at KELTRON

NAGAR, Kannur. The products include Metalized Polypropylene Film Capacitors (MPP

Capacitors), A.C Shunt/ L.T Power Capacitor and Servo Controlled Voltage Stabilizers Ior

Industrial and eIence application.

Keltron Crystals Ltd:

Keltron Crystals Ltd (KXL) is a subsidiary oI Kerala State Electronics evelopment Corporation

Ltd. The Company is located at KELTRON NAGAR in Kannur. The Company has been

manuIacturing various types oI precision piezo electric Quartz Crystals Irom 1976. It was the

second Crystal manuIacturing Unit to be set up in the country. The Company has an installed

capacity oI 2.084 million numbers oI Quartz Crystals per annum. In the HSN classiIication, the

product is termed as Mounted Piezoelectric Crystals under the head 8541.00. The Company`s

product range Ior Crystals is extensive and covers Irequencies Irom 1 KHz to 175 MHz. Quartz

Crystals are used Ior accurate control oI Irequency in electronic circuits and Iind application in

various types oI communication equipment, microprocessor based systems and time keeping

devices.

THE AMALGAMATION

In the year 2008-09, the Company has undergone a transIormation both structurally and Iunctionally.

The Government oI Kerala sanctioned on 27-05-2008 the merger oI the Iour subsidiaries oI Kerala State

Electronics evelopment Cooperation Ltd (KSEC) at Kannur viz. Keltron Resistors Ltd. (KRL),

Keltron Magnetics Ltd. (KML), Keltron Crystals Ltd. (KXL), and Keltron Component Complex Ltd.

(KCCL) into one company. The amalgamated Company was to Iunction under the name, Keltron

Component Complex Ltd (KCCL).

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

The amalgamated Keltron Component Complex Ltd is a major indigenous manuIacturer oI Aluminium

Electrolytic Capacitors, MPP Capacitors, Carbon & Metal Film Resistors, and Piezoelectric Quartz

Crystals. KCCL markets its products under the brand name 'KELTRON oI its parent Company. It has

the state oI the art manuIacturing Iacility with sophisticated automatic machines Irom Japan and Europe.

The Company`s Quality System has been conIerred with the ISO 9001 accreditation by KPMG. The

company registered a turnover oI INR 45Crores in 2009-10 and has aggressive growth plans targeting a

turnover oI 200Crores by 2015

FUTURE PLAN;

The company continues the activity oI reducing the material costs through value engineering, internal

R& eIIort etc. EIIorts are made to increase the volume oI production and sales to enhance its market

share countering the competition Irom domestic as well as Ioreign suppliers.

The company had designed Motor Start Capacitors meeting UL SaIety requirements and the product has

been certiIied by UL India Pvt Ltd. The company is hopeIul oI receiving orders Ior these types oI

capacitors Irom manuIactures oI compressors/motors who export their end-products to Canada & USA.

In September 2008, the Company had commissioned a new plant Ior the manuIacture oI Elements Ior

MPP Capacitors and Power Correction Capacitors. It has also expanded its product range by

commencing the sales oI Power Correction Capacitors in the range oI 1KVA to 30KVA. The Company

is also planning to enter into the manuIacture oI Large Can Capacitors (High CV Capacitors).

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

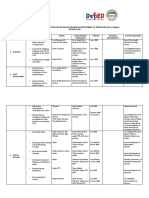

SHARE HOLDING PATTERN AFTER AMALGAMATION

S| No Shareho|der No of shares

a|d up share

cap|ta|

Shareho|d|ng

percentage

kerala SLaLe LlecLronlc

uevelopmenL CorporaLlon LLd

223 223 73

2 CovernmenL of kerala 73 73 24

3 lu8l 44 44 47

4 llCl 6 6 2

lClCl 8ank LLd

6 LlC 6

7 ClC LLd 4 4 3

unlLed lndla lnsurance Co LLd 3

SluCC 42 42 4

ubllc 3466 3466 2

1ota| 303S762S 303S762S0 100

Table 3.1

BOARD OF DIRECTORS

Table 3.2

NAME TITLE

C. PRASANNAKUMAR CHAIRMAN

Lt Col. PARESH AGARVAL MANAGING IRECTOR

K. RAHAKRISHNAN IRECTOR

U. V. PRAVEEN IRECTOR

PRINCESS PARVATHY BHAI IRECTOR

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

PRODUCT RANGE;

1?LS

8adlal capaclLors Alumlnlum LlecLrolyLlc CapaclLors

2 Axlal lead Lype Alumlnlum LlecLrolyLlc CapaclLors

3 AC MoLor SLarL Alumlnlum LlecLrolyLlc CapaclLors

4 Large Can Alumlnlum LlecLrolyLlc CapaclLors

M ( MeLallzed oly ropylene) CapaclLors

SERIES

FEATURES OPERATING

TEMPERATURE

RANGE

WORKING

VOLTAGE

CAPACITANCE

(VDC)

RANGE( F)

BODY

COLOUR

Radial lead Standard

85C

-40C to 85C Ior

WV 160V

-25C to 85C Ior

WV ~ 160V

6.3 ~ 450 V

0.1 ~ 22000 nF

Orange

Radial lead type

Horizontal

Correction 85C

(Nonpolar)

