Beruflich Dokumente

Kultur Dokumente

FLY ASH SAND LIME BRICK - AN ALTERNATIVE WALLING MATERIAL Wa

Hochgeladen von

DIPAK VINAYAK SHIRBHATEOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FLY ASH SAND LIME BRICK - AN ALTERNATIVE WALLING MATERIAL Wa

Hochgeladen von

DIPAK VINAYAK SHIRBHATECopyright:

Verfügbare Formate

Flyash Sand Lime Brick- An Alternative Walling Material

FLY ASH SAND LIME BRICK – AN

ALTERNATIVE WALLING MATERIAL.

1. INTRODUCTION

About 80 million tonnes of fly ash is being produced

and thrown out as a waste, from about 60 Thermal Power stations

functioning in our country. This fine material not only creates pollution

but also poses serious disposal problem. One of the best ways of

utilizing this hazardous pollutant is to convert it into a building material

like brick. Brick is considered to be the most common walling material,

used by the man from pre-vedic period. The conventional burnt clay

brick has been causing severe depletion of fertile land, directly affecting

the country’s green revolution campaign. Production of fly ash sand

lime bricks can, to a certain extent, help to solve the above mentioned

problems.

C.O. E. & T., Akola. 1

Seminar 2000-2001

2. MATERIALS

Fly ash is a siliceous material with association of

amorphous/Glassy mass. The constituent particles of fly ash react with

lime at elevated temperature and pressure of steam to form calcium

silicate hydrate and calcium aluminates hydrate. The nature and extent

of formation of calcium silicate hydrate depends upon many factors like

physico-chemical and mineralogical characteristics of raw materials,

molar ratio of calcium oxide and silica, and proportioning and curing

conditions. In the present study, three fly ash samples containing

unburnt carbon 0.5, 4.3, 7.9 percent have been taken. Different mixes

having Fly ash, sand and lime in 70 : 20 : 10, 60 : 30 : 10, 50 : 40 : 10 by

weight were prepared for producing Bricks.

TABLE –1

Raw materials Requirement CBRI

(a) Fly Ash 50-60%

(b) Sand 30-40%

(c) Lime 8-10%

(d) Ordinary Portland cement --

(e) Gypsum 0.5-2.0%

Accelerator NIL

Dept. of Civil. Engg. 2

Flyash Sand Lime Brick- An Alternative Walling Material

3. PROCESS DETAILS

The CBRI has developed four technological options to

produce fly ash sand lime bricks are as under :

i) Shaping of bricks at high pressure and steam curing at high

pressure known as Autoclaved Flyash sand lime bricks.

ii) Shaping of bricks at high pressure and steam curing at atmospheric

pressure.

iii) Shaping by vibro-compaction and steam curing at high pressure.

iv) Shaping by vibro-compaction and steam curing at atmospheric

pressure called C Bricks.

Option No.1:-

Shaping of bricks at high pressure and steam curing at

high pressure.

This option involves four major operations namely

proportioning of raw materials using screw feeds or box feeder, dry and

wet mixing by means of pair of double shaft mixer, shaping by suitable

press, enabling to impart a pressure of 200-240 Kg/Cm 2 and steam curing

at 10 – 14 Kg/cm 2 in autoclaves.

C.O. E. & T., Akola. 3

Seminar 2000-2001

1. Proportioning Unit 6. Belt Conveyor

2. Bucket Elevator 7. Hydraulic Press

3. Double Shaft Mixer 8. Off- Take Belt Conveyor

4. Water Spraying 9. Trolley with Bricks

5. Double Shaft Mixer 10. Autoclave

SCHEMATIC DIAGRAM FOR PRODUCTION OF BRICKS BY HIGH PRESSURE

SHAPING AND HIGH PRESSURE STEAM CURING

Dept. of Civil. Engg. 4

Flyash Sand Lime Brick- An Alternative Walling Material

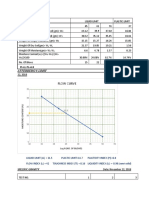

VARIATION OF COMPRESSIVE STRENGTH WITH LOSS ON

IGNITION

C.O. E. & T., Akola. 5

Seminar 2000-2001

Inference:

This option has a potential handle a fly ash with

unburnt carbon as high as 8% to produce bricks of compressive strength

more than 100 Kg/Cm 2 . In other words with this option even pond ash

can directly be used for brick production.

