Beruflich Dokumente

Kultur Dokumente

Swage Nipples WT

Hochgeladen von

Syed AhsanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Swage Nipples WT

Hochgeladen von

Syed AhsanCopyright:

Verfügbare Formate

Swages & Bull Plugs

Swage Nipples

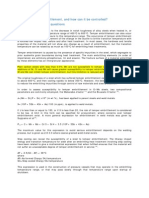

LINE PIPE SWAGES

Size range 1/8 NPS / 6 DN 8 NPS / 200 DN

Manufactured from A106 Grade B seamless pipe or cold drawn bar which is heat treated in accordance with ASTM A234

Choice of raw material dependant upon size and reduction.

Available standard, extra heavy, schedule 160, or double extra heavy

End finishes available: current API threads, beveled, square cut (for socket-weld), or grooved

Available concentric and eccentric

Size

API or

O.D.

Pipe

NPS DN

1/4

3/8

10

Reduced to

Length

LB

KG

Extra Heavy

Weight

IN

MM

NPS

DN

.540

15

1/8

21/4

57

15

1/8

1/4

6

8

21/2

21/2

63

63

.25

.25

6

8 & 10

23/4

23/4

70

70

3

3

3

.675

IN MM

Standard

Weight

LB

KG

Dbl Ex. & 160

Weight

LB

KG

.25

.11

.11

.11

.38

.38

.17

.17

.33

.33

.15

.15

.50

.50

.23

.23

76

76

76

.50

.50

.50

.23

.23

.23

.75

.75

.75

.34

.34

.34

1/2

15

.840

20

1/8

1/4 & 3/8

3/4

20 1.050

25

1/8

1/4 & 3/8

1/2

6

8 & 10

15

88

88

88

.66

.66

.66

.30

.30

.30

1.00

1.00

1.00

.45

.45

.45

102

102

102

1.00

1.00

1.00

.45

.45

.45

1.50

1.50

1.50

.68

.68

.68

114

114

114

114

1.17

1.17

1.17

1.17

.53

.53

.53

.53

2.00

2.00

2.00

2.00

.91

.91

.91

.91

165

165

165

165

165

3.00

3.00

2.33

2.33

2.33

1.36

1.36

1.06

1.06

1.06

4.25

4.25

4.25

4.25

4.25

1.93

1.93

1.93

1.93

25 1.315

33

1/8

1/4 & 3/8

1/2 & 3/4

31/2

6

38 & 10

1/2

15 & 20

31/2

11/4

32 1.660

42

1/4 &3/8

1/2 & 3/4

1

8 & 10

15 & 20

25

1/4 & 3/8

1/2 & 3/4

1

1-1/4

41/2

8 & 10 415 & 20 1/2

25

432

1/2

41/2

1/4 & 3/8

1/2 & 3/4

1

1-1/4

1-1/2

61/2

68 & 10

1/2

15 & 20

625

1/2

32

640

1/2

6-

11/2

40 1.900

50 2-3/8

48

60

4

4

4

2.00

2.00

2.00

.90

.90

.90

1/2

73

1/2 & 3/4

1

1-1/4

1-1/2

2

15 & 20

25

32

40

50

7

7

7

7

7

178

178

178

178

178

3.00

3.00

3.00

3.00

1.36

1.36

1.36

1.36

3.50

3.50

3.50

3.50

3.50

1.60

1.60

1.60

1.60

1.60

8.00

8.00

8.00

8.00

8.00

3.64

3.64

3.64

3.64

3.64

80 3-1/2

88

1/2 & 3/4 15 & 20

1

25

1-1/4

32

1-1/2

40

2 & 2-1/2 50 & 65

8

8

8

8

8

203

203

203

203

203

4.50

4.50

4.50

4.50

2.00

2.00

2.00

2.00

6.00

6.00

6.00

6.00

6.00

2.73

2.73

2.73

2.73

2.73

11.00

11.00

11.00