- 40C

to

85C

25 = 50 V

1 = 18 nF

Orange

SE Radial lead

105 C

- 40C to 105C Ior

wv 160v-25 c

to105 c Ior

wv~160v

6.3 ~ 450 V

0.1 ~ 10000 nF

Orange

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

Radial lead

Bi-polar 85C

(Nonpolar)

- 40C

to

85C

6.3 ~ 100 V

0.1 ~ 2200 nF

Orange

Radial lead

low E.S.R

85C

- 40C

to

85C

6.3 ~ 160 V

1 ~ 4700 nF

Orange

Axial lead Standard

85 C

-40C to 85C Ior

WV 160V

-25C to 85 C Ior

WV ~ 160V

6.3 ~ 450 V

0.1 ~ 22000 nF

Orange

MS/M

AC Motor Start

Capacitor Single

Can (MS)& ouble

Can (M)

-30C

to

70C

115 ~ 330VAC

20 ~ 250 nF

Green

Aluminium

Snap-in

85C

-40C to 85C Ior

WV 160V -25C

to85C

Ior WV ~ 160V

10 = 450V

47 = 47000 nF

Orange

Lug Terminal

85C

-40C to 85 C Ior

WV _ 160V

-25C to85C Ior

WV ~ 160V

16 = 400 V

150 ~ 100000 nF

Green

Screw Terminal

85 C

-40C to 85C Ior

WV _ 160V

-25C to85C

Ior WV ~ 160V

16 = 450 V

220 = 100000 nF

Greeen

Table 3.3

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ORGANISATIONAL CHART

Fig. 4.1

SIC

PC I

M D

HOD

EDP

HOD

QA

HOD

E & D

HOD

MAT

HOD

E & F

HOD

PLG

HOD

MFG

HOD

R & D

HOD

MKT

HOD

FN

HOD

CAL

HOD

PE

HOD

P & A

SIC

PC II

SIC

PC III

SIC

PC IV

C

n

A

I

k

M

A

N

8

C

A

k

D

C

I

D

I

k

L

C

1

C

k

S

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ABBREVIATIONS;

HOD: Head OI The epartment

SIC: Section In Charge

PLG: Planning

MFG: ManuIacturing

PC: Production Centre

MKT: Marketing

FN: Finance

P&A: Personnel & Administration

PE: Plant Engineering

CAL: Calibration

R&D: Research & development

E&F : Etching & Forming

MAT: Materials

E&D: Engineering & esign

QA: Quality Assurance

EDP: Electronic ata Processing

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

CHAPTH

ttC1ICA1 ALtAS

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

FUNCTIONAL AREAS AT KCCL

The various business processes, their interaction and sequences are identiIied by the nature oI business.

Following business processes perIormed in the organization are classiIied into the Iollowing sixteen

departments;

1. Personnel & Administration Department

2. Finance Department

3. Marketing Department

4. Planning Department

5. Engineering & Design Department

6. Materials Department

7. Production Department

8. Etching & Forming Department

9. Plant Engineering Department

10.Calibration Department

11.Quality Assurance Department

12.Research & Development Department

13.Electronic Data Processing Department

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

PERSONNEL AND ADMINISTRATION DEPARTMENT

Men, material and machines are regarded as the three important Iactors oI production. Human beings

constitute the organization at all levels and are regarded as the chieI dynamic Iactor oI production.

The management makes an eIIort to co-ordinate human and material resources in such a manner

that organizational objectives are achieved. It is not very diIIicult to handle material resources, but

without the eIIicient use oI Human Resource Management, it can never accomplish the objectives oI the

business.

KCCL has a very eIIicient Personnel and Administration epartment. Manager is the staII

oIIicer in the organization. He gives advice to the eputy Administration OIIicer, Assistant Personnel

OIIicer and Supervisor. The eputy Administration OIIicer gives direction to the security oIIice. The

security guards are under the control oI Security OIIicer. There are two assistants under Assistant

Personnel OIIicer.

DEPARTMENTAL CHART OF PERSONNEL AND ADMINISTRATION DEPARTMENT

Fig.5.1

CLnL8AL

MAnACL8

L8SCnnLL ClllCL8 AuMlnlS18A1lCn ClllCL8

1?lS1 ASSlS1An1 PLLL8 SLCu8l1? 18AnSC81

1

LS1A1L

MAnACL8

o

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

FUNCTIONS

The main Iunctions perIormed by the Personnel and Administration epartment in KCCL are as

Iollows;

Manpower Planning

Recruitment & Placement oI employees

Co-ordination & Training oI employees

Keeping personal records oI employees

Arrange in-house and external training to employees

Time keeping

PerIormance appraisal

Promotion oI employees

Wage administration

Administration oI standing orders and adopting welIare measures

MAN POWER PLANNING:

For meeting the requirements oI employees, management must decide beIore hand as to what type oI

men is to be recruited and in what number they are required. T he Iirst problem is solved by job analysis

and the second problem is tackled type oI men is to be recruited and in what number they are required. T

he Iirst problem is solved by job analysis and the second problem is tackled through man power

planning. A proper and systematic man p|power planning programme requires proper Iorecasting and

planning Ior Iuture. It should consider developing man power requirements Ior the whole organization,

to create and evaluate the man power inventory and to develop required talents among the employees

selected Ior promotion.

