Beruflich Dokumente

Kultur Dokumente

Durgapur Steel Plant

Hochgeladen von

Sharmistha Mitra0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

243 Ansichten11 SeitenThe Durgapur Steel Plant was established in the late 1950s with an initial annual capacity of 1 million tonnes of crude steel. It later underwent expansion and modernization, increasing its capacity to produce 2.088 million tonnes of hot metal, 1.8 million tonnes of crude steel, and 1.586 million tonnes of saleable steel annually. It utilizes state-of-the-art technology and ISO quality management systems. The plant sources raw materials like iron ore, coal, and limestone and produces a variety of steel products after extensive processing and pollution control measures.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe Durgapur Steel Plant was established in the late 1950s with an initial annual capacity of 1 million tonnes of crude steel. It later underwent expansion and modernization, increasing its capacity to produce 2.088 million tonnes of hot metal, 1.8 million tonnes of crude steel, and 1.586 million tonnes of saleable steel annually. It utilizes state-of-the-art technology and ISO quality management systems. The plant sources raw materials like iron ore, coal, and limestone and produces a variety of steel products after extensive processing and pollution control measures.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

243 Ansichten11 SeitenDurgapur Steel Plant

Hochgeladen von

Sharmistha MitraThe Durgapur Steel Plant was established in the late 1950s with an initial annual capacity of 1 million tonnes of crude steel. It later underwent expansion and modernization, increasing its capacity to produce 2.088 million tonnes of hot metal, 1.8 million tonnes of crude steel, and 1.586 million tonnes of saleable steel annually. It utilizes state-of-the-art technology and ISO quality management systems. The plant sources raw materials like iron ore, coal, and limestone and produces a variety of steel products after extensive processing and pollution control measures.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

:: DURGAPUR STEEL PLANT

Set up in the late 50's with an initial annual capacity oI one

million tonnes oI crude steel per year, the capacity oI Durgapur

Steel Plant (DSP) was later expanded to 1.6 million tonnes in

the 70's. A massive modernisation programme was undertaken

in the plant in early 90's, which, while bringing numerous

technological developments in the plant, enhanced the capacity

oI the plant to 2.088 million tonnes oI hot metal,1.8 million

tonnes crude steel and 1.586 million tonnes saleable steel. The

entire plant is covered under ISO 9001: 2000 quality management system.

The modernized DSP now has state-oI the-art technology Ior quality steel making. The

modernized units have brought about improved productivity, substantial improvement in

energy conservation and better quality products. DSP`s Steel Making complex and the entire

mills zone, comprising its Blooming & Billet Mill, Merchant Mill, Skelp Mill, Section Mill

and Wheel & Axle Plant, are covered under ISO: 9002 quality assurance certiIication.

With the successIul commissioning oI the modernized units, DSP is all set to produce 2.088

million tones oI hot metal, 1.8 million tones oI crude steel and 1.586 million tones oI saleable

steel annually.

PRODUCT-MIX TONNES/ANNUM

Merchant Products 2,80,000

Structural 2,07,000

Skelp 1,80,000

Wheels & Axles 58,000

Semis 8,61,000

Total Saleable steel 15,86,000

Location

Situated at a distance oI 158 km Irom Calcutta, its geographical location is deIined as 230 27'

North and 880 29' East. It is situated on the banks oI the Damodar river. The Grand Trunk

Road and the main Calcutta-Delhi railway line pass through Durgapur.

Environment control

Durgapur Steel Plant has always made relentless eIIorts to maintaining a healthy and clean

environment. The units in DSP are provided with necessary pollution control Iacilities and the

liquid eIIluents and chimney emissions Irom the plant are well within norms.

DSP has undertaken massive aIIorestation to maintain clean environment. Some 3,266 acres oI

land have been covered with 14 lakh plantations. In order to develop healthy awareness about

the environment amongst the younger generation, eco-clubs have been Iormed in DSP schools.

Centre for Human Resource Development

DSP has always attached maximum importance on proper training and development oI its

employees. Its Centre Ior Human Resource Development has all modern Iacilities including

the state-oI-the-art Electrical and Electronics laboratory, Hydraulics and Pneumatics laboratory

and workshop Ior eIIective training and development oI its employees.

Communication

The Public Relations Department publishes monthly house journals in English, Bengali and

Hindi Ior extensive inIormation oI company aIIairs to the employees. DSP also has an in-house

TV studio (DSTV) along with all modern Iacilities, which telecast news and a gamut oI other

programs covering various aspects oI plant and township activities.