Brief Project Profile :

Capacity of plant : 40,000 bricks per day in 3 shifts

Total capital investment : Rs. 350 lacks.

Cost of Purchased Equipment : Rs 200 lacs.

Man power requirement : 100 persons.

Land Required : 0.6 Hectere

Installed power : 300 KW

Estimated cost of Production : Rs 1400 per 1000 bricks.

Dept. of Civil. Engg. 6

Flyash Sand Lime Brick- An Alternative Walling Material

Option No – 2:

Shaping of bricks at high pressure and steam curing at

atmospheric pressure

In this option proportioning and shaping operations are done exactly as

in option no.(1). The steam curing of green bricks is done in ordinary

chambers at 1 Kg/Cm 2 pressure instead of autoclaves.

Inference:

This option has a potential to handle a fly ash having

unburnt carbon upto 5% to produce bricks of compressive strength more

than 80 Kg/Cm 2 .

Brief Project Profile.

Capacity of Plant : 40,000 bricks per day in shifts.

Total capital investment : Rs.300 lacs.

Cost of purchased equipment : Rs. 130 lacs.

Manpower Requirement : 100 persons.

Land Requirement : 0.6 Hecters.

Installed Power : 300 K W.

C.O. E. & T., Akola. 7

Seminar 2000-2001

1. Proportioning Unit 6. Belt Conveyor

2. Bucket Elevator 7. Hydraulic Press

3. Double Shaft Mixer 8. Off- Take Belt Conveyor

4. Water Spraying 9. Trolley with Bricks

5. Double Shaft Mixer 10. Steam curing chamber

SCHEMATIC DIAGRAM FOR PRODUCTION OF BRICKS BY HIGH

PRESSURE SHAPING AND ATMOSPHERIC PRESSURE STEAM CURING

Dept. of Civil. Engg. 8

Flyash Sand Lime Brick- An Alternative Walling Material

VARIATION OF COMPRESSIVE STRENGHT WITH LOSS ON

IGNITION

C.O. E. & T., Akola. 9

Seminar 2000-2001

Option No – 3:-

Shaping by Vibro-compaction and steam curing at

high pressure.

Under this option, mixing of raw materials is done in

a pan mixer and shaping is done in a vibro-compaction machine which

produces a low moulding pressure. The green bricks are dried before

subjecting to steam curing at high pressure in autoclaves.

Inference

The fly ash having higher unburnt carbon can be used

for producing bricks of adequate strength by adopting this option i.e.

vibro-compaction moulding and high pressure steam curing.

Brief Project profile :

Capacity of Plant : 3000 bricks per shift.

Total capital investment : Rs. 8 lacs.

Cost of purchased equipment : Rs. 6 lacs.

Man Power Requirement : 14 persons.

Land requirement : 800 Sq. metres.

Installed power : 10 KW.

Estimated cost of production : Rs.1100/- per 1000 bricks.

Dept. of Civil. Engg. 10

Flyash Sand Lime Brick- An Alternative Walling Material

1. Flyash 5. Shaping Machine

2. Sand 6. Autoclave

3. Lime 7. Ready Bricks

4. Pan Mill

SCHEMATIC DIAGRAM FOR PRODUCTION OF BRICKS BY VIBRO-

COMPACTION SHAPING AND HIGH PRESSURE STEAM CURING

C.O. E. & T., Akola. 11

Seminar 2000-2001

VARIATION OF COMPRESSIVE STRENGTH WITH LOSS

ON IGNITION

Dept. of Civil. Engg. 12

Flyash Sand Lime Brick- An Alternative Walling Material

Option No – 4

Shaping by vibro-compaction and steam curing at

atmospheric pressure. Under this option, proportioning, mixing and

shaping operations are done exactly as in option No – 3 excepts for the

steam curing of green bricks at 1 Kg/Cm 2 in ordinary chambers.