REQUIREMENTS AND PLACEMENTS

As KCCL is Govt. Company, recruitment oI candidates is done through employment exchanges.

For executive posts the company approaches proIessional and employment exchanges.

As and when a vacancy arises, Personnel and Administration epartment notiIies it to

employment exchanges. II suitable candidates are not available with the latter body, they issue a NAC.

Then the Personnel epartment publishes vacancies in leading newspapers. AIter receiving the

applications Irom the candidates, the department goes Ior scrutinizing them. The company calls the

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

selected candidate Ior interview. For this the company has a selection board, represented by concerned

department head, a nominee oI the Government oI Kerala and the Personnel Manager. This board

conducts interviews and selects suitable candidate. Then the company gives appointment order to the

selected candidate along with terms and conditions Ior appointment. II the person is willing to abide by

the terms, he is directed to sign and return one oI the copies oI the order.

TRAINING

In KCCL internal as well as external training is given to employees. Fresh hands will be selected as

trainees Ior a period oI one year. For existing employees, it is conducting reIresher training by way oI

lectures, work educational classes, external training etc.

Types oI training program in KCCL can be described as;

1. Introduction or orientation training

There are two phases oI induction training program. The 1

st

phase is generally conducted

by the Personnel epartment. It is concerned with giving the new employee a Iriendly welcome,

brieIing him in the matters concerned with the company`s background, products health and

welIare plans etc.

2. ReIresher training

On Iirst appointment, employees are initially given on-the-job training. ue to

technological developments and improved techniques oI managements and production the

training initially given will become out oI date creating the necessity oI giving new training. For

this Regional Worker`s Training Education Centre oIIicers come to KCCL and give training.

KEEPING TRAINING RECORDS OF EMPLOYEES

All the details regarding the training given to employees are recorded in KCCL Ior Iuture

reIerence. etails such as name oI employees, date oI birth, qualiIication, type oI training,

department in which he is working, joining date, training period etc are recorded.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

PERFORMANCE APPRAISAL

PerIormance appraisal is the systematic evaluation oI an individual`s perIormance in the

job and his potential Ior development. Appraisal is the evaluation oI work quality. It is the

systematic and objective way oI judging the relative work or ability oI an employee in

perIorming his job. Ordinarily the evaluation is done by immediate supervisors. So it is

technique used to know the work oI an employee qualitatively on-the-job in comparison with

other employees. It is one oI the oldest and usual practices oI management.

In KCCL at the end oI the training period the trainees are absorbed according to his

perIormance during the training period. The Personnel epartment provides perIormance

appraisal Iorms Ior selI-appraisal, executive appraisal and annual perIormance appraisal. SelI

appraisal Iorm is Ior selI assessment oI the employees. The other two are Iilled by the concerned

department supervisors. epending upon the perIormance oI the trainee the Personnel

epartment decides whether the probation period is to be extended or not. On the basis oI his

perIormance during the probation period, the department then decides about the regular

placements oI the employee.

TIME KEEPING

Every employee is given a separate card with speciIic number having Iour digits. The

workers, employees, supervisors & executives have diIIerent serial number. A master roll is kept

by the organization. Electronic punching system in KCCL is used to record the time oI entry and

exit oI each employee. Maximum halI an hour late is permitted to every employee. In the second

halI, late coming is not allowed.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

WAGES AND SALARIES

The three categories oI employees, i.e, Executives, Supervisors and Workmen are covered

under MOS signed in April 1996. According to this MOS a senior worker will get a total salary

at around Rs.12,000/- p.m. while a newly inducted workman will get a minimum remuneration

oI Rs.7000/-p.m. Similarly will get supervisor category will get a salary oI around 14,000/-p.m.

The Junior Executive will get around Rs.16,000/-p.m. and the Senior Executive will get

Rs.25,000/-p.m. The A pattern oI workmen is diIIerent Irom those in executive and supervisor

category. The A Ior workmen is based on the Consumer Price Index at all India level. The A

oI executives and supervisors will be based on Kerala Government norms.

ALLOWANCES AND BENEFITS

O Variable Dearness Allowances

VA is an allowance given to the ordinary workers every month. It varies every three

months. It is Iixed as per All India Consumer Price Index, 1960 series.

O House Rent Allowance

This is an allowance given to the employee by the employer in order to compensate the

higher rents prevailing in big cities.

O Conveyance Allowance

It is the allowance used to meeting expenses on conveyance Ior perIorming oIIice duties. A

workman gets Rs.25 as CA.

O Shift Allowance

The general shiIt is Irom 8.30 to 4.30 pm and other 3 shiIts such as 7 to 3, 3 to 11 and 11.pm

to 7.am.The employees who are working in these 3 shiIts apart Irom general shiIt are given

compensation known as shiIt allowance being Rs.5, Rs.7 and Rs.10

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

O Food Subsistence Allowance

There is a reduction in the price oI Iood provided by the company to the employees. The

employees should given only the one Iourth oI the cost oI the Iood. aily a cup oI tea is Iree

to all employees.