Durgapur - The Happening City

Durgapur, which is on the main Kolkata New Delhi line, is Iast turning into the most

happening city in the region. From a sleepy settlement, the town today boasts oI a variety oI

educational institutions, posh shopping malls, complexes with eateries and a multiplex, etc.

With the change in the mindset oI the people has come a change in the liIestyle also. Quality

consciousness has steeped in, accompanied with quality brands making their presence Ielt in

the market. Durgapur is Iast turning into the central location Ior the entire region with the

entry oI big business houses and entrepreneurs, the city is all set to undergo a change in its own

liIestyle and in the outlook oI its residents.

Contact Us :

Durgapur Steel Plant

BR Kanungo

DGM (Comm.) & ChieI oI Communications

Email :cocprdspgmail.com

Tel : 91 - 0343 - 2574368/2574318 (teleIax)

Raw Materials

Iron ore, coal and limestone are the three basic raw materials Ior the steel industry. Durgapur

Steel Plant draws its coal Irom the adjacent Jharia-Ranigunj coal belt. A good amount oI prime

coking coal, having Iairly low ash content, is also imported. Bulk oI iron ore lumps and Iines

come Irom the mines at Bolani in Orissa. Lime stone comes Irom a variety oI sources:

Birmitrapur (Orissa), Jaisalmer (Rajasthan), and Jukehi and Nandwara (Madhya Pradesh).

Raw Materials Handling

To improve and ensure consistency in raw material quality, the Iacilities, which have been

installed, are:

O BeneIiciation/washing Iacilities, both Ior lump ore and Iines at Bolani

O Screening oI lump iron ore inside the plant,

O Selective crushing oI coal at Coal Handling Plant,

O Base blending Iacilities Ior Sinter Plant,

O Silo-cum- Blending bunkers

As part oI the modernisation programme, new raw material handling storage and blending

Iacilities with selective crushing oI coal have been installed in order to ensure consistency in raw

material quality.

The beneIiciation/washing Iacilities, both Ior lump ore and Iines at Bolani, have a capacity to

process 3.44 million tonnes (wet basis) per annum so as to be capable oI catering to the entire

requirement oI the plant aIter modernisation.

Durgapur is the only steel plant in the country to have a coal washery at the plant site.

Raw Materials Handling Complex

Durgapur Steel Plant consumes about 7.4 million tonnes oI diIIerent raw materials annually

which comprises over 1.84 million tonnes oI coal and 2.9 million tonnes oI iron ore lump and

Iines. Besides the two major raw materials, the plant also requires limestone, dolomite,

manganese ore, bauxite, silico manganese, Ierro manganese, Ierro silicon, etc.

Coke Ovens & Coal Chemicals

No oI batteries - 5

No. oI ovens per battery - 78

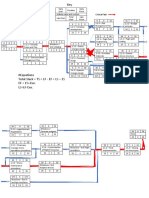

The coke ovens and coal chemicals zone is divided into Iour basic sections namely coal

preparation plant, coal carbonisation plant, coke handling plant and coal chemicals. Presently,

DSP is operating only three batteries.

The Blast Furnace grade coke produced in Coke Ovens is directly used in Blast Furnaces while

the undersized coke is used Ior sinter making.

The volatile matters, which emanate during the process oI coke making subsequently produce a

variety oI by-products like naphthalene oil, heavy creosote oil, light oil, crude tar partially

distilled tar, 'Raja brand Iertiliser, nitration grade benzene, nitration grade toluene, industrial

grade toluene, light solvent naphtha etc.

The coke oven gas is generally used in combination with the Blast Furnace gas and BOF gas as

Iuel and is carried through pipelines to the diIIerent areas oI the plant. The adjoining Alloy Steels

Plant under SAIL is also supplied with this Iuel gas Irom DSP.

Sinter Plant

In order to enhance the productivity oI blast Iurnaces, a high percentage oI sinter charge is a

prerequisite. Sinter is an agglomeration oI iron ore Iines, coke and limestone in the Iorm oI

cakes. To ensure sinter burden in the blast Iurnaces at 75 per cent, a total oI 3 million tonnes oI

sinter was envisaged Ior a production oI about 2 million tonnes oI hot metal. A technologically

modern and Iuel eIIicient sintering machine having 198 sq metres sintering area has been added

as part oI the modernisation scheme to produce 1.7 million tonnes oI sinter. The balance

requirement will be met Irom the revamped old sinter plant.