11.00

11.00

5.00

5.00

5.00

5.00

5.00

90

1/2 thru 1100

1/2

2 thru 3

15 thru

40

50 thru

80

8

8

203

203

5.50

5.50

2.50

2.50

7.50

7.50

3.40

3.40

13.50

13.50

6.14

6.14

1/2 & 3/4

15 & 20

1

25

1-1/4 & 132 & 40

100 4-1/2 114

1/2

50

2

65

2-1/2

80 & 90

3 & 3-1/2

9

9

9

9

9

9

229

229

229

229

229

229

7.50

7.50

7.50

7.50

7.50

3.40

3.40

3.40

3.40

3.40

10.00

10.00

10.00

10.00

10.00

10.00

4.50

4.50

4.50

4.50

4.50

4.50

18.00

18.00

18.00

18.00

18.00

18.00

8.20

8.20

8.20

8.20

8.20

8.20

140

1 thru 125 thru

1/2

40

2 & 2-1/2 50 & 65

3 & 3-1/2 80 & 90

4

100

11

11

11

11

279

279

279

279

11.50

11.50

11.50

11.50

5.23

5.23

5.23

5.23

17.00

17.00

17.00

17.00

7.73

7.73

7.73

7.73

33.00

33.00

33.00

33.00

15.00

15.00

15.00

15.00

150 6-5/8 168

1 thru 125 thru

1/2

40

2 & 2-1/2 50 & 65

3 & 3-1/2 80 & 90

4

100

5

125

12

12

12

12

12

17.00 7.73

305

17.00 7.73

305

17.00 7.73

305

17.00 7.73

305

17.00 7.73

25.00

25.00

25.00

25.00

25.00

11.40

11.40

11.40

11.40

11.40

46.00

46.00

46.00

46.00

46.00

21.00

21.00

21.00

21.00

21.00

50 thru

80

100 &

125

150

13

13

13

330 29.00 13.20 44.00

330 29.00 13.20 44.00

330 29.00 13.20 44.00

20.00

20.00

20.00

78.00

78.00

78.00

36.00

36.00

36.00

21/2

31/2

65 2-7/8

5125

9/16

200 8-5/8 219

2 thru 3

4&5

6

See page 1 for certification of raw material and marking. Select sizes of 1 NPS/25 DN and smaller swages in EX and 160 weights available in

A106. All sizes on this page have been processed in a manner strictly conforming to the requirements of ASTM A234 from material fully meeting

all requirements of that specification. The correct marking for swage nipple to denote conformance with this specification is WPB. All sizes 1

PS / 25 DN and smaller will be made from hex barstock. Most sizes 1-1/4 NPS / 32 DN and larger will be made from pipe, and where pipe is

not a practical raw material, round barstock will be used. No sacrifice of properties will result from such practice.

Bull Plugs

LINE PIPE BULL PLUGS

Nominal Pipe Size range 1/8 NPS / 6 DN 8 NPS / 200 DN

Manufactured from A106 Grade B seamless pipe or cold drawn bar which is heat treated in accordance with ASTM A234

Choice of raw material dependant upon size and reduction.

Available standard, extra heavy, schedule 160, or double extra heavy or solid

End finishes available: current API threads, beveled, square cut (for socket-weld), or grooved

All bull plugs can be tapped.

Size

Pipe

API or O.D.