O Medical Reimbursement

All employees are eligible Ior medical reimbursement scheme. This scheme also extends to

Iamily members depended on the employee. The amount oI the beneIits is given on the basis

oI service oI employees

O Blood Donation Forum

Keltron having a blood donation Iorum with assistance Irom employees Ior donating blood to

the needy people. The IT dept. helps in checking out blood group. Also the management has

decided to allow once day leave Ior the blood donor.

WELFARE MEASURES

O Washing, toilet and bathroom Iacility

O For drying clothing

O Facility Ior sitting

O First aid equipment

O Canteen

O Crutch

O Library

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ADMINISTRATION OF STANDING ORDERS

In KCCL Standing Order Act 1946 is applicable to workmen in the industrial employment.

This standing order deIines company management, workmen, workmen trainee, workmen`s

classiIication, address and other particulars, probation, seniority, temporary appointment,

transIer, resignation, salary, leaves etc.

GROUP INSURANCE SCHEME

The group insurance scheme is applicable Ior every employees working in the organization.

PROVIDENT FUND

Provident Iund is the Iund that provides Ior Iuture. This Iund is credited by the amount deducted Irom

salary oI the employee every month to which the management adds its own share at a certain rate. When

the employee retires Irom the service, he receives the Iull amount standing in the credit oI his Iund which

includes periodical interest added.

WORK FORCE

Total Employees : Around 700

Permanent Employees : 315

Employees on Contract : 70

Casuals And Apprentice

TRADE UNIONS

O INTUC

O CITU

O KEO (Keltron Employees Organisation)

O KEU (emocratic Keltron Employees Union)

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

FINANCE DEPARTMENT

Finance is the liIe blood oI any business organization. It mainly concerns with acquisition and use

oI Iunds by the Iirm. Adequate amount is always necessary Ior any type oI business. This business

process regulates all types oI commercial transaction.

FUNCTIONS OF FINANCE DEPARTMENT

O Preparation and maintenance oI accounts related document and records

O Recording oI bank transactions like cash withdrawals, maintenance oI details oI check payments

etc

O Maintenance oI commercial accounts, income tax

O Payment oI company bills viz , telephone, electricity and monthly returns oI proIessional tax,

sales tax and CST & VAT

KEY FINANCIAL ACTIVITIES

1) Financial analysis, planning and control

Assessing the Iinancial perIormance and condition oI the Iirm

Forecasting and planning the Iinancial structure oI the Iirm

Instituting appropriate system oI control to ensure that actions oI managers are

concurrent with the goals oI the Iirm

2) Management oI Iirm`s asset structure

etermine the capital budget

Managing the liquid resource

Establishing credit policies

Controlling the level oI industries

ebt and dividend policy

Choosing the special instrument oI Iinancing

Negotiating and developing relation with various suppliers

On the basis oI current assets value SBI-Kannur and Catholic Syrian Bank- Kannur give cash

credit Iacility to Keltron.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

DEPARTMENTAL STRUTURE OF FINANCE DEPARTMENT

Fig.5.2

Abbreviations;

HO : Head OI the epartment

OIC : OIIicer In Charge

PS : Private Secretary

PCu (llnAnCL)

S

SALA8?

ACCCun1S

CLnL8AL

ACCCun1S

SALLS

ACCCun1S

CCS1lnC

ClC ClC ClC ClC

CASPlL8

ACCCun1S

ASSlS1An1

ACCCun1S

ASSlS1An1

CASPlL8

ACCCun1S

ASSlS1An1

1?lS1

ACCCun1S

ASSlS1An1

PLLL8

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

The company`s expenditure has been classiIied into the Iollowing heads;

Materials consumed

Personnel cost

Financing charges

Selling and distribution heads

Excise duty

Other operating expenses

Miscellaneous expenditure

ASSOCIATED BANKS

State Bank oI India, Kannur

Catholic Syrian Bank, Kannur

Syndicate Bank, Kannur

As 80 oI the raw materials Ior the production oI capacitors are imported, Keltron has to provide Letter

oI Credit. The details oI the banks that gives LC Ior this purpose is given as;

NAME OF BANKS CREDIT LIMIT (in lakhs)

State Bank oI India, Kannur 525

Catholic Syrian Bank, Kannur 175

Table 5.1

AUDITING

The company has eIIicient external auditors. Moreover there is an eIIicient internal check system also.

Besides this statutory auditors appointed by the company law board audits the accounts and records oI

the company. AIter completing the audit, copy oI the report is sent to the Accountant General

Trivandrum and also presented beIore the shareholders. II there are any comments Irom the auditors

shareholders, the company should provide suIIicient explanation to these comments.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

The audit in Keltron consists oI;

Internal Audit

Statutory Audit

Audit oI Controller and Audit General oI India

CONTROL

Budget Ior a succeeding year is prepared and presented to the BO during January or February each

year. It is prepared on the basis oI sales projection provided by marketing department. Raw materials

requirement will be estimated on the basis oI comparison with previous year`s Iigures. Total budget is

split up into Iour quarters and procurement oI materials capital and other expenses are controlled on the

basis oI these allocations.

DIVIDEND

The company has regularly paid dividend to its shareholders since 1985-86. The last time it paid a

dividend oI 10 in year 1993-94. Since then it is not able to pay dividend.