Sinter mix, a mixture oI Iines oI iron ore, limestone, coke, dolomite and Ilue dust, blended

proportionally at the RMHC, is a prepared material which is selI Iluxing. In ignition strands it is

burnt under controlled conditions to Iorm a porous cake type substance called sinter, which used

in blast Iurnaces enhances productivity and reduces coke rate.

Raw Material Preparation & Handling

Raw Material Handling Plant

Durgapur Steel Plant requires annually over 7.4 million tonnes oI diIIerent raw materials,

which comprises over 1.84 million tonnes oI coal and 2.9 million tonnes oI iron ore lump

and Iines. Besides the two major raw materials, the plant also requires limestone,

dolomite, manganese ore, bauxite, silico manganese, Ierro manganese, Ierro silicon, etc.

Blast Furnaces

Blast Furnaces

Blast Iurnaces are reIerred to as the mother unit` oI an integrated steel plant. Iron ore as

available in nature is basically an oxide. It is charged into a blast Iurnace either as lump ore or in

the Iorm oI sinter and reduced to molten iron by the coke at temperatures ranging Irom 1, 200

1, 400 degrees centigrade. The limestone, acting as Ilux, absorbs the impurities in the molten

iron and goes out as slag. The major portion oI liquid hot metal is transIerred to steel melting

shop Ior conversion to steel and the rest portion is cast into pig iron in pig casting machines.

Blast Iurnace slag high in lime-content is used Ior cement making.

There are three numbers oI blast Iurnaces operating presently at DSP. The useIul volume oI two

Iurnaces is 1,400 cubic meters each and that oI the other one is 1,800 cubic meters. The Iurnaces

are presently operating at a productivity level oI 1.3-1.4 tonnes/cubic meter/day. The Iurnaces

are equipped with sophisticated and modern computerised control system and are operated with

high blast temperatures (1,100 degree centigrade) and high top pressure (0.7 Kg/ sq. cm). The

cast houses are provided with Iacilities like twin tap holes, rocking runners etc. There are also

two numbers oI Slag Granulation Plants, which convert molten blast Iurnace slag into granulated

Iorms Ior ready use in the cement industry. There are three pig casting machines, with a total

capacity oI 2,12,000 tonnes/year.

Blast Iurnaces

No 1 No 2 No 3

(being modernised)

No 4

Capacity (t/day) 1, 250 1, 820 1, 820 2, 340

UseIul volume (cum) 1, 323 1, 400 1, 400 1, 800

Stoves 3 3 3 3

Productivity (t/cu m/day) 1.000 1.3 1.3 1.3

Steel Melting Shop

Mixers - 2 x 1, 300 t

Converters - 3 x 110 t (nominal heat size)

Molten iron is Iurther reIined at the Steel Melting Shop (SMS) to produce steel, which is hard

and malleable.

At DSP, there are 3 converters (Basic Oxygen Furnace) oI 110-130 tonnes each. The SMS also

has a Vacuum Arc Degassing (VAD) unit Ior making special grades oI steel.

A major portion oI the steel is routed through the Continuous Casting Plant. Another major

portion oI the steel is taken to the teeming bay, where it is top poured into 8 tonne ingot moulds

Ior making ingot steel. A portion oI highly controlled steel is cast at the Special Casting Bay into

Iluted ingots and special quality blooms. Fluted ingots are bottom poured and are used Ior

making wheel steel Ior DSP`s Wheel & Axle Plant. A portion oI the liquid steel is also bottom

poured to make axle ingots.

Continuous Casting Plant

The state oI the art CCP has 2 Nos machines having 6 strands each. The other basic details are as

Iollows: -

Design limits- 80-150 sq .mm, casting radius- 6 metres

Casting time 85 minutes, Cut-oII lengths- 6 / 9 / 12 metre

No oI ladle treatment stations-2

Mould level controller - Automatic (Radio-active Co-60)

The steel ladle Irom BOF is taken to the ladle treatment station. At the ladle treatment station,

liquid steel is rinsed with nitrogen to homogenise its temperature and composition. AIter the

rinsing, the ladle containing liquid steel is placed on the turret and brought over the tundish. The

tundish acts as a buIIer and enables the liquid steel to move homogeneously down through the

six nozzles, provided at the bottom oI the tundish into moulds. The automatic mould level

controller controls the steel level in the mould. The subsequent primary and secondary cooling

transIorms the liquid steel into billets oI the required dimensions and is drawn out with the help

oI a withdrawal and straightener unit and cut into the required length by the shear provided in

each strand. The continuous casting process is the result oI a unique synchronisation between

Basic Oxygen Furnace and CCP. Once a ladle is emptied, another ladle is brought into casting

position and the casting continues.