NPS DN

Length

IN

MM

IN

MM

Standard

Weight

LB

KG

Extra Heavy

Weight

Solid

Weight

Dbl Ex. & 160

Weight

LB

KG

LB

KG

LB

KG

1/8

.405

10

50

.10

.05

.20

.01

.40

.20

1/4

.540

15

50

.11

.05

.20

.01

.40

.20

3/8

10

.675

15

21/4

57

.14

.06

.33

.15

.28

.13

1/2

15

.840

20

21/2

63

.33

.15

.50

.23

.50

.23

3/4

20 1.050

25

23/4

70

.50

.23

.80

.36

.75

.34

25 1.315

33

76

.66

.30

1.38

.63

1.00

.45

11/4

32 1.660

42

31/4

83

1.00

.45

2.25 1.00

1.50

.70

11/2

40 1.900

48

31/2

89

1.17

.53

3.00 1.40

2.00

.90

50

2-3/8

60

102

2.25

1.0

2.50

1.14

5.00 2.25

3.50

1.60

21/2

65

2-7/8

73

127

3.00

1.40

3.50

1.59

8.00

3.60

80

3-1/2

88

152

4.50

2.00

6.00

2.73

11.00

5.00

31/2

90

100

61/2

165

5.50

2.50

7.50

3.41

13.50

6.00

178

7.50

3.40

10.00

4.55

18.00

8.00

100 4-1/2 114

125

59/16

140

81/2

216 12.50

5.70

17.00

7.73

33.00

15.00

150 6-5/8 168

10

254 17.00

7.70

25.00

11.36

46.00

21.00

200 8-5/8 219

11

279 29.00

13.00

44.00

20.00

78.00

35.00

Home Contacts News Products Swages

Oil

Spec Pup

Hammer Swivel API

Sleeve

Couplings

Chokes

Catalogues

Country

Blinds Joints

Unions Joints Fittings Cplgs

Send mail to Webmaster with questions or comments about this web site.

Copyright 2009 CSP Products Ltd

Das könnte Ihnen auch gefallen

- 5a MSS SP 67 Butterfly ValvesDokument19 Seiten5a MSS SP 67 Butterfly ValvessghinausNoch keine Bewertungen

- Industrial Silencers: "Sounds Like Success"Dokument11 SeitenIndustrial Silencers: "Sounds Like Success"Syed AhsanNoch keine Bewertungen

- Cavity Vent in Gate ValvesDokument10 SeitenCavity Vent in Gate ValvesSyed Ahsan50% (2)

- Blower Silencers Technical Literature PDFDokument25 SeitenBlower Silencers Technical Literature PDFSyed AhsanNoch keine Bewertungen

- Flowserve - Edward Valves: Pressure Locking and Over-Pressurization of Double Seated ValvesDokument8 SeitenFlowserve - Edward Valves: Pressure Locking and Over-Pressurization of Double Seated ValvesSyed AhsanNoch keine Bewertungen

- Ventsil Techlit 94 1548 PDFDokument7 SeitenVentsil Techlit 94 1548 PDFVILLAINZ83Noch keine Bewertungen

- Self Cleaning Strainer CatalogDokument12 SeitenSelf Cleaning Strainer CatalogSyed AhsanNoch keine Bewertungen

- Wavistrong From Design To Installation Manual PDFDokument9 SeitenWavistrong From Design To Installation Manual PDFSyed AhsanNoch keine Bewertungen

- Temper Embrittlement - J FactorDokument2 SeitenTemper Embrittlement - J FactorSyed Ahsan100% (1)

- ASME B16.5 Flanges PDFDokument50 SeitenASME B16.5 Flanges PDFPedro De Mesquita Soares CamposNoch keine Bewertungen

- Post Weld Heat TreatmentDokument2 SeitenPost Weld Heat TreatmentgullenariNoch keine Bewertungen

- Stress Itensification FactorsDokument51 SeitenStress Itensification FactorsSyed AhsanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Refinery Presentation PetronasDokument13 SeitenRefinery Presentation PetronasMukesh VishnoiNoch keine Bewertungen

- Report On Importing To South AfricaDokument19 SeitenReport On Importing To South AfricaNadine KadriNoch keine Bewertungen

- Chartering and OperationDokument35 SeitenChartering and Operationmarines0587% (15)

- Lubricant Industry CrisilDokument0 SeitenLubricant Industry CrisilHarinesh PandyaNoch keine Bewertungen