RECORDS MAINTAINED

Cash book

Bank book

Journal book

General ledger

Asset register

Purchase journal, Sale pay book, Creditors ledger

Salary register

Subsidiary registers like TA advance, Salary advance, Medical advance, Festival advance and

OT payment register

o

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

MARKETING DEPARTMNENT

Marketing is the perIormance oI business activities that direct the Ilow oI goods and services

Irom the producer to the customer. It is system oI interacting business activities designed to plan,

promote and service to existing and potential customers. The main Iunction oI marketing is to vies the

customer as the very purpose oI business. It emphasizes on identiIication oI a market opportunity and

IulIilling the needs oI customer. Without marketing there is no consumer and without the customer there

is no use Ior the product or service the company is producing.

At KCCL, the marketing department acts as a guide ,and lead the company`s other department in

developing, producing, IulIilling and servicing products and services Ior their customers.

Communication is vital and the marketing department typically has a better understanding oI the market

and customer needs. The goal and guidelines set by the Marketing epartment are in line with the vision

and mission oI the company. The upper management is also involved in and endorses co-operation by

all department in Iollowing and implementing the plan and integrating a consistent message into all

communication channels.

OB1ECTIVES

To generate maximum business at possible price

Speedy realization oI payments

To encourage dealers Ior doing more business and Ior doing immediate payment by oIIering

turnover discount and cash discount

Optimum satisIaction to customers through timely supply oI products, quality products,

competitive price possibly at international level.

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

DEPARTMENTAL STRUCTURE OF MARKETING DEPARTMENT

Fig.5.3

ELEMENT OF MARKETNG MIX

1. Product

Marketing department ensures that the product is oI the same grade as speciIied by the customer

and meets the quality standard. Currently 7 main types oI aluminum electrolytic capacitors are available.

2. Price

The prices are based on pricing policies taken by the company based on the market condition.

The pricing decisions are taken by the Marketing epartment aIter studying the market condition and

also comparing the competitor`s price.

MAkkL1ING

MANAGLk

SALLS CIIICLk SALLS CIIICLk

SALLS ASSIS1AN1 SALLS ASSIS1AN1 SALLS ASSIS1AN1 SALLS ASSIS1AN1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

3. Promotion

It deals with advertising and sales promotion Ior the product. Since the company goes Ior

Industrial marketing department, mainly on electronic segment, it concentrates on direct marketing as a

means oI promotion which enjoys the advantage oI two ways communication. KCCL has corporate

marketing oIIices in Trivandrum, Kannur and has branch oIIices in Mumbai, Kolkata, Ahmedabad, New

elhi, Chennai and Hydrebad. And they also have agents in most oI the places in India.

4. Packaging

iIIerent type oI packing is done Ior diIIerent type oI capacitors. Radial & Axial type capacitors

are generally bulk packed in the Polythene bags which are heat sealed to avoid direct atmospheric

exposure. Individual primary packing in Polythene bag is provided with label which carries outgoing

Inspection Repot No., Capacitors series, Capacitors value, working Voltage, Capacitor Tolerance and

Capacitors size, Capacitor Part No., Temperature, Quality and date oI Packing, Sealed bags are then

packed in cardboard Ior shipment.

Motor start and large Can electrolytic capacitors are generally packed in primary cardboard by

employing suitable separators to avoid damage during transits. The primary cartons are then put into

mother cardboard cartons beIore shipment.

5. Place

In this industry the place is not that much important. In the production plan is set up in

Kalliassery, a rural area in Kannur

MARKETING ACTIVITIES IN KCCL

Keltron carries out the marketing oI KCCL as on contract basis. As holding, KSEC carries out the

Iunction oI marketing on commission basis (charging 7.5 commission). All those years the exports are

done through ET&T department. But Irom 1997 onwards the export is done directly by KSEC.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

AGENTS

Agents are appointed by KCCL because it is not possible Ior the company to cater to the need oI

all the customers who are situated at various cities oI which are Iar Irom their branches. Agents are

appointed as per the recommendation made by the branch oIIicers to the management. Criteria Ior

appointment oI an agent are the Iollowing:

An agent should have a business in the potential area or in the particular industry. The person to

appointed as the agent should be Iinancially strong. The agent should have suIIicient technical

knowledge to deal with customer problems. The agent should have suIIicient market as well as oIIice.

InIrastructure like Iax, telephone, where house etc. The person appointed as agent should have good

contacts in the industry.

AIter satisIying the above conditions the appointed agent enters into an agreement with the

company which is signed both by the agent as well as the wise president and the marketing manager oI

the company.

CASH DISCOUNT

For quick and better cash Ilow, cash discount at 3 may be oIIered to the customers Ior

payment by /Local Cheque against delivery/receipt oI the materials. The OEMs/dealers, whose

earlier bills are outstanding Ior more than 75 days Irom the date oI invoice, will not be eligible Ior cash

discount.

ADVERTISEMENT

The products manuIactured by Keltron are not consumer goods as they are used Ior Iurther production

so it has no requirement to spend huge amount on advertisements. Advertisement thus given is, dealer

shared advertisement. ealers are allowed to release advertisement in newspapers and media on shared

basis. Company would share 50 oI the advertisement cost subject to 0.5 oI the turnover achieved in

respective Iinancial year.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

DISTRIBUTION CHANNEL

As any other Iirm Keltron also use both direct distribution network and dealer network. Earlier emphasis

was given to direct network but now-a-days majority oI the sales is through dealers. There are

authorized dealers Ior the company who carry out the required sales operation.