The billets are gradually shiIted to the cooling beds and then stacked orderly at the despatch end

Ior outside despatch. The details about the cast number and quality oI the billets are marked on

the billet stack. The Merchant Mill oI Durgapur Steel Plant utilises billets Ior rolling TMT bars

and other merchant rounds, while a sizeable portion is sold in the domestic and Ioreign markets.

Rolling Mills

Ingots weighing 8 tonnes each are heated in the soaking pits (numbering 20) Ior about 7 to 12

hours at around 1, 200 degrees centigrade and thereaIter rolled in the 42 primary and the 32

secondary blooming mills. These are rolled Iurther into diIIerent shapes and sizes in diIIerent

Iinishing mills.

Blooming mill

Installed Mill capacity - 1.47 million tonnes/year

Ingot weight - 8 tonnes

42" Mill:

42" x 102" reversible Blooming Mill

Output bloom size (min) - 300 mm x 250 mm

32" Mill:

32" x 84" reversible Intermediate Mill

Output bloom size (min) - 180 mm x 180 mm

Billet Mill

Installed Mill capacity - 0.957 tonnes / yr.

Type - Continuous Morgan design

Horizontal stands - 6, Vertical stands - 2

Product Range

Billets - 100 mm square to 125 mm square

Sleeper bars - 352 mm x 12.5 mm

Skelp slabs - 140 mm x 75 mm to 240 mm x 90 mm

The ingots aIter heating are rolled in the Blooming Mill to make blooms oI the sizes mentioned

in the table and then a part oI the same are then Iurther rolled in the Billet Mill Ior making rolled

billets or slabs as per the above details.

Section mill

The Section Mill rolls out light and medium structural like joists, channels and angles.

Mill capacity - 0.2 million tonnes / year

Re-heating Iurnaces - 2 x 40 t/hr

Roughing Mill - 2 high reversible

Intermediate Mill - 2 stands oI 3 high non-reversible

Finishing Stand - 2 high non-reversible

Product range:

Joists - 200 mm x 100 mm, 175 mm x 85 mm

150 mm x 75 mm, 116 mm x 100 mm

Channels - 200 mm x 75 mm, 175 mm x 75 mm

150 mm x 75 mm, 125 mm x 65 mm

Angels - 150 x 150 mm, 130 x 130 mm

110 x 110 mm, 100 x 100 mm

Fish plate bars Ior 52 kg rails

Merchant Mill

Merchant mill

The Merchant Mill produces plain round and Thermo-Mechanically Treated (TMT) bars in the

range oI 16mm - 28mm. The entire product range oI TMT bars and rods at DSP is branded and

has been able to create a niche market.

Capacity - 0.28 million tonnes / year

Type oI mill - continuous Morgan design

Horizontal stands - 13, Repeaters - 4

Product range

Plain rounds - 12 - 32 mm dia

TMT bars - 12 - 25 mm dia

Skelp Mill

The Skelp Mill produces skelp in the range oI 146 to 235 mm primarily Ior tubes and pipes

making industry.

Capacity - 0.25 million tonnes / year

Type oI Mill - Continuous Loewy design

Horizontal stands - 11

Vertical stands - 6

Product range

Strips & Skelps - 75-242 mm wide to 1.47-2.34 mm thick

Railway Products

Durgapur Steel Plant is the only major indigenous supplier oI wheel sets, loco wheels, carriage

and wagon wheels, and axles to the Indian Railways. As per demand oI the Railways, the plant

has developed loco wheels, which were imported earlier. The Wheel & Axle Plant is producing

wheels manuIactured as per the latest IRS speciIications, i.e. R-19/93 Ior carriage and wagon

wheels, R-34/99 Ior loco wheels and R-16/95 Ior axles.

The wheel plant oI the Wheel & Axle Plant is provided with six PLC controlled band saws Ior

accurate slicing oI the 14 and 16 Iluted ingots. A Iully computerised 63/12 MN oil hydraulic

press is there Ior Iorging and punching oI the wheel blanks along with a Iully computerised

vertical wheel mill and other down stream Iacilities. All the wheels are 100 per cent rim-

quenched, tempered and tested as per IRS speciIications.

Machining oI these Iorged rolled and heat-treated wheel blanks are carried out in the 15 CNC

machines. All the wheels are ultrasonically tested and inspected by RITES on behalI oI the

Indian Railways. A number oI sophisticated and modern online testing Iacilities are there to

conIorm to the stringent testing requirements oI the Indian Railways.