It is worth while to mention here that if cement is added as binder in this

option wet curing of 28 days can replace the steam curing.

Inference : In this option, fly ash with higher percentage of unburnt

carbon is not found to be suitable for producing good quality of bricks.

Therefore, it is necessary to go in for a flyash with lower percentage of unburnt

carbon, obviously hopper ash can directly be used. With such fly ash being light

in colour, use of an appropriate pigment can also be made to produce

red/chocolate coloured bricks.

Brief Project Profiles :

Capacity of plant : 3000 bricks per shift.

Total capital investment : Rs. 3 lacs.

Cost of purchased equipment : Rs.1.25 lacs.

Manpower : 10 persons.

Installed power : 10 KW

Estimated cost of production : Rs. 1000/- per 1000 bricks.

C.O. E. & T., Akola. 13

Seminar 2000-2001

1. Flyash 5. Shaping Machine

2. Sand 6. Chamber

3. Lime 7. Ready Bricks

4. Pan Mill

SCHIMATIC DIAGRAM FOR PRODUCTION OF BRICKS BY VIBRO-

CPOMECTION SHAPING AND ATMOSPHERIC PRESSURE STEAM

Dept. of Civil. Engg. 14

Flyash Sand Lime Brick- An Alternative Walling Material

VARIATION OF COMPRESSIVE STRENGTH WITH

LOSS ON IGNITION

C.O. E. & T., Akola. 15

Seminar 2000-2001

4. PROPERTIES

A) ENGINEERING PROPERTIES :

i) Shrinkage : Depending on the characteristics properties of raw

materials and the process adopted for production, these bricks

show a drying shrinkage of the order of 0.02 to 0.04 %.

ii) Absorption Properties : The saturation coefficient tends to one,

indicating openness in the pore structure. This facilitated easier

evaporation of the water absorbed by the external face in wet

season. The initial rate of absorption ranges between 25 to 35,

which is comparable to conventional bricks thus imparting similar

bonding characteristics.

iii) Prism strength : Masnory prisms with different mortars and having

a height to base ratio of 2 were tested in compression to assess

masnory strength. Observed prism strengths with 1: 1: 6, 1:1:9

(cement : Lime : Sand ) and 1:6 (Cements : Sand) mortars were

between 0.40 to 0.43 to the unit strength. This value is certainly

better than that of conventional bricks, which ranges between 0.3

to 0.35.

Dept. of Civil. Engg. 16

Flyash Sand Lime Brick- An Alternative Walling Material

B) PHYSICAL PROPERTIES :

i) Compressive strength - 40 – 80

(Wet comp. Strength) Kg/Cm 2

ii) Water absorption - 15 – 20 %

iii) Durability - Good

iv) Efflorescence - Free from Efflorescene.

v) Bulk Density - 1400 – 1600

Kg/Cm 2

vi) Shape - Uniform

vii) Finish - Smooth

5. ADVANTAGES

C.O. E. & T., Akola. 17

Seminar 2000-2001

In presence of moisture, fly ash reacts with lime at

ordinary temperature and forms a compound possessing cementitious

properties. After reactions between lime and fly ash, calcium silicate

hydrates are produced which are responsible for the high strength of the

compound. Bricks made by mixing lime and fly ash are, therefore,

chemically bonded bricks. These bricks are suitable for use in masonry

just like common burnt clay bricks. These bricks have the following

advantages over the clay bricks.