- Marine Insurance: Coverage Classes of Inland InsuranceDokument1 SeiteMarine Insurance: Coverage Classes of Inland InsuranceKit ChampNoch keine Bewertungen

- 2 2 2 A EnginesimulatorDokument2 Seiten2 2 2 A Enginesimulatorapi-254328029Noch keine Bewertungen

- MaterialDokument4 SeitenMaterialAmit PandeyNoch keine Bewertungen

- Sb07 Gypfloor Silent 03Dokument14 SeitenSb07 Gypfloor Silent 03Anna AldokhinaNoch keine Bewertungen

- Storage Construction Fruist & VegetablesDokument8 SeitenStorage Construction Fruist & VegetablessuilanroNoch keine Bewertungen

- Catalogo Proteccion Catodica CadweldDokument22 SeitenCatalogo Proteccion Catodica CadweldnakenoNoch keine Bewertungen

- Rotational Molding: 1 History 2 Equipment and ToolingDokument8 SeitenRotational Molding: 1 History 2 Equipment and ToolingEnachi Georgiana FlorinaNoch keine Bewertungen

- Steel Structure in The IBSDokument90 SeitenSteel Structure in The IBSToy Yi YingNoch keine Bewertungen

- EASA Compliant Aircraft Maintenance Program - Review of Critical Item Part 3Dokument6 SeitenEASA Compliant Aircraft Maintenance Program - Review of Critical Item Part 3TDHNoch keine Bewertungen

- Apparel Industry Plant LayoutDokument9 SeitenApparel Industry Plant LayoutHemant KumarNoch keine Bewertungen

- 02 - Sola-Morales - Manuel - La Piel de Las Ciudades - Esp EngDokument2 Seiten02 - Sola-Morales - Manuel - La Piel de Las Ciudades - Esp EngMaría José FreireNoch keine Bewertungen

- Chapter 1 - Traffic VolumeDokument18 SeitenChapter 1 - Traffic VolumeIsuru BiyanwilaNoch keine Bewertungen

- Retail ManagementDokument265 SeitenRetail ManagementAsmita Shashank TaysheteNoch keine Bewertungen

- Scania Mining Solutions PDFDokument32 SeitenScania Mining Solutions PDFMohanraj Venu100% (1)

- Good Sample of SOPEPDokument63 SeitenGood Sample of SOPEPGenghu Ye100% (3)

- Annexure - II For SOP On SOP - Pharmaceutical GuidanceDokument4 SeitenAnnexure - II For SOP On SOP - Pharmaceutical Guidancerehmat aliNoch keine Bewertungen

- The Global Leader in Railway Wheels.: A World Apart in ReliabilityDokument4 SeitenThe Global Leader in Railway Wheels.: A World Apart in ReliabilityMANOJNoch keine Bewertungen

- JFTLV H Laö Mhö, Yö&33004@99Dokument131 SeitenJFTLV H Laö Mhö, Yö&33004@99Latest Laws TeamNoch keine Bewertungen

- Warehousing Including Warehousing Decision in Detail and DistributionDokument31 SeitenWarehousing Including Warehousing Decision in Detail and DistributionNimishaNandan100% (1)

- Airbus AC A330 20140101Dokument575 SeitenAirbus AC A330 20140101Kareem Lagi50% (2)

- Task Sheet 1Dokument4 SeitenTask Sheet 1crystal galapon100% (3)

- SOP Slump TestDokument2 SeitenSOP Slump TestLloyd R. PonceNoch keine Bewertungen

- SES - 17 TABLERO CONTROL (Autoguardado)Dokument101 SeitenSES - 17 TABLERO CONTROL (Autoguardado)Miguel BermudezNoch keine Bewertungen

- Aviation ResumeDokument4 SeitenAviation Resumeapi-3709957100% (1)

- DanCut Rev1 en PDokument8 SeitenDanCut Rev1 en PDaniel ConwayNoch keine Bewertungen