Fig.5.4

MARKETING PLAN AND STRATEGY

Every year Marketing epartment Iixes a yearly and quarterly target with the authorized dealers by

consulting the production regarding the likely demand Ior the product. Further it collects inIormation

Irom its customers and on this basis the company may modiIy the production requirement to suit the

customer`s requirement also segmentation oI the market is done on the basis oI customers and

applicability. This process helps the company to pick the best market where it can be a tough

competitor.

CUSTOMER COMPLAINTS

In order to attain maximum customer support importance is given Ior aIter sale services. Keltron also

takes keen interest in diagnosing and solving customer complaints.

MANUIAC1UkLk

(kLL1kCN)

AU1nCkISLD DLALLkS

NLW DLLnI

AnAMLDA8AD

nDLkA8AD

CnLNNAI

MUM8AI

kCLkA11A

8ANGALCkL

1nIkUVANA1nAUkAM

k

L

1

A

I

L

L

k

S

C

U

S

1

C

M

L

k

S

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

CUSTOMER SATISFACTION

Customer satisIaction is measured through analysis oI customer Ieedback and complaints, reports oI

marketing personnel, questionnaires, survey oI OEM`s and other suitable methods.

GUARNTEE AND WARRANTEE

One-year guarantee is given to OEM and Government units. In case there are any deIects or shortage in

the quantity the company replaces it and / or provides Iull quantity. A complaint register is provided to

locate complaints.

COMPETITORS

The major competitors in India Ior Aluminum electrolyte capacitors are Punusumi India Ltd.,

Uptron, Webelson, Philips, Incap, Elcap, Elnet, etc. Indigenous competitors are not a threat to KCCL.

But ,due to liberalization oI economy and bringing capacitors under OGL, the company has to compare

with international brands like Rubycon,Panasonic,Sansung,Elna,etc.

BRAND NAME

The brand name oI the company`s product is KELTRON

PACKING

The capacitors are generally packed in the Iollowing ways;

Bulk packing polyethylene bags

Taped Ammo box packing

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

SALES TURN OVER FOR 10 YEARS

Table: 5.2

YEAR

TURN OVER (IN LAKHS)

2000-01

2819.37

2001-02

2693.29

2002-03

3014.21

2003-04

3089.85

2004-05

2448.6

2005-06

2455.2

2006-07

2382.50

2007-08

2159.42

2008-09

3306.12

2009-10

4470.72

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

PLANNING DEPARTMENT

Planning is the step in the direction oI setting up oI an enterprise. The process in the planning

includes the decision taken in advance, when is to be done and Ior what purpose is to be done by

considering all constraints.

In KCCL, planning is to done in all areas like production, materials, etc. and every planning

starts with Iorecasting. Marketing department will prepare an annual budget based on demand, trend and

prices existing in the market. By using this, the planning department prepares the usual yearly

production plan. This then sent Ior the consent oI the M, to commence production. Besides yearly

production plan, 3 month production plan and even a monthly production plan will also be prepared

depending upon the requirement oI the market. uring these times the speciIication may vary Irom the

usual speciIication on which the production is carried out. The prepared plan will be then Iorwarded to

the materials department, production department and all other concerned departments. The production

department checks and makes sure that the plant is capable producing that concerned product upon the

needed speciIications. The material department checks the availability oI raw materials in the stores.

Materials is not available, the purchase department will make arrangement Ior purchasing the materials

and aIter the materials have arrived, special work order is given to the production departments

OBE1ECTIVES

The work order prepared is analyzed and the pending work order list should be given

Material shortage list should provided

To reduce wastage as possible

To attain maximum productivity

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

DEPARTMENTAL STRUCTURE OF PLANNING DEPARTMENT

Fig.5.5

Abbreviations;

HO : Head OI the epartment

OIC : OIIicer In Charge

SIC : Section In Charge

PLANNING COMMITTEE

The planning committee includes;

O Head oI the planning department

O Head oI the marketing department

O Head oI the production department

O Head oI the personnel department

O Head oI the Iinance department

CIC] SIC

nCD

1IS1]ASSIS1AN1 ASSIS1AN1 ASSIS1AN1 1IS1]ASSIS1AN1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

First a monthly budget is prepared and given to each department and Irom the concerned departments

Iurther implementation takes places. Every week a meeting is conducted oI all department heads with

the M. The main objective is to highlight the problem Iaced by each department, to determine

objectives, policies, and strategies to Iinalize a Ieasible solution to the problem.