Wheel & Axle Plant

Annual production oI Iinished wheels - 1,00,000 nos.

Production rate in rolling/Iorging - 25 nos./hr

Production rate in machining - 22 nos./hr

Engineering shops

Durgapur Steel Plant has a number oI captive engineering shops Ior repairs and supply oI spare

parts. The Central Engineering Maintenance has a Machine Shop, Structural Shop, Fitting and

Assembly Shops. The Foundry produces Ingot moulds and bottom plates Ior the steel melting

shop. There are also Auxiliary Repair Shops such as Electrical, Wagon and Loco repair.

Research and Control laboratories

The Research & Control laboratories are entrusted with the responsibility oI maintaining quality

oI products and also developing new products. It is well equipped Ior carrying out sophisticated

chemical, metallurgical and other tests.

Computerisation

An extensive computerisation has been undertaken in DSP Ior personnel, commercial, process

control, production and maintenance applications. The Production Planning and Control network

is thoroughly used Ior tracking oI customer orders, material, monitoring oI quality parameters

and ensuring availability oI accurate, real time data to all agencies needing access to the data.

Quality Assurance

In order to be Iully competitive on the quality Iront, Durgapur Steel Plant has set out to acquire

ISO 9000 certiIication Ior all its units. The Merchant Mill is the Iirst to secure the prestigious

ISO 9002 certiIicate. Subsequently, steel melting shop, basic oxygen Iurnace shop, continuous

casting plant, and wheel and axle plant were also awarded the ISO 9002 certiIication and

recently the Skelp Mill has been awarded the ISO 9002 certiIication.

Durgapur Steel Plant

PRODUCT-MIX TONNES/ANNUM

Merchant Products 2,80,000

Structural 2,07,000

Skelp 1,80,000

Wheels & Axles 58,000

Semis 8,61,000

Total Saleable steel 15,86,000

Durgapur Steel Plant

Community & Development

The abode of steelmen

The Durgapur Steel Plant township is spread over a sprawling 40 kms and has more than 25,000

dwelling units. And it has housing Iacilities Ior the employees oI DSP, ASP and other business

associates. The other amenities include schools, both primary and secondary, a modern 640 beds

hospital with modern medical Iacilities, the picturesque park, a number oI cultural centres, a

stadium with a sitting capacity oI 15,000, etc.

Peripheral Development

Contribution to the region's development

Over the years, it has contributed in a major way Ior providing tube well Iacilities in the water-

scarce peripheral areas. Another notable contribution has been the eIIorts taken towards

enlightenment oI the region through up-gradation or additions to educational Iacilities in

basically rural areas surrounding the steel township. It has also assisted in developing roads and

other Iacilities.

Durgapur Steel Plant has played a major role in encouraging and developing small-scale

industries in the region.

Das könnte Ihnen auch gefallen

- An Industrial Vist Report On Durgapur Steel PlantDokument34 SeitenAn Industrial Vist Report On Durgapur Steel PlantChandarshekar Swaminathan50% (2)

- Vocational Training: Durgapur Steel PlantDokument28 SeitenVocational Training: Durgapur Steel PlantBaptu Roy100% (1)

- Coal Based Sponge Iron IndustryDokument4 SeitenCoal Based Sponge Iron IndustrychaitanyabhansaliNoch keine Bewertungen

- Steel Plant Report FinalDokument54 SeitenSteel Plant Report Finalkranthi chaitanyaNoch keine Bewertungen

- Vocational Training ReportDokument34 SeitenVocational Training ReportRavi kumarNoch keine Bewertungen

- Bokaro Steel Plant An OverviewDokument20 SeitenBokaro Steel Plant An OverviewAðitya SínghNoch keine Bewertungen

- A Project Profile On The Steel Melting Shop Prepared by APITCO LimitedDokument6 SeitenA Project Profile On The Steel Melting Shop Prepared by APITCO LimitedSrikant MahapatraNoch keine Bewertungen

- List of FiguresDokument22 SeitenList of FiguresvishalNoch keine Bewertungen

- Drive Failure and Interruption in SCP Machines of Battery 567, Coke PlantDokument37 SeitenDrive Failure and Interruption in SCP Machines of Battery 567, Coke Plantnarendramaharana39Noch keine Bewertungen

- Central Coalfield Limited (CCL) : by Ashish Raushan MBA MarketingDokument11 SeitenCentral Coalfield Limited (CCL) : by Ashish Raushan MBA MarketingAaditya RajNoch keine Bewertungen