1) Possess crushing strength more than that of good quality clay bricks

and can therefore be used as a load bearing member.

2) Have cement colour in appearance, are uniform in shape and smooth

in finish and require no plastering for building work.

3) Are lighter in weight than ordinary clay bricks. Are less porous than

the ordinary clay bricks.

4) Have more Durability than the ordinary clay bricks.

6. CONCLUSION

Dept. of Civil. Engg. 18

Flyash Sand Lime Brick- An Alternative Walling Material

Good quality building bricks can be produced from fly

ash by adopting an appropriate technology from the four technological

options described above. One can pick up the best suitable option in the

given set of conditions governed by characteristic properties of available

raw materials, desired Engineering properties of the end product and

financial investments.

7. REFERENCES

C.O. E. & T., Akola. 19

Seminar 2000-2001

(1) New Building Materials and Construction World. (July,2000)

(2) NTPC Guide For users of Coal Ash. (Oct.99)

(3) Net information from www.goggle.com.

( Sub : Flyash Sand lime bricks )

Dept. of Civil. Engg. 20

Flyash Sand Lime Brick- An Alternative Walling Material

C.O. E. & T., Akola. 21

Seminar 2000-2001

Dept. of Civil. Engg. 22

Flyash Sand Lime Brick- An Alternative Walling Material

C.O. E. & T., Akola. 23

Seminar 2000-2001

Dept. of Civil. Engg. 24

Das könnte Ihnen auch gefallen

- Deepak Agrawal - Afforadable Housing SynopsisDokument10 SeitenDeepak Agrawal - Afforadable Housing Synopsissaurabh_agrawal_48100% (1)

- Tile Industry in KeralaDokument3 SeitenTile Industry in KeralaRahul RajNoch keine Bewertungen

- NABORS Design Review Letter ReportDokument52 SeitenNABORS Design Review Letter ReportSNLeaderNoch keine Bewertungen

- PPRA Building and Ass Civil Eng WorksDokument71 SeitenPPRA Building and Ass Civil Eng WorksFaith SharonNoch keine Bewertungen

- KGN-GDD-033-2018 - Tender For Supply Installation Construction Commissioning of Kengen Detergent Plant - 0Dokument127 SeitenKGN-GDD-033-2018 - Tender For Supply Installation Construction Commissioning of Kengen Detergent Plant - 0Eric MuyaNoch keine Bewertungen

- CGN LHPPU 235 2018 19 Proposed Asian Quarter's Transport Termini Civil Works Cluster I RoadsDokument80 SeitenCGN LHPPU 235 2018 19 Proposed Asian Quarter's Transport Termini Civil Works Cluster I Roadstony mwashumaNoch keine Bewertungen

- EOT KC-06C (Extention of Time)Dokument4 SeitenEOT KC-06C (Extention of Time)Arshad MahmoodNoch keine Bewertungen

- Fencing Works For Nyamonye Cattling RingDokument27 SeitenFencing Works For Nyamonye Cattling RingSolidr ArchitectsNoch keine Bewertungen

- Mubarek Kedir Primary School Building EIA ReportDokument89 SeitenMubarek Kedir Primary School Building EIA Reportabrham astatikeNoch keine Bewertungen

- Tender Document For Construction of Car Parking Sheds at The Western Regional Offices EldoretDokument77 SeitenTender Document For Construction of Car Parking Sheds at The Western Regional Offices EldoretKevin KephaNoch keine Bewertungen

- Impacts of Civil Engineering Infrastructures in The Sustainability of The EnvironmentDokument12 SeitenImpacts of Civil Engineering Infrastructures in The Sustainability of The Environmentandang ikhsanNoch keine Bewertungen

- Standard Method of Measurement of Building Works Qatar 1973 - Google SearchDokument2 SeitenStandard Method of Measurement of Building Works Qatar 1973 - Google SearchSaad Barghouthi50% (2)