DUTIES

The main duties oI planning department are;

Prepare the yearly plan based on the yearly marketing, budget and production capacity

Work out material input requirements on the basis oI plan

Prepare monthly plan Ior production

Authorize production based on the plan through work order procedure

Monitor and control use oI material oI production operation

Training oI personnel in the department

o

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

FLOW CHART OF PLANNING

Fig: 5.6

Yearly production plan

Marketing

E &

Annual material indent

Monthly production plan Marketing

E &

Monthly material indent

Job work outside

Work order closing & Analysis

r

o

d

u

c

L

l

o

n

w

o

r

k

o

r

d

e

r

S

l

l

L

L

l

n

g

w

o

r

k

o

r

d

e

r

l

o

r

m

l

n

g

w

o

r

k

o

r

d

e

r

A

s

s

e

m

b

l

l

n

g

w

o

r

k

o

r

d

e

r

Production process

Work order issue

1

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ENGINEERING AND DESIGN DEPARTMENT

Engineering epartment will receive the external document or drawings. This drawing are controlled

and given to the concerned person Ior reIerence. The drawing received Irom the customer, are converted

into stage drawing and Iurther manuIacturing process layout.

For the modern products it is useIul to document and analyze the design logic. This means charting

with the desired product attributes and then identiIying the necessary characteristics Ior raw materials

and process steps. Such an approval goes Ior a name as engineering.

In KCCL, the Engineering and esign epartment is concerned with preparing bill oI materials,

altering materials, giving technical support to manuIacture and giving designs according to the order to

suit the customer requirements.

DEPARTMENTAL STRUCTURE OF ENGINEERING AND DESIGN DEPARTMET

HO : Head OI the epartment Fig: 5.7

OIC : OIIicer In Charge

SIC : Section In Charge

nCD (LNGINLLkING DLSIGN)

CIC]SIC (LNGINLLkING

DLSIGN)

SIC (LI8kAk)

DLSIGN

LNGINLLkING

CCDIIICA1ICN LI8kAk (1LCnNICAL)

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

MATERIALS DEPARTMENT

Stores and materials department is one oI the most important departments in an industry. This

department Iacilitates the smooth Iunctioning oI production. The main objective oI this department is to

procure raw materials / components / consumables as per procurement plans based on production

requirement schedule. They also procure indirect parts / products consumables or services needed Ior all

other processes. This department receives and preserves the raw material till it is issued Ior

manuIacturing.

In KCCL, the Purchase epartment, Raw material stores and Finished Goods stores come

under the Material epartment.

FUNCTIONS

O Purchasing oI raw material, components, consumable space capital, goods at least cost

O Vendor evaluation and selection

O Maintenance and proper use oI purchasing materials

O Receipt, storage, issue and stock control oI materials

O Training oI persons in department

PURCHASE DEPARTMENT

The term purchasing in a narrow sense reIers merely to the act oI buying an item at a price. A

broader understanding makes it a managerial activity, which goes beyond the simple act oI buying and

includes the planning and policy activities covering wide related and complementary activities.

Purchasing is the key stone oI material management. The purchase committee includes head oI material

department, QA department, engineering and design department, R & , Iinance department with M.

OB1ECTIVE

Purchase oI quality input in right time. Cost reduction through product purchase.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ACTIVITIES OF PURCHASE DEPARTMENT

IdentiIication oI the requirements

Selection oI proper source oI supply

eciding on quality and quantity

Finalising delivery schedule and price

Selecting the supplier

Placing the purchase order

Arranging transportation oI material and goods

Receiving the goods and materials and sending them to the stores

Accepting the goods aIter getting quality approval

IMPORT OF MATERIALS

Planning department Iorwards the material requirement to purchase department on periodic basis (yearly

/ halI yearly). Then the purchase department Iloats enquiry to the established vendor. On receipt oI the

quotation, a comparison oI price and other terms are made and purchase is Iinalized on the most

competitive price tendered. The dispatching is generally by sea. In some cases where the material called

Ior urgent required import is resorted by air. The part oI destination is Chennai and consignment is

cleared through our clearing and Iorwarding agents appointed there. Payment is by irrevocable letter oI

credit/sight, remittance. The raw materials imported by Keltron are eligible Ior concessional rate oI

customer duty Ior which they submit details in a speciIied Iormat through eputy Commissioner oI

Central Excise Kannur to commission oI customs Chennai. The Iorwarding agents clear the consignment

oI Chennai port and dispatch the same to Keltron. The terms oI price as per Reserve Bank oI India

regulation is Iree on board. So insurance is converted by Keltron and in the amount oI damages loss, iI

any in transit claim is aIIected to the underwrite Ior getting the loss settled.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

PROCESS FLOW CHART - PURCHASE

Fig: 5.8

UkCnASL kLUSI1ICN 1C UkCnASL SLC1ICN

SLLLC1 SU8CCN1kAC1CkS IkCM AkCVLD CCN1kAC1CkS LIS1

SLND CU1 LNUIk UA1ING SLCIIICA1ICN IkCM

CCN1kCLLLD CCILS

CCMAkL kICL AND kLVICUS LkICkMANCL CN UALI1

DLCIDL CN VLNDCkS]AkCVL UkCnASL

kLAkL UkCnASL CkDLk

VLkII CkDLk ICk 1LCnNICAL]CCMMLkCIAL

CCMLIANCL AND SIGN

AkkANGL LL11Lk CI CkLDI1]C1nLk AMLN1 ICkMALI1ILS

WnLkLVLk kLUIkLD

ICLLCW U WI1n VLNDCk ICk DLLIVLk

AkkANGL CCLLLC1ICN CI DCCUMLN1S IkCM 8ANk

CUS1CMLk CLLAkLNCL 1kANSCk1 1C IAC1Ck

kLCLIVL MA1LkIAL VLkII UAN1I1 LCCAL CLLAkLNCL 1kANSCk1 1C IAC1Ck

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

RAW MATERIALS STORE

AIter inspection, the purchased materials are taken into stores Ior preservation, iI they are meant Ior

stock. Non stock items are directly taken to assembly lines Irom inspection. Preservation, storage can

contribute to eIIective operations.