- Bhilai Steel Plant: An OverviewDokument9 SeitenBhilai Steel Plant: An OverviewAKANKSHA LAKRA100% (1)

- Bokaro An OverviewDokument55 SeitenBokaro An OverviewSunny SinhaNoch keine Bewertungen

- Durgapur Steel Plant: Presentation of Vocational Training atDokument17 SeitenDurgapur Steel Plant: Presentation of Vocational Training atRaushan KumarNoch keine Bewertungen

- SAIL IISCO Marketing Project PDFDokument74 SeitenSAIL IISCO Marketing Project PDFABCDNoch keine Bewertungen

- Coke Oven Life Prolongation - A Multidisciplinary ApproachDokument31 SeitenCoke Oven Life Prolongation - A Multidisciplinary ApproachJorge MadiasNoch keine Bewertungen

- Industry Statistics: Major Industrial Areas/ Zones in OrissaDokument17 SeitenIndustry Statistics: Major Industrial Areas/ Zones in OrissaBhavani PrasadNoch keine Bewertungen

- TSML Report - ShazDokument21 SeitenTSML Report - ShazUmer AleemNoch keine Bewertungen

- Blast Furnace in BSPDokument51 SeitenBlast Furnace in BSPAbhishek KhareNoch keine Bewertungen

- JSL Brochure - CorpDokument20 SeitenJSL Brochure - Corpdoctorcarbon100% (1)

- Steel PlantDokument20 SeitenSteel PlantRohith KancherlaNoch keine Bewertungen

- DSP Overview 10-07-2017Dokument46 SeitenDSP Overview 10-07-2017Binod Kumar Padhi0% (1)

- AttachmentDokument3 SeitenAttachmentKaushik Kumar AushNoch keine Bewertungen

- Pankaj Final Industrial Training Report 1234Dokument36 SeitenPankaj Final Industrial Training Report 1234pankaj madhheshiyaNoch keine Bewertungen

- A Brief History of Coal Mining & Coal Deposits in India PDFDokument41 SeitenA Brief History of Coal Mining & Coal Deposits in India PDFSheshu BabuNoch keine Bewertungen

- Nippon Steel & Sumikin Engineering's Blast FurnaceDokument4 SeitenNippon Steel & Sumikin Engineering's Blast Furnacekalai100% (1)

- AmiimDokument9 SeitenAmiimRanjan SahooNoch keine Bewertungen

- Present Professional ExperienceDokument3 SeitenPresent Professional Experiencerahul srivastavaNoch keine Bewertungen

- DIUPL Project TextDokument29 SeitenDIUPL Project Textca_akr0% (1)

- Gujarat NRE - AssignmentDokument20 SeitenGujarat NRE - AssignmentMangesh GulkotwarNoch keine Bewertungen

- Embr 1 PDFDokument32 SeitenEmbr 1 PDFKamod RanjanNoch keine Bewertungen

- Iron and Steel Industries in IndiaDokument13 SeitenIron and Steel Industries in IndiaShyam AbhishekNoch keine Bewertungen

- New Resume SunilDokument5 SeitenNew Resume SunilAnish Kumar DhirajNoch keine Bewertungen

- Steel Making IntroductionDokument17 SeitenSteel Making IntroductionHari sadu100% (2)

- SLR English Exe - SummaryDokument31 SeitenSLR English Exe - SummarybalaasenthilNoch keine Bewertungen

- Pellet Plant Over ViewDokument7 SeitenPellet Plant Over ViewBipin MishraNoch keine Bewertungen

- Steel PlantDokument21 SeitenSteel PlantKaran Sagar KathuriaNoch keine Bewertungen

- New-Project Tata SteelDokument24 SeitenNew-Project Tata Steelsomnath banerjeeNoch keine Bewertungen

- A Review On Stamped Charging of CoalsDokument31 SeitenA Review On Stamped Charging of CoalsJorge MadiasNoch keine Bewertungen

- Iduction Quarry Se West BokaroDokument37 SeitenIduction Quarry Se West BokaroVijay JainNoch keine Bewertungen

- What Is SteelDokument10 SeitenWhat Is SteelKristo Ver TamposNoch keine Bewertungen

- JSPL Full IT Report by Avnish JhaDokument44 SeitenJSPL Full IT Report by Avnish JhaAviNoch keine Bewertungen

- Steel: The Indian Steel IndustryDokument43 SeitenSteel: The Indian Steel IndustrySylvia GraceNoch keine Bewertungen