- DR OetkarsMOM12April2019Dokument4 SeitenDR OetkarsMOM12April2019SakibNoch keine Bewertungen

- Improved Clay Brick ProductionDokument4 SeitenImproved Clay Brick ProductionBrajesh SumanNoch keine Bewertungen

- Site Analysis For Real Estate Developments + Case StudyDokument17 SeitenSite Analysis For Real Estate Developments + Case StudyRABIRAJ K (RA1811201010073)Noch keine Bewertungen

- Defective Work - Minimising The ProblemsDokument5 SeitenDefective Work - Minimising The ProblemsMdms PayoeNoch keine Bewertungen

- Updated On 27 September 2018: Government of The People'S Republic of BangladeshDokument73 SeitenUpdated On 27 September 2018: Government of The People'S Republic of BangladeshSAE/SO Damudya MahbubNoch keine Bewertungen

- 34 Summer 2008Dokument13 Seiten34 Summer 2008AnneBricklayerNoch keine Bewertungen

- Fixed Chimney-Bull's Trench KilnDokument9 SeitenFixed Chimney-Bull's Trench KilnadagooodNoch keine Bewertungen

- GET Draft ISSB Construction Manual (Final - 2)Dokument35 SeitenGET Draft ISSB Construction Manual (Final - 2)Crystal Waddell-Gardiner100% (1)

- Bonded Labour and Brick KilnsDokument137 SeitenBonded Labour and Brick KilnsSobia AhmedNoch keine Bewertungen

- BQX Socio-Economic ImpactsDokument35 SeitenBQX Socio-Economic ImpactsNeil deMause100% (1)

- Auroville Materials & CostDokument6 SeitenAuroville Materials & CostGayathri Chandrasekaran0% (1)

- Nyamango Site Meeting 9 ReportDokument18 SeitenNyamango Site Meeting 9 ReportMbayo David GodfreyNoch keine Bewertungen

- Contemporary Nigerian Residential ArchitectureDokument46 SeitenContemporary Nigerian Residential ArchitectureSamuel Hugos100% (1)

- Low Cost HousingDokument20 SeitenLow Cost HousingYashvardhan Singh RajawatNoch keine Bewertungen

- Chakala BOQ Segregated - 22032014Dokument13 SeitenChakala BOQ Segregated - 22032014Santosh ThakurNoch keine Bewertungen

- Progress Meeting No M-02!05!10-2010Dokument4 SeitenProgress Meeting No M-02!05!10-2010Upali KarunarathneNoch keine Bewertungen

- 6.schedule of Requiremes - Section 6Dokument11 Seiten6.schedule of Requiremes - Section 6ismal sirajNoch keine Bewertungen

- Low Cost HousingDokument15 SeitenLow Cost HousingIPSITA SWAINNoch keine Bewertungen

- Variation LetterDokument2 SeitenVariation LetterHaiSorkerNoch keine Bewertungen

- Paving Expert p13-McCormickDokument15 SeitenPaving Expert p13-McCormickSankar CdmNoch keine Bewertungen

- Project Report of Fly-Ash Bricks UdyogDokument9 SeitenProject Report of Fly-Ash Bricks UdyogVijayNoch keine Bewertungen

- Xypex Crystalline Repair System: Repair of Concrete Spalling and HoneycombingDokument3 SeitenXypex Crystalline Repair System: Repair of Concrete Spalling and HoneycombingUcok DedyNoch keine Bewertungen

- Fly Ash Bricks PPT FrantDokument13 SeitenFly Ash Bricks PPT FrantRavi Shankar100% (1)

- Shoreline Housing Needs Assessment: DraftDokument38 SeitenShoreline Housing Needs Assessment: Draftapi-328224013Noch keine Bewertungen

- Notice Inviting Tenders: ContdDokument4 SeitenNotice Inviting Tenders: ContdPragya DubeyNoch keine Bewertungen