PURPOSE

1. To establish and maintain storage proceedings

2. Receipt oI correct materials

3. Proper storage oI materials without deterioration in quantity

4. Issue oI correct materials Ior use

SCOPE

Raw materials, Components, Consumables Ior production in capacitor as well as E&F plants oI

KCCL

General stores

Spares

Equipments, tools etc

INVENTORY CONTROL TECHNIQUES

ABC ANALYSIS

It is not desirables to keep the same degree oI control oI all items. The Iirm should pay

maximum attention to those whose value is highest. The Iirm should thereIore classily inventories to

identiIy which items should receive the most eIIort on control. The highest value items are classiIied as

A` class, and would be in tightest control. The C` class represents the least value and would be under

simple control. B` class item Iall in between the two categories and require reasonable attention and

management. The items Iall in A` class are Aluminum Ioil, Tissue paper, Condenser, Chemicals and

paddles, etc which are given must care.

VITTAL, ESSENTIAL, ESIRABLE (VE)

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

MA1OR RAW MATERIAL

Aluminum Ioil, Robber bung, Tab lend, Sleeves PVC, Metro phenol, Bitumen Shalimer, Solder wire

Ilex, Brass bullet, PVC tubes, Clamps, Label and Gasket

There are mainly 299 major raw materials used Ior diIIerent production process. The material handling

equipment used in stores are Trolley, Cash, Pulley block and rum trolley.

LOCATION

The Raw Material stores in two locations one is attached to capacitor production plant and other on is

in the Etching and Forming building

STOCK CONTROL

O Stock control oI spares, general items and consumables is done by stores

O Bin cards are marked with Reorder Level and Reorder Quantity

STOCK VERIFICATION

Materials are veriIied physically at least once in a year against records

SCRAPS MANAGEMENT

Scraps arising out oI production processes are consolidated at scraps yard in diIIerent locations as

marked Ior each. All scraps are disposed oII on sealed tender or otherwise periodically.

SUB CONTRACTORS

It may sometimes become necessary to get some speciIic job work done like sleeve printing etc. through

outside source. In such cases the planning department issue work orders and then the contract is given

by the materials department to one oI the sub contractors on the basis oI the list they maintain. The

materials are received by Keltron Irom the sub contractors and sent Ior inspection. The bill oI the party

is sent to accounts Ior eIIective payment.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

SAFETY MEASURES

Petroleum, Oil and Lubricants are stored in separate area. High speed diesel oil stored in overhead tank

in a separate Ienced area. Stores door is sealed at the close oI working hours with signature oI the OIC

on gummed paper pasted on the door, which is checked at time oI opening next day.

RECORDS MAINTAINED

a) Store Requisition Note

b) Bin Card

c) Store Return Note

d) Material Gate Pass

e) Purchase Requisition

ORGANISATION CHART OF RAW MATERIALS STORE

Fig: 5.9

HO (materials)

OIC stores

SIC stores (1) SIC stores (11)

Assistant Store Keeper

Assistant Store Keeper

Helper Helper Helper Helper Helper Helper

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

FINISHED GOODS STORE

Raw materials aIter passing through various operations is converted to Iinished goods which are ready

Ior sale. These goods are stored in the Iinished goods store. The First In First out (FIFO) method is used

at the time oI dispatching. II the buyer reject any batch oI Iinished goods are taken to Raw material

department and the inIormation is sent to QA department and then re-credited to the FG stores.

FUNCTIONS

O The produced capacitors aIter being passed by the QA department are sent to stores with delivery

note.

O The primary packing is done and the cartoons are labeled and the cartoons are placed in the

speciIied Bin according to the location.

O For accounting purpose a copy oI the delivery note goes to EP department.

O The EP prepares the packing list. On the basis oI the packing list the materials are taken Irom

their respective location and secondary packing is done and Iinally makes the materials ready Ior

dispatch.

O The invoice Ior the goods to be dispatched is prepared.

O ocuments Ior dispatch;

a. Forwarding note to transport

b. eclaration

c. Sales tax Iorm

d. Copy oI invoice

e. Packing list

O Materials are then transported, iI required by the customer

O Receive a lorry receipt or parcel way bill, through courier or local hand delivery

O Ensure that the materials are received on time by the consigned party

O Maintains document pertaining to central excise submission oI monthly returns to Central Excise

authority.

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

ORGANISATION CHART OF FINISHED GOODS STORE

Fig: 5.10

HO (materials)

OIC stores

Store keeper Store keeper

Helper Helper Helper Helper

Helper Helper

o

JN8IJIkIe 0I mANAemeNI JN KeRAIA - AIAPPkZHA

FLOW CHART OF FINISHED GOODS STORES

Fig: 5.11

Credited materials

collecting Irom

manuIacturing

VeriIying

primary

packing &

labeling

Issuing oI

materials

against PS

checking

strapping

Checking oI

invoice

against BA