- How's Steel Manufactured?: Raw Materials For IronmakingDokument6 SeitenHow's Steel Manufactured?: Raw Materials For IronmakingUpendra93Noch keine Bewertungen

- Recycling of Steel Plant Wastes Through CorexDokument1 SeiteRecycling of Steel Plant Wastes Through CorexSubhransu Sekhar SahooNoch keine Bewertungen

- SLR Brochure 2017 2Dokument13 SeitenSLR Brochure 2017 2Jyotirmoy BarmanNoch keine Bewertungen

- SAILDokument18 SeitenSAILManak Jajoriya100% (1)

- Unit Operations of Bokaro Steel Plant and Their Environmental AspectsDokument52 SeitenUnit Operations of Bokaro Steel Plant and Their Environmental AspectsGopalSingh100% (2)

- Light and Medium Merchant MillDokument35 SeitenLight and Medium Merchant MillPeram Bharath Kumar Reddy100% (1)

- JSWDokument41 SeitenJSWsushantmishra85100% (1)

- Sinter PlantDokument14 SeitenSinter PlantKannan ThangarajuNoch keine Bewertungen

- Coal Handling Plant: at Heads of CHP MeetDokument46 SeitenCoal Handling Plant: at Heads of CHP MeetMANISH SHARMANoch keine Bewertungen

- Design, Manufacturing and Testing of Induction Furnace: Submitted byDokument65 SeitenDesign, Manufacturing and Testing of Induction Furnace: Submitted byGuru ChaudhariNoch keine Bewertungen

- Seminar Report (L&T)Dokument27 SeitenSeminar Report (L&T)Pushpendu SinghNoch keine Bewertungen

- NMDCDokument31 SeitenNMDCRavi TejaNoch keine Bewertungen

- Coke Oven New1Dokument6 SeitenCoke Oven New1abhishekgarg98Noch keine Bewertungen

- CMR Jan 13Dokument7 SeitenCMR Jan 13James WarrenNoch keine Bewertungen

- Blast FurnaceDokument28 SeitenBlast Furnaceavanisharma_1991Noch keine Bewertungen

- Durgapur Steel Plant: LocationDokument13 SeitenDurgapur Steel Plant: LocationAnish PatelNoch keine Bewertungen

- Project ReportDokument39 SeitenProject ReportMd Sahanawaz100% (2)

- Retrofit Masterpact M PlugnplayDokument21 SeitenRetrofit Masterpact M Plugnplaynot bookNoch keine Bewertungen

- Financial Statement and Ratio Analysis of Tata MotorsDokument120 SeitenFinancial Statement and Ratio Analysis of Tata MotorsAMIT K SINGH100% (1)

- Tail RotorsDokument4 SeitenTail Rotorsvenmeen14Noch keine Bewertungen

- BW Portal ImplementationDokument58 SeitenBW Portal ImplementationNarendra ChoudaryNoch keine Bewertungen

- ALCAN LABS BANBURY RecollectionsDokument191 SeitenALCAN LABS BANBURY RecollectionspermaxNoch keine Bewertungen

- Jewelry Holiday BrochureDokument8 SeitenJewelry Holiday BrochureugurozverenNoch keine Bewertungen

- 2017 Plates Gemini - ENGLISHDokument8 Seiten2017 Plates Gemini - ENGLISHAhmed FadhilNoch keine Bewertungen

- Iso 12944Dokument4 SeitenIso 12944Kiran Kumar Yanmangandla100% (2)

- 28385-1 Quotation 333kW Containerized Soluttion Genesis ElectricityDokument10 Seiten28385-1 Quotation 333kW Containerized Soluttion Genesis ElectricityNelsonNoch keine Bewertungen

- CMAA Standards of Practice PDFDokument131 SeitenCMAA Standards of Practice PDFNjilou Lagatic100% (2)

- Model Building Estimate With Standard Revised Data SSR 2012 13 Useful For All Engineering Dpartments1Dokument163 SeitenModel Building Estimate With Standard Revised Data SSR 2012 13 Useful For All Engineering Dpartments1Ravi KumarNoch keine Bewertungen

- CPM Method Wilmont's Drone Case PDFDokument2 SeitenCPM Method Wilmont's Drone Case PDFRwa Gihuta100% (3)

- Residential Slabs and Footings Workshop 1 DayDokument1 SeiteResidential Slabs and Footings Workshop 1 DayredpuffNoch keine Bewertungen

- Neil Armstrong Interview (1969)Dokument8 SeitenNeil Armstrong Interview (1969)Aviation/Space History LibraryNoch keine Bewertungen