- Low Cost TechniquesDokument24 SeitenLow Cost TechniquesAkanksha Rajput100% (1)

- Making of Brick by The Using of RedDokument18 SeitenMaking of Brick by The Using of RedAnubhav shuklaNoch keine Bewertungen

- C106 Vol-1 (NIT ITT FOT) - MMRDA-1Dokument105 SeitenC106 Vol-1 (NIT ITT FOT) - MMRDA-1Monish MNoch keine Bewertungen

- Ecological Construction of Low Cost Building in Public and Government SectorsDokument10 SeitenEcological Construction of Low Cost Building in Public and Government SectorsPicasso DebnathNoch keine Bewertungen

- Low Cost Housing in KeniyaDokument76 SeitenLow Cost Housing in Keniyackbose3296Noch keine Bewertungen

- Construction Material::-C.S.E.B (Compressed Stabilized Earth Blocks)Dokument18 SeitenConstruction Material::-C.S.E.B (Compressed Stabilized Earth Blocks)Sampurna Maharjan100% (1)

- ACI 370 Minutes - 2011 Spring (Tampa)Dokument3 SeitenACI 370 Minutes - 2011 Spring (Tampa)HenryNoch keine Bewertungen

- Tender - BQ Ecd Construction of ClassroomsDokument64 SeitenTender - BQ Ecd Construction of ClassroomsMutai KiprotichNoch keine Bewertungen

- Architectural Design Guide EastAfricaDokument21 SeitenArchitectural Design Guide EastAfricaRitchie SsebagalaNoch keine Bewertungen

- Clay BrickDokument26 SeitenClay BrickWerku Koshe Hareru0% (1)

- L 0017568609 PDFDokument30 SeitenL 0017568609 PDFJ GNoch keine Bewertungen

- Cseb PDFDokument5 SeitenCseb PDFLungelo100% (1)

- Boq Lab PDFDokument15 SeitenBoq Lab PDFmahlaqa tariqNoch keine Bewertungen

- Green Roof Details and Design For ArchitectureDokument15 SeitenGreen Roof Details and Design For ArchitectureGen Lamsis AlmoraNoch keine Bewertungen

- Construction of Earthen Houses Using Cseb - Bangladesh PerspectiveDokument7 SeitenConstruction of Earthen Houses Using Cseb - Bangladesh PerspectiveshainojkNoch keine Bewertungen

- SDP - BBR1 - 14B2 - 008R - Recomendation For Extension of Time No PDFDokument2 SeitenSDP - BBR1 - 14B2 - 008R - Recomendation For Extension of Time No PDFAiman ZhafriNoch keine Bewertungen

- Tender Evaluation ExampleDokument15 SeitenTender Evaluation ExampleNhial Panom PuotNoch keine Bewertungen

- The Fly Ash Brick Production TechnologyDokument18 SeitenThe Fly Ash Brick Production TechnologyVishal KedarNoch keine Bewertungen

- Fly AshDokument16 SeitenFly AshSavita Sehrawat0% (1)

- Produccion ECO LADRILLODokument9 SeitenProduccion ECO LADRILLOMiguelAngelDelgadoD'AppollonioNoch keine Bewertungen

- 54 ObadaDokument13 Seiten54 ObadaAli SherNoch keine Bewertungen

- Ijiset V2 I6 99Dokument29 SeitenIjiset V2 I6 99Hayotjon RamazonovNoch keine Bewertungen

- Educational Multimedia On Hydraulics and PneumaticsDokument89 SeitenEducational Multimedia On Hydraulics and PneumaticsDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Dipak Vinayak Shirbhate VSRDIJCSIT 3479 Research Communication June 2014Dokument4 SeitenDipak Vinayak Shirbhate VSRDIJCSIT 3479 Research Communication June 2014DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- New File ListDokument2 SeitenNew File ListDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- 2 Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Research Paper 4 8 August 2014Dokument8 Seiten2 Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Research Paper 4 8 August 2014DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Aahan's BirthdayDokument22 SeitenAahan's BirthdayDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Salary Slip - May 2014Dokument5 SeitenSalary Slip - May 2014DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Girls Hostel FormDokument1 SeiteGirls Hostel FormDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Quality Circles For Vikramshila StudentsDokument22 SeitenQuality Circles For Vikramshila StudentsDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Quality Circle A Case Study: Prof. D.V. Shirbhate Principal, Vikramshila Polytechnic DarapurDokument34 SeitenQuality Circle A Case Study: Prof. D.V. Shirbhate Principal, Vikramshila Polytechnic DarapurDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Boys Hostel FormDokument1 SeiteBoys Hostel FormDIPAK VINAYAK SHIRBHATE100% (1)

- Classification of EnterprenuersDokument12 SeitenClassification of EnterprenuersDIPAK VINAYAK SHIRBHATE100% (2)

- Prospectus Data 2013-14Dokument12 SeitenProspectus Data 2013-14DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Domestic Water Heater PDFDokument39 SeitenDomestic Water Heater PDFDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Prospectus For 14-15Dokument44 SeitenProspectus For 14-15DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Inplant TrainingDokument1 SeiteInplant TrainingDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Prospectus For 13-14Dokument42 SeitenProspectus For 13-14DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Pramod Naik's Letter Director MsbteDokument1 SeitePramod Naik's Letter Director MsbteDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Creativity & The Business IdeaDokument12 SeitenCreativity & The Business IdeaDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Autocad 2009 Tips and Tricks DVSDokument24 SeitenAutocad 2009 Tips and Tricks DVSDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Importance of Diploma Education For Rural StudentsnnDokument55 SeitenImportance of Diploma Education For Rural Studentsnnvspd2010Noch keine Bewertungen

- Nss Allotment Request Letter ModifiedDokument2 SeitenNss Allotment Request Letter ModifiedDIPAK VINAYAK SHIRBHATE75% (4)

- Leave ApplicationDokument2 SeitenLeave ApplicationDIPAK VINAYAK SHIRBHATE100% (2)

- Rule 3Dokument1 SeiteRule 3DIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Proposal For New PolytechnicDokument7 SeitenProposal For New PolytechnicDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Microbes in Human Welfare PDFDokument2 SeitenMicrobes in Human Welfare PDFshodhan shettyNoch keine Bewertungen

- Pieces 1 Cod Amount Product Detail 36 Cotton Pant RemarksDokument4 SeitenPieces 1 Cod Amount Product Detail 36 Cotton Pant RemarksFaizan AhmadNoch keine Bewertungen

- CH 10 - Reinforced - Concrete - Fundamentals and Design ExamplesDokument143 SeitenCH 10 - Reinforced - Concrete - Fundamentals and Design ExamplesVeronica Sebastian EspinozaNoch keine Bewertungen

- Fortune Falls - Lou VaneDokument402 SeitenFortune Falls - Lou VanetesteNoch keine Bewertungen

- Evidence Based DesignDokument4 SeitenEvidence Based Designmartinadam82Noch keine Bewertungen

- Soft Tissue SarcomaDokument19 SeitenSoft Tissue SarcomaEkvanDanangNoch keine Bewertungen

- Chapter 1 Fundamentals of Taxation by Cruz, Deschamps, Miswander, Prendergast, Schisler, and TroneDokument25 SeitenChapter 1 Fundamentals of Taxation by Cruz, Deschamps, Miswander, Prendergast, Schisler, and TroneReese Parker100% (4)

- Lab CompilationDokument11 SeitenLab CompilationJanita SiddiquiNoch keine Bewertungen

- Pescatarian Mediterranean Diet Cookbook 2 - Adele TylerDokument98 SeitenPescatarian Mediterranean Diet Cookbook 2 - Adele Tylerrabino_rojoNoch keine Bewertungen