- Mech Sem6Dokument17 SeitenMech Sem6Nidhi GandhiNoch keine Bewertungen

- The Dry Port ConceptDokument103 SeitenThe Dry Port ConceptCristian MarcialesNoch keine Bewertungen

- E 10231Dokument1.024 SeitenE 10231Gab AntNoch keine Bewertungen

- 9-12-23 NASPO Goodyear Authorized Dealer ListDokument426 Seiten9-12-23 NASPO Goodyear Authorized Dealer ListYip DavidNoch keine Bewertungen

- Tronox LP Eng GesichertDokument3 SeitenTronox LP Eng GesichertForeverNoch keine Bewertungen

- Return Air Grilles: RM LouverDokument2 SeitenReturn Air Grilles: RM LouverYe Wunna TunNoch keine Bewertungen

- Group 10 Poletown DilemmaDokument3 SeitenGroup 10 Poletown DilemmaNaveen Choudhury100% (1)

- IBM Tivoli Provisioning Manager V7.1.1 Deployment and IBM Service Management Integration Guide Sg247773Dokument762 SeitenIBM Tivoli Provisioning Manager V7.1.1 Deployment and IBM Service Management Integration Guide Sg247773bupbechanhNoch keine Bewertungen

- Albion TradingDokument1.074 SeitenAlbion TradingalcatéiaNoch keine Bewertungen

- WPQT PHSSDokument1 SeiteWPQT PHSSFerdie OSNoch keine Bewertungen

- wtwtwCreate a document containing text that should be properly aligned. Use the replace all option to replace each instance of same word. Save and protect your document. Steps for Replace all: • Click Replace option in “Find and Replace” option in “Home Tab”. • Type the word in Find what option you want to replace. • Now type the word with which you want to replace previous word in Replace with option. • Now click on Replace all option.Dokument60 SeitenwtwtwCreate a document containing text that should be properly aligned. Use the replace all option to replace each instance of same word. Save and protect your document. Steps for Replace all: • Click Replace option in “Find and Replace” option in “Home Tab”. • Type the word in Find what option you want to replace. • Now type the word with which you want to replace previous word in Replace with option. • Now click on Replace all option.Sahil RajputNoch keine Bewertungen

- CCD 0001920Dokument2 SeitenCCD 0001920Freddy Jose BracamonteNoch keine Bewertungen

- Codes Standards Pubs UpdateDokument30 SeitenCodes Standards Pubs UpdatejosethompsonNoch keine Bewertungen

- Method Statements For Eskom Substations - Stringing, Erection, Earthing and Cabling PDFDokument27 SeitenMethod Statements For Eskom Substations - Stringing, Erection, Earthing and Cabling PDFTreenel TradingNoch keine Bewertungen

- Mitsubishi Case StudyDokument19 SeitenMitsubishi Case StudyAmar KunamNoch keine Bewertungen

- Fire Departments - Safety Checklist For Fire Station Facility (Final)Dokument2 SeitenFire Departments - Safety Checklist For Fire Station Facility (Final)DAVE HOWARDNoch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- Fire Fighting Pumping Systems at Industrial FacilitiesVon EverandFire Fighting Pumping Systems at Industrial FacilitiesBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityVon EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityBewertung: 5 von 5 Sternen5/5 (2)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesVon EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNoch keine Bewertungen

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersVon EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersBewertung: 4 von 5 Sternen4/5 (32)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Fundamentals of Risk Management for Process Industry EngineersVon EverandFundamentals of Risk Management for Process Industry EngineersNoch keine Bewertungen

- Epidemiology and Demography in Public HealthVon EverandEpidemiology and Demography in Public HealthJaphet KillewoBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- Handbook of Hazardous Chemical PropertiesVon EverandHandbook of Hazardous Chemical PropertiesBewertung: 5 von 5 Sternen5/5 (1)

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EVon EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EBewertung: 3 von 5 Sternen3/5 (6)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- What Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedVon EverandWhat Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedBewertung: 5 von 5 Sternen5/5 (2)

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- Culture, Health and Illness: An Introduction for Health ProfessionalsVon EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNoch keine Bewertungen

- Workbook to Accompany Maintenance & Reliability Best PracticesVon EverandWorkbook to Accompany Maintenance & Reliability Best PracticesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- The Invisible Rainbow: A History of Electricity and LifeVon EverandThe Invisible Rainbow: A History of Electricity and LifeBewertung: 4.5 von 5 Sternen4.5/5 (21)