- The Brew Your Own Big Book of Clone Recipe - Brew Your OwnDokument716 SeitenThe Brew Your Own Big Book of Clone Recipe - Brew Your OwnFrederico Ribeiro67% (3)

- 1Manuscript-BSN-3y2-1A-CEDILLO-222 11111Dokument32 Seiten1Manuscript-BSN-3y2-1A-CEDILLO-222 11111SHARMAINE ANNE POLICIOSNoch keine Bewertungen

- Lesson 4: Health and Fitness AdvertisingDokument4 SeitenLesson 4: Health and Fitness AdvertisingCatherineNoch keine Bewertungen

- Ural Evelopment: 9 9 Rural DevelopmentDokument17 SeitenUral Evelopment: 9 9 Rural DevelopmentDivyanshu BaraiyaNoch keine Bewertungen

- Krispy Kreme Doughnut Recipe - Immaculate BitesDokument2 SeitenKrispy Kreme Doughnut Recipe - Immaculate Bitesdaisydrops6Noch keine Bewertungen

- CatalogDokument12 SeitenCatalogjonz afashNoch keine Bewertungen

- PL00002949Dokument5 SeitenPL00002949Nino AlicNoch keine Bewertungen

- OphthalmoplegiaDokument5 SeitenOphthalmoplegiaPatricia Feliani SitohangNoch keine Bewertungen

- The Way Out of Alcoholism by Jack BolandDokument38 SeitenThe Way Out of Alcoholism by Jack BolandIma AardvarkNoch keine Bewertungen

- Broucher Design - 02Dokument8 SeitenBroucher Design - 02ಉಮೇಶ ಸಿ. ಹುಕ್ಕೇರಿ ಹುಕ್ಕೇರಿNoch keine Bewertungen

- Rotary Vane PumpsDokument7 SeitenRotary Vane PumpshebsonbezerraNoch keine Bewertungen

- Additional Activity 3 InsciDokument3 SeitenAdditional Activity 3 InsciZophia Bianca BaguioNoch keine Bewertungen

- Work of Asha Bhavan Centre - A Nonprofit Indian Organisation For Persons With DisabilityDokument10 SeitenWork of Asha Bhavan Centre - A Nonprofit Indian Organisation For Persons With DisabilityAsha Bhavan CentreNoch keine Bewertungen

- Decision Making in Perioperative Medicine Clinical Pearls 2021Dokument351 SeitenDecision Making in Perioperative Medicine Clinical Pearls 2021Dal RdzNoch keine Bewertungen

- An Assignment On "Mycology Laboratory Technique"Dokument1 SeiteAn Assignment On "Mycology Laboratory Technique"BsksvdndkskNoch keine Bewertungen

- Containers HandbookDokument26 SeitenContainers Handbookrishi vohraNoch keine Bewertungen

- Eko Serbia A.D. Beograd Rules For The Purchase of Fuel Through AccountsDokument2 SeitenEko Serbia A.D. Beograd Rules For The Purchase of Fuel Through AccountsMarko Perovic PerkeNoch keine Bewertungen

- Implementation of 5G - IoT Communication System 1 - RB - LAB EQUIPMENTDokument32 SeitenImplementation of 5G - IoT Communication System 1 - RB - LAB EQUIPMENTMaitrayee PragyaNoch keine Bewertungen

- Medical Nutrition Therapy For DiabetesDokument27 SeitenMedical Nutrition Therapy For Diabetesdr.Uci BaharNoch keine Bewertungen

- Osh e MeerDokument3 SeitenOsh e MeerfatduckNoch keine Bewertungen

- An Enhanced Model of Thermo Mechanical Loading On A Vaccum Insulated GlazingDokument29 SeitenAn Enhanced Model of Thermo Mechanical Loading On A Vaccum Insulated GlazingNguyễn SơnNoch keine Bewertungen